Heinrich Kipp work | Inventor of the spaetzle machine

- Details

- Hits: 10621

There is news from Heinrich Kipp Werk: Of the keypads and Workholding specialist is WIN Charter company and has a branch in Canada opened. In a representative survey from TÜV Saarland the company achieved the overall grade "very good" in terms of customer satisfaction and service quality. You can find this and other company announcements below:

Contents

- Kipp signs WIN charter for special sustainability

- Heinrich Kipp Werk opens a subsidiary in Canada

- New TÜV service certification

- Promotion of elite sport and education

- Heinrich Kipp Werk builds logistics buildings with green steel

KIPP signs the WIN charter for special sustainability

14.02.2023/XNUMX/XNUMX | The Henry Kipp Werk and the Tilt CCS have signed the Baden-Württemberg initiative WIN-Charta. Within this framework, small and medium-sized companies undertake to act particularly sustainably on the basis of 12 defined principles. Both companies disclose their commitment in a current sustainability report.

14.02.2023/XNUMX/XNUMX | The Henry Kipp Werk and the Tilt CCS have signed the Baden-Württemberg initiative WIN-Charta. Within this framework, small and medium-sized companies undertake to act particularly sustainably on the basis of 12 defined principles. Both companies disclose their commitment in a current sustainability report.

"Signing the WIN charter is a clear commitment to our economic, ecological and social responsibility," explains Nicholas Kipp, Managing Director of the Kipp Group. "Sustainability and environmental protection have been at the top of our agenda for many years." The control panel specialist has currently defined two focus areas: the well-being of employees and energy and emissions.

Kipp offers a wide range of measures for Promotion of employee well-being such as a company suggestion scheme, flexible working hours with home office options and company health management. "In the future, we would like to further expand the topic of work-life balance," emphasizes Nicolas Kipp. “In this context, we recently received the 'berufundfamilie' certification. The audit is aimed at a tailor-made and needs-based further development of family and life-phase conscious personnel policy.”

Go to the Climate protection Kipp intends to introduce an environmental management system in 2023 and be certified according to ISO 14001. In addition, the switch to green electricity and LED lighting has already taken place. Machines are cooled by free cooling at low outside temperatures. Waste heat from the compressors is used to generate hot water and for space heating.

"We will make further efforts to reduce greenhouse gas emissions and increase our energy efficiency," he said Alexander Kruppa, Managing Director of KIPP CCS. "This includes the introduction of energy controlling to make our energy flows transparent."

Heinrich Kipp Werk opens a subsidiary in Canada

30.11.2022/XNUMX/XNUMX | With the new sales company in Canada, das Kipp Werk now! 12 locations worldwide – including Germany. Because the control panel specialist sees further growth potential in foreign markets, it has focused on international expansion in recent years.

30.11.2022/XNUMX/XNUMX | With the new sales company in Canada, das Kipp Werk now! 12 locations worldwide – including Germany. Because the control panel specialist sees further growth potential in foreign markets, it has focused on international expansion in recent years.

"There is also great demand for Kipp products abroad," explains the managing director Nicholas Kipp. "That's why we made the decision a few years ago that our company must increasingly have a presence abroad." Previously, the Heinrich Kipp factory had worked more closely with trading partners in the countries, who are now also benefiting from the expansion. The entire program can be accessed immediately. Fast order processing is guaranteed.

Kipp usually delivers within Europe in a day or two the goods from the central logistics center in Germany. Customers based abroad also benefit from comprehensive service, including professional technical advice. In order to do justice to the increasing international expansion, KIPP is currently also expanding its logistics center with the aim of ensuring fast and sustainable delivery capability in the future.

New TÜV service certification

16.12.2021/XNUMX/XNUMX | Of the TÜV Saarland every two years, the German customers of Kipp Werk are asked about their satisfaction with the services. They want to know which criteria are particularly important and how they assess individual process steps. This year, the survey was conducted online for the first time.

"We are particularly pleased that 99,4% of customers surveyed will order from us again," says the managing director Nicholas Kipp. "This confirms our service strategy and gives us an incentive to continue offering an optimal service." Compared to the last survey, there were hardly any deviations: the five most important criteria are: article availability (grade 1,56), product quality (1,36), on-time delivery (1,47) and quick order processing (1,44) and delivery (1,56).

The product range includes 55.000 parts. Thanks to a high degree of vertical integration, large storage capacities and an advanced logistics center, the company can guarantee good delivery capability. Standard items are available from stock, urgent orders are delivered within 24 hours.

Promotion of elite sport and education

25.11.2021/XNUMX/XNUMX | Heinrich Kipp will support the future Olympic youngsters in Baden-Württemberg. As a partner company of top-class sport, the company will offer young athletes as a training company. With a special dual career, competitive sport and work should be compatible.

25.11.2021/XNUMX/XNUMX | Heinrich Kipp will support the future Olympic youngsters in Baden-Württemberg. As a partner company of top-class sport, the company will offer young athletes as a training company. With a special dual career, competitive sport and work should be compatible.

Technical and commercial training, dual studies, practical semesters and bachelor's and master's theses are conceivable and can be arranged. Visited at the start of the cooperation Charlotte Gallbronner, a promising young talent in German biathlon, the Kipp factory in Sulz am Neckar. She was accompanied by Kristin Redanz, Managing Director of the Foundation for Young Olympic Talents in Stuttgart. Nicolas Kipp, who runs the company in the fourth generation with his father Heinrich Kipp, found out about the everyday training and school life of top athletes.

Karl Josef Rebmann, member of the management and organization and staff at Kipp, appreciates this type of cooperation and has been gaining experience in working with top athletes and Olympic training centers for over a decade. He has accompanied numerous athletes and is enthusiastic about their professional organization. The top athletes appreciate the opportunity to reconcile sporting and professional careers.

The control unit specialist is committed to promoting and partnering top-class sport. The environment also benefits from this. For example, training units for schools are planned as part of physical education classes with future top athletes. Ralph Kauffer, Personnel Manager at Kipp, is looking forward to future dual students and trainees. He too would like to “provide a touch of top-class sport” to the region.

Heinrich Kipp Werk builds logistics buildings with green steel

01.04.2021/XNUMX/XNUMX | “We focus on long-term growth,” says Nicholas Kipp, Managing director of the Kipp factory. “We are once again committed to sustainable action and support with CO2 neutral steel protects the climate.” The new logistics center will have a total area of 4300 m2 to have. The logistics expansion includes a shuttle warehouse, order picking, offices and a lounge. 400 t of reinforcing steel are required for the new building. Those responsible opted for certified green steel from Sülzle Stahlpartner in Rosenfeld.

CO2 Kipp is equal to loads in steel production Compensation contribution the end. Heinrich Sülzle handed over a corresponding certificate to the builders Nicolas and Heinrich Kipp. With the climate contribution, Kipp supports regional projects and campaigns in emerging and developing countries. Some examples are forest protection afforestation in Uruguay, drinking water in Zimbabwe and Photovoltaics in India.

Sülzle steel partner is the first company in Germany to offer certified green steel. "Innovative and leading companies have a high level of awareness of climate protection and sustainability," says Michael Frey from the architects Schmelzle + Partner. Mr. Frey is in charge of Kipp's new building project. “By using CO2 Kipp implements sustainable construction using neutral structural steel and thereby supports global projects on renewable energies. "

Archive for further company news

Kipp receives the TOP JOB 2019 award

02.07.2019 | The Heinrich Kipp plant was founded by a. D Wolfgang clement (r.) with the TOP JOB seal for outstanding employer qualities excellent. The award is presented by the Center for Employer Attractiveness Zeag GmbH and the University of St. Gallen.

02.07.2019 | The Heinrich Kipp plant was founded by a. D Wolfgang clement (r.) with the TOP JOB seal for outstanding employer qualities excellent. The award is presented by the Center for Employer Attractiveness Zeag GmbH and the University of St. Gallen.

The award with the top job seal underlines the employer qualities of the medium-sized company in the 100th year of its existence. "As an owner-managed, traditional company, we stand for reliability and fairness," emphasizes the managing director Nicholas Kipp out. At the same time, the manufacturer relies on modern structures to survive the competition. The owner family ensures good development opportunities and an attractive environment. Particular value is placed on family-friendly working hours and part-time options. A lot is also done in Sulz for health.

100 years Heinrich Kipp Werk

11.06.2019/100/XNUMX | The leading manufacturer of standard elements and operating parts, Heinrich Kipp Werk KG from Sulz am Neckar, is celebrating its XNUMXth anniversary this year. It all started with spaetzle machines, In 1919 the company founder Christian Kipp developed his first own products for the Food production.

11.06.2019/100/XNUMX | The leading manufacturer of standard elements and operating parts, Heinrich Kipp Werk KG from Sulz am Neckar, is celebrating its XNUMXth anniversary this year. It all started with spaetzle machines, In 1919 the company founder Christian Kipp developed his first own products for the Food production.

From 1952 the company focused on clamping means: The adjustable tilt clamping lever brought about a small revolution in mechanical engineering at the time. Today, Kipp offers its customers real added value with modern production technologies and fully automated logistics.

The range includes over 42.000 Productsthat are available from stock. These include product lines such as "Nature grip". The environmentally friendly grips are made of biopolymer plastic from renewable raw materials. This process is only possible thanks to the latest production technologies.

The product line Feature grip on the other hand, takes the ongoing digitization into account: Integrated electromechanical and sensory Elements provide reliable feedback on certain parameters through visual signals. This ensures process reliability, which is becoming increasingly important in mechanical engineering.

The Digitalization does not only apply to product developments. The topic is of central importance for processes and services in all areas of the company. The company will start in 2019 with a new web shop platform. Further expansion into new markets is also planned for the future. The presence abroad not only guarantees the customer access to the entire program, but also fast order processing. High-quality and innovative products with good availability: With this concept, the celebrant would like to shape the next 100 years.

The Novonox brand becomes Novonox hygienic

01.07.2018 | The previously stand-alone brand Novonox has been operating under the new name since April 2018 Novonox hygienic including all business processes integrated into the Heinrich Kipp plant. The company is thus expanding its existing range in the important stainless steel sector. In the future, Novonox customers will thus have access to Kipp's comprehensive logistics and service network.

01.07.2018 | The previously stand-alone brand Novonox has been operating under the new name since April 2018 Novonox hygienic including all business processes integrated into the Heinrich Kipp plant. The company is thus expanding its existing range in the important stainless steel sector. In the future, Novonox customers will thus have access to Kipp's comprehensive logistics and service network.

The Stainless steel products of the Novonox hygienic line are specifically designed for the food, pharmaceutical, chemical and packaging industries. The provider now guarantees representatives of these sectors the support of a full-range supplier with manufacturer expertise.

"We decided to take the important step of integration in order to optimize our range selection and expand our know-how in the field of hygienic design," explains the managing director Nicholas Kipp.

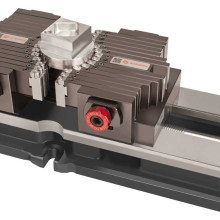

Clamping technology for workpiece, device and machine tool

Clamping technology for workpiece, device and machine tool

The Novonox hygienic product line includes Operating parts and machine elementsthat conform to HD (Hygienic Design) and HU (Hygienic Usit) industry standards. Due to their average surface roughness of Ra < 0,8 μm and the optimal cleanability, the surfaces and transitions of the HD products reliably meet hygiene requirements.

With the HU products, one relies on one sealing and Connection Technology from the same mould. The best example is the Novonox hygienic screw system, which creates a unique, absolutely tight and dead space-free connection with the sealing and washers from Freudenberg Sealing Technologies.

Who is the Heinrich Kipp factory?

The Heinrich Kipp factory is a family-run company in the 4th and 5th generation. It was founded in 1919. The Kipp Group is an association of six German partner companies for the automotive and standard parts sectors. 900 employees at 29 locations make the group a global player. The manufacturer of Workholding, standard elements and control panels for mechanical engineering and other industries produces in Germany with a high level of vertical integration with a large machine park. This means that standard elements, assemblies and special solutions can be implemented. The product range includes 55.000 quickly available operating parts, standard elements and clamping technology. Product development takes place in-house. Kipp pays particular attention to sustainability.

You might also be interested in...

This snap lock locks securely

clamping technology | Intelligent, safe, efficient!

Ergonomic controls and standard parts

Indexing bolts / locking bolts from Kipp

Clamping lever with safety function or solid plastic handle

Kipp clamping technology for fixture and machine tool

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.