Profile rail brakes ensure safety at Krause + Mauser

- Details

- Hits: 8369

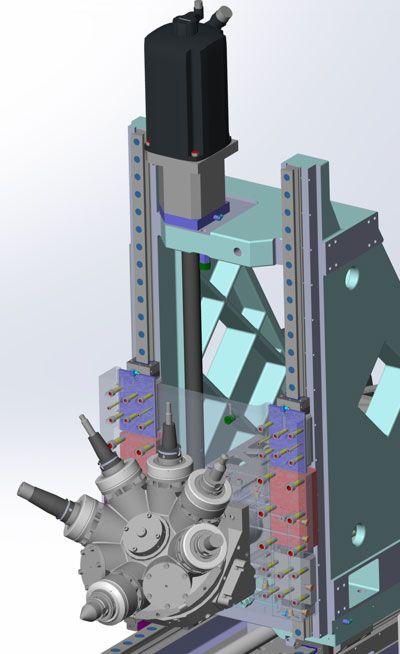

In the newly developed Krause+Mauser "Reflex" rotary transfer machine for machining steering knuckles, the play-free "Roba-guidestop" profile rail brakes from Mayr Antriebstechnik for maximum functional reliability. The brakes act directly on the moving masses of the vertical axes and thus offer reliable protection for people and material.

In the newly developed Krause+Mauser "Reflex" rotary transfer machine for machining steering knuckles, the play-free "Roba-guidestop" profile rail brakes from Mayr Antriebstechnik for maximum functional reliability. The brakes act directly on the moving masses of the vertical axes and thus offer reliable protection for people and material.

The Krause + Mauser group of companies supplies numerous well-known automobile manufacturers worldwide with specialized, highly productive machines. At its locations in Vienna and Oberndorf am Neckar, the renowned mechanical engineering specialist designs and produces systems and machining centers for the manufacture of all drive train parts of a vehicle, such as parts for the engine, gearbox, clutch or chassis axles.

The Krause + Mauser group of companies supplies numerous well-known automobile manufacturers worldwide with specialized, highly productive machines. At its locations in Vienna and Oberndorf am Neckar, the renowned mechanical engineering specialist designs and produces systems and machining centers for the manufacture of all drive train parts of a vehicle, such as parts for the engine, gearbox, clutch or chassis axles.

The company has recently developed a new type of machine in the form of a rotary transfer machine with efficient machining technology for the production of steering knuckles, wheel carriers, cylinder heads and other workpieces. The clearance-free Roba-guidestop profile rail brakes from Chr. Mayr GmbH + Co. KG from Mauerstetten, which are used in the vertical axes of this machine, reliably protect against damage.

The rotary transfer machine has a total of up to six stations, one for loading and unloading the workpieces and up to five processing stations. "The basic unit of each processing station is the same. At each station, however, different tools are used, with which different processing steps are performed on the workpiece, "explains Gerhard Rausch, Group Manager Mechanical Design at Krause + Mauser in Oberndorf. Each processing station has a crown turret with eight tool places each. "The individual workpieces made of aluminum in the rotary transfer machine in each case two revolutions, then a pair of knuckle - one left and one right - finished".

So nobody gets hurt

Two Roba-guidestops sit on the vertical guide rail of each processing station Safety brakes. Size 45 brakes have a nominal holding force of 15 kN and are used as holding brakes during operation. “The main task of the safety brakes in our rotary transfer machine is to protect people.

Two Roba-guidestops sit on the vertical guide rail of each processing station Safety brakes. Size 45 brakes have a nominal holding force of 15 kN and are used as holding brakes during operation. “The main task of the safety brakes in our rotary transfer machine is to protect people.

The two brakes, as a redundant system with two independent brake circuits, meet the guidelines for personal safety without any problems, "explains Gerhard Rausch. "They ensure vertical safety when, for example, employees have to go into the danger zone for maintenance work or to change the engine." Suspended loads represent a considerable risk and injury potential in machines and systems. If the load drops unintentionally or crashes be brought to a standstill within a very short time.

Devices for braking energy recuperation for electric drives

Devices for braking energy recuperation for electric drives

The backlash-free brake systems brake movements safely and quickly. They clamp with very high rigidity and act directly on the linear guide. This means they are attached directly to the masses that are to be slowed down or stopped. Drive elements between motor and moving mass such as spindle, Spindle nut, Shaft coupling or gearbox therefore have no effect on safety - unlike concepts with motor brakes, where all drive elements transmit the braking torque to the slide. In addition, every element between the brake and the slide has a negative effect on the rigidity. The Roba-guidestop are therefore considerably stiffer than the motor brakes, which are often subject to play, and than rod or band brakes.

Security through fail-safe principle

The safety brakes work according to the fail-safe principle, ie they are closed when de-energized. Prestressed disc springs press the brake shoes onto the "waist" of the rail, so the rail is clamped. The Roba-guidestop is hydraulically lifted with a nominal pressure of 70 bar. This is relatively low in relation to the very high holding forces. The specialist for safety brakes and clutches has designed the brake mechanism for relatively long stroke distances. This allows the brake compensate for manufacturing tolerances in rails without losing braking power.

The safety brakes work according to the fail-safe principle, ie they are closed when de-energized. Prestressed disc springs press the brake shoes onto the "waist" of the rail, so the rail is clamped. The Roba-guidestop is hydraulically lifted with a nominal pressure of 70 bar. This is relatively low in relation to the very high holding forces. The specialist for safety brakes and clutches has designed the brake mechanism for relatively long stroke distances. This allows the brake compensate for manufacturing tolerances in rails without losing braking power.

The backlash-free clamping of the brake directly onto the profile rail offers even more advantages: The additional stiffening of the NC axis increases the process accuracy and increases the cutting performance. When the axis is stationary, for example during machining, the brake takes over the load. As a result, in this phase, the drive motor can be switched off and taken out of regulation. This eliminates the control movements and thus protects the ball screw.

The closed brake absorbs axial forces. Service life and maintenance intervals are extended. "For us it is important that the design of the brakes is very compact," adds Gerhard Rausch. "Other systems need more space and extra screw-on options. Here, the clamping element is already in the machine, which saves space. "

You might also be interested in...

High-performance brake wind turbine with monitoring

Robco robot kit with safety brake from the construction kit

Predictive maintenance for clutches and brakes

Shaft coupling without play, precise and smart

Compensating coupling | For axial, radial and angular offset