Plastic recycling from and for industry and other uses

- Details

- Hits: 8237

For several years there has been a clear trend towards more Plastic recycling due to the worldwide increasing demands on a Recycling for plastic. Some industrial companies are already responding to this trend – and the trend is increasing. We report on their investments, strategies and innovations here.

Contents

- The first 100 Igus bikes hit the streets

- igus invests in recycling technology from Mura

- New process for PUR rigid foam recycling

- Compounds of high-performance materials from scrap tires

- Shredding, washing, sorting for plastic recycling

- Coperion builds state-of-the-art Recycling Innovation Center

- World's first urban bike made from recycled plastic

- World's first recycling program for energy and drag chains

- BASF establishes alliance against plastic waste with other companies

- Chemcycling as a new source of raw materials from plastic waste - video

The first 100 Igus bikes hit the streets

05.03.2024/XNUMX/XNUMX | "The igus:bike is now finally hitting the streets in the first small series under a new name,” says Frank Blase happily. The new branding will be announced at Cyclingworld Europe in Düsseldorf. 100 copies are currently being manufactured. After the road traffic approval, the first ones have now been delivered quickly 1200 pre-orders planned.

05.03.2024/XNUMX/XNUMX | "The igus:bike is now finally hitting the streets in the first small series under a new name,” says Frank Blase happily. The new branding will be announced at Cyclingworld Europe in Düsseldorf. 100 copies are currently being manufactured. After the road traffic approval, the first ones have now been delivered quickly 1200 pre-orders planned.

igus invests in recycling technology from Mura

09.10.2023/XNUMX/XNUMX | igus invests in the innovative Plastic recycling Technology of MuraTechnology. Construction of the first large-scale facility is scheduled for April 2023 in Teesside, Great Britain, started. The first line, with a capacity of 20.000 tons per year, will be operational this year. By 2025 in Saxony Boehlen the first plant in Germany was also built.

09.10.2023/XNUMX/XNUMX | igus invests in the innovative Plastic recycling Technology of MuraTechnology. Construction of the first large-scale facility is scheduled for April 2023 in Teesside, Great Britain, started. The first line, with a capacity of 20.000 tons per year, will be operational this year. By 2025 in Saxony Boehlen the first plant in Germany was also built.

New process for PUR rigid foam recycling

04.10.2022 | In a cooperation, Krauss Maffei, Rampf, Remondis and BASF the plastic recycling of PUR rigid foams and thus close the material cycle. This post-consumer waste comes from polyurethane (PUR) insulation materials from old refrigerators.

04.10.2022 | In a cooperation, Krauss Maffei, Rampf, Remondis and BASF the plastic recycling of PUR rigid foams and thus close the material cycle. This post-consumer waste comes from polyurethane (PUR) insulation materials from old refrigerators.

So that refrigerators work energy-efficiently and as little CO as possible2 cause emissions, manufacturers around the world use the insulation performance of polyurethane in almost all devices. But what happens at the end of the life cycle when the refrigerators and thus the PUR rigid foam have had their day?

The EU directive 2012/19/EU stipulates for the disposal of waste electrical and electronic equipment (WEEE) that rigid foam is produced as regrind, which has so far mainly been used for energy generation. Although 30% of the energy used in the production of PUR is recovered, the carbon is not kept in the material cycle. The four cooperation partners will change that. Using a new chemical recycling process depolymerization, a recycled polyol is obtained. This raw material is to be used in the production of PUR in order to close the material cycle.

To date, there have mainly been processes for the chemical recycling of PU that are based on industrial waste, mostly from production. They have a high degree of purity, which makes recycling significantly easier. Much more complex to handle is the recycling stream that comes from post-consumer waste comes from, because these are heavily contaminated with foreign substances such as other types of plastic and metals.

The aim of the development is an industrial process that produces high quality recycled polyols supplies, which are comparable to polyols obtained from fossil primary raw materials.

Reading tip: Reaching CO2 neutrality with plastic recycling

Reading tip: Reaching CO2 neutrality with plastic recycling

The chemical testing and qualitative assessment of the recyclate obtained is carried out by the BASF Polyurethanes GmbH in Lemfoerde. The basic requirement for the recycling project is that the collection and dismantling of the old refrigerators and freezers work well, for which the Remondis Electrorecycling GmbH in Lünen. the Rampf Eco Solutions GmbH in Pirmasens makes its experience in the chemical recycling of polyurethane and PET residues available for the project. Krauss Maffei contributes with its technologies for the production and recycling as well as the sustainable use of plastics at the end of the life cycle.

BASF is exhibiting at the Fair K 2022.

Compounds of high-performance materials from scrap tires

22.08.2022 | Tire Recycling Solutions SA (TRS), Préverenges, uses Buss' Compeo technology to implement its Intelligent Compounding concept to convert powder products obtained from old tires into innovative and high-quality compounds for industry.

The high-performance materials are manufactured using a proprietary process in which TPE / TPU based plastics be compounded with recycled rubber powder. The range of possible applications is large: They can be found in seals, logistics, Automotive engineering, construction industry, shoe industry and 3D Print.

Compeo compounding technology is a unique combination of high-performance, low-shear mixing and a conical discharge pump (CDP) for pressure build-up. With Elastomer know-how and the possibility of pilot-scale production runs on the Pratteln campus, Buss supported TRS in the development and evaluation of the innovative products up to the commissioning of their compounding plant.

Both companies are working closely together to expand the product platform worldwide and to install further compounding systems under TRS license. The associated disposal of old tires makes ecological sense, and every year more than 1,5 billion worldwide. attack. In some countries, these are still disposed of in landfills and are often incinerated, releasing toxic smoke and pollutants into the environment. Mixing the obtained powder into TPE / TPU plastics reduces this waste.

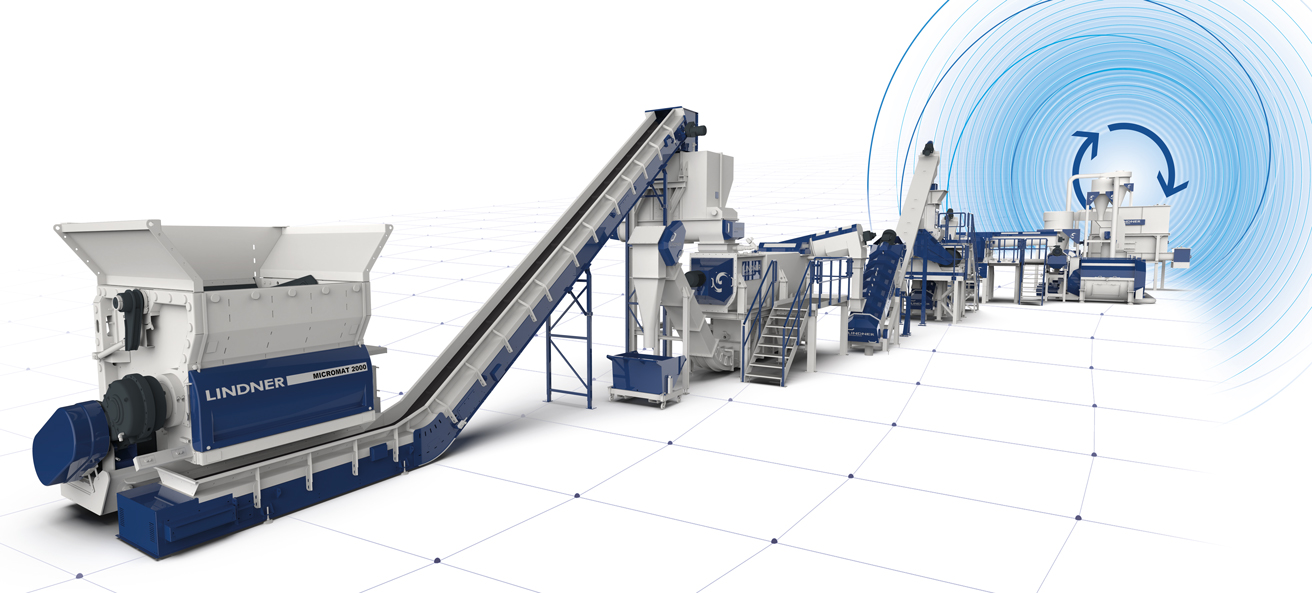

Shredding, washing, sorting for plastic recycling

25.07.2022/XNUMX/XNUMX | As a specialist in plastics recycling, Lindner is presenting a new system solution which directly Post-consumer hard plastics processed in injection molding. Plastic should be kept in the cycle for as long as possible and is increasingly being recycled in the Food industry be used. The perfect coordination of the upstream processes Shredding - Washing - Sorting. For this purpose, Lindner offers complete solutions with which the individual process steps for the processing of hard plastics, foils and PET can be efficiently optimized.

The shredding of old plastic is at the beginning of the plastic recycling process. At the new one Jupiter BW series the focus is on the optimal processing of plastic films for the downstream NIR sorting process. In addition to the constant volume flow and the uniform lumpiness, the optimized particle size is particularly important for NIR sorting. "With a grain size of DIN A4 to A3, we were able to achieve improved performance of the NIR systems for our customers," reports Stefan Scheiflinger-Ehrenwerth, head of product management at Lindner. “Every shredding process generates a certain proportion of fines in addition to the ideally chunky grain. With the gentle Jupiter BW set-up, we have managed to reduce the generation of fines by 50%, which is also confirmed by manufacturers of NIR sorting devices.”

Polyamide for electromobility and industrial applications

Polyamide for electromobility and industrial applications

The washing process is also an essential quality criterion for the high-quality regranulate production. Because plastics are increasingly being recovered from waste streams and, in this way, heavily soiled input materials are increasingly finding their way into plastics recycling, this is no easy task. “We know the problem only too well. But we also have the right solutions,” says Harold Hoffman, Managing Director of Lindner Washtech.

"We have ours patented pre-wash of the Rafter type adapted to the new requirements. The residence times can be increased by using a larger rotor, which of course has a positive effect on the degree of cleaning. In addition, we were able to sustainably increase the throughput, 3 t/h for films and 5 t/h for hard plastics, and we will be presenting this product innovation for the first time at the K trade fair,” adds Harald Hoffmann.

Lindner exhibits at the K 2022.

Coperion builds state-of-the-art Recycling Innovation Center

21.06.2022/XNUMX/XNUMX | Coperion GmbH starts building a new ultra-modern Plastic recycling technical centers at their production site in Nieder Biegen near Weingarten. The future Coperion Recycling Innovation Center is being built in the immediate vicinity of the existing test center for bulk material handling.

The Circular economy trend Through recycling, Coperion now has the new Innovation Center for the recycling of plastic in addition to the processes and systems designed for recycling. The company's experts will work with their customers to develop and test new sustainable plastic products and recycling processes. All essential process steps of recycling from material transport and dosing to extrusion, granulation and post-processing are covered. Also your own ResearchThe focus is on the company's activities for the recycling of plastics.

With the new construction of the technical center, Coperion is expanding its capacities to over 5000 m² at the locations in Germany alone. "The global demand for state-of-the-art and efficient recycling solutions for plastics will continue to increase in the coming years," comments Markus Parzer, President of the Polymer Division and Managing Director of Coperion GmbH.

Technology center showcases Barnes Group injection molding expertise

Technology center showcases Barnes Group injection molding expertise

"Not least because of the ever-increasing requirements of environmental legislation, such as within the framework of the European Green New Deals and changing consumer behavior and environmental awareness. With the decision in favor of the new Recycling Innovation Center for plastics, we are setting clear priorities in order to be there for our customers even better with our advanced technology and well-founded know-how and to accompany them on their way to more sustainability and a functioning circular economy".

Bernd Neumann, Site Manager Coperion Weingarten and Nieder Biegen adds: "We are confident that with the new Recycling Innovation Center, equipped with the latest technology for high-quality and innovative recycling processes, we will be able to create attractive added value for our customers in the plastics industry. At the same time, as an attractive employer in the region, Coperion will offer interesting and long-term jobs”.

Recycling as a central role in sustainability

The plastics industry will have to produce more sustainably in the future as a result of the changed consumer behavior of end consumers and increasingly strict environmental legislation worldwide. The recycling of plastics plays a central role in this. Many companies worldwide that process and process plastic from industrial and household waste and packaging are faced with the question of how recycling actually works at the highest quality can be implemented on an industrial scale. In the new Coperion Recycling Innovation Center, concrete solution approaches for all essential process steps of recycling will be tested and developed in the future. These can then be efficiently implemented in production from a single source.

“With this state-of-the-art technology center, we can offer our customers a first-rate solution for developing their processes and products. In addition to process and product solutions for the mechanical recycling of industrial and household waste, we can also work with our customers to develop and test innovative solutions for all other common recycling processes," explains Marina Matta, Team Leader Process Technology Engineering Plastics at Coperion. "In this way we are making a contribution to more sustainability. In addition, the Recycling Innovation Center is ideal for advancing our research and development activities for more efficiency and expanded feasibility in plastic recycling."

World's first urban bike made from recycled plastic

30.05.2022/XNUMX/XNUMX | On the Hannover Messe 2022 has Igus presented a world first with the concept of a robust and durable urban bike. The urban bike is made of 100% plastic, from the frame to the bearings to the timing belt. In a planned recycling version, most of the material will come from used plastics.

30.05.2022/XNUMX/XNUMX | On the Hannover Messe 2022 has Igus presented a world first with the concept of a robust and durable urban bike. The urban bike is made of 100% plastic, from the frame to the bearings to the timing belt. In a planned recycling version, most of the material will come from used plastics.

World's first recycling program for energy and drag chains

06.11.2019 | What happens when the maximum service life of a plastic energy or drag chain is reached? In most cases, it is simply disposed of and incinerated with other plastic waste. With the Igus green chainge recycling program a completely new approach is now being taken in Cologne: Users can send their plastic chains to Cologne for recycling – completely independently of the manufacturer.

06.11.2019 | What happens when the maximum service life of a plastic energy or drag chain is reached? In most cases, it is simply disposed of and incinerated with other plastic waste. With the Igus green chainge recycling program a completely new approach is now being taken in Cologne: Users can send their plastic chains to Cologne for recycling – completely independently of the manufacturer.

BASF establishes alliance against plastic waste with other companies

16.01.2019/30/XNUMX | Today, BASF co-founded a global alliance of around XNUMX companies to advance solutions that reduce and avoid the discharge of plastic waste into the environment, especially into the world's oceans. the Alliance against plastic waste in the environment (Alliance to End Plastic Waste, AEPW) has already committed $1 billion in funding with a goal of investing $1,5 billion over the next five years in various projects and collaborations.

New solutions for minimization and Management of plastic waste are to be developed and brought to market on an industrial scale. This also includes solutions for reusing plastics that have already been used in order to enable a circular economy.

Of central importance is the Identifying where the plastic waste comes from. Research from the environmental organization Ocean Conservancy shows that most of the plastic in the ocean comes from waste generated on land. Much of the plastic waste is carried by rivers and can be traced back to XNUMX major flows, mostly in Asia and Africa. Many of these rivers run through densely populated areas that lack proper waste collection and recycling infrastructure. This leads to an uncontrolled entry of waste into water bodies. The AEPW will start where the need is greatest.

Chemcycling as a new source of raw material from plastic waste

16.01.2019/XNUMX/XNUMX | Because the mechanical recycling of plastics is reaching its limits as the purity of the material decreases with each cycle, a BASF team developed a completely new approach to this challenge: The chemcycling project is a chemical recycling technology that replaces fossil resources for chemical production with recycled raw materials from plastic waste.

Source: This article is based on information from the following companies: BASF, Coperion, Igus, Kraussmaffei, Lindner, Rampf, Remondis, TRS.

You might also be interested in...

Reduce carbon footprint | That's how it's done!

Igus linear guide quiet, resistant, maintenance-free

Mineral cast machine bed | produce economically

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.