Ergonomic controls and standard parts

- Details

- Hits: 11052

The dangers in a production should not be underestimated: The Heinrich Kipp Werk has numerous controls and standard parts for a wide variety of industries in the portfolio. With many of them you can get the best possible Occupational and operational safety implement, be it in highly sensitive areas or under harsh environmental conditions. Here you will find the new developments:

Contents

- Ergonomic aluminum handwheels

- Detectable operating parts for the food industry

- Antibacterial controls defy viruses & co.

- Ergonomic clamping lever with solid plastic handle

- Constant expansion of the locking bolt portfolio

- Standard-compliant ESD control elements made of special plastics

- Clamping lever prevents unintentional opening or closing

- Individual control elements as special solutions from a single source

According to the German Social Accident Insurance (DGUV), in Germany in 2021 there were a total of 806.217 reportable accidents at work listed. Unauthorized access, incorrect machine operation and unwanted electrical discharges can also lead to significant damage. There is another aspect to consider in hygiene-sensitive areas: No foreign bodies may get into the products to be processed. Many of these and other dangers can be reduced with simple means. The Heinrich Kipp factory offers numerous operating elements and standard parts for this.

Ergonomic aluminum handwheels

26.07.2023/XNUMX/XNUMX | The new Aluminum handwheels by Heinrich Kipp are visually appealing, ergonomic and reliable. The controls are easy to use and fit seamlessly into the manufacturing process. Six designs in different sizes and two color variants are available.

26.07.2023/XNUMX/XNUMX | The new Aluminum handwheels by Heinrich Kipp are visually appealing, ergonomic and reliable. The controls are easy to use and fit seamlessly into the manufacturing process. Six designs in different sizes and two color variants are available.

The hand wheels of the new series are particularly light because they are made of aluminium. The Controls were specially designed for use in mechanical and plant engineering. With them z. B. manually adjust and adjust fittings, machine tools or geared motors. In addition, individual machine parts can be moved using the handwheel in emergency operation of a system.

The aluminum handwheels are available as spoked or disc handwheels with and without a crank and with a foldable or rotatable cylindrical handle. The latter has a conical shape and a cylindrical heel for optimal haptics and very good grip. When folded, the cylinder handle disappears completely in the control element. This reduces interference contours during the process. At the same time, the risk of injury is minimized. The low height of the variants with and without a foldable handle, the material-related low weight on the one hand and the low tolerance in concentricity and axial run-out of less than 0,4 mm on the other are further features.

There are non-positive and positive-locking variants for fastening the handwheels:

- with fitting hole

- with fitting hole and keyway

- with fitting hole and cross hole or

- with fitting hole, keyway and cross hole

A black hub cap improves the look and reduces the ingress of dirt. All models are powder-coated and therefore durable. They are available in either silver or black. The spoked handwheels are available in diameters of 125 and 160 mm, the disc handwheels from 80 to 125 mm.

Detectable operating parts for the food industry

14.02.2023/XNUMX/XNUMX | Kipp has the new detectable control panels for the food technology and pharmaceutical industry designed. Leave with them for contamination in the manufacturing process prevent major failures. When small splinters come loose from damaged components and get into the products, it is often the consumers who first discover the fault. Expensive product recalls are the result.

Visually detectable operating parts help with their blue color, which is rather untypical in the food sector. Affected products are easier to identify when they come into contact with food. The controls meet the increased hygiene requirements, because the Materials comply with the EU10/2011 standard and are FDA compliant. Thanks to cleaning-optimized geometries, the cross handle, for example, with its closed handle contour and smooth surface, is very easy to clean. There are also bow handles, wing handles, star handles and knurled knobs clamping lever. They are all colored ultramarine blue, similar to RAL5002.

In the metal detectable Control panels allow the components to be detected using induction technology. This helps if a control panel accidentally enters the production process in whole or in fragments. Special detection systems reliably select out the foreign bodies, even if they can no longer be seen with the naked eye. Fragments of up to 0,027 cm³ (3 x 3 x 3 mm) can be detected and ejected.

In the future, various material combinations make the grips even more flexible. The forms remain identical – the one used Plastic gives them completely new properties.

Antibacterial controls defy viruses & co.

10.02.2023/XNUMX/XNUMX| The antibacterial operating parts of the Medigrip Product series were developed for applications in which the highest hygiene standards are required or in which the spread of germs must be prevented. They were, inter alia, for use in the Medical Technology

The handles are made entirely of plastic enriched with micro-silver. This ensures that a large part of the viruses or bacteria on the product surface are broken down after just a few hours. This means that with the antibacterial controls from the Heinrich Kipp factory Dramatically minimize risk of infection upon contact leaves.

The number of germs present is significantly reduced between the cleaning cycles. In addition, the robust components are resistant to a large number of detergents and moisture.

Ergonomic clamping lever with solid plastic handle

25.10.2022/XNUMX/XNUMX | Kipp's new clamping levers offer a very high strength and rigidity at a low weight. They have a handle made of solid plastic and are suitable for all areas of use. The ergonomic clamping levers offer a modern look and a pleasant feel. The special high-performance plastic of the grip levers is a glass fiber reinforced Thermoplastic.

Constant expansion of the locking bolt portfolio

16.05.2022/XNUMX/XNUMX | Kipp's large range of locking bolts currently includes 45.000 parts and is constantly being supplemented with further components. Wired ones have been added Locking bolt, locking bolt for hygienic applications, which with eccentric lever or with an integrated status sensor. Functions can be operated remotely using the locking bolts with Bowden cable.

Standard-compliant ESD control panels made of special plastics

28.10.2021/XNUMX/XNUMX | Electrostatic discharge can be uncomfortable in everyday life. In industrial production, such discharges can damage or even destroy sensitive electronic devices, components or devices. To prevent such damage, workplaces in ESD Zones (electrostatic discharge or electrostatic discharge) must be equipped in accordance with standards down to the smallest component. The Heinrich Kipp factory offers safe ESD for this keypads.

28.10.2021/XNUMX/XNUMX | Electrostatic discharge can be uncomfortable in everyday life. In industrial production, such discharges can damage or even destroy sensitive electronic devices, components or devices. To prevent such damage, workplaces in ESD Zones (electrostatic discharge or electrostatic discharge) must be equipped in accordance with standards down to the smallest component. The Heinrich Kipp factory offers safe ESD for this keypads.

Clamping lever prevents unintentional opening or closing

24.01.2021/XNUMX/XNUMX | The Heinrich Kipp factory expands its portfolio by one clamping lever with safety function. The clamping levers thus prevent unintentional opening or closing. Changes to the clamping point can only be made when the grip lever is pressed. the keypads thus ensure a safer production environment as well as rehabilitation and Medical Technology. The way the new clamping levers work is as simple as it is effective.

Individual control panels as special solutions from a single source

26.03.2020/XNUMX/XNUMX | In the areas of control panels, the Heinrich Kipp factory Workholding and standard parts at any time customer-specific developments based on his high level of vertical integration and in-depth experience. The bandwidth ranges from modified standard parts to completely new user-specific developments. Customers receive everything from a single source - from advice and development to series production. The efficient implementation of individual projects comes from Sulz am Neckar.

26.03.2020/XNUMX/XNUMX | In the areas of control panels, the Heinrich Kipp factory Workholding and standard parts at any time customer-specific developments based on his high level of vertical integration and in-depth experience. The bandwidth ranges from modified standard parts to completely new user-specific developments. Customers receive everything from a single source - from advice and development to series production. The efficient implementation of individual projects comes from Sulz am Neckar.

"If our large product portfolio reaches its limits, we will be individual," explains Gerd Wiedemaier, Team leader special parts processing at Kipp. “We develop special solutions for prototype construction and series production alike.” With production in Germany, the company is close to the customer – a big advantage in coordination-intensive projects. The modern development department and in-house tool making ensure professional and efficient implementation. Certified manufacturing processes and flexibly designed assembly stations ensure the highest quality with on-time availability.

Countless standard elements for many industries

The development partner for a wide variety of industries supplies all types of standard parts, products for machine operation, Workholding and operating parts including parts such as handwheels, ball locking pins, star grips, star grips, bow grips, hand cranks, clamping levers, pressure pads, cylindrical grips, knurled screws etc. made from e.g. B. steel, stainless steel, plastic for the Automotive industry, supplier industry, mechanical engineering, woodworking industry, food and packaging technology, medical technology as well as in the sports and rehabilitation sector.

For example, for a customer from plant engineering Eccentric lever made of stainless steel with captive nut and brass retaining pressure piece. The tightening force of the nut is increased again here when the eccentric lever is closed. This allows the user to operate the lever without tools. Another example of a special solution is a Plastic clamping lever in mini format in the customer's corporate design. Kipp has produced an individual plastic injection mold for this control unit, with which the special clamping lever shape could be realized.

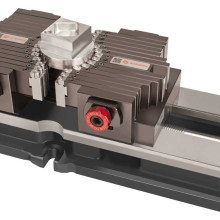

Clamping technology for workpiece, device and machine tool

Clamping technology for workpiece, device and machine tool

"In general, the implementation of special solutions is a way for us to stay very close to the customer," says Gerd Wiedemaier. “From the experience in these projects, we can derive valuable know-how of what is currently needed on the market. So sooner or later, many special solutions will find their way into our standard range. ”

Archive for Controls News

- Digitization is gaining traction

- Diverse standard elements for the packaging industry

- Lockable operating handles for more safety

- Diverse standard elements for the packaging industry

- Operating elements for adjusting and locking monitor holders

- Serving at and with nature - trade fair statement

Digitization is gaining traction

17.09.2019/XNUMX/XNUMX | The Heinrich Kipp factory presents the new Pipe handle Bighand and smart products from the Feature grip product line (image).

17.09.2019/XNUMX/XNUMX | The Heinrich Kipp factory presents the new Pipe handle Bighand and smart products from the Feature grip product line (image).

The product line Feature grip takes into account the ongoing digitization: Electromechanical and sensory elements are integrated in the components and solutions, so that users can make their manufacturing processes more stable and precise and benefit from greater process reliability. Examples of the smart products are a quick-release clamp with a force sensor and spring pressure pieces equipped with status sensors Locking.

The newly designed tubular handle offers due to its ergonomic oval handle shape and the optimal tube size ensure a secure and comfortable hold. It consists of an oval aluminum tube and end pieces as well as cover caps Thermoplastic, whereby the end pieces are provided with locating bushes made of stainless steel. Bighand adapts optimally to the environment thanks to the variable color design. The tubular handle is suitable for use in the furniture industry, sports equipment construction as well as mechanical and plant engineering.

Using one Robot for the automatic loading of CNC machines, the manufacturer demonstrates how he implements customer-specific solutions for CNC machine manufacturers in terms of clamping technology and automation.

Lockable operating handles for more safety

26.07.2019 | Claw and Buttons from the Heinrich Kipp factory are used for manual fixation and clamping. They are used, for example, in mechanical engineering, Tooling, plant construction as well as test devices and medical devices. The new, lockable operating handles score particularly well in security-relevant areas. They prevent unauthorized loosening of the Gland or connection.

New in the range are among others lockable five-star handlesthat are suitable for use in device construction. The lockable handles are also used in the packaging industry, in special machine and tool construction and in the camping industry. The grips themselves are made of thermoplastic, the steel parts are blue passivated and the lock cylinders are made of die-cast zinc. This material composition guarantees heat resistance up to 100 °C.

Switches, buttons, controls for food machines

Switches, buttons, controls for food machines

There are lockable five-star handles with internal and external thread in the sizes M8 and M10 as well as the size M6 as a variant with internal thread. The external threads are each 20 mm long. The scope of delivery includes two keys that can be removed in either position (open or closed). Since the five-star handles are lockable in the standard version, several handles can be opened or closed with one key, which simplifies daily use. On request, the manufacturer will produce special variants with different locking or other thread variants.

Diverse standard elements for the packaging industry

04.09.2019 | The Heinrich Kipp factory is presenting a variety of products for the packaging industry, including a new rotary latch in hygienic design from the stainless steel product range Novonox hygienic. The Stainless steel rotary latch with T-handle has a mirror-polished stainless steel surface, matching transition radii and a concentric circumferential silicone seal.

04.09.2019 | The Heinrich Kipp factory is presenting a variety of products for the packaging industry, including a new rotary latch in hygienic design from the stainless steel product range Novonox hygienic. The Stainless steel rotary latch with T-handle has a mirror-polished stainless steel surface, matching transition radii and a concentric circumferential silicone seal.

The product thus corresponds to DIN EN 1672-2: 2009 (Hygiene Machine Ordinance) and is tested according to GS-NV 2:2013/06 for food processing machines. In addition, the handle is easy to clean: water, cleaning agents and other liquids can drain off completely, thus preventing contamination.

The Novonox hygienic product range has been added to the extensive range since last year Stainless Steel-Range. Thanks to their low-corrosion, robust and hygienic properties, these products are suitable for use in the packaging industry.

New position indicator are used to check position values for direct attachment to the axis or spindle in a machine or system. Handwheels and hand cranks enable manual format adjustments on packaging machines, while the versatile clamping levers can be used as operating elements or for clamping different components. With the aluminum profile system, for example, workbenches, test benches or complete production systems can be implemented as required according to the modular principle. Last but not least, suitable adjustable feet ensure that all machines stand securely.

Operating elements for adjusting and locking monitor holders

21.04.2017/XNUMX/XNUMX | Monitors, touch panels, display and operating housings are used in industrial environments in machines, systems and even commercial vehicles. Because commercially available monitor mounts reach their limits, RK Rose+Warrior developed a flexible and adjustable system that meets the demands of the industry. To the special robustness and flexibility of this special monitor mount the built-in control panels from Heinrich Kipp Werk also contribute.

21.04.2017/XNUMX/XNUMX | Monitors, touch panels, display and operating housings are used in industrial environments in machines, systems and even commercial vehicles. Because commercially available monitor mounts reach their limits, RK Rose+Warrior developed a flexible and adjustable system that meets the demands of the industry. To the special robustness and flexibility of this special monitor mount the built-in control panels from Heinrich Kipp Werk also contribute.

Serving at and with nature - trade fair statement

22.06.2016/2016/XNUMX | At the Automatica XNUMX in Munich we are represented Markus Pfeffer, Sales Engineer, Heinrich Kipp Werk KG, Sulz, presented new product lines of control elements.

You might also be interested in...

This snap lock locks securely

clamping technology | Intelligent, safe, efficient!

Indexing bolts / locking bolts from Kipp

Heinrich Kipp work | Inventor of the spaetzle machine

Clamping lever with safety function or solid plastic handle