Frequency inverter | For the optimal speed on the electric motor

- Details

- Hits: 13278

frequency converter have been controlling the speed and thus the speed of electrical machines for over 50 years. Engines are infinitely adjustable, which is the case in many industries these days Automotive industry, air conditioning, food technology, handling technology, processing machines and much more. is essential. We present you here New developments and Application examples before like the Kostal converter with encoderless control.

Contents

- Frequency converters 2024 – The most important things in brief

- Frequency converter innovations

- Modular frequency converter with maximum performance

- Small frequency converter for speeds up to 100.000 rpm-1

- Frequency converter with configurable functions

- Cost-optimized frequency converters for beginners

- Frequency converters and motor starters - regardless of the application

- Decentralized and control cabinet frequency converter for IIoT

- Network-capable frequency converters for the smart factory

- Frequency converter for three-phase synchronous + asynchronous motor

- Realistically simulate the frequency converter before making a selection

- Inverters now with Profinet, Ethercat and Biss interfaces

- Mobile app for control cabinet and frequency converter

- Frequency converters for special industries

- Archive for frequency converters

- Frequently asked questions

Frequency converters 2024 – The most important things in brief

Modern frequency converters are essential for precision Motor Control in the industry. Current trends include improved energy efficiency, integration of IoT technologies for remote monitoring and control, and user-friendly programmability.

These developments enable optimized performance and cost savings by enabling real-time adjustments and predictive maintenance support. This significantly increases operational reliability.

Below we present the new products and refer to their applications:

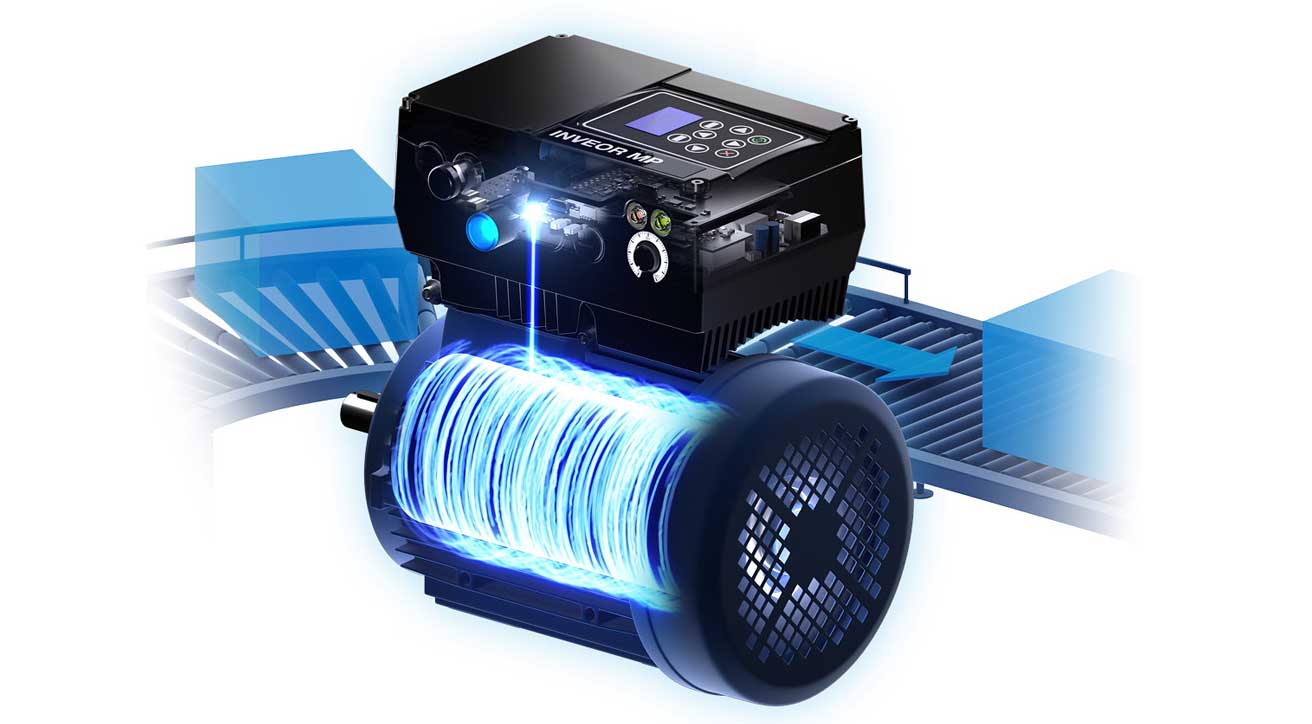

Modular frequency converter with maximum performance

22.02.2024/XNUMX/XNUMX | The modular Inveor concept of frequency converters from costal allows all types of motors to be controlled without sensors. You can choose motors or engines regardless of the manufacturer Transmission combine with this frequency inverter.

22.02.2024/XNUMX/XNUMX | The modular Inveor concept of frequency converters from costal allows all types of motors to be controlled without sensors. You can choose motors or engines regardless of the manufacturer Transmission combine with this frequency inverter.

You can also save costs in the long term because Inveor controls all types of engines with maximum efficiency. Through assembly directly on the engine you save space, the acquisition costs for the switch cabinet, as well as for long, shielded motorscables.

The control procedure of the inverter comes complete without Sensor out of. This reduces the costs for the encoder, its installation and maintenance. At the same time, the system becomes heavy-duty capable because the most sensitive component is eliminated.

The inverter is more efficient than the Ecodesign Directive requires. It can also regulate future engine types. He can be seen on the Hannover Messe 2024.

Small frequency converter for speeds up to 100.000 rpm-1

30.11.2022 | BMR electrical and electronic equipment manufacturing presented a new frequency converter with the SFU400. The small, highly efficient converter is as big as a packet of cigarettes. It is suitable for driving AC and DC motors at speeds up to 100.000 rpm-1. A maximum output power of 48 VA is possible from a supply voltage of 380 V. A braking resistor of 2 W is integrated in this format. This enables the spindle to be braked safely and quickly.

30.11.2022 | BMR electrical and electronic equipment manufacturing presented a new frequency converter with the SFU400. The small, highly efficient converter is as big as a packet of cigarettes. It is suitable for driving AC and DC motors at speeds up to 100.000 rpm-1. A maximum output power of 48 VA is possible from a supply voltage of 380 V. A braking resistor of 2 W is integrated in this format. This enables the spindle to be braked safely and quickly.

The connection is made via screw terminals. A digital and analog input each for start-stop and speed specification as well as for a temperature sensor and two parameterizable digital outputs are available. One RS232 interface can be contacted via a pin strip. There is an optional connection dongle with which a USB interface can be implemented. With the specially developed SFU terminal software, users can parameterize and configure the device.

It is installed where the power is needed. This allows the length of the connection lines to be as short as possible. EMC interference can be reduced so drastically because the assembly is kept as close to the spindle as possible. A plastic housing protects against dirt and helps to avoid defects caused by touch.

This frequency converter finds space in every housing and in every application. The SFU 400 are suitable for CAD/CAM machines, dental applications, printed circuit boards or spindles. There is one for testing purposes sample kit.

Frequency converter with configurable functions

04.07.2022 | SEW Eurodrive has the compact frequency converter for this year's Hanover Fair Movitrac advanced featured. It offers configurable functions for a wide range of automation tasks. The standard standby mode also saves energy. Because if machines and systems are not used, it is worth it, especially in the case of short-term interruptions such as weekends, free shifts or production breaks. The standard standby function reduces energy consumption and enables the machine or system to be restarted immediately.

04.07.2022 | SEW Eurodrive has the compact frequency converter for this year's Hanover Fair Movitrac advanced featured. It offers configurable functions for a wide range of automation tasks. The standard standby mode also saves energy. Because if machines and systems are not used, it is worth it, especially in the case of short-term interruptions such as weekends, free shifts or production breaks. The standard standby function reduces energy consumption and enables the machine or system to be restarted immediately.

The frequency converter optimizes the magnetic flux in the motor. This allows Magnetization losses reduced by up to 70% will. The heating of the engine is measurably less. Thanks to the compact design and the optimized use of materials, SEW saves valuable resources right from the production stage. At the end of the product life cycle, the materials used can be separated and Recyclingrecycle.

The Movitrac advanced frequency converter is part of the modular automation kit Movi-C. Like all devices in the modular system, it has interfaces that enable vertical digitization from the control level to the drive. This enables automatic start-up and reading of sensors close to the engine. The continuous recording of the system parameters enables better maintenance planning and minimizes downtimes. Predictive maintenance and condition monitoring are possible. Automatic commissioning also saves time and reduces errors. The preconfigured software modules Movikit provide support.

Technical data, security functions and interfaces

The mains voltage of the Movitrac advanced frequency inverter is 1 x AC (alternating voltage) 200 - 240 V, 3 x AC (alternating voltage) 200 - 240 V or 3 x AC (alternating voltage) 380 - 500 V, the nominal power ranges from 0,25 to 315 kW at one Overload capacity of 150%. The motor control controls and monitors synchronous and asynchronous three-phase motors with and without giver, asynchronous motors with LSPM technology or synchronous and asynchronous Linear motoren. State-of-the-art control methods tailored to the motor type and the application are available here.

The Movitrac advanced has an STO (Safe Torque Off) in PL d function in the basic device. security features such as SBC (Safe Brake Control), SLS (Safe Limited Speed) or SDI (Safe Direction) can be configured, as can the safe one Communication via Profisafe/Proginet and Fail Safe over EtherCAT. The Movilink DDI digital data interface can also be configured. the cabling is provided by single-cable technology from SEW using a standardized hybrid cable for power supply and data transmission.

The Movitrac advanced is suitable for applications in conveyor technology, in hoists, agitators or palletizers. The frequency converter can also be used with agitators in combination with an industrial gearbox be used. This means that applications in a power range of up to 315 kW can be implemented without any problems.

Cost-optimized frequency converters for beginners

16.03.2022/80/XNUMX | The new frequency inverters of the FR-CSXNUMX series from Mitsubishi Electric are user-friendly and efficient. They are also around 20% cheaper and 30% more compact than conventional models. Thanks to their quick and easy start-up, they are particularly suitable for beginners.

16.03.2022/80/XNUMX | The new frequency inverters of the FR-CSXNUMX series from Mitsubishi Electric are user-friendly and efficient. They are also around 20% cheaper and 30% more compact than conventional models. Thanks to their quick and easy start-up, they are particularly suitable for beginners.

Frequency converters and motor starters – application doesn’t matter

17.01.2022/XNUMX/XNUMX | The Nordac family of products NORD offers electronic drive technology for the control cabinet or as a decentralized variant for use in the field and thus for almost every application. The frequency converters and motor starters cover a wide power range up to 160 kW. They offer high performance and security.

17.01.2022/XNUMX/XNUMX | The Nordac family of products NORD offers electronic drive technology for the control cabinet or as a decentralized variant for use in the field and thus for almost every application. The frequency converters and motor starters cover a wide power range up to 160 kW. They offer high performance and security.

Decentralized and control cabinet frequency converter for IIoT

20.10.2021/XNUMX/XNUMX | Presented in the field of frequency converters NORD In autumn 2021, two new developments for Industrial Internet of Things (IIoT) applications: the Nordac Pro SK 500P control cabinet inverter with up to 22 kW output and the Nordac ON decentralized frequency inverter for up to 1,0 kW output.

20.10.2021/XNUMX/XNUMX | Presented in the field of frequency converters NORD In autumn 2021, two new developments for Industrial Internet of Things (IIoT) applications: the Nordac Pro SK 500P control cabinet inverter with up to 22 kW output and the Nordac ON decentralized frequency inverter for up to 1,0 kW output.

Network-capable frequency converters for the smart factory

17.11.2020 | Mitsubishi Electric presents the next generation of the FR-E series. The FR-E800 has a unique selling point with its standard corrosion detection function. In addition, the highly flexible, compact frequency converter offers compatibility with all common networks, too TSN (Time Sensitive Networking).

17.11.2020 | Mitsubishi Electric presents the next generation of the FR-E series. The FR-E800 has a unique selling point with its standard corrosion detection function. In addition, the highly flexible, compact frequency converter offers compatibility with all common networks, too TSN (Time Sensitive Networking).

Frequency converter for three-phase synchronous + asynchronous motor

30.09.2020 | B&R (Bernecker + Rainer) Automation presents the new Acopo Sinverter family P86. It includes frequency converter for three-phase Synchronous and asynchronous motors with and without donors. The frequency converters cover a power range from 0,75 to 75 kilowatts. They are particularly suitable for use in conveyor technology, packaging technology, material processing or hoists.

The frequency converters already meet the future standard for efficiency classes (IE) of the EN 61800-9-2. The drives can be configured easily and are very flexible. They are equipped with the two-channel Safe Torque Off (STO) safety function according to SIL3 / PLe.

The frequency converters were designed for dynamic use. Depending on this, they provide up to 2% of the nominal torque for 220 s. Asynchronous motors (IE2, IE3), synchronous motors and reluctance motors can be controlled in open and closed control loops. The integrated Powerlink interface, numerous I/Os, embedded allow maximum flexibility in system design Encoder and optional interface cards.

The P86 portfolio is extremely robust. The devices were specially developed for applications in harsh environmental conditions. Vibration, dust, shock and temperatures up to 60 ° C withstand them without any problems and remain consistently efficient.

The P66, P76, P86 and P96 models now cover different drive profiles for three-phase Asynchronous and synchronous motors with a power supply of 200 to 600 V. The products offer outputs from 0,18 to 200 kW. Because of your Scalability and its integration into B&R Automation, the Acopo Sinverter frequency converter series is ideal for small machine modules through to complex systems.

Realistically simulate the frequency converter before making a selection

15.05.2020/XNUMX/XNUMX | How will the frequency converter behave in real operation? Which sequences does the application require? Which converter type is suitable? What happens in case of overload? Does the converter work as described? Questions about questions now the converter simulator from Yaskawa answered.

With the GA500 and GA700 frequency inverters, these questions can now be answered with the Drive programming simulator just answer. The practical tool offers a realistic simulation of all frequency converters of both series, of display, buttons and I / O terminals.

The virtual frequency converter can then be programmed and operated via the keypad on the screen in the same way as its real counterpart. He'll be about that virtual input terminals controlled. Starts and stops can be set and input functions can be activated. The reaction can be read from the virtual output terminals and saved. Alarms and errors such as overload or the like can be simulated.

The settings can then simply be adopted for real frequency converters. Reads the Drivewizard control software Enter the data on a PC or smartphone and transfer it to the device. The simulator is free. Yaskawa recommends it for those who want to get to know the in-house frequency converters better, want to test their own sequences or use it to create parameter sets for real drives. The simulation software is also very suitable for training courses.

The frequency converters GA500 and GA700 are compact and cover outputs of up to 30 kW or until 355 kW away. They are suitable for various motor types such as asynchronous motors, permanent magnet motors or synchronous reluctance motors. The areas of application range from simple conveyor belts or presses to complex systems with networked drives or safety-relevant areas. In addition, the frequency converters can be commissioned in just a few minutes thanks to the intuitive operating concept.

Inverters now with Profinet, Ethercat and Biss interfaces

06.02.2020 | Developed on the basis of the new development platform SD4x Sieb & Meyer a sustainable converter family with immediate effect. The frequency converters support new interfaces such as Profinet, Ethercat or Biss and offer a range of additional functions. Users expect higher speeds and significantly better performance. The developers start with the SD4S.

06.02.2020 | Developed on the basis of the new development platform SD4x Sieb & Meyer a sustainable converter family with immediate effect. The frequency converters support new interfaces such as Profinet, Ethercat or Biss and offer a range of additional functions. Users expect higher speeds and significantly better performance. The developers start with the SD4S.

The frequency converter is designed for small high-speed spindles or high-speed motors in the power range of a few 100 W. The SD4x family offers a clear improved processor performance: The new 5-bit processor is up to 2 times faster than the current SD32x product family. It allows higher resolution and more accurate calculations. Sieb & Meyer has also switched from fixed-point to floating-point arithmetic. This allows the frequency converters to be designed more flexibly.

With the new processor, more complex tasks can be solved faster and control solutions can be implemented with higher resolution and dynamics. On the memory side, the 500 times larger memory also increased significantly. In summary, the optimized performance, higher speeds and low motor heating without a sine filter are the main advantages of the SD4x converter family. The improvements allow completely new areas of application.

Small, high-speed spindles and precision machining

The SD4S inverter was designed for small high speed spindles or motors in the power range of a few hundred watts. It is used, for example, in dental milling machines or machines for precision machining, such as in the watchmaking industry. Because the necessary insulation strength in the motors is often not provided with small spindles, the SD4S now enables galvanic isolation of the thermal contact. The overall width is only 40 mm.

The parameterization takes place via a standard Ethernet interface, which replaces the fault-prone USB interface. Furthermore, the SD4S has parameterizable digital interfaces for measuring systems such as Biss-C, Endat2.2 and TTL. A web server enables information to be called up without additional parameterization software. The integrated real-time clock allows interactions with external events or processes and an exact analysis of errors. Sieb & Meyer will continuously expand the performance classes of the SD4S.

Mobile app for control cabinet and frequency converter

09.01.2020 | NORD has created a mobile commissioning and maintenance solution for control cabinets and frequency converters with the Nordcon app and the Bluetooth stick Nordac Access BT. Both tools are used, among other things, to monitor the drive of the frequency inverter via dashboard.

09.01.2020 | NORD has created a mobile commissioning and maintenance solution for control cabinets and frequency converters with the Nordcon app and the Bluetooth stick Nordac Access BT. Both tools are used, among other things, to monitor the drive of the frequency inverter via dashboard.

Frequency converters for special industries

With sensorless control for logistics

13.03.2023/XNUMX/XNUMX | With the frequency converters from costal the exact rotor position can be determined efficiently without a position encoder. This is particularly interesting for use in logistics and intralogistics, where frequency converters are widespread. With the patented pulse injection process in the Inveor series, rotor position sensors, connections, interfaces and maintenance are no longer required. By eliminating the Sensors the frequency converters become more robust, offer high starting torques and overloads as well as the dynamics often required in logistics.

"When it comes to sensorless positioning, other systems available on the market quickly reach their limits because the positioning can only be as good as the signal coming from the Motor is pulled. We have created a very advanced solution with our special pulse injection process and the Integrated Sensorless Position Control (ISP) feature. The aim is to revolutionize the frequency converter market with our sensorless motor control," comments the sales manager Jurgen Bader.

Devices for braking energy recuperation for electric drives

Devices for braking energy recuperation for electric drives

The pulse injection procedure determines the exact rotor position based on the anisotropy of the motor without any additional position encoder. The engine itself is used as a sensor. This allows high-performance, sensorless control of all motor types, such as all synchronous and synchronous reluctance motors - a very efficient and future-proof alternative to asynchronous motors. The high-resolution speed control can be compared to the performance of an incremental encoder. The Kostal converter thus achieves a position accuracy that is as high as that of systems with encoders. It guarantees an infinite number of repetitions without drifting and jerk-free starting and stopping with very high dynamics and consistently high precision.

Integrated sensorless position control (ISP) another feature is available that is second to none. With the completely sensorless positioning function, many standard positionings in logistics can be mapped.

The encoderless frequency converters are particularly suitable for Heavy duty inserts under difficult environmental conditions. Without sensors, there are no problems caused by moisture, vibration, heat, cold, radiation or dust. The frequency converter is also compact, has a high breakaway torque for the lowest speeds and an overload capacity of 200%. This makes the Inveor ideal for use in baggage transport systems at airports.

With the pulse injection process, the frequency converters efficiently control all motor types and exceed the requirements of the Ecodesign Policy. Due to the extended speed setting range down to standstill, no switching points and no controlled operation are necessary.

Conveyor technology in airports and parcel distribution centers

28.07.2021 | North part presents the new Nordac Flex SK 205E frequency inverter from its Nordac Flex series. It was developed specifically for luggage transport systems at airports and conveyor systems in parcel distribution centers. The performance range of the compact frequency inverters goes up to 22 kW.

28.07.2021 | North part presents the new Nordac Flex SK 205E frequency inverter from its Nordac Flex series. It was developed specifically for luggage transport systems at airports and conveyor systems in parcel distribution centers. The performance range of the compact frequency inverters goes up to 22 kW.

Converter for controlling compressors in fuel cells

11.02.2020 | Celeroton introduces a special frequency converter that is used to control compressorsen in fuel cells Systems. The CC-550-7500 allows sensorless control of brushless DC motors (BLDC) and Permanent Magnet Synchronous Machines (PMSM).

11.02.2020 | Celeroton introduces a special frequency converter that is used to control compressorsen in fuel cells Systems. The CC-550-7500 allows sensorless control of brushless DC motors (BLDC) and Permanent Magnet Synchronous Machines (PMSM).

The modulation and control can be matched to almost any electrical machine. That guarantees one maximum efficiency in the frequency converter and minimal motor losses. Pulse width modulation (PWM) with different switching frequencies and pulse amplitude modulation (PAM) can be used in a converter. Thanks to PAM technology, an output filter between the motor and converter is not necessary.

Developed in-house sensorless regulation of the inverter allows the speed control without Encoder or hall sensor. Auto tuning, automatic controller parameterization and support from trained Celeroton engineers ensure quick and easy commissioning.

Intelligent drives for smart building automation

February 18.02.2019, 102 | The frequency converters "VLT HVAC Drive FCXNUMX" from Danfoss make a significant contribution to the realization and modernization of more energy-efficient buildings. By efficiently controlling standard asynchronous, permanent magnet and synchronous reluctance motors, these frequency converters exploit the energy saving potential through speed control of pumps, compressorsen and fans in building technology.

February 18.02.2019, 102 | The frequency converters "VLT HVAC Drive FCXNUMX" from Danfoss make a significant contribution to the realization and modernization of more energy-efficient buildings. By efficiently controlling standard asynchronous, permanent magnet and synchronous reluctance motors, these frequency converters exploit the energy saving potential through speed control of pumps, compressorsen and fans in building technology.

Condition-based maintenance helps users optimize maintenance costs and reduce expensive repairs. New software functions in the inverter help the system operator to identify possible faults at an early stage, before they lead to a system shutdown and thus to an expensive, unplanned repair.

The Pressure transmitter PTU 025 is connected directly to the frequency converter and measures the differential pressure in ventilation systems. The filter contamination and air volume flow are displayed on the display of the VLT HVAC Drive or via a fieldbus output to a higher-level controller. The ventilation system thus runs ErP-compliant and the filter is replaced at the optimum time as required.

The Remote monitoring system informs the user about the current status of the drives via the Internet from any location using a PC, tablet or smartphone. If necessary, the intelligent frequency converters also take over control functions of the ventilation system in order to relieve or even replace the central PLC. A corresponding expansion module is simply integrated into the inverter.

Frequently asked questions

What does a frequency converter do?

A frequency converter, also known as an inverter, regulates the speed of a three-phase motor operated on an AC mains by varying frequency and voltage. In this way, the alternating voltage and thus the speed can be changed.

What types of frequency inverters are there?

There are two types of frequency converters: voltage led and current led. Current-controlled inverters ensure that the current to frequency ratio remains constant. This predestines them for applications in the higher MW range. Voltage-controlled frequency converters keep the ratio of voltage to frequency constant and are suitable for use in the lower megawatt to kilowatt range.

How does a frequency converter work?

A frequency converter, also called Variable Frequency Drive (VFD), is a device that controls the speed of an electric motor by changing the frequency and voltage of the current supplied to the motor.

By adjusting the frequency of the current supplied to the motor, the frequency converter can control the Dcontrol the speed of the engine. A higher frequency increases the speed while a lower frequency reduces it. At the same time, the voltage is adjusted to ensure that the motor works efficiently and delivers the desired performance.

This ability to provide precise control makes variable speed drives essential for applications that require variable motor control, such as pumps, fans, conveyors, and other machines that require speed changes.

Where is a frequency converter needed?

Frequency converters are indispensable components in modern automation technology and play a crucial role in a variety of industrial applications. They enable precise control of the Speed of electric motors, which is essential in sectors such as mechanical engineering, manufacturing and water management.

Frequency converters prove their value, particularly where it is important to precisely adapt the motor power to the respective process requirements - for example in conveyor belts, ventilation systems or pumping stations. Their ability to improve energy efficiency and reduce wear and tear on engines means they not only help reduce costs but also provide support sustainability goals.

With their increasing integration into intelligent control systems and IoTsolutions open up new avenues for frequency converters for optimized operational processes and future-proof Industry 4.0 applications.

You might also be interested in...

Artificial Intelligence | trends and developments

Predictive maintenance for robotics, machines and systems

Mitsubishi Electric | Automating the World

Cobot | Discover collaborative robots as a new employee

Intelligent CNC control for machine tools

battery production | Facts and Technologies

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.