DC motor as an all-round talent for countless applications

- Details

- Hits: 12714

The DC motor is a multi-talent. The all-rounder is not only suitable for many applications in the Automotive engineering, where he is in e.g. B. steering is used. also in the Medical Technology it is used in pumps or surgical instruments. Countless other applications can be found in smart homes, scanners, toys, drones, to name just a few. We present them to you here New developments:

Contents

- DC motor as a multi-talent for modern vehicles

- BLDC Motor Innovations from Minebea Mitsumi

- DC motor and other drives for medical technology

- BLDC motor for driverless transport systems in logistics

- Sonic motors for durable devices

- Ironless motors for battery powered applications

- Brushless DC outrunners with high power density

- Brushless DC motor for Micro Drive servo drive

DC motor as a multi-talent for modern vehicles

31.03.2022/XNUMX/XNUMX | The brushless DC motor is a key component for many applications in the Vehicle. The EC motor, which is only about 5 cm small, can be found in the drive to the steering. Schaeffler develops and manufactures DC motors in Bühl with immediate effect. The automotive supplier is thus entering a growing field of business.

The DC motor is becoming increasingly popular when used in modern vehicles: the electric motor can be found in Dual-clutch transmission, hybrid transmission, rear-axle steering, thermal management or seat adjustment. Schaeffler now builds the DC motors itself in Bühl. They are used as standard in a hydrostatic clutch actuator. With the help of the motors, the required pressure is built up here in order to Clutch to operate.

Rotary encoders for axes in drives, machines and systems

Rotary encoders for axes in drives, machines and systems

"EC motors are true all-rounders and vehicles can no longer be imagined without them," says dr Jochen Schroeder, Head of the Electromobility division at Schaeffler in Bühl. Compared to motors that have mechanical sliding contacts, brushless DC motors are much more durable, more efficient and work much more reliably. Incidentally, the abbreviation EC stands for “electronically commutated”. The electronic commutator electronically changes the voltage from one motor winding to the next.

High level of vertical integration facilitates adjustments

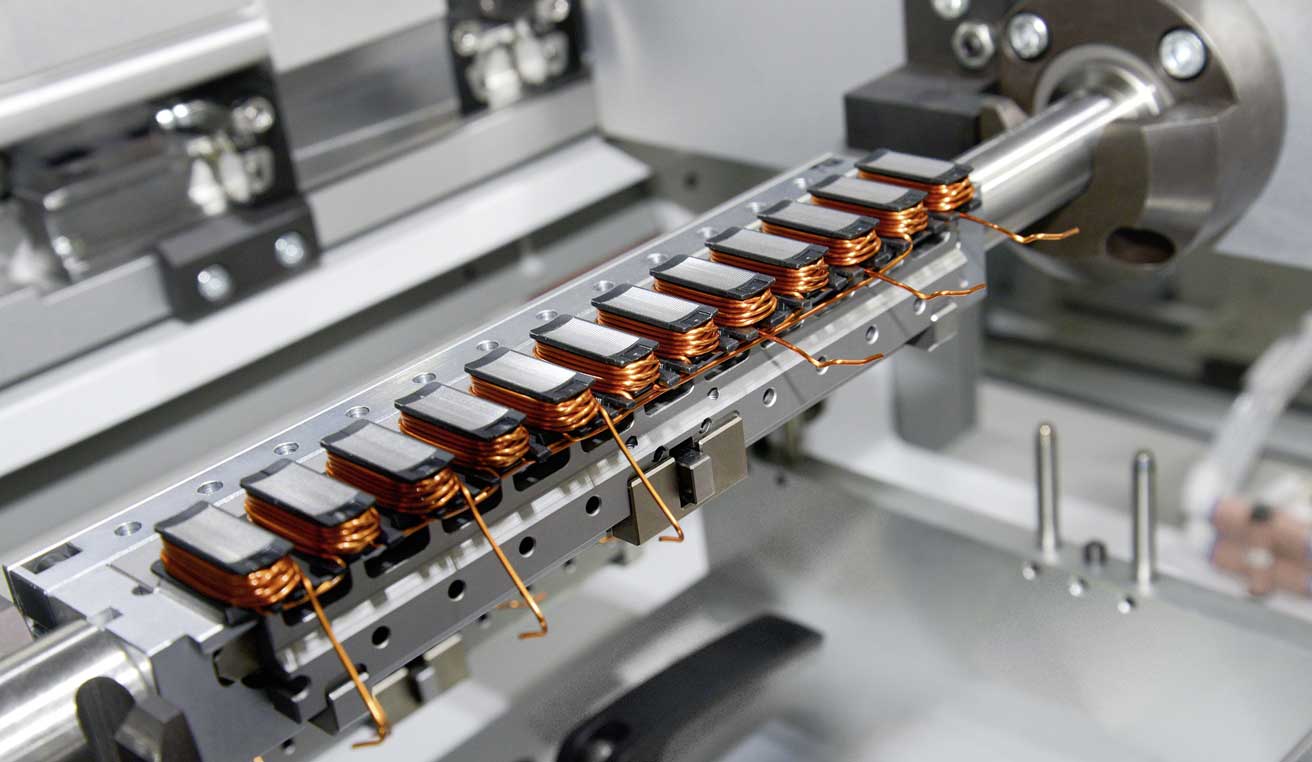

A DC motor from Schaeffler is characterized by the single tooth construction with the stator it contains. The stator teeth are individually stamped, stacked, insulated with injection molding and then assembled into a chain after being wrapped with enameled copper wire. This design offers a significantly higher power density compared to the full cut, in which the laminated core of the stator consists of a closed ring.

"In the production of DC motors, we rely on in-house production from stamping the stator teeth to the finished product,” says Mr. Schröder. This high level of vertical vertical integration offers many advantages. The employees in production can react more flexibly to customer requests for adjustments and continuously optimize production itself, because the entire process chain from the individual part to the finished motor is implemented in Bühl.

Sensor technology protects WKA rotor blade from ice and damage

Sensor technology protects WKA rotor blade from ice and damage

The complete production line for the series production of the DC motors was realized in just over a year. It is the result of the collaboration of a cross-site teams from Bühl, Höchstadt, Herzogenaurach and Haguenau. The production comprises a total of around 25 process steps. These run fully automated and fully interlinked with two integrated injection molding machines, winding machines and end-of-line testing.

A driverless transport system supplies the system with individual parts and transports the finished products. "The tight schedule could only be met because all employees worked closely together on this project," says Benjamin Hofrth, Head of Operations in the Actuator Systems division at Schaeffler in Bühl. He is responsible for setting up production, in which more than one million DC motors will be manufactured every year from now on.

"For the development and production of future DC motors, our team in Bühl relies particularly on flexibility," says Mr. Hoffarth. This is how a specially developed production kit of stators with three diameter gradations (53 mm, 75 mm and 86 mm) cover different motor sizes and thus different applications. The aim is also to adapt the future EC electric motor portfolio so that it can be used in the areas of actuators, e-mobility and industry as diverse as possible.

Schaeffler is exhibiting at the Hannover Messe 2022.

BLDC Motor Innovations from Minebea Mitsumi

16.11.2021 | BLDC motors are all-rounders and are therefore suitable for countless applications. For example, the BLDC motor converts into a power tool, pump, conveyor belt, Robot and other machines efficiently convert electrical energy into motion. With their property of high power density can be in large numbers z. B. save weight in the car and thus reduce fuel and pollutant emissions. Minebea Mitsumi offers such a brushless motor portfolio. We report here on their applications and new developments.

16.11.2021 | BLDC motors are all-rounders and are therefore suitable for countless applications. For example, the BLDC motor converts into a power tool, pump, conveyor belt, Robot and other machines efficiently convert electrical energy into motion. With their property of high power density can be in large numbers z. B. save weight in the car and thus reduce fuel and pollutant emissions. Minebea Mitsumi offers such a brushless motor portfolio. We report here on their applications and new developments.

DC motor and other drives for medical technology

01.03.2021 | koco Motion offers a comprehensive product range of drive technology for medical technology, which is currently booming. With the DC motor, bell rotor motor, brushless DC motor, precision gear motor, precision servo motor and miniature stepper motor portfolio of Constar, almost all developer wishes can be fulfilled. Medical pumps, surgical instruments, respirators or prostheses, for example, are possible applications.

01.03.2021 | koco Motion offers a comprehensive product range of drive technology for medical technology, which is currently booming. With the DC motor, bell rotor motor, brushless DC motor, precision gear motor, precision servo motor and miniature stepper motor portfolio of Constar, almost all developer wishes can be fulfilled. Medical pumps, surgical instruments, respirators or prostheses, for example, are possible applications.

BLDC motor for driverless transport systems in logistics

24.01.2020 | EBM-Papst presents intelligent drives for driverless transport systems and shuttle applications for innovative logistics. As a novelty, the drive specialist is presenting a driving and steering system that uses BLDC brushless direct current motors for mobile Battery operated applications is operated. The DC motors are also used in shuttle applications.

24.01.2020 | EBM-Papst presents intelligent drives for driverless transport systems and shuttle applications for innovative logistics. As a novelty, the drive specialist is presenting a driving and steering system that uses BLDC brushless direct current motors for mobile Battery operated applications is operated. The DC motors are also used in shuttle applications.

The market for driverless transport systems (AGV) is growing disproportionately. The drives for Freely navigating AGVs must meet high requirements. The users require intelligent networking via bus systems and rapid commissioning. Fulfilling this requires a high power density with minimal installation space and maximum efficiency.

BLDC motors for driving and steering system and shuttle

The new Driving-wheel steering system from EBM-Papst is an innovative drive solution for mobile battery-powered applications. It enables the surfaces to be moved by the vehicles and consists of Motor, Transmission, Sensor and wheel.

EBM-Papst uses the brushless DC motors ECI-63 and ECI-80 in the new drive-steering system or as a direct drive Wheel Drive. The BLDC require little installation space. The brushless DC motors and achieve a high torque with just 24 V. For a short time, the BLDC can deliver three times the output. The integrated intelligence in the motors allows predictive maintenance and condition monitoring in the sense of green intelligence. Together with the Optimax gearboxes, robust, compact and intelligent drives are created.

Shuttles are currently the trend Intralogistik. Nowadays, warehouses are built taller in order to keep a warehouse's space consumption as low as possible. All storage positions on all levels are then approached by shuttle vehicles. The requirements for positioning accuracy, service life and dynamics are also met by the brushless motors ECI-63 and ECI-80 in combination with the Optimax gear units.

Sonic motors for durable devices

10.01.2020 | koco Motion have now Sonic motors included in his program. The drives, which are available in sizes from 14 to 32 mm in diameter, are often used in toothbrushes, massage or facial cleansing devices. The Drives from the manufacturer are compact, run quietly and are very reliable. Visually, the Sonic motors hardly differ from normal rotary drives.

10.01.2020 | koco Motion have now Sonic motors included in his program. The drives, which are available in sizes from 14 to 32 mm in diameter, are often used in toothbrushes, massage or facial cleansing devices. The Drives from the manufacturer are compact, run quietly and are very reliable. Visually, the Sonic motors hardly differ from normal rotary drives.

Archive for DC Motor News

- Brushless DC outrunners with high power density

- Ironless motors for battery powered applications

- Vibration motor for automobiles and other applications

- 200 watt coreless motor

- Brushless DC motor for Micro Drive servo drive

- Brushless DC motor with Profinet interface

- Brushless DC motors with individual control

- Customized BLDC motors with integrated electronics

- DC motors with and without brushes

- BLDC motors with and without iron, electronically commutated

Brushless DC outrunners with high power density

11.12.2019 | Brushless external rotor motors combine a small installation space with a high power density. koco Motion presents a new addition to the product family with the BO6452N3B, which offers impressive characteristics thanks to the choice of materials and magnets. Outputs in the four-digit range can be generated from small sizes. The portfolio of these brushless DC motors from Koco Motion includes drives with a diameter of 10 to 90 millimeters.

11.12.2019 | Brushless external rotor motors combine a small installation space with a high power density. koco Motion presents a new addition to the product family with the BO6452N3B, which offers impressive characteristics thanks to the choice of materials and magnets. Outputs in the four-digit range can be generated from small sizes. The portfolio of these brushless DC motors from Koco Motion includes drives with a diameter of 10 to 90 millimeters.

Ironless motors for battery powered applications

12.11.2019/XNUMX/XNUMX | Koco Motion's ironless DC motors have already proven themselves in many applications. They are very efficient, offer high speeds and a long service life. The drive specialist is now expanding its series of Coreless motors to new versions that are specially designed for the requirements of medical technology and safety technology.

12.11.2019/XNUMX/XNUMX | Koco Motion's ironless DC motors have already proven themselves in many applications. They are very efficient, offer high speeds and a long service life. The drive specialist is now expanding its series of Coreless motors to new versions that are specially designed for the requirements of medical technology and safety technology.

Brushless DC motor for Micro Drive servo drive

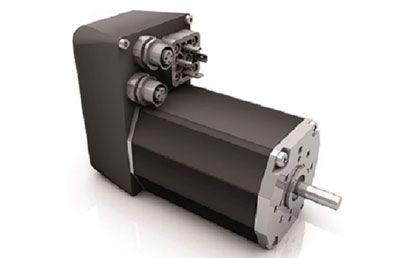

15.04.2019/24/48 | With the brushless DC motors (45 to 65 volts) of the BG 75, BG 95(S), BG XNUMX and BG XNUMX series dark engines has been the market leader in the power range from 20 to 1100 W for years. As part of a product partnership with Siemens, the drives are now also available in a specific version that is compatible with the new Simatic Micro-Drive servo drive system.

15.04.2019/24/48 | With the brushless DC motors (45 to 65 volts) of the BG 75, BG 95(S), BG XNUMX and BG XNUMX series dark engines has been the market leader in the power range from 20 to 1100 W for years. As part of a product partnership with Siemens, the drives are now also available in a specific version that is compatible with the new Simatic Micro-Drive servo drive system.

By simply integrating the servo drive into the Simatic world the engineering time is significantly reduced. The integration into Siemens Automation services is made possible via the TIA Portal and simplifies commissioning and service. Communication takes place via Profinet IRT with Profisafe and Profidrive profiles. The new Safety Integrated function SLT (Safely Limited Torque) ensures a limited torque by monitoring the motor current during operation.

Smart components in the engine, together with a patented data transmission, put the controller in a default state after connecting to the motor. Complicated drive tuning and parameterization of the controller control loops are therefore a thing of the past.

Brushless DC motor with Profinet interface

08.05.2018 | The BLDC drive BG 65 from dark engines is equipped with an integrated Profinet interface and is compatible with Siemens controllers of the S7 series. The DC motor can be easily integrated into PLC controls using function blocks.

08.05.2018 | The BLDC drive BG 65 from dark engines is equipped with an integrated Profinet interface and is compatible with Siemens controllers of the S7 series. The DC motor can be easily integrated into PLC controls using function blocks.

With a continuous power output of 60 to 190 W and a peak of 341 W, the BG 65 PN electric motor with its compact design is suitable for industrial automation and the Engineering. Because of its built-in absoluteencoders no referencing is necessary.

The manufacturer sees areas of application for the BG 65 PN, for example, in linear axes or lifting cylinders for positioning tasks. With its integrated modular system, the drive specialist can offer planetary and worm gears to match the motor with a continuous torque of up to 160 Nm.

Vibration motor for automobiles and other applications

17.12.2018 | Koco Automotive presents its new integrated vibration motor VC2039, which can be used in a wide variety of applications with little construction effort. In the waterproof and foam-proof housing, the DC motor withstands increased pressures in liquid media, such as those that occur when foaming into a steering wheel.

17.12.2018 | Koco Automotive presents its new integrated vibration motor VC2039, which can be used in a wide variety of applications with little construction effort. In the waterproof and foam-proof housing, the DC motor withstands increased pressures in liquid media, such as those that occur when foaming into a steering wheel.

200 watt coreless DC motor

15.02.2018/XNUMX/XNUMX | At the SPS IPC Drives, the company has two new powerful ironless drives presented, which supplement the previous sizes in the diameter range from 4 to 25 mm. The new Glocken Anker DC motors in the 30 and 32 mm diameter range feature robust copper-carbon commutation and offer peak power of up to 200 W.

15.02.2018/XNUMX/XNUMX | At the SPS IPC Drives, the company has two new powerful ironless drives presented, which supplement the previous sizes in the diameter range from 4 to 25 mm. The new Glocken Anker DC motors in the 30 and 32 mm diameter range feature robust copper-carbon commutation and offer peak power of up to 200 W.

Brushless DC motors with individual control

22.01.2018/XNUMX/XNUMX | If a mechanically commutated DC motor reaches its limits in terms of service life or performance, it is time to switch to brushless DC motors. The demand for brushless DC motors is unbroken - and the trend is rising. on this koco Motion set and offers a comprehensive BLDC motor Program that leaves (almost) no user wishes unfulfilled. Depending on the application, the electronic commutation of DC motors can achieve a service life of more than 20.000 operating hours.

22.01.2018/XNUMX/XNUMX | If a mechanically commutated DC motor reaches its limits in terms of service life or performance, it is time to switch to brushless DC motors. The demand for brushless DC motors is unbroken - and the trend is rising. on this koco Motion set and offers a comprehensive BLDC motor Program that leaves (almost) no user wishes unfulfilled. Depending on the application, the electronic commutation of DC motors can achieve a service life of more than 20.000 operating hours.

Customized BLDC motors with integrated electronics

19.08.2015/XNUMX/XNUMX | Again and again it is the service life that pushes a mechanically commutated DC motor to its limits due to spark erosion and mechanical friction. However, as soon as applications require a correspondingly high running time, the brushless DC motors from koco Motion as an alternative because they are electrically commutated. Only the wear of slide or ball bearings still limits the service life here. The DC motors with integrated electronics now offer a simple solution.

19.08.2015/XNUMX/XNUMX | Again and again it is the service life that pushes a mechanically commutated DC motor to its limits due to spark erosion and mechanical friction. However, as soon as applications require a correspondingly high running time, the brushless DC motors from koco Motion as an alternative because they are electrically commutated. Only the wear of slide or ball bearings still limits the service life here. The DC motors with integrated electronics now offer a simple solution.

DC motor with and without brushes

15.02.2015/70/XNUMX | Not even available a few years ago, direct current (DC) motors now account for XNUMX percent of the total koco Motion portfolio – and the trend is rising. The drive specialist's extensive range of DC motors, which can also be customized, now covers a power range from 0,06 to 1670 W. Brushed and brushless motors are available in numerous designs for a wide variety of applications, which are becoming more and more durable.

15.02.2015/70/XNUMX | Not even available a few years ago, direct current (DC) motors now account for XNUMX percent of the total koco Motion portfolio – and the trend is rising. The drive specialist's extensive range of DC motors, which can also be customized, now covers a power range from 0,06 to 1670 W. Brushed and brushless motors are available in numerous designs for a wide variety of applications, which are becoming more and more durable.

BLDC motors with and without iron, electronically commutated

13.02.2014/XNUMX/XNUMX | The demand for engines with a longer service life is growing in all industrial sectors. If a mechanically commutated DC motor reaches its limits in this respect, it is time to convert the application to brushless DC motors. Only a year ago, the manufacturer and distributor of compact, highly integrated, electric drives and controls koco Motion brushless DC motors added to its portfolio. Today he already offers a range of products that leaves almost nothing to be desired.

13.02.2014/XNUMX/XNUMX | The demand for engines with a longer service life is growing in all industrial sectors. If a mechanically commutated DC motor reaches its limits in this respect, it is time to convert the application to brushless DC motors. Only a year ago, the manufacturer and distributor of compact, highly integrated, electric drives and controls koco Motion brushless DC motors added to its portfolio. Today he already offers a range of products that leaves almost nothing to be desired.

You might also be interested in...

Linear motor | With linear actuator and electric cylinder

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

spindle bearing | The Vacrodur high-performance elements