Medical technology Grippers for the mega trend

- Details

- Hits: 7646

It's a megatrend that the Medical Technology due to the growing world population will also grow strongly in the next few years. In order to be able to meet the demand, it must be massively automated. Gimatic offers mechatronic grab and a lot of know-how within the Barnes Group. TG Ritter completes the Medtec Pharma competence.

Contents

Medical technology is changing: in the third world only a few people are cared for today. In the second world, only about half the population has access to medical care and medicines. In contrast, medical technology for the first world is constantly being improved. Especially the production of Individual medication is steadily increasing here.

Gripper know-how for medical technology

Gripper know-how for medical technology

Medical technology systems are available in more variants, batch sizes are becoming smaller and innovation cycles are becoming shorter. The established Track Order in the manufacture of pharmaceuticals will soon move into the production of medical components. As a leading manufacturer, Gimatic offers customer-specific Gripper solutions a concentrated competence. Medical technology 4.0 can come.

Medical technology expertise of the Barnes Group

The Gimatic Group is a member of the American Barnes Inc. and has access to a network with other companies in the group. Barnes, for example, also includes Otto Männer GmbH in Balingen am Kaiserstuhl, a specialist in precision molds and valve gate hot runner systems.

These come for high quality Plastic parts from the injection molding process. Otto Männer supplies major manufacturers in the medical technology and pharmaceutical industries.

These vacuum grippers handle everything

These vacuum grippers handle everything

Gimatic and Otto men work on a number of joint projects from Malta to Taiwan to China. The network within the Barnes Group extends across the flow of information from tool creation to the gripper interface - quickly and directly.

TG Ritter special knowledge

The Gimatic managing director Johannes Lörcher is also the owner of TG Ritter Spezialmaschinen GmbH. The specialist has advised and brokered very complex production systems in the pharmaceutical industry since 1958. The pharmaceutical engineer trains the employees at Gimatic in matters of rules and regulations. They find out what makes the industry's customers tick.

The Gimatic managing director Johannes Lörcher is also the owner of TG Ritter Spezialmaschinen GmbH. The specialist has advised and brokered very complex production systems in the pharmaceutical industry since 1958. The pharmaceutical engineer trains the employees at Gimatic in matters of rules and regulations. They find out what makes the industry's customers tick.

The Italian Gimatic group has developed from a component supplier to a system supplier in recent years. The German Gimatic Vertrieb GmbH in Hechingen has extensive expertise within the group in system construction for gripper systems for the increasing Automation built in Industry 4.0.

In Hechingen, solutions for the automated removal of injection molded parts are created molds. The high level of vertical integration ensures the pneumatic and mechatronic components installed there, Sensors, sensor boxes through to I/O link interfaces from a single source.

NFC RFID technology is available for monitoring and saving the gripper data such as drawings and parts lists. Production data can be called up globally via your own or the customer's cloud.

From the standard gripper to the individual indication

Gimatic delivers for the Laboratory automation customer-specific components in larger quantities. Series products that are tailored to the application serve as the basis for such projects. This applies, for example, to technical changes to the function or adjustments to interfaces, color, labeling, etc.

Gimatic also offers a very wide range of grippers and mechatronics for handling and removing plastic parts from injection molding machines. From the standard gripper to the customer-specific gripper to the development partnership, everything is possible at Gimatic.

DC motor and other drives for medical technology

DC motor and other drives for medical technology

Robotics illustrates this flexibilityapplication from Japan. A GMP gripper is used for the production of individual medicine for cancer treatment. The robot selects the specific indication for the patient from a range of pharmaceuticals. Then it is cleaned and the next indication is put together. The video shows the implementation in a Denso robot.

Gripper for plastic components with multiple cavities

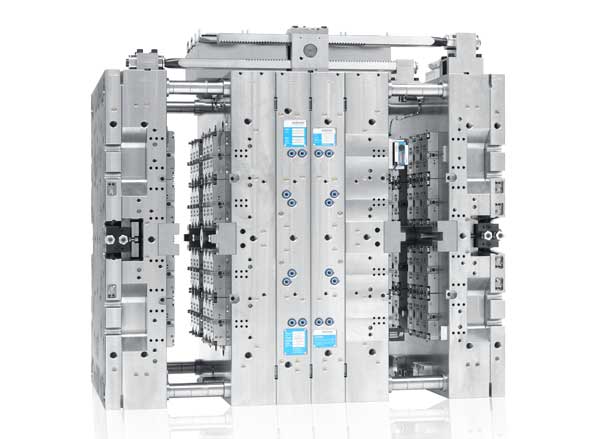

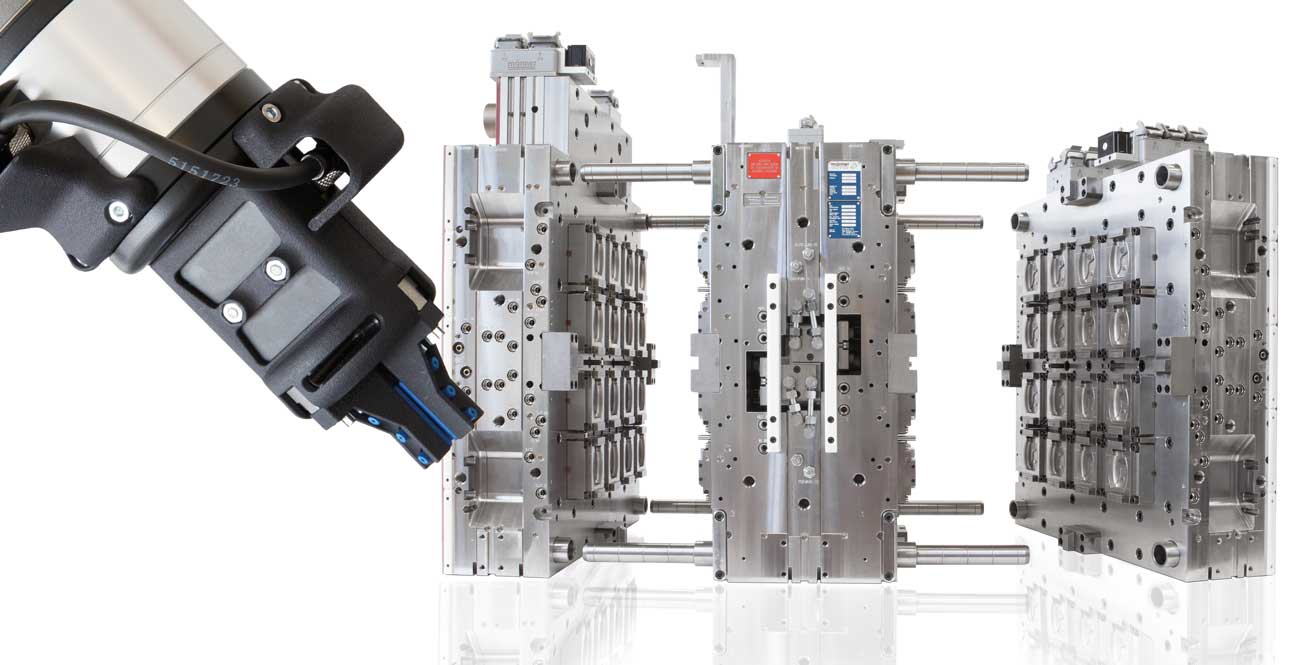

Together with Otto Männer, Gimatic implements another demanding application: grippers for removing plastic parts from injection molds that are Multiple cavities feature. You take z. B. Inhalers, Home Car, Drug Delivery Solutions, Hospital Products or Pipette Racks.

Together with Otto Männer, Gimatic implements another demanding application: grippers for removing plastic parts from injection molds that are Multiple cavities feature. You take z. B. Inhalers, Home Car, Drug Delivery Solutions, Hospital Products or Pipette Racks.

The high cavity of the molds is the challenge here. Such shapes add to the weight of the gripper. Because often only for these applications little robots are used with a low payload, attention must be paid to lightweight construction.

Molds with high cavities have a large installation space. Therefore the position of the components must be based on the Distances between the nests can be optimized in the various thermal states. A close exchange with the manufacturer of the mold is essential here. The interfaces and interfering contours between robot gripper and injection mold are considered together from the start of development.

The range for such grippers includes small 2-fold or 2 + 2 shapes up to very large designs. A project is currently underway with 94 cavities in dimensions of 1000 x 1000 mm.

There are also applications in which 16, 32 or even more components have to be removed at once. Each molded part has a sensors queried individually and tracked from the time of collection. The pressure sensors and Controllers come from Priamus, a sister company. The sensors detect and select bad parts directly in the tool. The information is passed on to the gripper, which can sort out the bad parts.

The status of the components is often accompanied by the new one 3 point sensor Pross from Gimatic used. It can be used to query three gripper positions. This increases the query options with the same weight and installation space.

Interview with Johannes Lörcher

How tall is he Share of medical technology - pharmaceutical industry on the overall business at Gimatic?

How tall is he Share of medical technology - pharmaceutical industry on the overall business at Gimatic?

The MED-Pharma business is still small, the trend is growing and now very noticeable.

How do you appreciate them Effects of the corona crisis on the MED / Pharma industry in general and how do these affect Gimatic?

We are happy that the corona pandemic is having a positive effect on our business in this industry. That somewhat compensates for the order situation in the machine tool sector. Here, however, the downturn is affecting us much less than other suppliers, some of whom are in free fall.

You are managing director at Gimatic and owner of TG knight Spezialmaschinen GmbH? How do you manage this balancing act of managing two companies?

It works very well. The TGR is a small agency that receives a commission for its services. The employees are specialists with a very high level and work very independently. We coordinate regularly. I also keep in regular contact with major customers and partners. Over the years I have acquired a good, solid, medical-technical half-knowledge about regulations, GMP, etc., which in turn benefits me at Gimatic.

And there is also a business one Intersection between Gimatic and Ritter?

Indeed there are. For example, one of our partner companies is Brevetti CEA based in Vicenza / Italy. The specialist in visual inspection is now a Gimatic top customer - incidentally with a customer-specific special product.

gripper | pneumatic + electric from various manufacturers

gripper | pneumatic + electric from various manufacturers

You might also be interested in...

Robot Gripper | Automated little hands

These vacuum grippers handle everything

Gimatic | The smart gripper specialist

vacuum pump | Innovations for Industry 4.0 + branch-specific

Robot grippers and EOAT solutions

gripper | pneumatic, electrical, magnetic

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.