Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

WEG is expanding its W22X series of explosion-proof motors to include IEC size 800 for medium and high voltage applications. A special exhibition model of the currently largest motor in this series offers outputs of up to 5,6 MW and for voltages of up to 11 kV. The W22X 800 is available in a four-pole version. At full load and a voltage of 6,6 kV, it has an efficiency of 97,4%. The special motors of the subsidiary Antriebstechnik Katt will also be on display, including the ultra-compact water-cooled motor series for outputs of up to 440 kW.

WEG is expanding its W22X series of explosion-proof motors to include IEC size 800 for medium and high voltage applications. A special exhibition model of the currently largest motor in this series offers outputs of up to 5,6 MW and for voltages of up to 11 kV. The W22X 800 is available in a four-pole version. At full load and a voltage of 6,6 kV, it has an efficiency of 97,4%. The special motors of the subsidiary Antriebstechnik Katt will also be on display, including the ultra-compact water-cooled motor series for outputs of up to 440 kW.

Siemens completes the range of "Simotics FD" low-voltage motors and now covers a power range from 200 to 1600 kW and shaft heights from 315 to 450 mm. The motors are optimized for converter operation and are particularly energy-saving in the partial load range. In combination with Sinamics low-voltage converters, they form an integrated drive system (IDS) and achieve system efficiency class IES2. Compared to the reference system of the standard, this means a reduction in losses of 35%.

Siemens completes the range of "Simotics FD" low-voltage motors and now covers a power range from 200 to 1600 kW and shaft heights from 315 to 450 mm. The motors are optimized for converter operation and are particularly energy-saving in the partial load range. In combination with Sinamics low-voltage converters, they form an integrated drive system (IDS) and achieve system efficiency class IES2. Compared to the reference system of the standard, this means a reduction in losses of 35%.

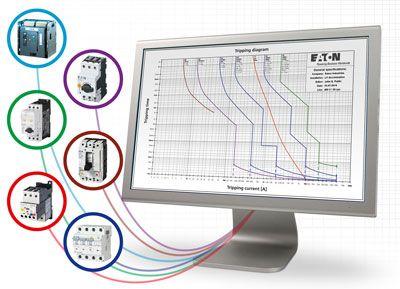

Eaton has updated and expanded the functionality of its free "Curveselect" software tool, which now also includes the adjusted characteristics of the "IE3 ready" motor protection switch. With the characteristic program, tripping characteristics of protective devices can be conveniently visualized, compared and documented. Curveselect enables users to competently assess the interplay between different Eaton devices and Eaton components in combination with other manufacturers' protective devices.

Eaton has updated and expanded the functionality of its free "Curveselect" software tool, which now also includes the adjusted characteristics of the "IE3 ready" motor protection switch. With the characteristic program, tripping characteristics of protective devices can be conveniently visualized, compared and documented. Curveselect enables users to competently assess the interplay between different Eaton devices and Eaton components in combination with other manufacturers' protective devices.

Without a rare earth one Efficiency of 97% achieve? That works with the alternative motor winding in the three-phase asynchronous motor (DAM) and three-phase generator, which the company Environmental technology marketing on the Trade press days 2020 has presented. These motors get by without permanent magnets.

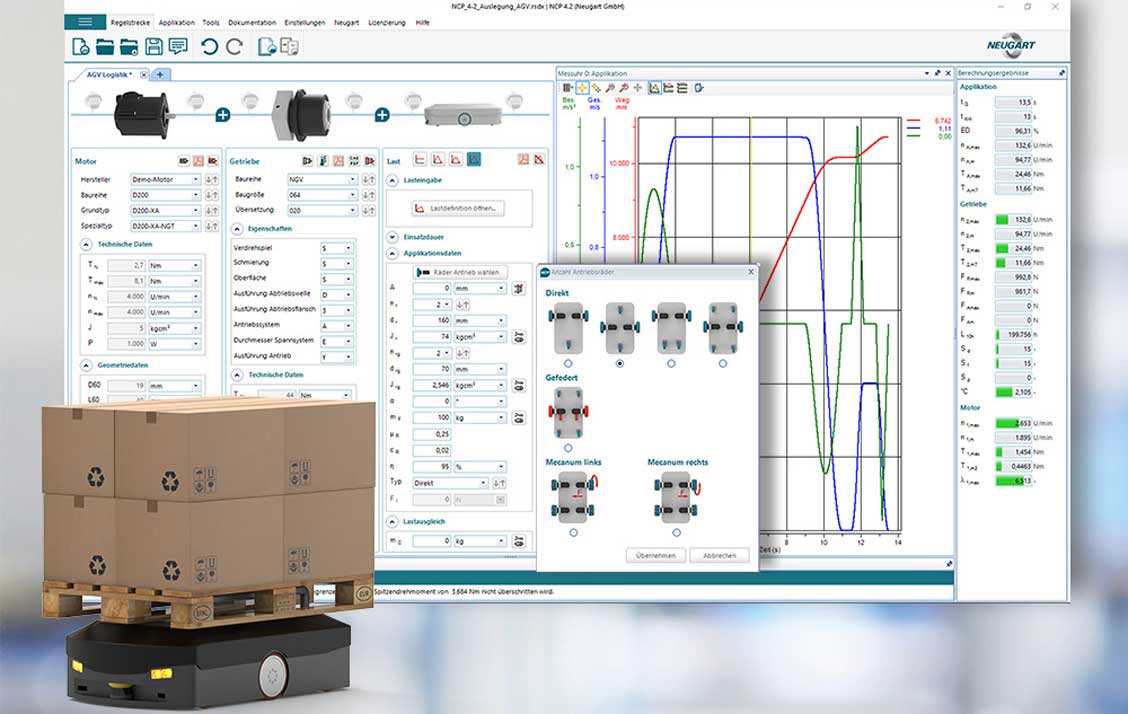

With the free Motor gear configurator users can directly choose the most cost and energy efficient Motorconfiguration and transmission design for your application. The proven Neugart calculation program (NCP) is now available as a user-friendly configuration tool in the new software version NCP 4.2. Customers of the transmission specialist can now download the new version from the company's website.

Interview with

Interview with

"We've been picking up speed on 2010 right from the start and are just coming to 2008's results."

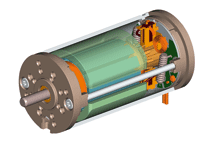

The new 63 mm motor from Bühler is the latest in a series of brushed permanent magnet DC motors. It combines high performance, quiet operation and long life with a flexible design for easier integration into a wide variety of drive systems. By using the latest magnetic technology based on inexpensive ferrite magnets in combination with an optimized design of the magnetic circuit, the 12-part armature structure guarantees maximum power density. Optimized for maximum copper filling anchor plate section and the use of particularly low-loss material allow maximum torque while optimally utilizing the available space.

The new 63 mm motor from Bühler is the latest in a series of brushed permanent magnet DC motors. It combines high performance, quiet operation and long life with a flexible design for easier integration into a wide variety of drive systems. By using the latest magnetic technology based on inexpensive ferrite magnets in combination with an optimized design of the magnetic circuit, the 12-part armature structure guarantees maximum power density. Optimized for maximum copper filling anchor plate section and the use of particularly low-loss material allow maximum torque while optimally utilizing the available space.

The new generation of DST high torque motors in sizes 135 to 400 from Baumüller is now also available with a hollow shaft or integrated thrust bearing in addition to the solid shaft version. The different versions of the DST motors provide more degrees of freedom in the design and enable the motor to be optimally integrated into the machine concept.

The new generation of DST high torque motors in sizes 135 to 400 from Baumüller is now also available with a hollow shaft or integrated thrust bearing in addition to the solid shaft version. The different versions of the DST motors provide more degrees of freedom in the design and enable the motor to be optimally integrated into the machine concept.