Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

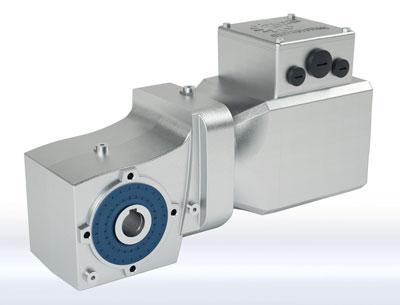

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

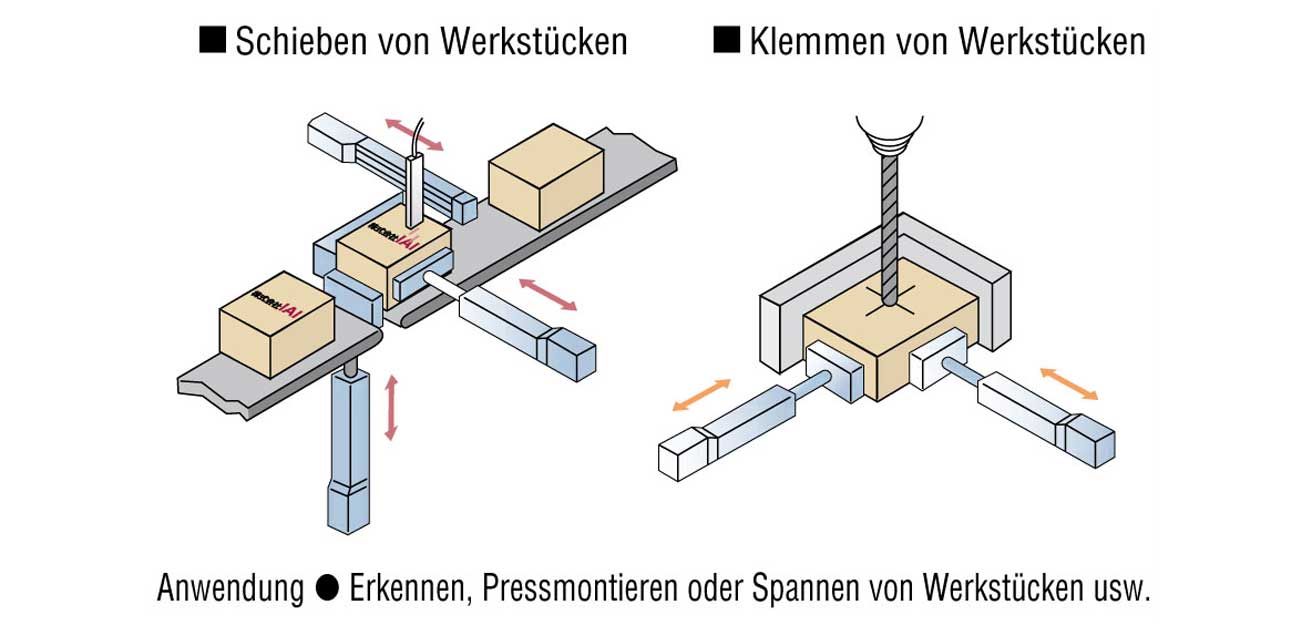

IAI compares the advantages of modern electric cylinders Pneumaticsylinder based on the "Robo Cylinder" product series: They are not susceptible to load fluctuations, enable jerk-free starting and stopping, simple speed regulation and the control of a wide variety of positions with the highest level of repeatability.

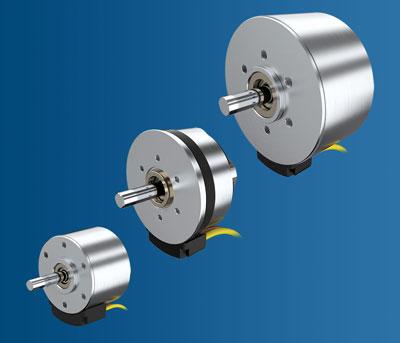

koco Motion be expanded now Servomotor and servo controller offer up. Significantly larger drives are now being added to the small servo motors and servo controllers, gearless drives and torque motors. Thanks to a distributor partnership with the Italian Motor Power Company (MPC) drives with a power output of up to 8 kW are now available.

Baumüller offers many of his electric motors with water cooling. With a new one synchronous motor the drive specialist has now expanded its DST 2 series to include torques from 325 to 60.000 Nm. But also with all other electric motors Water Cooling the very compact design is more powerful than the fan-cooled motors.

In the newly developed Krause+Mauser "Reflex" rotary transfer machine for machining steering knuckles, the play-free "Roba-guidestop" profile rail brakes from Mayr Antriebstechnik for maximum functional reliability. The brakes act directly on the moving masses of the vertical axes and thus offer reliable protection for people and material.

In the newly developed Krause+Mauser "Reflex" rotary transfer machine for machining steering knuckles, the play-free "Roba-guidestop" profile rail brakes from Mayr Antriebstechnik for maximum functional reliability. The brakes act directly on the moving masses of the vertical axes and thus offer reliable protection for people and material.

In the ski season tens of thousands are drawn to ski in the Alps every day. Fail-safe technology is required so that there are no long queues at the cable cars. The ropeway world market leader Doppelmayr / Garaventa therefore relies on long-life, low-maintenance geared motors from NORD.

In the ski season tens of thousands are drawn to ski in the Alps every day. Fail-safe technology is required so that there are no long queues at the cable cars. The ropeway world market leader Doppelmayr / Garaventa therefore relies on long-life, low-maintenance geared motors from NORD.

Parallel kinematic hexapods position in six degrees of freedom and work much more precisely than is possible with serial, i.e. stacked systems. Physik Instrumente now presents a compact hexapod for industrial automation.

Parallel kinematic hexapods position in six degrees of freedom and work much more precisely than is possible with serial, i.e. stacked systems. Physik Instrumente now presents a compact hexapod for industrial automation.

More and more applications in the fields of robotics, prosthetics, laboratory automation, medical technology, pumps and the equipment of aircraft cabins require high torque with a very short overall length. With the market launch of the flat brushless DC motor family BXT with grooved winding meet these requirements.

More and more applications in the fields of robotics, prosthetics, laboratory automation, medical technology, pumps and the equipment of aircraft cabins require high torque with a very short overall length. With the market launch of the flat brushless DC motor family BXT with grooved winding meet these requirements.

The DC motor is a multi-talent. The all-rounder is not only suitable for many applications in the Automotive engineering, where he is in e.g. B. steering is used. also in the Medical Technology it is used in pumps or surgical instruments. Countless other applications can be found in smart homes, scanners, toys, drones, to name just a few. We present them to you here New developments:

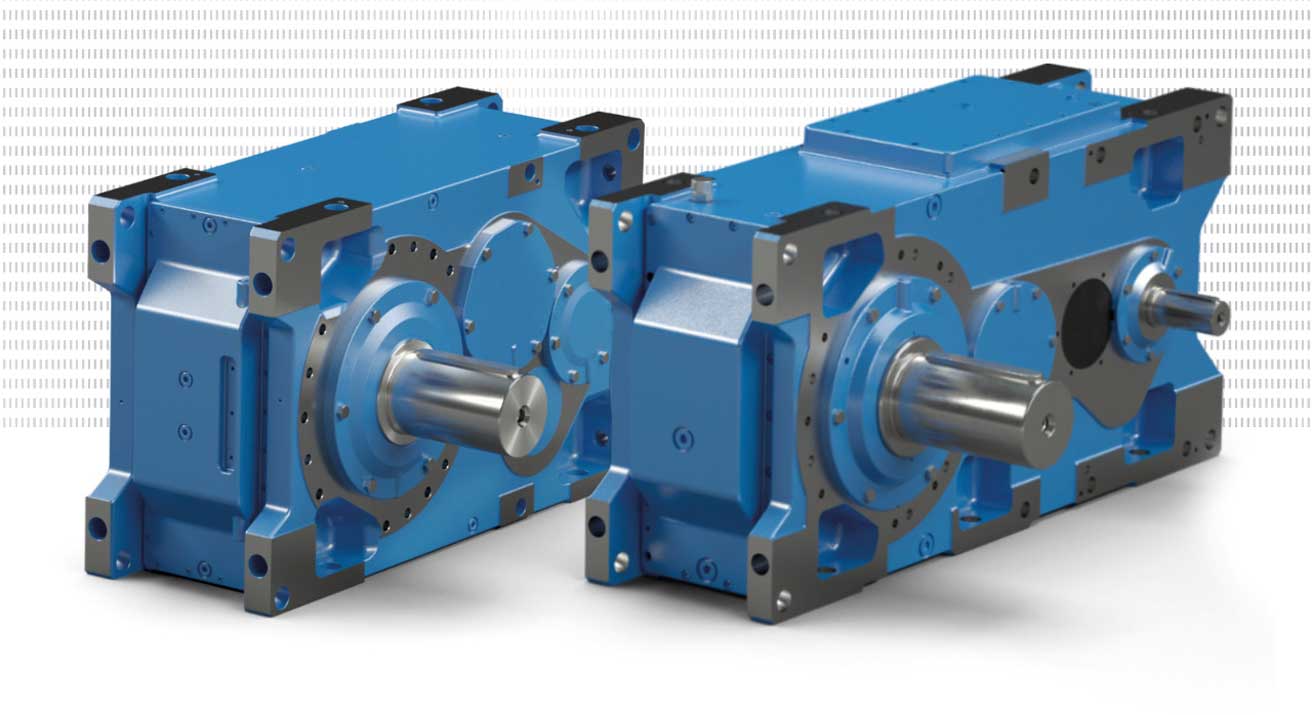

NORD has evolved from a gearbox manufacturer to a value chain partner for complete solutions Drive Technology developed. The product portfolio also includes the industrial gear Maxxdrive series for maximum output torques of 282.000 Nm for heavy-duty applications. Nord Drivesystem is currently presenting a new industrial gearbox for hoists. The example of a Bascule bridge shows how an individual drive solution with a short delivery time is created. You can find this and other news below:

Which one constructor doesn't know them - that Oldham coupling and the three-part construction of two aluminum hubs and a cross disc made of acetal. Also known for their high radial displacement compensation, there is more Potential Buyers / Aggregators in an Oldham clutch from Orbit Drive Technology.

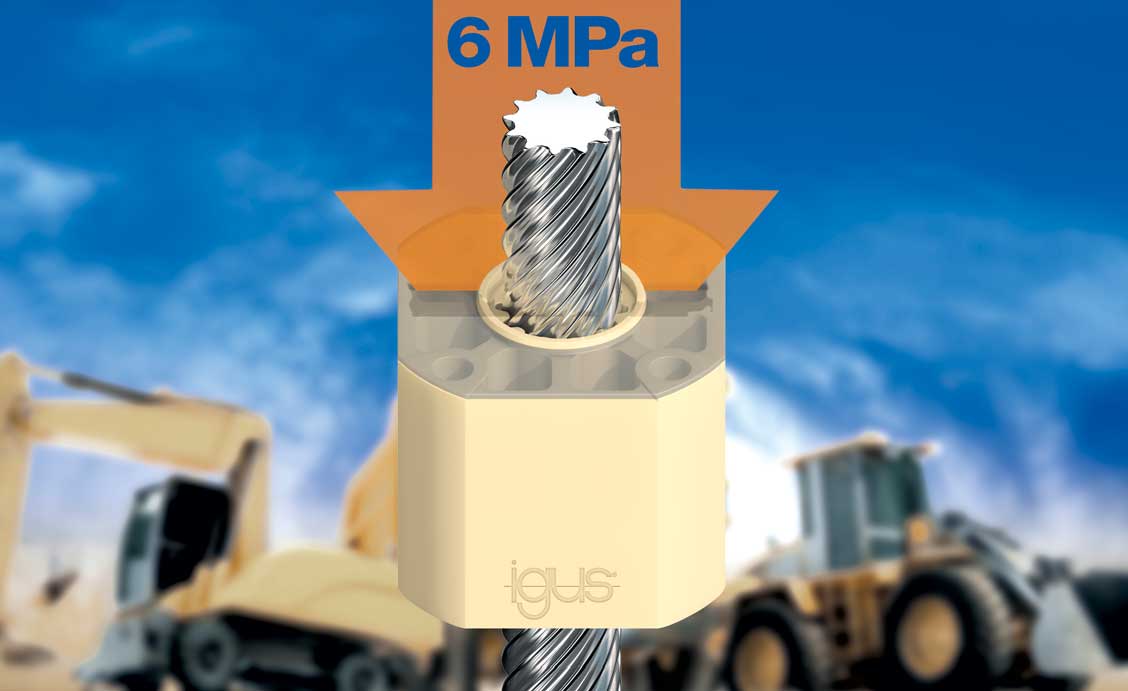

How fit Plastic and heavy load together? Igus knows and offers one for this Spindle nut in the new thread nut design. The polymer nut Dry spin JGRM Made from injection molding is therefore an inexpensive alternative to the ball screw nut for the ball screw. Together with one Screw it moves heavy loads wear-resistant and lubricant-free.

NORD presents a new one IE5 synchronous motor (Image) which is a significant improvement in Energy Efficiency reached a new generation of switch cabinetconvert and a Profisafe module for that functional safety of machines and systems. The energy-efficient permanent magnet synchronous motor of the latest generation significantly reduces the losses in comparison with the current IE4 series.

NORD presents a new one IE5 synchronous motor (Image) which is a significant improvement in Energy Efficiency reached a new generation of switch cabinetconvert and a Profisafe module for that functional safety of machines and systems. The energy-efficient permanent magnet synchronous motor of the latest generation significantly reduces the losses in comparison with the current IE4 series.