These vacuum grippers handle everything

- Details

- Hits: 2655

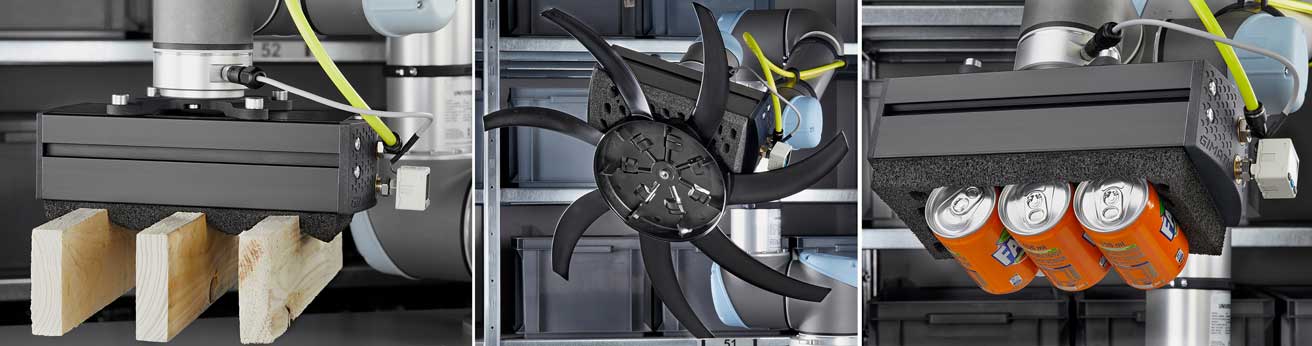

The new Vacuum gripper Series FGS-120 from Gimatic is modular, very flexible and energy efficient. With the modular vacuum grippers, differently shaped components in various sizes and different porosities can be handled very easily. A integrated vacuum generator provides the vacuum and makes the grab suitable for use in various industries. In packaging technology or intralogistics, the vacuum cups or vacuum plates reliably grip sheet metal, Plastic, Glass, wood, cardboard or cans.

Contents

Modular vacuum grippers for handling

Vacuum grippers are widely used in industry for the effective handling of products of all kinds modular vacuum grippers the necessary flexibility for different production requirements. They enable quick and precise gripping of workpieces and thus contribute to higher productivity. A wide selection of gripping systems and accessories enables individual adaptation to specific production processes.

Energy efficient vacuum ejectors

Oct 09.10.2023, XNUMX | Gimatic wants to be on the Fakuma 2023 draw particular attention to its extremely light and efficient multi-stage ejectors. They work according to that Venturi principle and can be used very flexibly. They are available in sizes small, medium and large.

Oct 09.10.2023, XNUMX | Gimatic wants to be on the Fakuma 2023 draw particular attention to its extremely light and efficient multi-stage ejectors. They work according to that Venturi principle and can be used very flexibly. They are available in sizes small, medium and large.

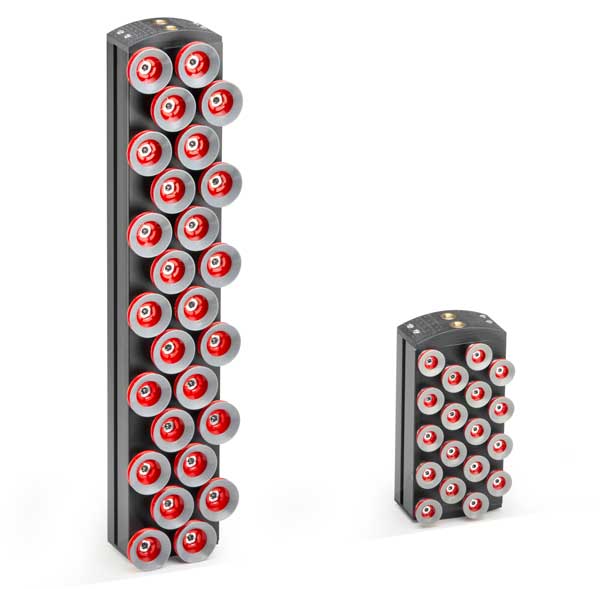

Around 150 different ones cartridges and vacuum pumps are available in eight product families. The ejectors are integrated into vacuum pumps made of POM or aluminum. They feature a retaining cap and silencer for custom installation. The range of vacuum ejectors also includes solutions with additional functions such as automatic blow-off in each cycle.

The ejectors are very efficient, compact and can be installed in the machine exactly where the vacuum is needed. Integrated in a gripper, the user benefits from high performance with low energy consumption.

Gripper with integrated vacuum generator

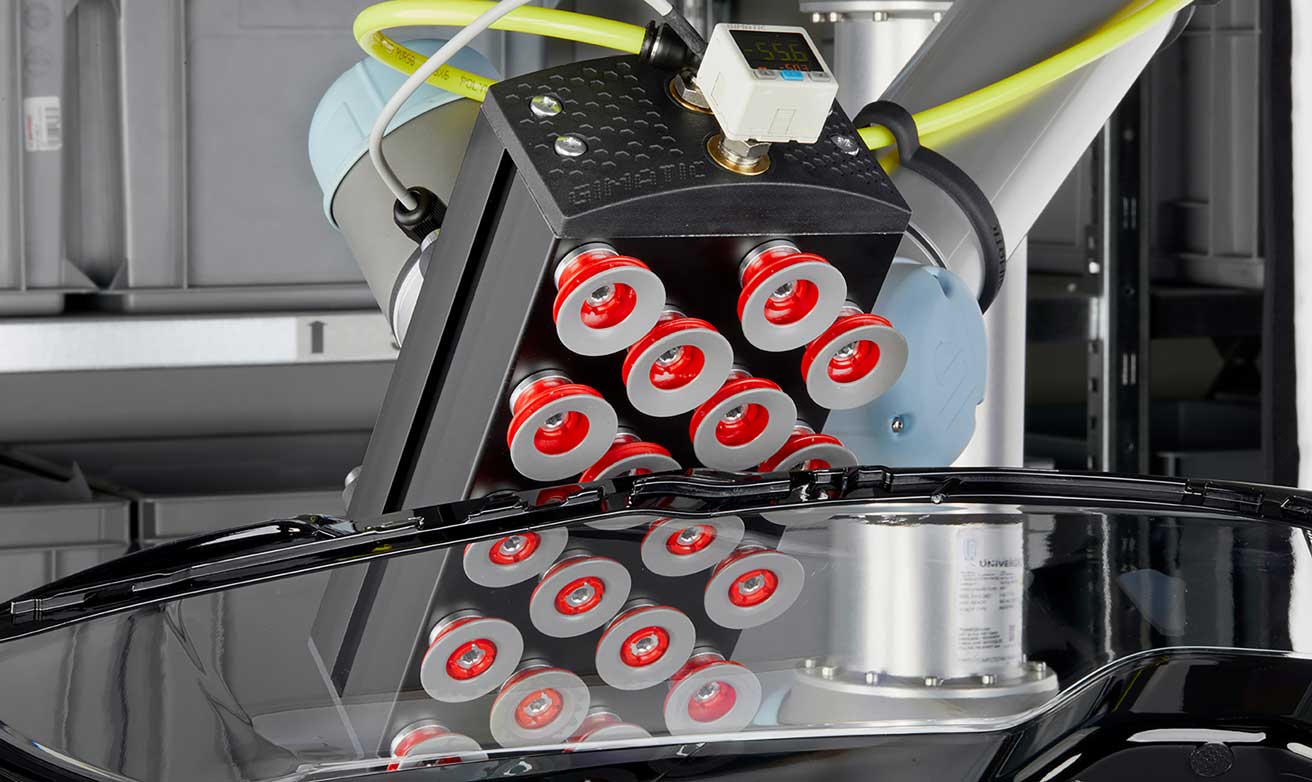

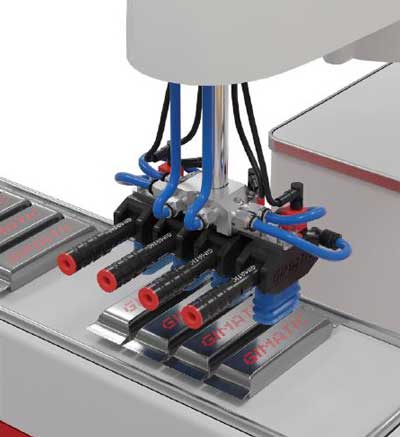

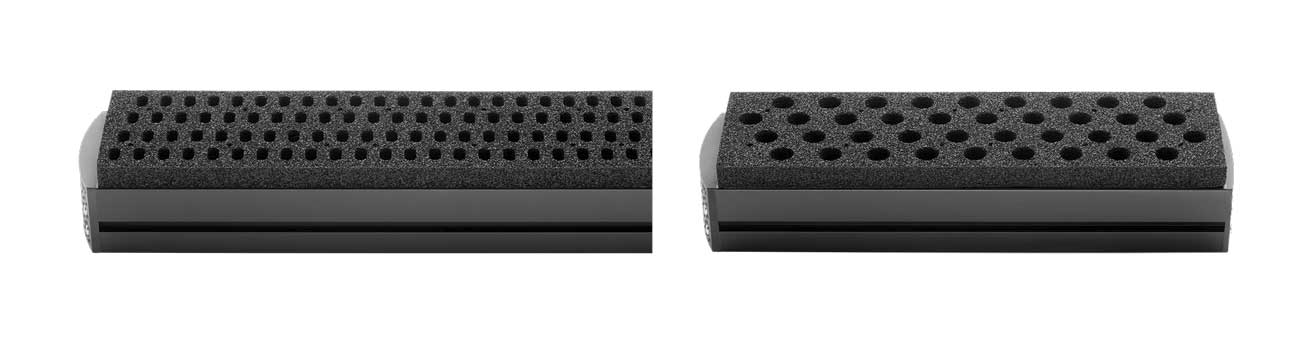

April 12.04.2023, XNUMX | Gimatic presents at the Interpack 2023 the new vacuum gripper series FSG-120. With an integrated vacuum generator, these are available in two versions: with self-closing valves or with calibrated bores in different grids. The standard products are 120 mm wide with lengths of 200, 400, 600, 800, 1000 and 1200 mm.

In addition, the vacuum grippers can also be adapted to specific applications in customer-specific versions. Take over the vacuum generation multi-stage ejectors of type EJ-LARGE-HF-3. These vacuum generators offer high suction power with low energy consumption. The design of the vacuum gripper does not have any moving mechanical parts and no heat is generated. Workpieces are gripped with foam or with polyurethane suction cups.

In addition, the vacuum grippers can also be adapted to specific applications in customer-specific versions. Take over the vacuum generation multi-stage ejectors of type EJ-LARGE-HF-3. These vacuum generators offer high suction power with low energy consumption. The design of the vacuum gripper does not have any moving mechanical parts and no heat is generated. Workpieces are gripped with foam or with polyurethane suction cups.

Foam grippers or suction pads

The 20 mm thick foam of the vacuum gripper is made of EPDM. It can be used in temperatures from -40° to 135 °C. The foam is easy to assemble and remove again. Leave behind when removing the foam no Residues on the extruded plastic part of the vacuum gripper. The different sizes of the foam offer a theoretical gripping force of 175 N to 2590 N payload on a flat surface and when the gripping surface is completely occupied by the gripped workpiece or object.

The suction cups of the vacuum grippers made of polyurethane (PU) materials are available with a diameter of 35 mm or 55 mm. The suction cups can be used in a temperature range from +10° to +45 °C. Polyurethane suction cups offer particularly high wear resistance. In addition, the suction cups adapt very well to uneven and porous surfaces. The different sizes offer a theoretical gripping force of 380 N to 2000 N payload on a flat surface with the gripping surface completely covered by the gripped object.

Vacuum gripper with two functional principles

There are two functional principles: vacuum grippers with calibrated bores and vacuum grippers with self-closing valves: The vacuum grippers with self-closing valves demonstrate their advantages in applications and formats where a high vacuum level must be maintained, even if the entire gripping surface cannot be used. These vacuum grippers are more flexible, faster, less sensitive to dust and more efficient because smaller pumps can be used. In the vacuum channel of this version there is a chamber with a metal ball. If no object to be recorded is found, the ball moves and hermetically seals the channel.

gripper | pneumatic + electric from various manufacturers

gripper | pneumatic + electric from various manufacturers

The execution with calibrated holes is predestined when no self-closing valves can be used (e.g. for vertical handling) or when the gripping system takes up around 90% of the gripping surface. Ambient temperatures of up to 180 °C are also possible with these grippers. They also score with their low weight. Here the vacuum channel has a constriction in the form of a calibrated micro bore. If no object to be recorded is found, a so-called known leak occurs in the vacuum chamber.

Gimatic exhibits at Interpack 2023.

Frequently asked question

How does a vacuum gripper work?

A vacuum gripper is a tool that uses vacuum technology to grip and hold objects. The gripper is connected to a vacuum pump that creates a vacuum under the gripper. Due to the negative pressure, the gripper sucks the surface of the object to be gripped. Once the vacuum is stable, the gripper can pick up the load and hold it in place until released. Vacuum grippers have the advantage of securely gripping delicate or irregularly shaped objects without damaging or deforming them. They work very precisely, which makes them ideal for use in the automotive or electronics industry.

You might also be interested in...

Robot Gripper | Automated little hands

Medical technology Grippers for the mega trend

Gimatic | The smart gripper specialist

Robot grippers and EOAT solutions

gripper | pneumatic, electrical, magnetic

Gripper: mechatronic, servo-controlled, IO-Link

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.