Microwave technology for curing and processing times that are up to 4 times faster

- Details

- Hits: 5790

With the new modular microwave technology "Raku Microwave Curing" from Rampf ultra-fast curing and processing times are achieved when mixing and dosing sealing systems, adhesives and potting compounds. The focus is on the thermal activation of one- and two-component plastic systems using microwave radiation.

With the new modular microwave technology "Raku Microwave Curing" from Rampf ultra-fast curing and processing times are achieved when mixing and dosing sealing systems, adhesives and potting compounds. The focus is on the thermal activation of one- and two-component plastic systems using microwave radiation.

The curing time of sealing systems, adhesives and potting compounds is crucial for shorter cycle and throughput times. The patented microwave technology can increase the reactivity of one- and two-component plastic systems based on polyurethane, epoxy and silicone up to four times.

The material is thermally activated directly after the discharge nozzle via electromagnetic waves before it is applied to the component. The radiation is transmitted to the activation zone via waveguides and applied only for a fraction of a second. Viscosity and reactivity are thus infinitely variable and can be regulated very quickly and flexibly directly in the process.

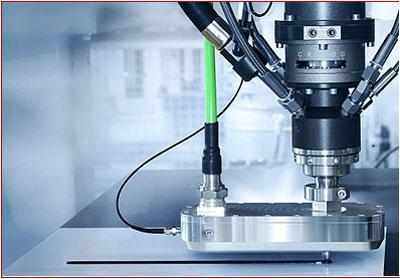

Dosing machine for sealing foam, adhesive + potting compound

Dosing machine for sealing foam, adhesive + potting compound

The handling strength is achieved much earlier, whereby the component can be loaded earlier and fed to a further processing step. In many cases, the annealing cycle can be significantly shortened by the microwave heating. Ideally, even a tempering furnace can be completely dispensed with.

In the case of two-component reaction resins, the adaptation of the material formulation further improves its interaction with the microwave radiation. This guarantees the optimum combination of reaction resin and mixing and dosing system for every customer application.

Another advantage is the higher machine availability. In a two-component low-pressure machine, the mixing and activation of the material usually takes place in one step. Raku Microwave Curing manages for the first time to separate the mixing and activation process. As a result, the contamination in the mixing head is significantly reduced, which in turn reduces the number of rinsing operations.

You might also be interested in...

Structural resin and composite for the high demands of aviation

Ultra high-performance concrete for the large, heavy machine bed

Mineral cast machine bed | produce economically

Reduce carbon footprint | That's how it's done!

Industrial liquid gasket, adhesive and potting compound