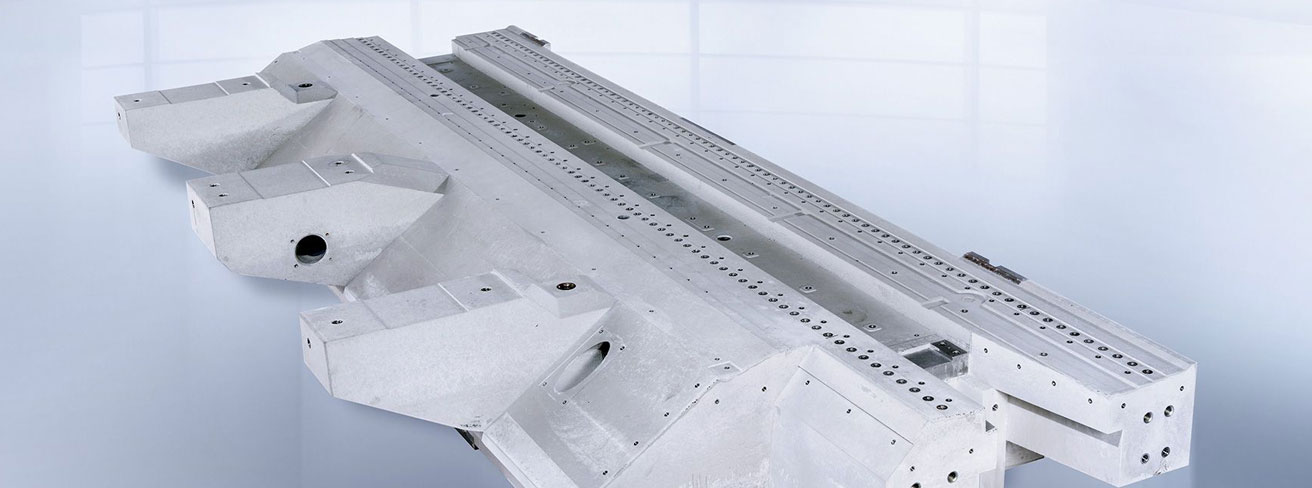

Ultra high-performance concrete for the large, heavy machine bed

- Details

- Hits: 8779

Ultra high-performance concrete: Modesty definitely played no role in the naming of this material. But the name does justice to the properties. And that's why it's from Rampf Machine Systems newly developed premium concrete with the brand name Epudur is the preferred material when it comes to a large, heavy one Machine bed or frame components for machines in highly dynamic mechanical engineering. These machine beds are optimized according to the requirements and in terms of casting technology.

When asked about the secret of his ongoing success, a well-known star chef replied that his craft is ultimately based on three pillars: The first is based on the Ingredients: He always purchases these from the same suppliers and ensures constant quality. The second is that recipe: Meticulously and always identical, he harmonizes the ingredients of his dishes with one another. The third pillar is that Process And the know-how: The perfect choreography of cooking, cooking and resting times ensures that his dishes always come to the table in a high quality and tasty way.

Machine bed according to market requirements

But what does the metaphor have in common with high-performance concrete for mechanical engineering or what is used every day Rampf Machine Systems happens? Machine builders literally build components of the highest quality on machine beds or frames, which Rampf for the most suitable reasonmaterials created.

Easily produce mineral casting machine bed economically

Easily produce mineral casting machine bed economically

The “cooks” from Rampf always have to master the process equally well and reliably. "Our machine beds are in demand in machines where high vibration damping, pressure resistance and maximum precision are in the foreground", explains the managing director Dirk Hausmann.

Just a few decades ago, these were almost exclusively gray cast iron solutions, today system components made from epoxy resin-bonded mineral cast are often the better alternative. But why now ultra high-performance concrete UHPC for machine beds? Similar to an innovative chef, the engineers at keep asking themselves how they can translate changed market requirements, for example for machine tools, into new recipes and solutions.

Rely on nanotechnology for high-performance concrete

“There is no such thing as the best machine bed material per se, it always depends on the task of the machine. Every material has its strengths and weaknesses, no recipe is so good that it cannot be improved, ”says dr Thomas Abel, Laboratory Manager at Rampf Machine Systems. For several years now, the company has been testing solutions such as high-strength premium concrete with high load-bearing capacity as a cost-effective variant of the materials that have been used up to now.

Liquid resin and epoxy resin for prototypes, models and molds

Liquid resin and epoxy resin for prototypes, models and molds

With the newly developed ultra high-performance concrete epudure they are now breaking new ground and relying on the latest nanotechnology. In addition to high-quality premium cement, selected components such as chippings, sand and rock flour are used in fine-tuned doses. High-performance superplasticizers ensure a self-compacting process, additional vibration energy is not required. Only a little more water has to be added as a chemical reaction partner for the high-performance concrete.

The result is a high-performance concrete as flowable materialwhich, compared to normal building material concrete, has a significantly reduced pore volume for the later machine bed.

Easy integration of casting parts

"When it comes to compressive strength, modulus of elasticity and damping properties, Epudur offers cured products Peak values for the construction that makes high-strength precious concrete an economic competitor to previous materials, ”emphasizes Dr. Thomas Abel. Due to its high dynamic stability, system solutions made from Epudur are preferably used in production, where maximum precision is required with high weight and highly dynamic stress.

"When it comes to compressive strength, modulus of elasticity and damping properties, Epudur offers cured products Peak values for the construction that makes high-strength precious concrete an economic competitor to previous materials, ”emphasizes Dr. Thomas Abel. Due to its high dynamic stability, system solutions made from Epudur are preferably used in production, where maximum precision is required with high weight and highly dynamic stress.

Applications can be found, for example, in the bed and frame components from CNC Machine Tools for milling, turning, grinding and eroding processing or as a base frame for dynamically highly stressed power machines such as motors, generators, turbines and centrifuges. Overall, the mechanical key figures of the construction are comparable to those of the reaction resin-bonded mineral casting materials that have been tried and tested for years, or in some cases even better.

Mineral cast machine bed for stable six-axis robots

Mineral cast machine bed for stable six-axis robots

“However, Epudur offers additional advantages and design potential, which ultimately translate into lower costs,” says Dirk Haumann. So both are omitted The Brand Every form of technical compaction from Epudur: The fresh concrete compacts itself without any pores and voids and shows only little shrinkage when it hardens. The integration of cast-in parts such as threaded anchors, load elements, pipes and hoses is comparatively easy to do. Formworks are possible with steel, plastic or even wood reinforcement.

Recycling as rubble

For large, heavy and complex components, solutions made from Epudur usually perform better than the versions made from gray cast iron or using a polymer concrete. "In addition, ultra-high-performance concrete is non-flammable and very resistant to aging at both low and high temperatures," says Dr. Thomas Abel. "Our Potting materials polymer or cement based are also characterized by their ecological balance of the concrete. In the end, these can be recycled as building rubble, landfill class 1, non-hazardous waste. "

For large, heavy and complex components, solutions made from Epudur usually perform better than the versions made from gray cast iron or using a polymer concrete. "In addition, ultra-high-performance concrete is non-flammable and very resistant to aging at both low and high temperatures," says Dr. Thomas Abel. "Our Potting materials polymer or cement based are also characterized by their ecological balance of the concrete. In the end, these can be recycled as building rubble, landfill class 1, non-hazardous waste. "

After several years of testing and optimization, the manufacturer is confident that the new Epudur has what it takes to be Material of the future has: "We now understand exactly how the process works," says Dr. Thomas Abel. “That is the reason why we do everything in-house. This is the only way we can guarantee process reliability and consistently high quality. "

Intelligent CNC control for new + old machine tools

Intelligent CNC control for new + old machine tools

Using proven mixing technology from Kniele, system solutions for series of up to ten tonnes can be produced at the Wangen plant (near Göppingen). The goal is to double this capacity in the near future.

You might also be interested in...

Structural resin and composite for the high demands of aviation

Microwave technology for curing and processing times that are up to 4 times faster

Reduce carbon footprint | That's how it's done!

Plastic recycling from and for industry and other uses

Rampf Group with a new plant in Canada and 15 years in Japan