Vacuum technology specialist Leybold celebrates its 170th anniversary

- Details

- Hits: 8074

Traditional companies are only sustainable if they are innovative. The specialist for Vauum technology Leybold this combination of tradition and innovation has been impressively successful over the course of its company history. Today the company is proud of its 170. Birthday to celebrate a very special milestone in 2020.

Content of the company portrait:

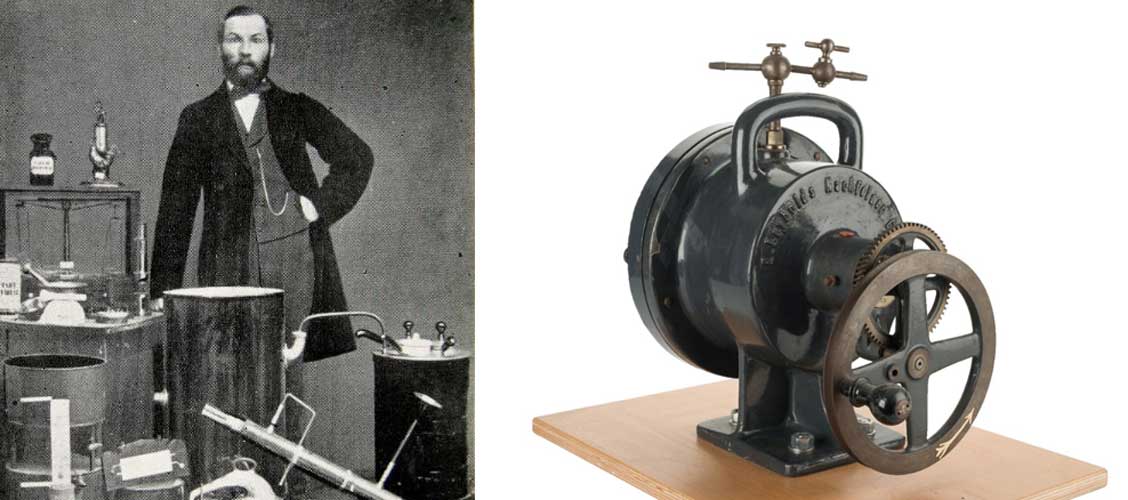

The merchant laid the foundation for success Ernest Leybold when he moved from Rothenburg ob der Tauber to Cologne in 1850 and founded his first company - initially as a commission and shipping business for medicine jars, ointment pots, thermometers and scales. In 1854 he expanded his range to include physical, pharmaceutical and chemical apparatus. In 1870, Leybold finally sold his business, which continued to operate under the name E. Leybold's Successor.

Triumphant advance of vacuum technology

The triumphant advance of Vacuum technology started working with in 1906 dr Wolfgang Gaede, Professor of physics in Karlsruhe. Gaede's work ethic was characterized by efficiency: "If I pursue an idea out of scientific interest, an invention always springs out".

The triumphant advance of Vacuum technology started working with in 1906 dr Wolfgang Gaede, Professor of physics in Karlsruhe. Gaede's work ethic was characterized by efficiency: "If I pursue an idea out of scientific interest, an invention always springs out".

The cooperation between Leybold and Gaede was correspondingly fruitful: Among other things, it produced innovations that are still very important today, such as the invention of the molecular air pump, the basic principle of the turbomolecular pump (1911) and the use of the diffusion pump (1913 ). The sturdy ones vacuum pumps are still used in applications today. But Gaede's gas ballast device, patented in 1935, for efficiently pumping out vapors can still be found in many applications today.

Introduction of vacuum coating technology

The use of vacuum metallurgy started in 1913. At this time, the head of the physical test laboratory at WC Heraeus GmbH, dr William Rohn, a process in Hanau for melting high-purity metals under vacuum. Interrupted by the First World War, the "process for vacuum melting and tempering metals and alloys" was only patented after the war, in 1918. It succeeded in 1931 Wilhelm Carl Heraeus Steaming metals onto glass - another milestone in vacuum coating technology.

Industrial use of vacuum

In the same year joined E. Leybold's successor dr Manfred Dark a managing director who successfully managed the company for a long time (until 1967). The era was formative, also because vacuum technology was increasingly used industrially during this period. Accordingly, in addition to scientific and technical knowledge, management skills were required to bring the knowledge into process engineering applications.

In the same year joined E. Leybold's successor dr Manfred Dark a managing director who successfully managed the company for a long time (until 1967). The era was formative, also because vacuum technology was increasingly used industrially during this period. Accordingly, in addition to scientific and technical knowledge, management skills were required to bring the knowledge into process engineering applications.

They already secured themselves in 1948 and 1955 Metallgesellschaft AG as well as the Degussa AG Investments in E. Leybold's successor. This resulted in synergies that ensured success on the world markets and led to the merger of E. Leybold's successor and Heraeus Hochvakuum GmbH in 1967. The result was a well-mixed portfolio of vacuum technology and vacuum process technology. Further growth was flanked by product developments such as liquid helium cryopumps (1962) and helium leak detectors. In 1963, Leybold also presented ion atomizing pumps for the first time.

Strong growth and economic turmoil

The 1980s were characterized by strong growth and Leybold already had around 1987 5600 employeeswho generated sales of over a billion deutschmarks. In the same year, fundamental restructuring took place in the ownership structure: the metal company left as a partner and WC Heraeus also separated from the shares. Degussa was now the sole shareholder.

As a Leybold AG the headquarters was relocated to Hanau. Vacuum technology settled in Cologne, science and technology teaching aids in Hürth and vacuum process engineering in Hanau. With the opening of the fall of the Berlin Wall in 1989 and economic upheavals in the western industrialized countries, the new Leybold AG experienced great economic turbulence. As a result, Degussa sold its shares to the Oerlikon-Bührle Group (Switzerland) in 1994. Leybold was merged with Balzers AG in 1995 to form the Balzers and Leybold Group.

Focus on semiconductor technologies

1997 founded the Leybold GmbH a wholly-owned subsidiary in China to benefit from the high potential of the emerging economic region and customer proximity from 1998 onwards. In 2000, the Oerlikon-Bührle Group was renamed Unaxis, accompanied by far-reaching restructurings by focusing on semiconductor-related technologies.

Energy-efficient vacuum pump, suction cups, sensors & Co.

Energy-efficient vacuum pump, suction cups, sensors & Co.

This required innovations in manufacturing technology. With the opening of the new Cologne production building for high vacuum technology in 2004, Leybold met the increased requirements in research and development. Supported by economic growth, the Unaxis Group was renamed Oerlikon in 2006. Leybold operated as Oerlikon Leybold Vacuum until it was sold to Atlas Copco.

Acquisition by and synergies with Atlas Copco

The Swedish company took over in 2016 Atlas Copco AB Leybold to 100%. The multi-brand group with customers in more than 180 countries has around 37.000 employees. Leybold is now part of Atlas Copco's Vacuum Technique division. Atlas Copco relies on the traditional brand strength of Leybold and on the addition of technological know-how.

The spherical roller bearing - the birthday movie

The spherical roller bearing - the birthday movie

For 170 years, the vacuum pioneer based in Cologne has been developing and delivering international vacuum pumps, systems, standardized and customized vacuum solutions as well as services for many different industries. As a provider of vacuum technology, Leybold is today a leader in many industrial applications such as metallurgy and industrial coating technology.

Complemented by applications in analysis technology, display manufacturing as well as research and development, vacuum is one of the leading providers worldwide. The synergetic performance of Atlas Copco and Leybold in the areas of dry industrial vacuum pumps and high vacuum pumps for science and research has created a technological platform for the development of sustainable high-performance products for the coming generations.