Gear motor integrated IE5 + motor in spur gear

- Details

- Hits: 13906

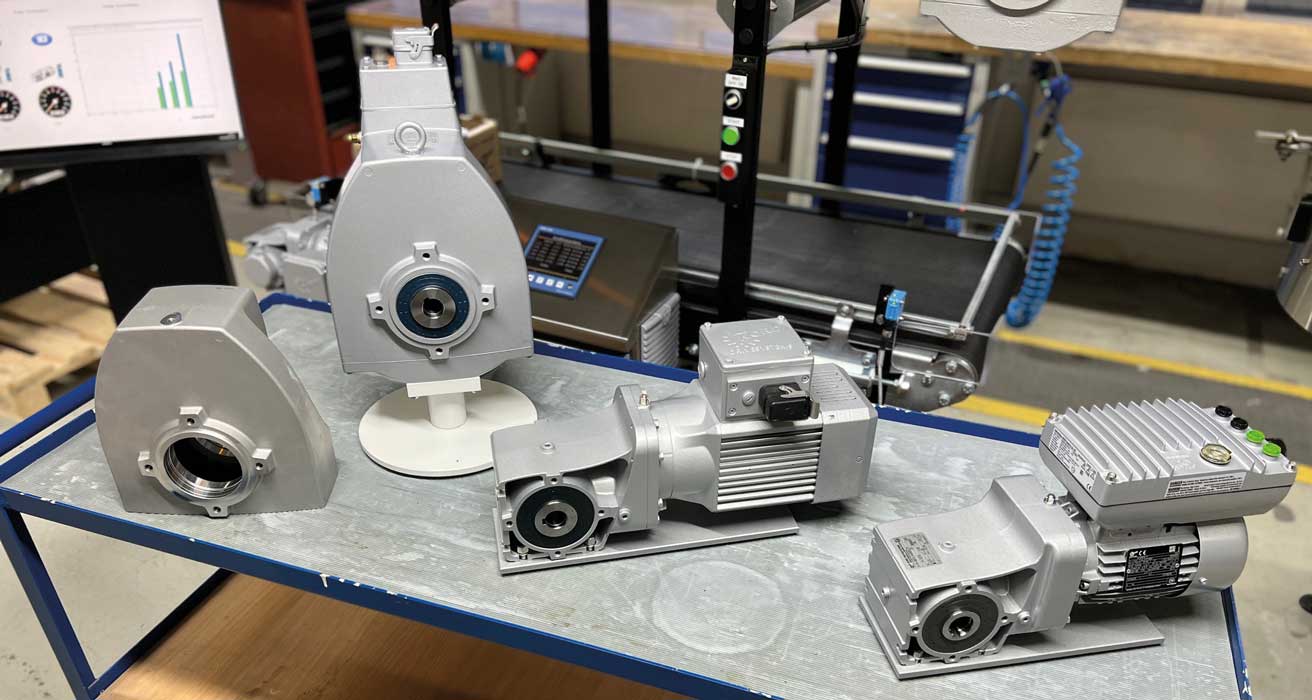

NORD presents the patented Gear Motor Duodrive in hygienic washdown design. This becomes a highly efficient one IE5 + synchronous motor in the housing of a single-stage Spur gears integrated. The innovative drive concept significantly reduces energy consumption while offering a high power density. In addition, the variants can be reduced in a targeted manner. The extended one is brand new Power range up to 3 kW.

Contents

- Gear motor power range extended to 3 kW

- Patented gear motor with 92% efficiency

- IE5 + motor in the gear motor

- Frequency converters for the Internet of Things

- Getriebebau Nord - the high-efficiency portfolio

Gear motor power range extended to 3 kW

25.04.2022/3/XNUMX | The patented gear motor Duodrive is now available with a power of up to XNUMX kW. The continuous torque is up to 250 Nm at speeds up to 1000 rpm-1. Gear ratios range from i=3 to i=18. Market-compatible connection dimensions facilitate replacement and integration into existing system designs.

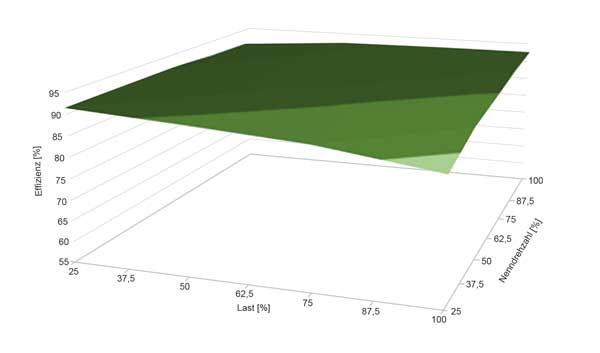

Patented gear motor with 92% efficiency

12.04.2021/XNUMX/XNUMX | The gear motor Duodrive With up to 92%, it has one of the highest efficiencies in this performance class on the market. Even in partial load operation, the electric motor achieves a very high level of efficiency. The first available geared motor size covers gear ratios from i=3,24 to i=16,2 and is designed for an output torque of up to 80 Nm and a speed of up to 1000 rpm-1 (rpm) designed. By combining the motor with the gearbox in one housing, the geared motor is very light and compact with a high power density.

The concept of the complete integration of the electric motor in the gearbox housing is completely new and has been patented by Nord Drivesystems. "With the compact geared motor Duodrive, users from intralogistics benefit food technology and pharmaceutical industry. In addition to the high system efficiency and reduced energy consumption they get many more benefits, ”reports Jörg Niermann, Head of Marketing at Nord. "Other important features are the high power density and the possibility of a consequent reduction in the number of geared motor variants with a smooth, unventilated and compact design at the same time."

Gear motor for conveyor technology

TCO consideration for conveyor systems in intralogistics

Intralogistics systems and conveyor systems for airports or parcel centers have to bring various requirements under one roof. Getriebebau Nord takes these into account in a comprehensive Total Cost of Ownership (TCO) approach. In addition to the costs, this also includes ecologically effective features.

A geared motor for the lower to medium power range does not in itself cause particularly high energy consumption and the costs incurred are also moderate. However, if you look up the amount of drives and their running hours of operation as well as the life cycle costs incurred, this reveals high economic and energetic savings potential.

Nord Drivesystems supplies between 50 and 20.000 drive systems per intralogistics and baggage handling system. Such a drive usually runs in one to three shifts in intralogistics systems. With an average installed power of approx. 0,75 kW, just one drive system represents roughly the electrical energy requirements of a single-family household. The power consumption of the conveyor technology of a complete intralogistics or baggage conveyor system quickly equals the energy requirements of an entire community.

If you compare a conventional one IE3 asynchronous motor with a corresponding IE5 + synchronous motor this results in a Energy savings of approx. 11%.

Energy efficiency, CO2 savings and sustainability

The new IE5 + synchronous motor with its consistently high degree of efficiency offers optimal performance in terms of energy consumption even in partial load and partial speed ranges. Replace one IE3 asynchronous motor with 83% motor efficiency through an IE5 + synchronous motor with 93% motor efficiency results in 16 operating hours per day and one CO2 Emission factor of 366 g / kWh a Energy savings of approx. 11%. That corresponds roughly 400 kWh and 0,15 t CO2 yearly.

Fewer wearing parts and scalability

The Duodrive geared motor is narrower than competitive products and offers a low Alley measurethat is made for conveyor technology. “We have also significantly reduced the number of wear parts on the engine. This significantly reduces the maintenance effort and friction losses, ”explains Mr. Niermann. "Less tooth engagement and fewer bearings do the rest."

Thanks to the minimized oil volume splashing losses are also lower. The Duodrive geared motor design can be installed in different installation positions without any modifications and with the same oil volume. This reduces the number of variants. The constant torque over a wide engine speed range also enables a targeted reduction in variants.

Water-cooled electric motors: compact, powerful, quiet

Water-cooled electric motors: compact, powerful, quiet

Because the performance of the geared motors without changing the external dimensions in the same design scalable no change to the system layout is necessary when adapting them. In this way, administrative expenses can be minimized and processes in geared motor manufacture, logistics, in the warehouse and service can be made leaner. In addition, the complete solution is easy to commission using plug-and-play.

Flexible gear motors for universal applications

The Duodrive gear motor can be flexibly combined with the Drive Electronics combine from north. This is how system solutions are created from a single source, in which all parts of the geared motors are seamlessly coordinated. Due to its design and operation on the frequency converter, the Duodrive can be used universally with the same motor variant.

The Duodrive gear motor can be flexibly combined with the Drive Electronics combine from north. This is how system solutions are created from a single source, in which all parts of the geared motors are seamlessly coordinated. Due to its design and operation on the frequency converter, the Duodrive can be used universally with the same motor variant.

“The new Duodrive geared motor combines the advantages of a modular system and higher efficiency with the possibilities of Variation reduction and thus pays for itself within a short period of time ", almost Jörg Niermann put together. “Using the high overload capacity of the motors and the large adjustment range of the single-stage gearbox, we tailor the system to individual customer requirements and design it specifically for the respective load spectrum of the system. We offer the right solution for every application. "

The gear motor can be provided with all standard hollow shaft dimensions from 20 mm to 40 mm as well as the flange versions B5 and B14 or a torque support. For the connection of the motor are according to customer requirements HAN plug from Harting, M12 circular connector or a terminal strip is provided. Also different options like for example encoderfeedback or a holding brake can be implemented with the Duodrive.

Gear motor for hygiene-critical areas

The Duodrive gear motor is easy to clean, it is corrosion-resistant and washdown able to. For hygiene-sensitive and harsh environmental conditions in the food technology or Pharma industry the gear motor is therefore ideally suited.

The Duodrive gear motor is easy to clean, it is corrosion-resistant and washdown able to. For hygiene-sensitive and harsh environmental conditions in the food technology or Pharma industry the gear motor is therefore ideally suited.

Due to the lower cleaning effort, users of this geared motor get a higher system availability and require less cleaning costs. The geared motor is optionally available with the particularly robust one Surface finishing NSD TupH from Getriebebau Nord. Degrees of protection up to IP69K are available if the connection is configured accordinglycables is possible.

Like the IE5 + synchronous motor from Nord, the new Duodrive gear motor also requires no fanbecause less heat has to be dissipated due to the reduced power loss. This results in low-noise operation with noise emissions of a maximum of only 65 dB (A). The lower vibrations due to the opposing motor shaft also have a positive effect on the volume.

Frequency converter innovations: decentralized, networked with app and much more.

Frequency converter innovations: decentralized, networked with app and much more.

The fanless operation also prevents germs and dusts from being swirled around. This not only benefits applications in clean rooms and hygienic environments. Also the air quality in the workplace is a better one. The lower heat loss results in more pleasant temperatures. The drive surfaces can be touched safely. This increases work safety. Overall, the Duodrive geared motor ensures a pleasant room climate in the industrial sector and in logistics centers, at the airport check-in or at goods issue in the B2C area.

IE5 + motor in the gear motor

The particularly energy-efficient IE5 + permanent magnet synchronous motors cause even lower losses than the IE4 motors from Nord, which are, for example, in the LogiDrive The manufacturer's system solution can be used. The IE5 + motor achieves its high efficiency over a wide torque range and enables economical operation in the partial load range. The higher power density with a small footprint is also advantageous. With a size 71 motor, z. B. up to 40% installation space compared to conventional ones Asynchronous motors save.

The particularly energy-efficient IE5 + permanent magnet synchronous motors cause even lower losses than the IE4 motors from Nord, which are, for example, in the LogiDrive The manufacturer's system solution can be used. The IE5 + motor achieves its high efficiency over a wide torque range and enables economical operation in the partial load range. The higher power density with a small footprint is also advantageous. With a size 71 motor, z. B. up to 40% installation space compared to conventional ones Asynchronous motors save.

The 71 size for the power range from 0,35 kW to 1,1 kW with a continuous torque of 1,6 to 4,8 Nm has been on the market since 2020. The drive specialist is now expanding its high-efficiency portfolio to include size 90 with continuous torque of up to 18,2 Nm or a power range of up to 4,0 kW. The IE5 + is available ventilated and in a smooth version. On request, it can be provided with a very smooth surface and combined with the surface refinement.

Frequency converters for the Internet of Things

The frequency converter Nordac ON was developed for the requirements of horizontal conveyor technology and the interaction with the IE5 + synchronous motor. The very compact converter offers an integrated Ethernet interface, complete pluggability and offers an economical plug-and-play solution for Internet of Things (IoT) environments.

The frequency converter for the decentralized use can be mounted directly on the motor. It covers smaller power ranges up to 1,0 kW. "While the Nordac ON was designed for operation with asynchronous motors, the Nordac ON + is designed for combination with synchronous motors and complements our high-efficiency portfolio for the new IE5 + motor generation," says Jörg Niermann in conclusion.

Getriebebau Nord - the high-efficiency portfolio

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Transmission North | The Block Case Inventor

Modular industrial gear units for heavy-duty tasks

Surface finishing + other protection for the drive technology

Getriebebau Nord Digital Trade Fair with online seminars

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.