Frequency converter from the modular system for control cabinet + field

- Details

- Hits: 25769

NORD is one of the pioneers of innovative frequency converter Technology and has been developing electronic for more than 30 years Drive Technology. The portfolio includes motor starters and converters. Nord Drivesystems presents the brand new Nordac ON Series for decentralized applications and small power ranges as well as the extended Nordac Pro SK 500P Inverter for the switch cabinet with up to 22 kilowatts of power. You can find these and other new products below:

Contents

- Functional safety for converters

- Frequency converters and motor starters - regardless of the application

- Decentralized and control cabinet converter for IIoT

- Frequency converters for conveyor technology in airports and parcel distribution centers

- Mobile app for control cabinet and frequency converter

- Electronics manufacturing in East Frisia

- Control cabinet converter with real-time Ethernet - Interview

- Frequency converter with integrated PLC for monitoring the drive

- Decentralized frequency converter with encoder connection

Functional safety for converters

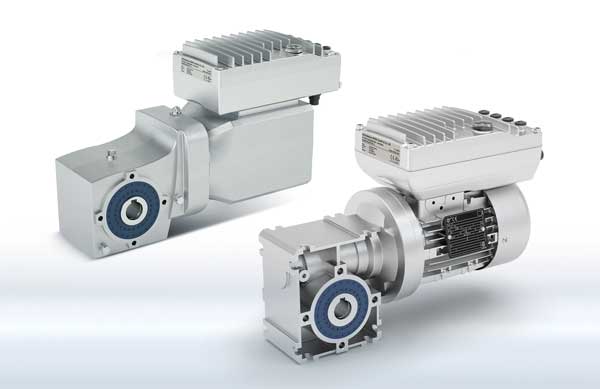

25.10.2022/XNUMX/XNUMX | A trade fair highlight from Getriebebau Nord at the SPS is the modular system LogiDrive: In addition to the previous system solutions such as the IE4 synchronous motor, which is integrated into a two-stage bevel-helical gearbox, this now also includes products such as the geared motor Duodrive, the frequency converter Nordac on (+) as well as the IE5+ motors.

25.10.2022/XNUMX/XNUMX | A trade fair highlight from Getriebebau Nord at the SPS is the modular system LogiDrive: In addition to the previous system solutions such as the IE4 synchronous motor, which is integrated into a two-stage bevel-helical gearbox, this now also includes products such as the geared motor Duodrive, the frequency converter Nordac on (+) as well as the IE5+ motors.

The Nordac Pro The product family includes compact frequency converters with an integrated multi-protocol Ethernet interface for various power classes from 0,25 to 22 kW. The basic version Nordac Pro SK 500P is particularly versatile. It offers high-quality connection and functional properties such as a CANopen interface, brake chopper, PLC function and a Posicon positioning controller. Pluggable operating and option modules make the products as flexible as possible.

The drive specialist supports the drive-based with its electronic drive technology functional safety for converters in switch cabinet and in the field. The drives are integrated in a safety-related manner via Ethernet and discrete inputs and outputs.

Getriebebau Nord is exhibiting at SPS 2022.

Frequency converters and motor starters - regardless of the application

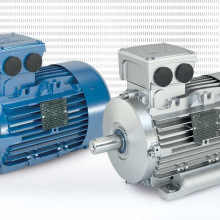

17.01.2022/XNUMX/XNUMX | the northac Product family from Nord Drivesystems offers electronic drive technology for the switch cabinet or as a decentralized variant for use in the field and thus for almost every application. The frequency converters and motor starters cover a wide power range up to 160 kW. They offer high performance and security.

That is especially worth mentioning Modular system to decentralized drive electronics that can be built on the motor or mounted close to the motor. With a power range of up to 22 kW and a wide range of functions, the decentralized drives are used in many applications around the world - from intralogistics to food technology and bulk material handling.

Inverter with scalable functions

All North frequency converter are scalable in function and equipment. So they can be adapted to any application. The frequency converters can also be installed quickly, are easy to operate and are compatible with all commercially available controls and bus systems.

Network-capable frequency converters from Mitsubishi Electric

Network-capable frequency converters from Mitsubishi Electric

Useful features guarantee a high level of user benefit, including PLC functionality for drive-related functions, energy-saving function for partial load range, Posicon positioning control, integrated brake chopper for 4-quadrant operation and functional safety with STO and SS1.

The frequency converters have a Closed-loop or open-loop functionality and were designed for the operation of asynchronous motors and synchronous motors. The precise current vector control achieves the optimum torque in a wide range of load and speed situations. The consistency of Nordac frequency inverters ensures uniform operation, a comparable range of functions and common options.

Predictive maintenance with condition monitoring

With their condition monitoring functions, all Nord frequency inverters offer solutions for predictive maintenance. They are also suitable for use in Industrial Internet of Things (IIoT) and Industry 4.0 Applications well equipped. The integrated PLC processes the data from connected actuators and sensors. It initiates sequence controls independently and transmits the drive and application data to the control center, networked components or an existing cloud.

Solar inverter with integrated yield optimization

Solar inverter with integrated yield optimization

The periodic or continuous recording of the drive and status data enables impermissible operating conditions to be recognized early and avoided. In this way, unplanned downtimes can be significantly reduced. The condition-based maintenance takes the place of time-based maintenance, so that a machine or system downtime can be planned. The company pursues a comprehensive TCO approach that optimally coordinates investment, operating and maintenance costs.

Decentralized and control cabinet frequency converter for IIoT

20.10.2021/2021/XNUMX | In the field of frequency converters, Getriebebau Nord will be presenting the same in autumn XNUMX two new developments for Industrial Internet of Things (IIoT) applications: the control cabinet converter Nordac Pro SK 500P up to 22 kW power and the decentralized converter Nordac ON for up to 1,0 kW power. The integrated multi-protocol Ethernet interface with Profinet, Ethernet IP or Ethercat is characteristic. The required protocol can easily be set using parameters. Because no additional Ethernet module is required, there is a reduction in the number of variants with additional space and cost savings.

Decentralized frequency converter for conveyor technology

Especially for the special requirements of the horizontal conveyor technology in the warehouse area, Getriebebau Nord has the decentralized frequency converter Nordac ON developed. The standardization covers all industry-specific requirements and guarantees high cost-effectiveness. Nord is thus expanding its high-efficiency portfolio with the new generation of IE5+ synchronous motors. Its integrated Ethernet interface, full pluggability and an extremely compact design are further features of the economical plug-and-play solution for IIoT.

Especially for the special requirements of the horizontal conveyor technology in the warehouse area, Getriebebau Nord has the decentralized frequency converter Nordac ON developed. The standardization covers all industry-specific requirements and guarantees high cost-effectiveness. Nord is thus expanding its high-efficiency portfolio with the new generation of IE5+ synchronous motors. Its integrated Ethernet interface, full pluggability and an extremely compact design are further features of the economical plug-and-play solution for IIoT.

The Nordac ON is mounted directly on the drive housing and covers smaller power ranges up to 1,0 kW. Are available two options: the Nordac ON for operation with asynchronous motors and the Nordac ON + for combination with synchronous motors.

The pluggable connections guarantee fast and uncomplicated commissioning and maintenance on site. The equipment includes a diagnostic interface, four digital inputs and, with the Nordac ON +, an additional protocol-based and therefore less susceptible to interference encoder interface.

There are optional modules for the functional safety (STO) that Surface finishing NSD Tuph as well as internal braking resistors for dynamic start-stop processes. If a motor mounting of the converter is not desired or impossible, there is an alternative to wall mounting, with which the frequency converter can be connected close to the drive.

Videos about Nordac ON

The following videos provide an insight into the features of the new frequency inverter series:

Product Overview

Converter for the control cabinet

The frequency converter generation Nordac Pro SK 500P is expanded by five performance levels and now covers a performance range of 0,25 to 22 kW away. With the integrated multi-protocol Ethernet interface, they are suitable for Industry 4.0 drives. A multi-encoder interface also makes it suitable for multi-axis operation and the USB interface is used for parameterization without voltage.

The switch cabinet converters are functional and versatile and offer a high level of quality connectivity. Different device variants are available. Plug-in modules for operation, safety and variable options make the control cabinet converters very flexible. Thanks to the compact design in booksize format, the converters can be saved in switch cabinet Install.

The modular frequency converter series offers a modern connectivity. So allows one USB interface the parameterization of voltage-free converters in the packaging. On the other hand, an SD card is used as a storage medium for parameters.

The control cabinet converters also have a CANopen Interface, five to six digital and two analogue inputs, two digital and one analogue output, one HTL / TTL incremental encoder interface, two potential-free multifunctionrelay as well as a universal encoder interface for connecting SIN/COS, Biss-SSI, Hiperface and Endat donors.

The Nordac Pro SK 500P can at the same time up to four encoder read. The frequency converter can control several motors sequentially in positioning mode. Further features of the frequency converter all-rounder are:

- integrated PLC for drive-related motion and logic control

- 200% overload reserve for perfect torque and speed performance

- Sensorless current vector control for asynchronous and synchronous motors (openloop and closedloop)

- Brake chopper for 4-quadrant operation

- Engine braking management

- integrated STO and SS1

Decentralized drives for the digital factory of the future

Decentralized drives for the digital factory of the future

All in all, the Nordac Pro SK 500P frequency inverters for the control cabinet are intelligent, communicative and easy to connect. That too Overall concept Nord has revised the device series and put the device series on a new, future-proof platform that is downwardly compatible with the current SK500E series.

Videos about the Nordac Pro SK 500P

The following videos illustrate the user-friendliness of the new frequency inverter series:

Universal Ethernet interface

The frequency converter has an industrial Ethernet interface for connection to the modern control system.

Bluetooth interface

The Nordac Access BT can be used to establish a wireless connection to mobile devices

USB interface

The integrated USB interface in the control cabinet converter enables offline parameterization.

Wiring aid

For quick and convenient installation, a holding shaft for the control terminal simplifies access for wiring the control signals.

Frequency converters for conveyor technology in airports and parcel distribution centers

28.07.2021/XNUMX/XNUMX | Nord Drivesystems introduces from the range of its powerful and efficient Nordac Flex series presented the new Nordac Flex SK 205E frequency converter. The Nordac Flex SK 205E was specially developed for baggage transport systems at airports and the conveyor systems in parcel distribution centers.

The performance range of the compact frequency converter goes up to 22 kW. The integrated Posicon control ensures precision in synchronous and positioning applications. A precise and fast current vector control ensures that the speed remains constant with changing loads. Thanks to its good energy efficiency, the variable frequency converter enables energy savings, especially in partial load operation. This even applies to applications for which no frequency converter is technically required.

The performance range of the compact frequency converter goes up to 22 kW. The integrated Posicon control ensures precision in synchronous and positioning applications. A precise and fast current vector control ensures that the speed remains constant with changing loads. Thanks to its good energy efficiency, the variable frequency converter enables energy savings, especially in partial load operation. This even applies to applications for which no frequency converter is technically required.

The frequency converters can be close to the drive in the field and integrated in the motor to install. The connection of power and data lines can be plugged in. The decentralized system enables short motor and encoder cables and short supply lines to sensors. Standard asynchronous motors, highly efficient synchronous motors and brake motors can be controlled with the frequency converters. For example, position-controlled transport systems encoder feedback can be implemented. Thanks to its high overload behavior during operation, dynamic movements with short start and stop times or cyclic operation can also be implemented.

Equipment from digital input to Ethernet interface

The frequency converters have four digital inputs and a digital output e.g. B. for error messages. The frequency converter can be monitored on the software side with the Nordcon app via an optional Bluetooth interface. Possible errors can be quickly diagnosed and eliminated. The standard configuration of the drive is possible via the integrated diagnostics interface with the free Nordcon software tool.

Voltage converter for 24 volt sensors in 48 volt drives

Voltage converter for 24 volt sensors in 48 volt drives

A total of six digital and two analog interfaces, two encoder interfaces and an integrated PLC for programming drive-related functions are part of the equipment on the frequency converters. Accessory side there are versatile expansions through optional modules, such as an interface to the Communicationwhich supports the standard Ethernet dialects. There are also extensions for functional safety such as Profisafe and STO.

Mobile app for control cabinet and frequency converter

09.01.2020 | Getriebebau Nord has with the Nordcon App and the bluetooth stick Nordac Access BT created a mobile commissioning and maintenance solution for control cabinet and frequency converters. Both tools are used for drive monitoring of the frequency converter from Nord via dashboard, its analysis using a convenient oscilloscope function and its parameterization. In addition to drive monitoring, the dashboard-based visualization can also be used to diagnose errors in the frequency converter.

Drives for grain terminals from Lachenmeier Monsum

Drives for grain terminals from Lachenmeier Monsum

The Parameterization of electric drives is easy and uncomplicated to implement with a help function and quick access to the parameters. In addition, the Bluetooth stick can be used in stand-alone mode for backup and recovery of drive parameters. The Nordcon app and the Nordac Access BT are available for all of the electric drive systems from Getriebebau Nord. They can be used on the decentralized inverters such as the new "Nordac Pro SK 500P".

Practical access to the drive data

The stick serves as a Bridge between a mobile frequency converter and the app. It is used directly on the frequency converter. This gives the user practical access to the drive data and retains full access control. The stick can also be used without the app, for example to back up parameter data.

The stick serves as a Bridge between a mobile frequency converter and the app. It is used directly on the frequency converter. This gives the user practical access to the drive data and retains full access control. The stick can also be used without the app, for example to back up parameter data.

If the frequency converter is damaged or the drive has to be replaced, the Conveniently import the original parameterization again. Parameter transfer between a drive and a PC is also possible. The app is available for the iOS and Android operating systems in the App Store or Google Play.

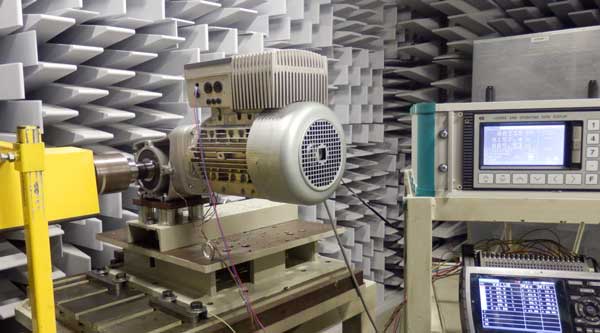

Electronics manufacturing in East Frisia

The frequency converters and motor starters have been manufactured in-house since 1984 Electronics production in Aurich, Lower Saxony (Ostfriesland). On an area of 5000 m2, more than 100.000 units are manufactured every year, from one-off production to series devices and individually configurable converters. You can read the whole report here read.

Control cabinet converter with real-time Ethernet - Interview

03.04.2019/XNUMX/XNUMX | At the Hanover Fair, Getriebebau Nord presented a new development in frequency converters. We have what it is and what it is suitable for Jörg Niermann reported in detail. We asked the Head of Marketing at Getriebebau Nord the following questions:

- which Highlight presents Nord at the Hannover Messe 2019?

- Can you tell us something more structure, function and tell variants?

- For which applications is it suitable Nordac Pro SK 500P?

Frequency converter with integrated PLC for monitoring the drive

16.05.2016/XNUMX/XNUMX | Getriebebau Nord uses frequency converters with an integrated PLC Self-monitoring of the drive a. They monitor the entire drive system with foresight, evaluate sensor data and use intelligent algorithms to assess the system status. vibrationsensors and oil sensors provide important data on wear. The vibration analysis allows conclusions to be drawn about the condition of the bearings and the gearing. Oil analysis can be used to determine when a lubricant needs to be changed.

16.05.2016/XNUMX/XNUMX | Getriebebau Nord uses frequency converters with an integrated PLC Self-monitoring of the drive a. They monitor the entire drive system with foresight, evaluate sensor data and use intelligent algorithms to assess the system status. vibrationsensors and oil sensors provide important data on wear. The vibration analysis allows conclusions to be drawn about the condition of the bearings and the gearing. Oil analysis can be used to determine when a lubricant needs to be changed.

That Predictive Maintenance However, it is also possible without external sensors and correspondingly higher costs, as shown by a "virtual sensors" functional model: The converter collects the process data of the drive system and calculates the maintenance time using an algorithm, which also includes product data and empirical values. The basis is the fieldbus-neutral reference architecture for condition monitoring in factory automation in accordance with VDMA standard sheet 24582.

Frequency converter innovations: decentralized, networked with app and much more.

Frequency converter innovations: decentralized, networked with app and much more.

In order to represent the real drive status as realistically as possible, the drive specialist compared the calculations with laboratory values and adapted the algorithm. This Software diagnostic functions are a particularly efficient solution that is also suitable for small drive sizes. With this new converter function, customers achieve longer service lives, improved availability and lower maintenance costs.

Decentralized frequency converter with encoder connection

30.04.2012/XNUMX/XNUMX | Conventional decentralized servo solutions are complex and expensive, but were often the only way to implement positioning applications in remote locations. Here, Getriebebau Nord offers the Series SK 200E an alternative based on a frequency converter.

30.04.2012/XNUMX/XNUMX | Conventional decentralized servo solutions are complex and expensive, but were often the only way to implement positioning applications in remote locations. Here, Getriebebau Nord offers the Series SK 200E an alternative based on a frequency converter.

The devices with a power range from 0,25 to 22 kW and in sizes from 1 to 4 are the only ones in their class to have a integrated positioning control and connection options for incremental and absolute rotary encoders. The SK 200E series, designed for cost-sensitive applications and suitable for mounting on the motor terminal box, also allows the use of standard asynchronous motors for applications that require relative or absolute position control. The integrated positioning control "Posicon" allows for the programming of up to 63 absolute positions. The desired positions can also have a fieldbusinterface are transmitted. In addition, up to six increments (so-called position increments) can be stored in the frequency converter.

For all tasks, the path calculation of the positioning control ensures a time-optimized and safe journey to the destination. Despite the low-priced device design, all converters offer comprehensive equipment in the basic version: In addition to the rotary encoder evaluation and the positioning control integrated brake chopper, a control unit for an electromagnetic brake and the high-quality sensorless current vector control, which holds the specified position even with strong load fluctuations. In addition, customers have a wide range of options for adapting the devices to their own requirements with internal and external expansion options.

You might also be interested in...

Gear motor integrated IE5 + motor in spur gear

Transmission North | The Block Case Inventor

IE5 + synchronous motor for variant reduction and TCO reduction

Easy-to-install IE3 asynchronous motor in eco-design

Universal motor in 20 variants for worldwide use

Modular industrial gear units for heavy-duty tasks

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.