Mineral cast machine frame for stable six-axis robots

- Details

- Hits: 14828

Sherpa Robotics sets with his camera controlled Six-axis robot for the automated loading of components on CNC machines machine frame made from epument mineral casting Rampf Machine Systems. The epoxy resin bonded material ensures the necessary stability of the “Sherpaloader” with a very good ecological balance. Not least because from now on the mineral cast will be produced without the addition of hard coal fly ash.

Content of the user report

- Robotics for feeding CNC machines

- Mineral casting will be even more environmentally friendly in 2021

- Development partner and system supplier

Robotics for feeding CNC machines

Is it worth it or is it not worth it? When asked about the use of Automation In mechanical engineering, the production of small to medium-sized batches, it is about the basics: the entry into Industry 4.0.

“Often the disadvantages of conventional robotic systems are for the loading of CNC machines decisive for a negative answer to this question. Because these robots need mechanical supply systems that are fragile and require a lot of effort in terms of conversion and maintenance, ”says knows Florian André, Managing Director at Sherpa Robotics.

Easily produce mineral casting machine bed economically

Easily produce mineral casting machine bed economically

According to Florian Andre, this problem is mainly faced by medium-sized contract and contract manufacturers in mechanical engineering who specialize in the processing of Lot sizes between 20 and 1000 have specialized. “On the other hand, fluctuating incoming orders, shorter delivery times, rising production costs and the lack of skilled workers require innovative solutions to make manufacturing more efficient, more flexible, more intelligent and less labor-intensive. That speaks for the use of automation solutions in this branch as well. "

Digital camera system records workpieces

One such intelligent solution is the CNC automation developed by Sherpa Robotics based in Stuttgart-Fellbach sherpal loader. By using a digital Camera system loading trolleys and a wide variety of workpiece types are automatically recorded without the need for grid plates or stacking magazines.

High-performance concrete for the individual machine bed

High-performance concrete for the individual machine bed

This will make the Setup time for loading the machine reduced to less than 5 min, a part change only takes 15 s. The robot is easy to operate, orders are controlled using "Easycontrol" without the need for trained specialists.

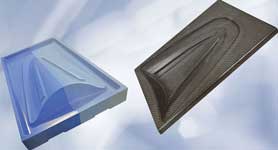

The robot arm and control cabinet of the Sherpaloader are on one Machine bed from Epument anchored. The footprint of the system is less than 1 m² and it is mobile: the robot can be positioned in front of the machine in use using a lift truck.

Features already integrated in the machine frame

Julian Schulze, Technical Manager at Sherpa Robotics: “We decided on a machine frame made from Epument, as this material guarantees the required stability and enables numerous features to be integrated into the frame and in the smallest of spaces. In addition, this mineral cast is the first choice for machine frames from an ecological point of view.

Mineral casting will be even more environmentally friendly in 2021

Since May 2021, the world's largest mineral casting producer has been realizing a further improvement in its ecological balance. In future it will be the Epument mineral casting material for machine beds and frame components in highly dynamic mechanical engineering without the addition of Coal fly ash manufacture. Instead, Rampf Machine Systems relies on a filler that is produced using a special process based on a very pure, natural Calcium carbonate will be produced. The material properties and the price of the material are retained, while the ecological balance continues to improve.

Stable machine frame for special machine

Stable machine frame for special machine

dr Thomas Abel, Director of Laboratory at Rampf Machine Systems: “One focus of the R&D efforts in our in-house laboratory has always been to improve the ecological balance of our materials. The use of hard coal fly ash is due to the CO produced during the extraction and combustion of hard coal2 Output is no longer up-to-date. In addition, the CO2 Price increases make production more expensive. In the search for an adequate alternative, we consequently concentrated on both the extraction process of the raw material and its regional availability. "

dr Thomas Abel, Director of Laboratory at Rampf Machine Systems: “One focus of the R&D efforts in our in-house laboratory has always been to improve the ecological balance of our materials. The use of hard coal fly ash is due to the CO produced during the extraction and combustion of hard coal2 Output is no longer up-to-date. In addition, the CO2 Price increases make production more expensive. In the search for an adequate alternative, we consequently concentrated on both the extraction process of the raw material and its regional availability. "

The raw material supplier is located close from Rampf Machine Systems. This minimizes the economic and ecological transport costs. Global warming also speaks in favor of excluding hard coal fly ash. Due to the rising temperatures in winter, there is a risk that their medium and long-term availability could be impaired. The new filler, on the other hand, is available in a consistently high quality. It is also less expensive to mine than hard coal.

Sustainable production for decades

Rampf has been making an important contribution to for decades more sustainable production. In the production of Epument mineral cast and also from Epudur ultra high performance concrete compared to melting steel and gray cast iron, up to 30% less primary energy is consumed. The combination of high casting accuracy and high-precision in-house molding technology saves the otherwise necessary transport trips to external processors.

Liquid resin and epoxy resin for prototypes, models and molds

Liquid resin and epoxy resin for prototypes, models and molds

In addition, fewer processing machines are required or avoided entirely. Compared to milling, the application of the precision surfaces are round 50% less CO2 Emissions at. Last but not least, machine beds and frame components made of high-performance concrete and mineral casting can be disposed of like normal building rubble. As a recycling material, they can ultimately be reused in industrial construction, road and path construction as well as surface sealing of landfills or green spaces.

Marc Dizdarevic, Managing Director of Rampf Machine Systems: “Our fly ash-free recipe supports our customers in further optimizing the ecological footprint of their products. With our materials, we are setting both ecological and technical accents on the market: unbeatable vibration damping, outstanding thermal stability, high Functional integration, maximum design freedom and optimal static and dynamic rigidity guarantee the production of powerful and ultra-precise machine tools and production machines. "

Marc Dizdarevic, Managing Director of Rampf Machine Systems: “Our fly ash-free recipe supports our customers in further optimizing the ecological footprint of their products. With our materials, we are setting both ecological and technical accents on the market: unbeatable vibration damping, outstanding thermal stability, high Functional integration, maximum design freedom and optimal static and dynamic rigidity guarantee the production of powerful and ultra-precise machine tools and production machines. "

Development partner and system supplier

As a development partner and system supplier, Rampf supplies customer-specific machine frames, trunk and basic machines as well as multi-axis positioning systems and motion solutions - a look behind the scenes:

You might also be interested in...

Reduce carbon footprint | That's how it's done!

Plastic recycling from and for industry and other uses

Rampf Group with a new plant in Canada and 15 years in Japan

Structural resin and composite for the high demands of aviation

Electro casting resins reliably cool electrical and electronic components