Rampf Group with a new plant in Canada and 15 years in Japan

- Details

- Hits: 15368

What's new at Rampf group? Rampf Composite Solutions is now operating in its new one Burlington plant, Canada. The company had previously celebrated 15 successful years in Japan. In 2005, the specialist for model and mold construction started casting resin systems, dosing systems and machine beds made of mineral cast in Osaka and has steadily expanded its market share ever since. You can find this and other Rampf news below:

Contents

- 15 successful years of the Rampf Group in Osaka, Japan

- State-of-the-art infrastructure in Burlington, Canada

- Archive for corporate news from the Rampf Group

- Receive seal of approval for health management

- Pioneering impression technology awarded

- Business result 2017 / 2018: sales increase of 8,5 percent

- Business result 2016 / 2017: Growth course and record investment

- Company founder Rudolf Rampf receives the Federal Cross of Merit

- Partnered with John Burn to sell block material

- Understanding of chemistry and technology brought together - interview

- Business result 2009 / 2010: Most successful balance sheet since foundation

State-of-the-art infrastructure in Burlington, Canada

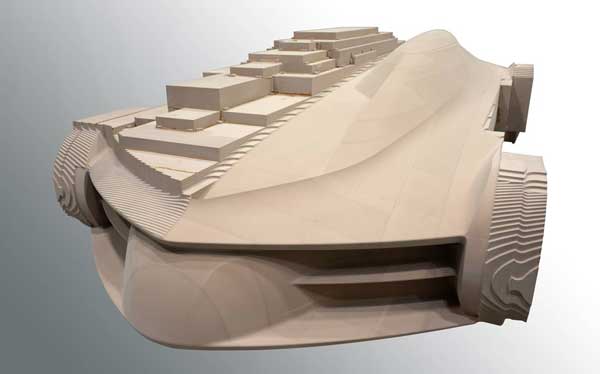

20.10.2020/XNUMX/XNUMX | The new work of Rampf Composite Solutions offers the most modern infrastructure on 6800 m². High-quality carbon fiber and glass fiber composite materials for the aviation industry are manufactured here, Safety Technology, Manufacturing engineering, Medical Technology, consumer goods industry and transport. Operations at the old plant, very close to the new building, ceased in September.

20.10.2020/XNUMX/XNUMX | The new work of Rampf Composite Solutions offers the most modern infrastructure on 6800 m². High-quality carbon fiber and glass fiber composite materials for the aviation industry are manufactured here, Safety Technology, Manufacturing engineering, Medical Technology, consumer goods industry and transport. Operations at the old plant, very close to the new building, ceased in September.

“The size and design of the new plant enables us to set up additional systems, to further improve the production processes and product quality, and to significantly shorten production and delivery times. This means that we will now be able to use the enormous potential in the fast-growing composites market even more efficiently and also take on larger projects for which we previously did not have enough space and manufacturing options, ”comments Larry Fitzgerald, Managing Director of Rampf Composite Solutions.

Ultra high-performance concrete for the large, heavy machine bed

Ultra high-performance concrete for the large, heavy machine bed

In Burlington, Canada, cutting-edge technologies are pioneering Carbon fiber and glass fiber composites manufactured. The core competencies of Rampf Composite-Solutions include the manufacture of composites with minimal manufacturing tolerances using the vacuumassisted resin injection process outside the autoclave, resin infusion, Metalcoating and value-added assemblies.

15 successful years of the Rampf Group in Osaka, Japan

November 30.11.2020, 25: Just in time for Christmas, the first container full of Raku tool Block materials in Japan. Today, the polyurethane and epoxy boards manufactured in Germany have long since established themselves in the Japanese market.

"In addition to block materials, we supply our Japanese customers with reactive casting resin systems for sealing, Glue and potting and associated dosing“Says Yoshiaki Naganuma, Managing Director of Rampf Japan.

“The latest addition to our portfolio are machine beds made from alternative materials such as Mineral casting, Ultra high performance concrete Ultra high performance concrete and hard stone."

An expert is available for solution-oriented advice and support for each product area. “By offering products and solutions made in Germany as well as dedicated customer service, we are living up to the excellent reputation of the Rampf Group in Japan.

An expert is available for solution-oriented advice and support for each product area. “By offering products and solutions made in Germany as well as dedicated customer service, we are living up to the excellent reputation of the Rampf Group in Japan.

That is the basis of our long-term success, ”emphasizes Yoshiaki Naganuma, who works with Rampf Japan Matthew Rampf, managing partner of the international Rampf Group.

“Yoshiaki Naganuma and his team are doing an excellent job. Thanks to their exemplary professionalism and their commitment, Rampf Japan has recorded considerable growth over the past 15 years and is well positioned to continue this success story, ”adds Matthias Rampf.

Industrial liquid gasket, adhesive and potting compound

Industrial liquid gasket, adhesive and potting compound

Archive for corporate news from the Rampf Group

Receive seal of approval for health management

12.12.2019/XNUMX/XNUMX | The Rampf Group is recognized for its exemplary behavior and its contribution to promoting the health of its employees Seal of quality "BFK - Healthy company" been awarded. This certification confirms that the company demonstrably implements the topics of occupational health and safety, psychological risk assessment and DGUV II (accident prevention regulations) as well as offering measures in company health management (OHM) and for the health promotion of its employees.

12.12.2019/XNUMX/XNUMX | The Rampf Group is recognized for its exemplary behavior and its contribution to promoting the health of its employees Seal of quality "BFK - Healthy company" been awarded. This certification confirms that the company demonstrably implements the topics of occupational health and safety, psychological risk assessment and DGUV II (accident prevention regulations) as well as offering measures in company health management (OHM) and for the health promotion of its employees.

The one introduced at all German locations in 2016 Rampf health management includes events and lectures on health-related topics, gymnastics courses and massages during the lunch break as well as the free provision of fruit and mineral water. In addition, all employees have the opportunity to train free of charge at the respective locations in selected fitness studios.

Pioneering impression technology awarded

30.06.2019/XNUMX/XNUMX | ramp Machine-Systems has for its molding technology for mineral cast frames received an award as part of the Innovation Award 2019 from the WIF - Economic and Innovation Promotion Agency for the district of Göppingen.

30.06.2019/XNUMX/XNUMX | ramp Machine-Systems has for its molding technology for mineral cast frames received an award as part of the Innovation Award 2019 from the WIF - Economic and Innovation Promotion Agency for the district of Göppingen.

For mineral cast machine frames precise surfaces To be able to achieve this by means of mechanical processing, large milling centers or guideway grinding machines are usually required. The resulting high costs and associated process uncertainties can now be avoided with Rampf's molding technology.

with new ones Materials as well as optimized manufacturing and processing processes, the numerous advantages of non-cutting machine frames made of mineral casting can also be used for longer precision surfaces. While previously molds in the hundredths of a millimeter range could only be reliably realized up to a mold length of 2,5 m, the mineral casting specialist now achieves evenness and straightness of 4 mm each with a mold length of 0,02 m.

Mineral cast machine frame for stable six-axis robots

Mineral cast machine frame for stable six-axis robots

Another advantage: The entire process is handled in-house, so users are not dependent on external processors and avoid expensive transport. Thomas Altman, Managing Director of Rampf Machine-Systems: "We are very pleased that we were able to convince the jury of the Innovation Award 2019 with this technological milestone. The award confirms our claim of never being satisfied with the status quo and of constantly working on the development of new products and processes.”

Business result 2017 / 2018: sales increase of 8,5 percent

16.10.2018 | The Rampf group is still on growth course: In the past 2017/18 financial year, the specialist for reactive resins, machine systems and lightweight composites generated consolidated sales of EUR 183,5 million, an increase of 8,5% compared to the same period of the previous year.

16.10.2018 | The Rampf group is still on growth course: In the past 2017/18 financial year, the specialist for reactive resins, machine systems and lightweight composites generated consolidated sales of EUR 183,5 million, an increase of 8,5% compared to the same period of the previous year.

The division once again grew the most Production Systems with dosing technology and automation solutions, which for the first time generated sales of more than 50 million euros, an increase of over 25%. With currently 216 employees, Rampf Production Systems from Zimmer o.R. is now also the largest company in the international Rampf Group in terms of number of employees.

In the business areas polymer Solutions (casting resins), Composite Solutions (Carbon fiber and glass fiber composite parts) as well as Eco Solutions (chemical recycling solutions) also achieved double-digit growth rates. Sales of machine beds and frame components made of cast mineral, hard stone and ultra-high-performance concrete (machine systems) increased slightly, while sales in model and mold construction (tooling solutions) matched the previous year's level.

Michael Koch GmbH: News from Ubstadt-Weiher

Michael Koch GmbH: News from Ubstadt-Weiher

"In view of the sometimes very difficult framework conditions, we can be satisfied with the results of the past financial year," is the conclusion of Michael Rampf (Image), Managing Partner of Rampf Holding. "The close cooperation with our customers and partners, and above all the committed commitment of our employees have enabled us to maintain our growth course." The Rampf companies in the USA, Canada, China and Japan are also continuing to grow. The Chinese branch in particular was able to significantly increase its sales compared to the previous year.

At the end of the past fiscal year on June 30, 2018, the company had worldwide 833 employees, 5% more than last year. Around three quarters of the workforce works at the five German locations and a quarter at the foreign subsidiaries. For the current financial year, the company expects sales growth of around 8% again. Around 19 million euros are to be invested, primarily in land and buildings, machinery and equipment, and IT infrastructure. In terms of personnel, the company is expected to grow by 5%.

Business result 2016 / 2017: Growth course and record investment

13.12.2017 | With innovative and tailor-made products for everything to do with reactive casting resins, machine systems and lightweight construction with composites, the companies in the Rampf Group in the 2016/17 financial year solid growth in almost all markets achieved. In the past fiscal year 2016/17, consolidated sales of EUR 169 million were generated, an increase of 10,5% compared to the same period of the previous year.

13.12.2017 | With innovative and tailor-made products for everything to do with reactive casting resins, machine systems and lightweight construction with composites, the companies in the Rampf Group in the 2016/17 financial year solid growth in almost all markets achieved. In the past fiscal year 2016/17, consolidated sales of EUR 169 million were generated, an increase of 10,5% compared to the same period of the previous year.

The international Rampf companies Production Systems, Eco Solutions, Polymer Solutions and Tooling Solutions as well as the Japanese Subsidiary Rampf Group Japan have asserted themselves well in a globalized and dynamic competitive environment and continued on their growth path, while Machine Systems confirmed the sales level of the past fiscal year.

With mineral cast machine beds and two-componentPlasticThe Chinese subsidiary has systems based on polyurethane, epoxy and silicone Rampf Taicang benefited greatly from the increasing quality requirements in the Chinese market. Due to the long-term positive market outlook, production capacities will be significantly increased in 2018 with the construction of a new production building.

Plastic recycling from and for industry and other uses

Plastic recycling from and for industry and other uses

The North American subsidiary has significant growth Rampf Group, Inc. achieved in the NAFTA markets with casting resin systems, mixing and dosing systems as well as materials for model and mold making. The successful integration of Innovative Polymers, Inc., a leading US supplier of polyurethane systems for tool and model making applications, which was acquired in July 2016, also contributed to this.

Composite solutions, the company based in Burlington, Canada, which specializes in the design, construction and manufacture of composite parts for the aerospace and medical industries, is also on a growth course: the company is doing very well with numerous projects and new applications, especially in the aerospace industry set up to make a significant contribution to the success of the RAMPF Group in the long term.

The number of employees has also increased in line with the sales development. Fiscal year 2016/17 ended June 30, 2017 were worldwide 794 employees work for the group of companies, 10,9% more than in the same period of the previous year. In the first five months of the current 2017/18 financial year, this number has increased further to over 830.

Company founder Rudolf Rampf receives the Federal Cross of Merit

07.11.2017 | In front of a historical backdrop and a large audience, the founder of the international Rampf Group Rudolph Rampf received the Federal Cross of Merit. Around 200 guests came to the historic Grafenberg wine press to attend the ceremonial handover by Economics Minister Nicole Hoffmeister-Kraut (CDU).

"You wrote a typically Swabian success story, although you were born in Austria and grew up in Bavaria," said Nicole Hoffmeister-Kraut at the beginning of your speech and thus referred to the character traits of ingenuity and diligence associated with Swabians. Because with a groundbreaking invention - the first model building board made of polyurethane in the early 1980s - and a lot of work, Rudolf Rampf built up an international group of companies from a one-man business, which now has over 800 employees.

Nicole Hoffmeister-Kraut recapitulated the career of the 72-year-old inventor and entrepreneur and emphasized that "people like you have helped make Baden-Württemberg a strong Business location and globalization winner is". With the successful change of generations in the company founded by Rudolf Rampf, which his sons now successfully run, he has proven his foresight as an entrepreneur.

Nicole Hoffmeister-Kraut recapitulated the career of the 72-year-old inventor and entrepreneur and emphasized that "people like you have helped make Baden-Württemberg a strong Business location and globalization winner is". With the successful change of generations in the company founded by Rudolf Rampf, which his sons now successfully run, he has proven his foresight as an entrepreneur.

The entrepreneur and committed citizen Rudolf Rampf acts according to the same principles. "He is a man of action, he puts his heart and soul into everything he tackles - be it the Rudolf Rampf Foundation for young people in Grafenberg, the well and school project in Angola or his commitment as a local politician and as a sponsor,” said Annette Bauer.

In his acceptance speech, Rudolf Rampf called on politicians to support German medium-sized companies and thus value-based economic model to strengthen: "The family entrepreneur is liable for his capital, his existence depends on the success of his business. That is why risks are carefully weighed up and we think and act in the long term.” His achievements as an entrepreneur and his social commitment were the focus of the evening event. "But I would never have been able to achieve all of this without my wife Eva-Marion," emphasized Rudolf Rampf. "She always stood by me in good and especially in bad times, was always the strong woman at my side and the strong foundation of our family."

Partnered with John Burn to sell block material

27.06.2017/XNUMX/XNUMX | Rampf Tooling Solutions has partnered with Birmingham based company John Burn + Co Ltd for the distribution of its branded block materials, close contour products and liquid caulking systems Raku tool closed in UK. These include, but are not limited to, styling, model, and tool block materials; Close Contour Pastes, Close Contour Blocks and Close Contour Castings; Finishing, laminating, casting and general purpose resins.

27.06.2017/XNUMX/XNUMX | Rampf Tooling Solutions has partnered with Birmingham based company John Burn + Co Ltd for the distribution of its branded block materials, close contour products and liquid caulking systems Raku tool closed in UK. These include, but are not limited to, styling, model, and tool block materials; Close Contour Pastes, Close Contour Blocks and Close Contour Castings; Finishing, laminating, casting and general purpose resins.

John Burn is a on materials for the Composite and Foundry-Industry specialized wholesaler. The 2173 m² warehouse of the company founded in 1904 ensures fast processing from receipt of order to delivery.

Paul moore, Business Development Manager at John Burn & Co Ltd: “We are delighted to be working with Rampf, ensuring a strong presence and short delivery times across the UK. Our company is ISO 9001:2008 certified by the NQA and we are of course committed to the highest quality standards.”

Understanding of chemistry and technology brought together - interview

02.02.2017 | The Rampf Group recorded strong sales growth in the last financial year and is focusing on new core competencies: What are these and the following additional questions we have in our interview with Michael and Matthias Rampf, both managing partners of Rampf Holding GmbH & Co. KG, Grafenberg, during our visit to Grafenberg:

- who is and what does Rampf?

- They had a 2015/16 strong sales growth from 7,7% after 17% the year before. How did you manage that?

- Which are the most important synergies between your member companies?

- How did the development of the new core competence come about? Composite Solutions and what goals have you set yourself here?

- The Tooling Solutions Are you the market leader with the block material Raku-Tool: What development potential does the technology still have?

- How is the situation with the machine systems?

- They are working through fossil renewable resources to replace: For which products and applications is this relevant?

- Your family business lives a family-friendly corporate culture: What do you offer your employees?

Business result 2009 / 2010: Most successful balance sheet since foundation

22.08.2011/XNUMX/XNUMX | At the balance sheet press conference of the Rampf Group at the company headquarters in Grafenberg last week, the managing partner of Rampf Holding Michael Rampf commented on this most successful financial year of the group since the company was founded in 1980.

The expected consolidated turnover as of 30.06.2011/XNUMX/XNUMX is 104,5 million euros. This corresponds to an increase in sales of 46% compared to the previous year 2009/2010 and an increase of around 15% compared to the previous peak year 2007/2008. National sales last year were EUR 41,4 million, international sales were significantly higher at EUR 61,3 million. “The international markets are enormously important for us. The share of international business accounts for around 60 percent of total sales,” says Michael Rampf. "Especially in the USA, we grew strongly during the crisis," says Rampf, who built up the Rampf Group, Inc. in Wixom, Michigan, USA in 2003-2004.

Im Fiscal year 2011/2012 the company will invest around 8 million euros. Investments are made in silicone production as the third pillar of Rampf Giessharze, in the expansion of the production of "large-volume" models at Rampf Tooling and in new product groups Eputronic, Epustone and Epugrind from Epucret Mineralgusstechnik. A new location is also in the middle of the planning phase. With an extension, Rampf Dosiertechnik will soon have additional floor space of around 3500 m² in Zimmer. The company's new building is scheduled to open in spring 2012 and will create space for a new logistics and service center, for expanded application technology and contract manufacturing.

The number of employees in the RAMPF Group has increased continuously by 8%. As of June 30.06.2011, XNUMX, the company employed people worldwide 444 employees, including 388 employees at the German locations.

Who is the Rampf Group?

The Rampf Group is a globally active family company in the field of chemical and engineering with the core competencies of machine systems, production systems, composite solutions, eco solutions, polymer solutions and tooling solutions. Founded in 1980, the manufacturer of materials for shaping, lightweight construction and joining as well as production engineering systems has its main location in Grafenberg. Rampf produces in its own production facilities in Germany, USA, Canada, China and Japan.

You might also be interested in...

Mineral cast machine bed | produce economically

Reduce carbon footprint | That's how it's done!

Plastic recycling from and for industry and other uses

Industrial liquid gasket, adhesive and potting compound

Mineral cast machine frame for stable six-axis robots