Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

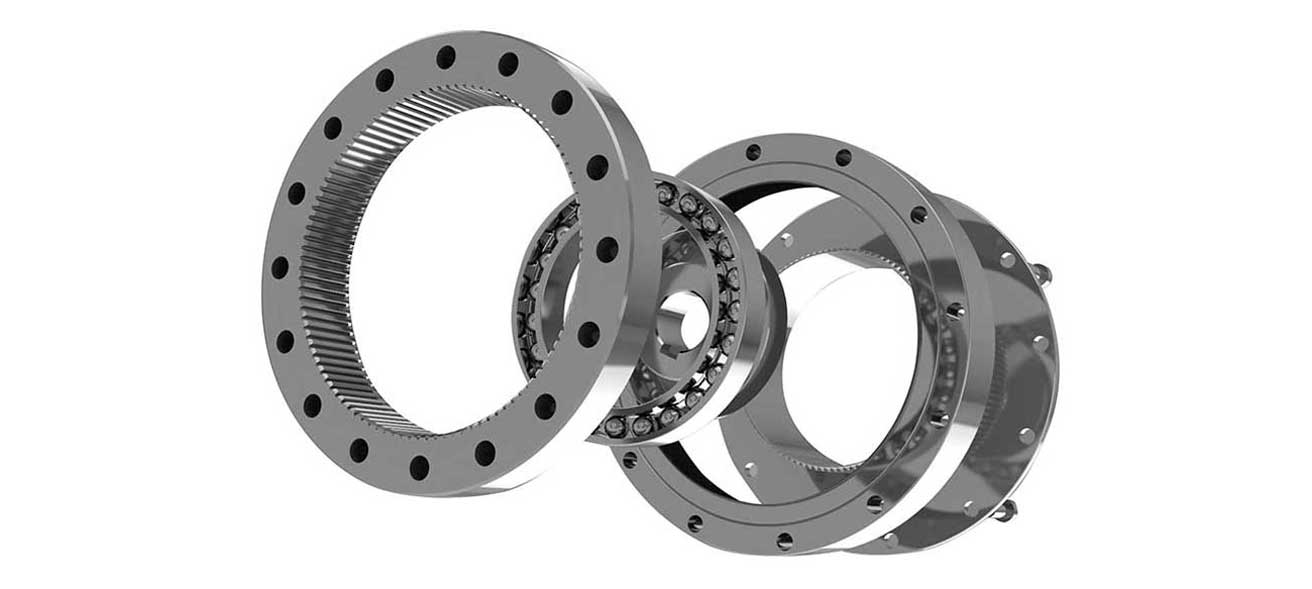

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

Two international companies headquartered in Germany have successfully completed a project of great importance for the construction industry in the Persian Gulf. With Drive Technology from NORD has SMS Group A heavy section rolling mill was built in the Kingdom of Bahrain. Only the most robust electric drives can withstand heavy mechanical stress and extreme heat, dirt and steam, as an application video and the following article show.

A complete virtual image of drive trains and transmissions is only possible if transmission, Rolling- and gear specialists can digitally link their simulation models with each other. Therefore, cross-company and cross-system data exchange is one of the most important prerequisites for generating Digital Twins. Schaeffler and SEW have created such a data exchange.

Strain wave gear are suitable for applications that require precise positioning and high repeatability. the Schaeffler Group puts on the Hannover Messe equal three new precision wave gears before: for Cobots, Industrial robots and torque applications. The kit for fully integrated Tribo strain wave gear from Igus has everything a Cobot needed to accelerate low-cost automation. We present these and other innovations to wave gears to you here:

The simply constructed ones Spur gears offer high efficiency and can effectively transmit torque between parallel shafts with minimal noise. This makes them suitable for use in manufacturing plants Automotive drives to wind turbines and other heavy industrial applications. This article highlights innovative New developments, applications and shows comprehensive Serviceservices that allow you to increase your efficiency and extend the operating life of your application.

The Angle gear transmit torque efficiently between crossing shafts, making them suitable for complex drive systems in the Automotive industry, in mechanical engineering or in aviation makes it particularly valuable. Find out more about the latest developments from various manufacturers and the versatile application possibilities of angle gears, especially from Bevel gears.

NORD has changed from Transmissionmanufacturer to the value chain partner for complete solutions Drive Technology developed. The product portfolio also includes the industrial gear Maxxdrive series for maximum output torques of 282.000 Nm for applications in heavy-duty industries. The example of one Bascule bridge shows how individual drive solutions can be created with short delivery times.

The Galaxy gear from Wittenstein belongs to a separate category of gearboxes. It is known for its innovative design, which uses multiple moving toothed pulleys to transmit torque. This design enables exceptionally high precision and performance and is often used in High performance applications used where traditional gear types such as planetary gear or spindle gears are not sufficient.

Regardless of whether they are used in Europe, China or the USA: The cradle of every Nordac Link field divider is in NORD Manufacturing plant in Aurich, East Frisia. The drive specialist started series production of its new one in 2017 field distributor Nordac Link series. The convenient drive solution for flexible, decentralized installation will be manufactured on Aurich location. This article gives a look behind the drive gates of the drive specialist.

Discover the latest developments from Tsubaki in the world of Drive and conveyor chains. This article provides information about innovative new products, shows their efficiency using user examples from the wood industry and automotive engineering, and presents you with exclusive service offers. Learn how to be eco-friendly roller chains Optimize your production processes in every industry and so on Reduce TCO costs.

A manufacturer of insulating fiberglass wool found out that premature wear of the components installed in a conveyor system conveyor chain was responsible for the declining product quality. He replaced the chain with a premium chain from the leading manufacturer of drive technology products Tsubaki. This not only solved the quality problems, but also tripled the service life of the system.

When it comes to the lack of service life, excessive wear and unreliability of drive chains, it is advisable to think outside the box and ask an alternative provider. In the present case, a Dutch one could Steel mill thereby increasing the productivity of its heat treatment in the long term. How? By him Tsukaki its failure-prone drive chains High-tech lifting chain with a service life of up to 15 years.

The Timing belts is a universally applicable drive element for many industrial sectors such as automotive, packaging technology, mechanical engineering, tool making, printing technology, textile engineering. The latest new development is the Breco timing belt from Mulco, which comes with a new coating material can handle extremely hot temperatures. Details about this and other innovations can be found below in this article: