Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

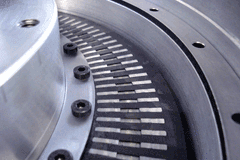

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

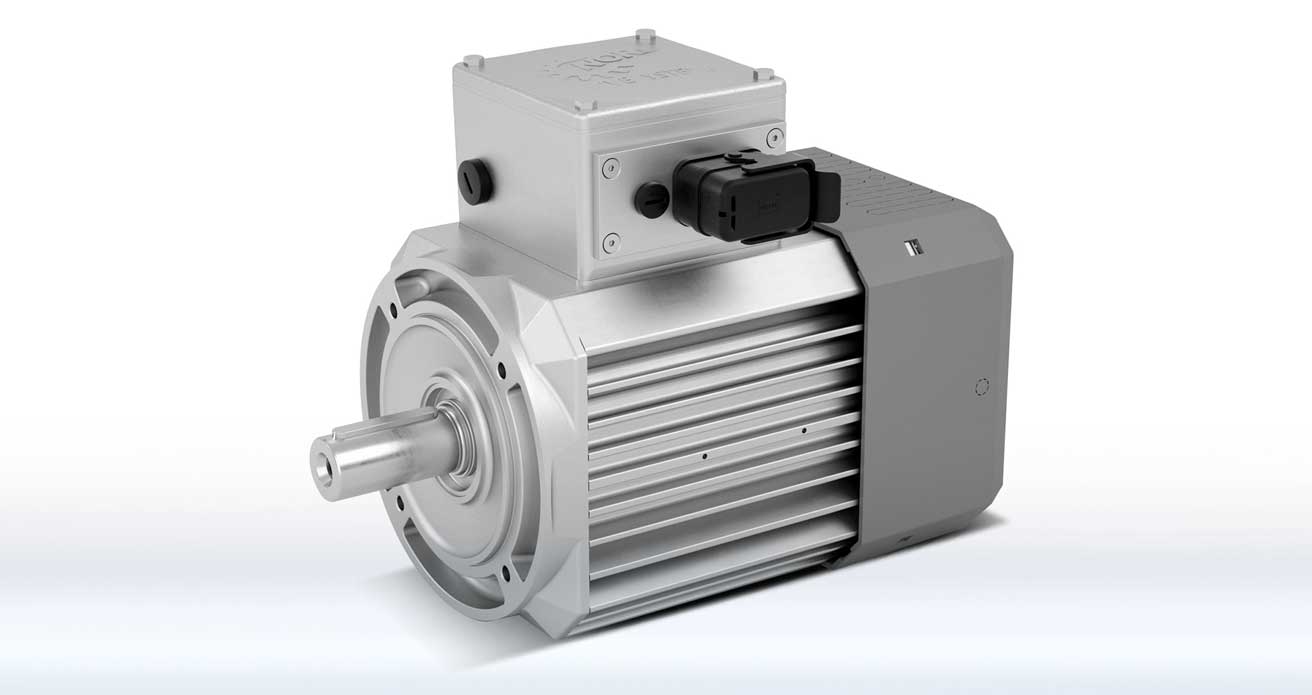

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

Compressed air is difficult to represent, but it is very good to save: under this slogan, Etaopt offers alternatives for industry without compressed air. With the award-winning suction and lifting device "Etavac-SH-ZPN", environmentally conscious companies receive a more efficient and environmentally friendly alternative to pneumatics and conventional vacuum ejectors. The device is based on the completely new vacuum technology "Etavac". A central component in this development is the new "Kannmotion" drive system from koco Motion and adlos.

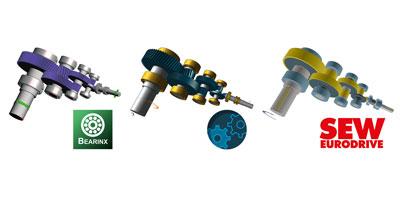

A complete virtual image of powertrains and gearboxes is only possible if gearbox, Rolling- and gearing specialists theirs simulation models digitally link with each other. Therefore, the cross-company and cross-system data exchange is one of the most important prerequisites for the generation of Digital Twins. Schaeffler and SEW have created such a data exchange.

A complete virtual image of powertrains and gearboxes is only possible if gearbox, Rolling- and gearing specialists theirs simulation models digitally link with each other. Therefore, the cross-company and cross-system data exchange is one of the most important prerequisites for the generation of Digital Twins. Schaeffler and SEW have created such a data exchange.

Growth in core Leantec-drive, five companies and three research institutions from Saxony and Thuringia engage with the aim of bringing a new type of electric drive on the market, closing the technological gap between direct drives and classic motor-gearbox combinations. Material, resource and energy efficiency contribute to the sustainability of the drive. One of the companies involved in the development of lightweight drive is Samag.

Growth in core Leantec-drive, five companies and three research institutions from Saxony and Thuringia engage with the aim of bringing a new type of electric drive on the market, closing the technological gap between direct drives and classic motor-gearbox combinations. Material, resource and energy efficiency contribute to the sustainability of the drive. One of the companies involved in the development of lightweight drive is Samag.

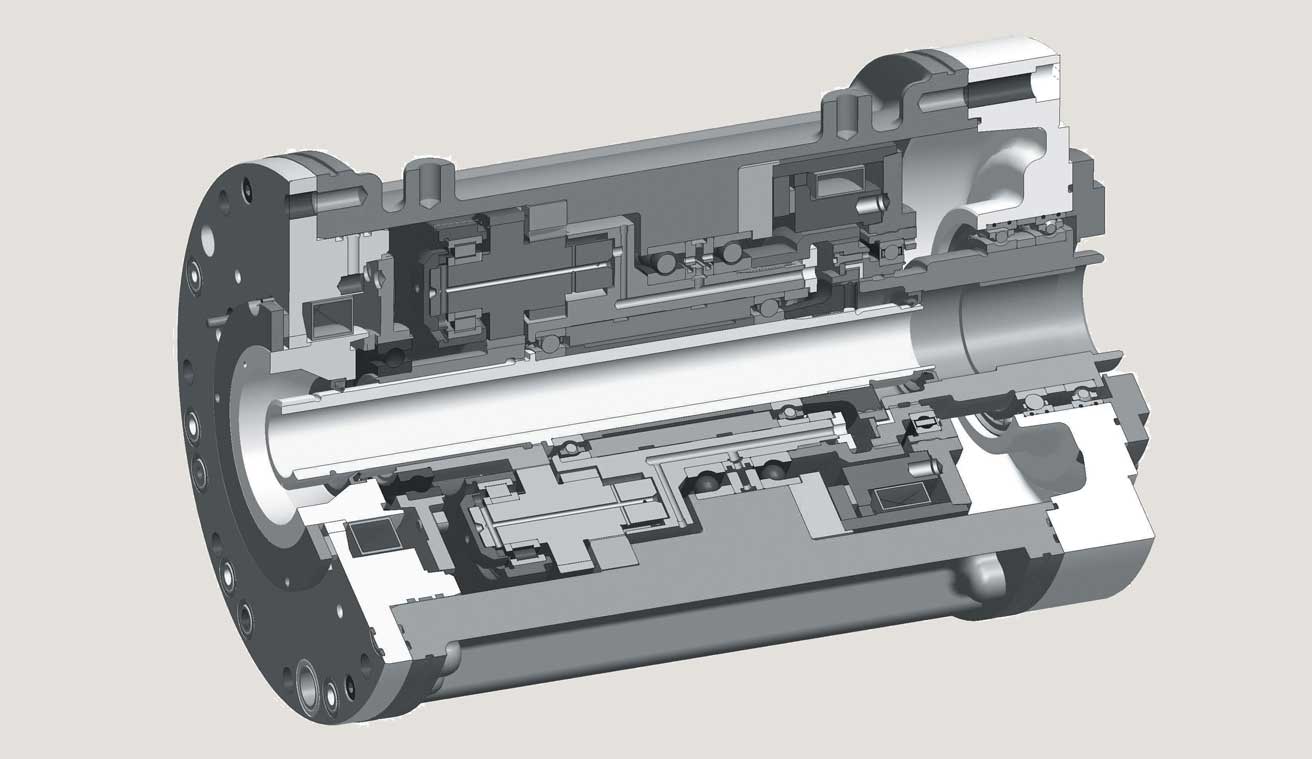

ZF Friedrichshafen presents a new one Hollow shaft gear for Main spindle drives in front. The new Transmission The series with hollow shaft will initially start with the HWG 280 and 380 variants. They belong to the “Duoplan” model family and, according to the manufacturer, have many advantages over conventional two-speed manual transmissions.

Servotecnica is expanding its product line for application areas such as medical technology, robotics or drone technology with new brushless flat motors of the SVTM F series. They offer high torque in the smallest of spaces with a simple design and high quality material selection.

Servotecnica is expanding its product line for application areas such as medical technology, robotics or drone technology with new brushless flat motors of the SVTM F series. They offer high torque in the smallest of spaces with a simple design and high quality material selection.

Wittenstein presents further developments of its "Galaxie" drive system, including a new size for axes with high requirements for compactness and precision with small to medium torques, an ultra-flat design and a gear version with or without hypoid pre-stage for space-saving machine integration. Practical exhibition models show these as well as the use and advantages of the gears in machine tools, milling heads and robot welding guns.

Wittenstein presents further developments of its "Galaxie" drive system, including a new size for axes with high requirements for compactness and precision with small to medium torques, an ultra-flat design and a gear version with or without hypoid pre-stage for space-saving machine integration. Practical exhibition models show these as well as the use and advantages of the gears in machine tools, milling heads and robot welding guns.

The highly efficient bevel gearboxes of the "Powergear HS" series from MS Graessner have been consistently developed for the requirements at the highest speeds. With small transmission ratios, they offer many advantages for a wide variety of applications. Modern angular gearboxes of today have to be fast, quiet, reliable and sustainable. Above input speeds over 2000 min-1 the stress and performance is very high. The Powergear HS gearbox even handles up to 8500 min-1.

The highly efficient bevel gearboxes of the "Powergear HS" series from MS Graessner have been consistently developed for the requirements at the highest speeds. With small transmission ratios, they offer many advantages for a wide variety of applications. Modern angular gearboxes of today have to be fast, quiet, reliable and sustainable. Above input speeds over 2000 min-1 the stress and performance is very high. The Powergear HS gearbox even handles up to 8500 min-1.

NORD presents a new one Universal motor in 20 variants with outputs from 0,12 to 45 kW. The motor is certified according to CE, UL, CCC, CSA, ISI and EAC. It fulfills the corresponding minimum efficiency requirements. This makes it suitable for the markets in Europe, USA, Canada, Russia, China, India and elsewhere. Of the Motor meets the new Ecodesign regulation and is through Bureau Veritas certified for shipping and offshore applications.

NORD goes one better in terms of energy efficiency and introduces its new one synchronous motor in front. It offers a consistently high level of efficiency over the entire adjustment range, and it really does LogiDrive concept for applications in the Intralogistik in terms of variant reduction and energy efficiency to a new level. The synchronous motor is now available in a ventilated or smooth version up to a power of 4 kW.

Security, precision and high integration density are achieved Siko through the use of magnetic sensors for motor feedback systems. Mr. Wiessler explains below what is special about these motor feedback applications and to what extent they are important for robotics and in particular for direct drives.

Security, precision and high integration density are achieved Siko through the use of magnetic sensors for motor feedback systems. Mr. Wiessler explains below what is special about these motor feedback applications and to what extent they are important for robotics and in particular for direct drives.

NORD protects his Drive Technology with different procedures: a special one Surface finishing, environmentally friendly paintwork or long-lasting surface coating. The drives are therefore safe from corrosion, chemicals, abrasion, scratches or bumps, as well as moisture.

Twenty years ago we would probably have suspected innovative high-tech applications and state-of-the-art sensors as the last thing in the cowshed. However, this traditional image of agriculture is long out of date. In some respects, farms are now like industrial companies. Today, almost one in five cowsheds in Germany has jumped on the digitalization train. The BLDC motors from Minebea Mitsumi PM DM should not be missing.

Twenty years ago we would probably have suspected innovative high-tech applications and state-of-the-art sensors as the last thing in the cowshed. However, this traditional image of agriculture is long out of date. In some respects, farms are now like industrial companies. Today, almost one in five cowsheds in Germany has jumped on the digitalization train. The BLDC motors from Minebea Mitsumi PM DM should not be missing.