Champion linear motor and ready-to-install linear unit

- Details

- Hits: 6981

Schaeffler sets new standards in things Linear unit and Linear motor. While the linear drives offer high percentage performance improvements, customer-specific linear modules increase the range. Find out what advantages you can get with the innovative linear actuatoren can generate in practice.

Contents

- Linear motor with top values for dynamics and energy efficiency

- Ready-to-install linear unit increases the range of the cobot

Linear motor with top values for dynamics and energy efficiency

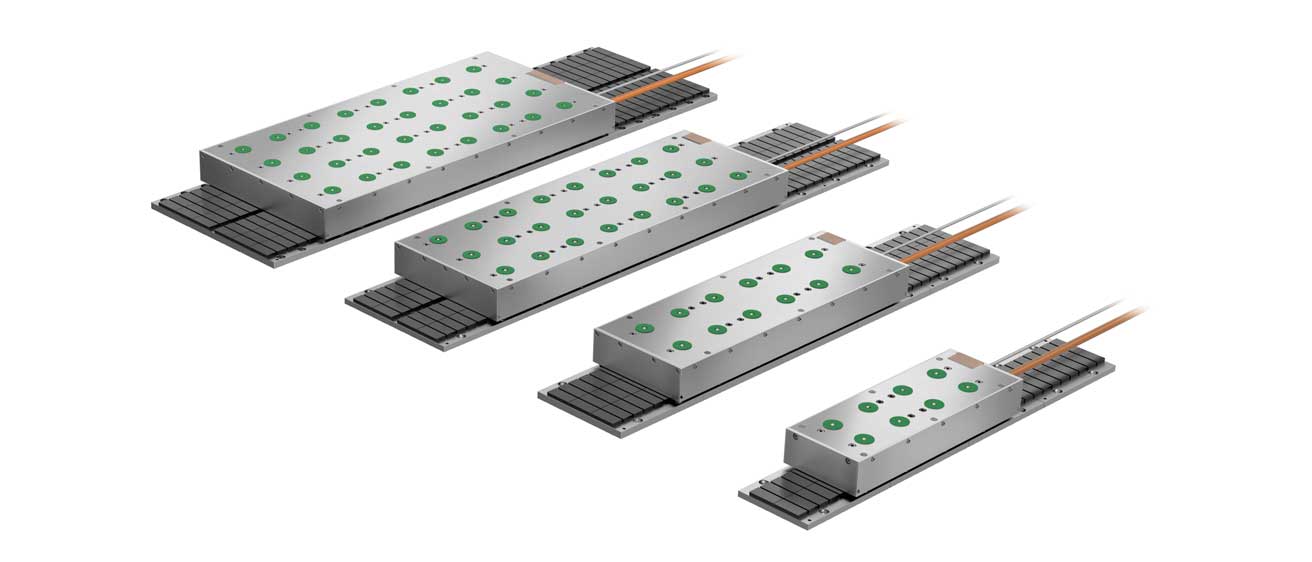

Oct 10.10.2023, XNUMX | Up to 50% lower power loss and up to 40% More nominal power: This is what the new L7 linear motors (pictured above) from Schaeffler bring to the user. Coupled with particularly low operating costs, significantly shorter processing cycles can be achieved. Higher machine accuracy is achieved due to the lower heating of the motor and machine frame also given.

Schaeffler has been delivering for many years water-cooled Iron linear motors of the L1 series with peak forces of up to 5171 N. With the new L7 series, Schaeffler is expanding its range of linear motors with peak forces of up to 24.300 N. Linear direct drives can therefore be used to a much greater extent in the main axes of machine tools and in handling systems .

L7 as a benchmark for efficiency and power density

The development engineers are concerned with optimizations copper windings, heat transfers and the cooling circuit, compared to the current benchmark, we managed to achieve up to 50% lower power loss with the same driving power or up to 40% more nominal power with the same power loss.

While motors with optimized peak power and power loss are offered on the market, the Linear motor L7 both strengths. It also offers excellent acceleration capabilities and even stays significantly cooler. This allows operating costs to be drastically reduced and productivity to be significantly increased.

Measuring torque with sensors inside the transmission

Measuring torque with sensors inside the transmission

For permanently oscillating movements that require the highest accelerations and Motor Long-term heating, the L7 motor shows its strengths: The high power reserve enables the workpiece to have a high degree of shape accuracy and the high acceleration capacity reduces cycle times. Thanks to very low power loss, little heat is released Machine bed initiated. This has a positive effect on the overall accuracy of the machine.

The right motor configuration for every task

The L7 linear motor family includes twelve motor sizes in four widths for the secondary section of 100, 150, 200 and 300 mm and in three lengths 350, 500 and 650 mm.

Alternatively, the high power reserve can be used downsizing to use. Because the moving mass is then reduced, this has a positive effect on the dynamic behavior. The dimensions of the motors allow existing axis designs to be easily converted into milling, turning and grinding machines as well as in laser processing.

Ready-to-install linear unit increases the range of the cobot

July 19.07.2020, XNUMX | For the multiple expansion of the area of application in the Robotic Schaeffler has a powered one Linear unit in program. Users can install the driven linear module tailored to their design as a horizontal axis and thus increase the reach.

The motor-driven linear axes from Schaeffler are available as individual complete solution available. With a compact structure, it consists of the following components:

- Tandem module Mdkuve

- Adapter plate for the Cobot

- Motor gear unit

- assembled motor cables

- Drag chain for cobot supply lines

- Motor controller.

Connection of the linear unit

The linear unit contains the customer-specific connection to its control Profibus, Profinet or Ethercat Interfaces. The linear axis has variable connection options for the motor Transmission Unit. Optionally his Drive Technology of the customer.

The linear units are available in different lengths Ball Screw Mdkuve-KGT, toothed belt drive Mdkuve-3ZR or optionally with a Linear motor as a drive element.

Linear axis adapted to the load capacity and moment load

In the Tandem module As the basis of the linear axis, the guide carriage is guided on two parallel profile rails Type curve as a four-row recirculating ball unit. The compact design of the linear guide enables applications under high load and moment loads, as is the case with collaborative robotics. By means of a triple Timing beltsdrive, the tandem modules offer the best possible reliability.

In the Tandem module As the basis of the linear axis, the guide carriage is guided on two parallel profile rails Type curve as a four-row recirculating ball unit. The compact design of the linear guide enables applications under high load and moment loads, as is the case with collaborative robotics. By means of a triple Timing beltsdrive, the tandem modules offer the best possible reliability.

A guide carriage with the six-row recirculating ball unit is suitable for applications with even higher requirements in terms of load capacity and moment load Kuse ..- XL in X-life quality as a guide system for the linear axes.

The linear unit is available in sizes of different lengths up to multi-part axes for longer distances. The compact linear axis can be easily converted into a new or existing one Automation integrable. Incidentally, Schaeffler offers assembly and installation services for this.

Technical characteristics of the linear axis

Tandem modules with Ball screw spindle drive are available up to a maximum length of 5,9 m. The repeat accuracy is 0,025 mm and the maximum speed 1,7 m / s. With the Belt drive Up to 18 m long, multi-part linear units can be implemented. This enables speeds of up to 5 m / s with a precision with repeat accuracy of ± 0,1 mm.

Interview: Digital Schaeffler service for rolling bearings

Interview: Digital Schaeffler service for rolling bearings

In addition to use in collaborative robots, the linear units are also suitable for use in the periphery of Handling, assembly and factory Automation.

You might also be interested in...

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

spindle bearing | The Vacrodur high-performance elements

linear guide | Precise, light, durable