Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

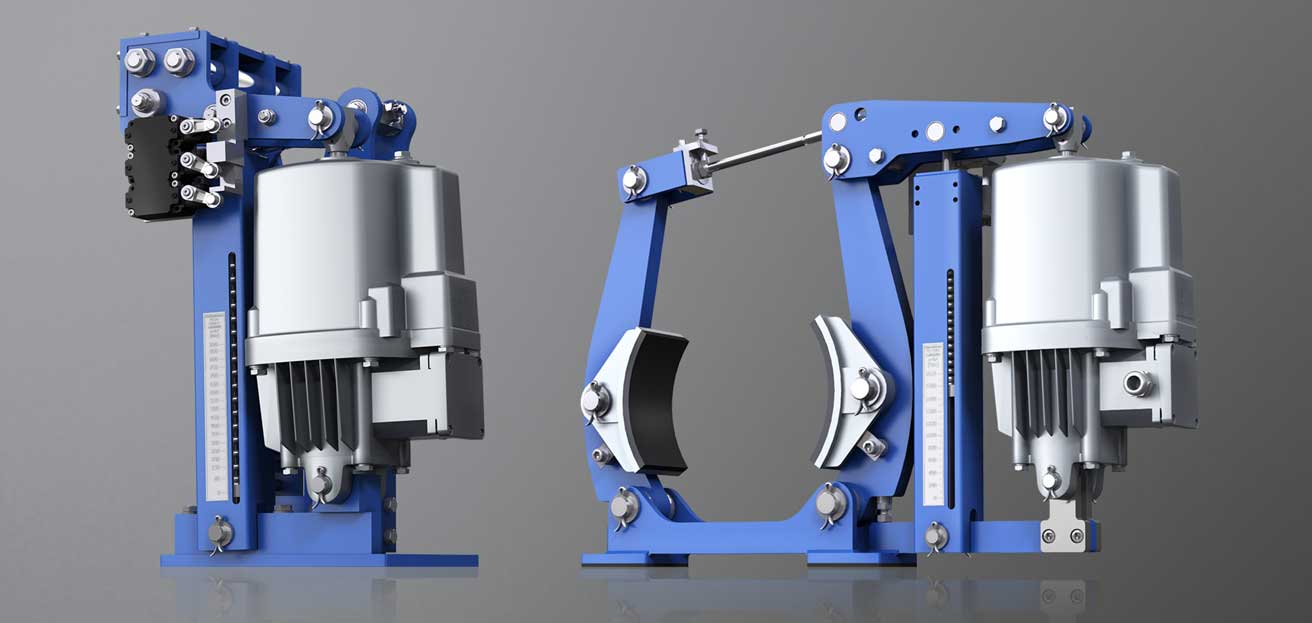

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

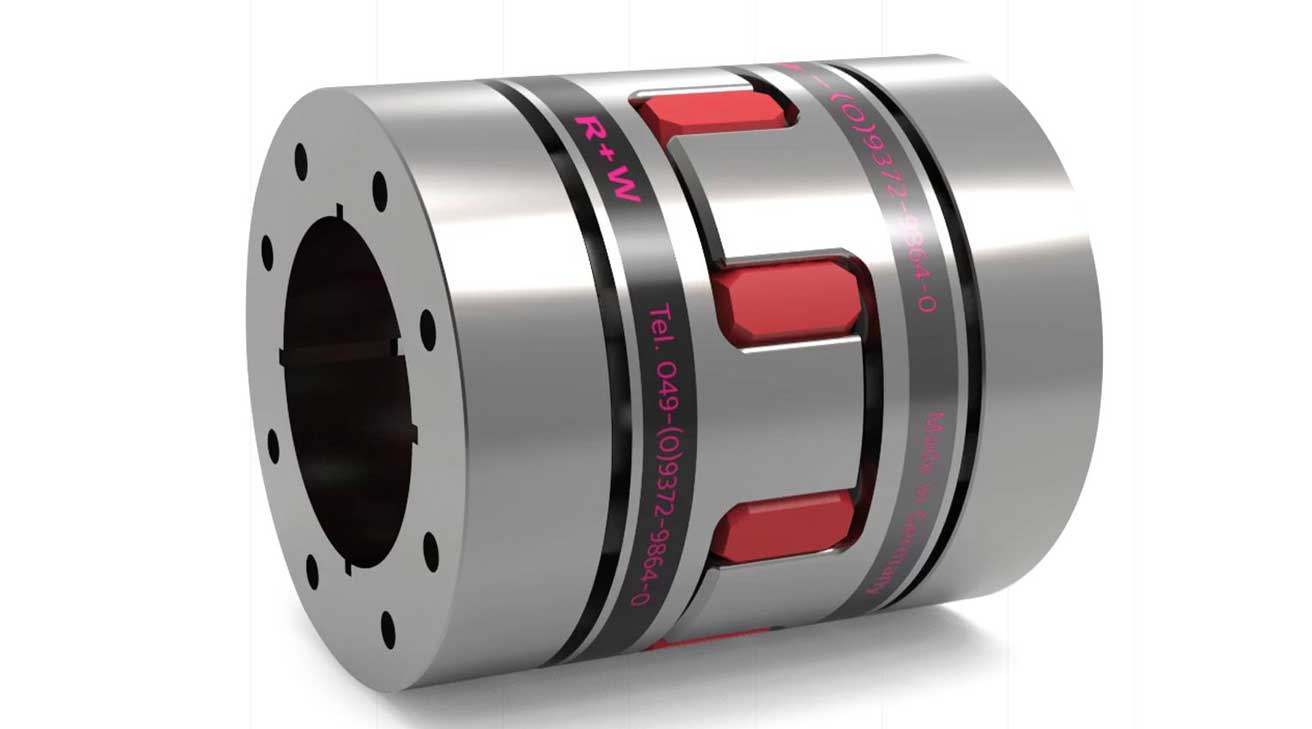

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

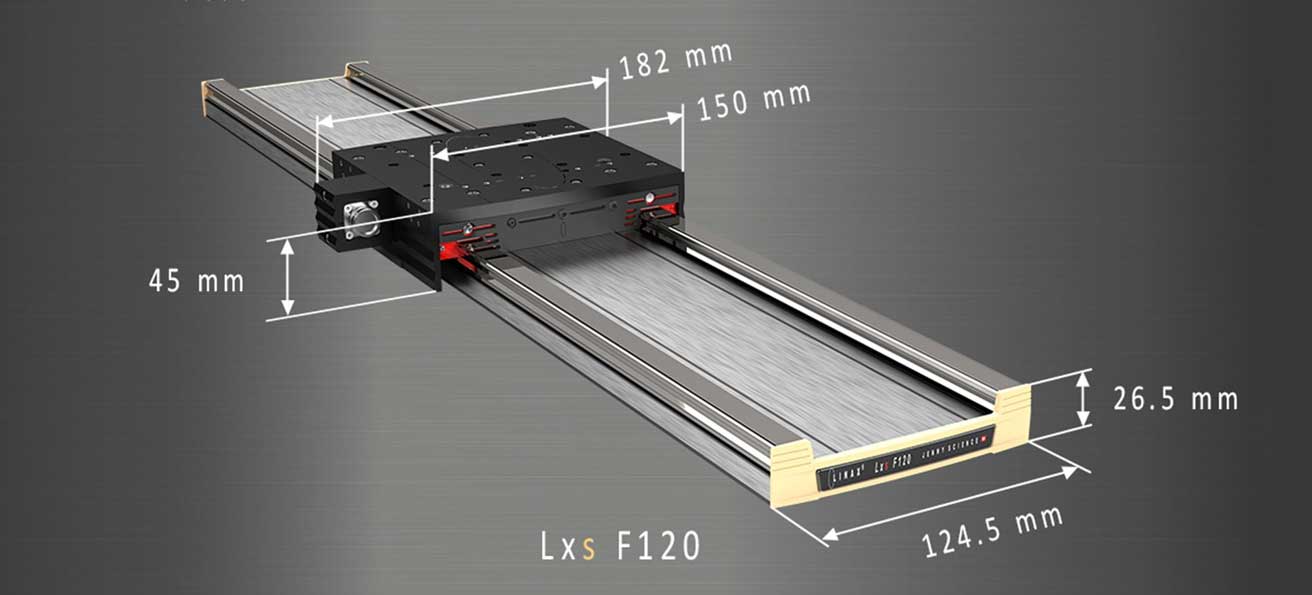

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

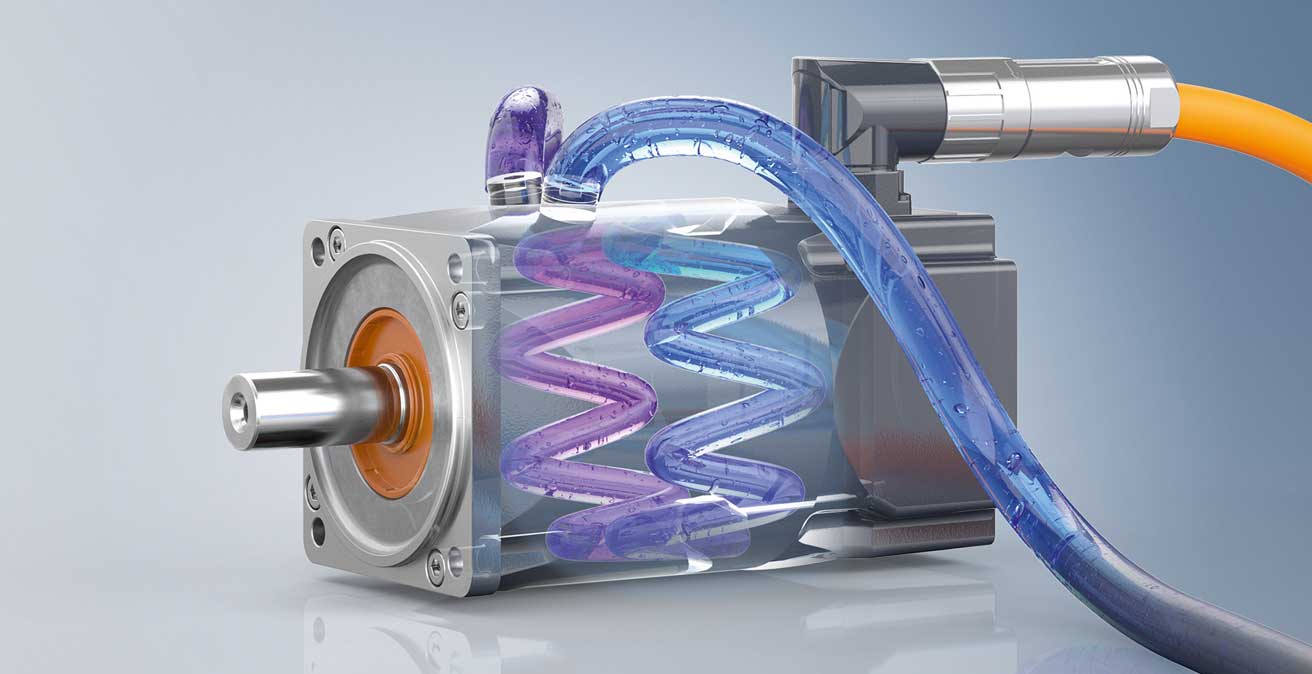

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

The Linear axis is a core building block in the Automation and precision metrology. We present new developments to you here various companies before, their functions and areas of application. Find out how you can generate advantages in your design with these linear axes.

If the installation space is small and at the same time a high drive power is required, are water-cooled electric motors the drive of choice. They are very efficient and tend to be more efficient than air-cooled motors, as the latter generate far more heat and friction losses. In addition, water has the best thermal conductivity coefficient. We present to you below New developments from the field of water-cooled electric motors.

Be it drinks, clothes, electrical appliances, the delivery directly to the house is in. This also applies to supermarkets. One of them left the RM Customs GbR build a small series of e-trikes to slow down traffic jams and help protect the environment. For more comfort and safety To steer make Brake cylinder of ACE Shock GmbH installed.

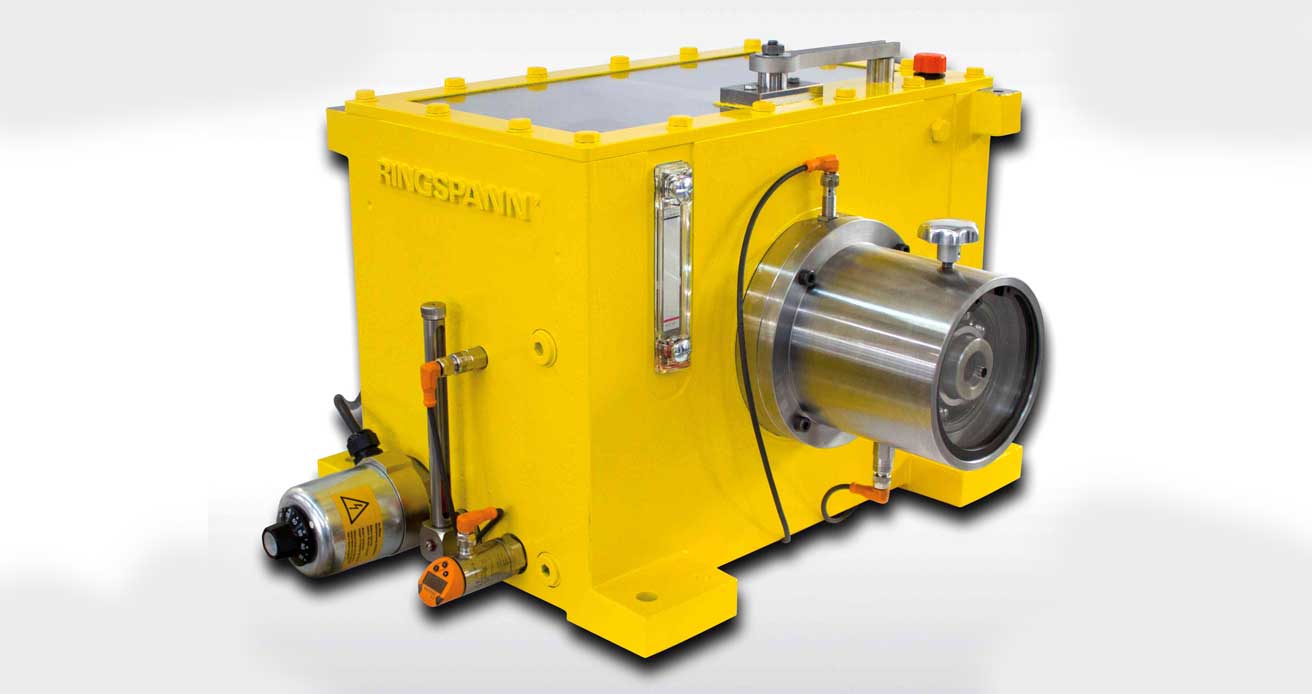

In the realization of a new mountain and valley railway for the Eagle's Lair in Hinterzarten wiegand of Brakes-Technology from Ringspann. It made the BCS 600 brake control and monitoring system the linchpin of the safety concept of its rail-guided wagon train system. The special challenge: Only personal-safe braking systems that comply with the EU cable car directive may be used in cable cars and chair lifts.

Handbikes are the Formula 1 cars among wheelchairs. For this reason, modern sports equipment for disabled people has also replaced classic wheelchairs in city marathons. This applies all the more the more the focus is on sporting competition. However, on rain-soaked roads, these vehicles sometimes run into problems in the curves. Dutchman Ad Aarts has developed such a handbike specifically for artificial and natural ice rinks. These are braked Oil brakes from ACE.

With the new Linear gantry robot "LGR-3" offers Fibro Läpple a modular system for loading and unloading machines as well as for handling workpieces. This allows a wide variety of customer requirements to be implemented flexibly. In the electrical design of the portal, the company uses to secure the Vertical axis on electromagnetic brakes "Roba-linearstop" from Mayr Antriebstechnik.

Attention skiers, tobogganers and mountain bikers: the leisure fun is enriched by an action-packed facet Pistenbock Cross as an ideal supplement for the snow-free months. The innovative vehicle is controlled in a similar way to tobogganing. High-quality vehicle components such as built-in rotation brakes from ACE Shock help to effectively dampen unexpected steering angles and smooth the overall steering curve for the benefit of driving comfort and safety.

Within the disc brake you first think of the bicycle. However, this type of brake is also used in industrial drive systems. These robust brakes can be precisely controlled and are very reliable. Whether as Thruster brake in lifting devices, electromagnetic for the machine tool, as a fixed caliper brake for holding or as a floating caliper brake in the function of a service brake: There are many applications for the type of brake invented by Frederick W. Lanchester.

Collisions in the drive train cause sudden high torque peaks that can damage or even destroy adjacent components. To limit the torque to a defined value, either the Slip clutch or snapping Overload Clutch to disposal. In the portfolio of Orbit Drive Technology the technical user will find a wide variety of safety clutches for a wide range of applications and wide torque ranges.

clamping ring, Collars and clamping couplings secure axes and shafts in jig construction and mechanical engineering. the shaft Collars are very versatile. Here you will find new developments of small drive elements such as Quick release clamping rings for packaging technology Clamping ring with mounting hole from Russia, the versatile wave rings from Misumi or Clamping rings for hollow shaft encoders from Orbit drive technology.

Discover the new products and applications Freewheel clutch, a key element in modern drive systems. This specialized type of coupling, also called Backstop known, allows free rotation in one direction while locking in the opposite direction to prevent unwanted backlash. Find out more about their versatile uses and technical advantages.

Discover the latest developments in the field of Dog clutch – decisive for high-performance drive systems. Our expert insight highlights how these couplings can increase efficiency and reliability. What is very important with elastomer couplings is the plastic or that elastomer, which need to be constantly improved so that they become more efficient.