Thermal Imaging Camera | Innovations for industrial applications

- Details

- Hits: 9366

Thermal Imaging Cameras are used for non-contact temperature measurement in research & development and in production. the infrared cameras have to meet a wide range of requirements from use in the high four-digit temperature range to the highest resolutions for microthermography through to Communicationcapability for Industry 4.0 applications. We present them here New developments before:

Contents

- Infrared camera with incredible 8 µm optics

- IR camera optimizes 3D printing processes from Fraunhofer ILT

- Remote online access to thermal imager data

- New apps for thermal imager and pyrometer

- Infrared camera in a protective housing for hot and cold outdoor areas

- Thermal imaging camera for quality assurance in glass production

- Bottom up IR camera inspection system for glass tempering

- Digital camera integrated in thermal imaging camera

- Thermal imaging camera with spot finder for series applications

- Thermal imaging camera with auto hot spot finder

- Archive for thermal imaging camera news

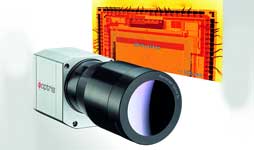

Infrared camera with incredible 8 µm optics

03.02.2024/640/XNUMX | The structures of electronic assemblies are becoming ever smaller and are very compact. So that the infrared camera PI XNUMXi from Optris The new one measures temperatures precisely and geometrically, even in chip-level structures Microscope optics MO2X equipped with 2x magnification.

03.02.2024/640/XNUMX | The structures of electronic assemblies are becoming ever smaller and are very compact. So that the infrared camera PI XNUMXi from Optris The new one measures temperatures precisely and geometrically, even in chip-level structures Microscope optics MO2X equipped with 2x magnification.

IR camera optimizes 3D printing processes from Fraunhofer ILT

04.12.2023/XNUMX/XNUMX | Of the 3D Print of metals is becoming increasingly popular. In particular, powder bed-based laser beam melting or Laser powder bed fusion (LPBF) allows delicate and very complex structures and always opens up new applications. The quality of the process depends heavily on the right temperatures. To measure this, the scientists use Fraunhofer ILT an infrared camera from Optris.

04.12.2023/XNUMX/XNUMX | Of the 3D Print of metals is becoming increasingly popular. In particular, powder bed-based laser beam melting or Laser powder bed fusion (LPBF) allows delicate and very complex structures and always opens up new applications. The quality of the process depends heavily on the right temperatures. To measure this, the scientists use Fraunhofer ILT an infrared camera from Optris.

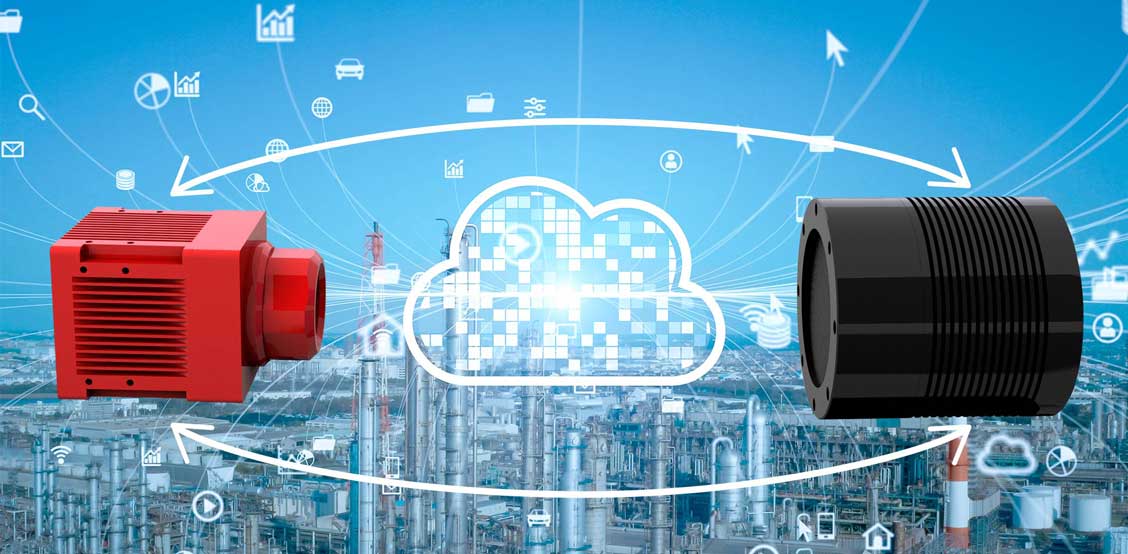

Remote online access to thermal imager data

22.02.2023/XNUMX/XNUMX | The increasing level of automation in industrial process technology also requires offers that process data and measurement results are available in the network. This is the only way processes can be monitored remotely. Dias Infrared has therefore created possibilities for remote data transmission with two software applications:

22.02.2023/XNUMX/XNUMX | The increasing level of automation in industrial process technology also requires offers that process data and measurement results are available in the network. This is the only way processes can be monitored remotely. Dias Infrared has therefore created possibilities for remote data transmission with two software applications:

The Pyrosoft Professional IO and Pyrosoft Automation SC/MC allow the remote transmission of measurement data, analysis and test results from the Pyroview thermal imaging cameras. In the Windows desktop app Pyrosoft Client Camera images, system and alarm status are provided. Even several processes from different systems can be clearly bundled.

The Pyrosoft Client app is available is free in the Apple App Store and on Google Play. It offers the same functionality as the Windows app of the same name. An individually configurable RTSP stream transmits individual images and the complete program interface with all relevant process information as a video stream in H.264 format. The transmission of the thermal imaging camera data is also via a I/O system possible. Here, Pyrosoft supports the connection via Profinet, Profibus, Modbus or TCP sockets.

New apps for pyrometer and thermal imager

09.11.2022 | Dr. Ulrich Kienitz, Managing Director of Optris GmbH, Berlin, invites you to visit the App Store at SPS 2022. There is demo software and many new products such as thermal imaging cameras and pyrometers.

09.11.2022 | Dr. Ulrich Kienitz, Managing Director of Optris GmbH, Berlin, invites you to visit the App Store at SPS 2022. There is demo software and many new products such as thermal imaging cameras and pyrometers.

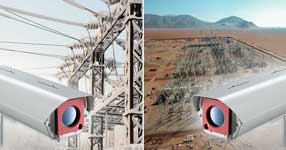

Infrared camera in a protective housing for hot and cold outdoor areas

14.10.2022/XNUMX/XNUMX | the Infrared camera under adverse environmental conditions is now possible in the new Outdoor protective housing from Optris. Very low or high temperatures, dust and humidity place high demands on the Electronics. Special measures are therefore often required to protect sensitive devices. This also applies to the infrared cameras of the PI and Xi series from Optris.

14.10.2022/XNUMX/XNUMX | the Infrared camera under adverse environmental conditions is now possible in the new Outdoor protective housing from Optris. Very low or high temperatures, dust and humidity place high demands on the Electronics. Special measures are therefore often required to protect sensitive devices. This also applies to the infrared cameras of the PI and Xi series from Optris.

Thermal imaging camera for quality assurance in glass production

28.08.2022 | Fluke has various solutions for temperature monitoring in glass manufacturing, forming and coating. Infrared thermometers and thermal imaging systems measure and analyze the temperature without contact. Comprehensive interfaces are available for recording and sending results in real time to the system control system. This helps the operator increase productivity and reduce operating costs.

28.08.2022 | Fluke has various solutions for temperature monitoring in glass manufacturing, forming and coating. Infrared thermometers and thermal imaging systems measure and analyze the temperature without contact. Comprehensive interfaces are available for recording and sending results in real time to the system control system. This helps the operator increase productivity and reduce operating costs.

Fluke MP-Series Infrared Line Scanners create live thermal images of moving processes, including the float glass manufacture or the tempering of flat glass. They check the temperature uniformity and detect damage, hot spots and cold spots. Datapaq data loggers are used to monitor the temperature progression in the oven.

They draw over those placed on the glass surface Thermocouples Temperature curves. A complete range of infrared pyrometers with suitable wavelengths helps in the production of ampoules, bottles, ultra-thin drawn glass for touchscreens and much more

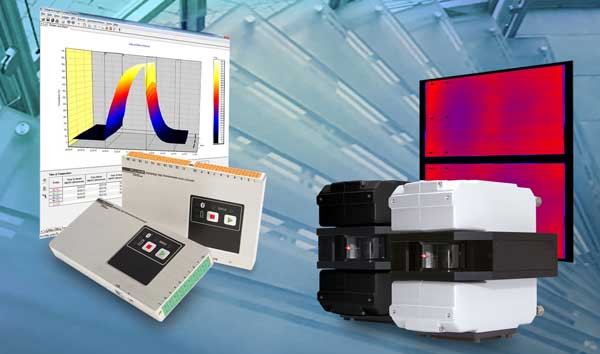

Bottom up IR camera inspection system for glass tempering

09.05.2022 | For the high energy efficiency in Buildings become default Low-E glass window and facade elements used. Designed as multi-pane insulating glass, the windows have a coated side with a very low emissivity. This is a major challenge for infrared measuring devices.

09.05.2022 | For the high energy efficiency in Buildings become default Low-E glass window and facade elements used. Designed as multi-pane insulating glass, the windows have a coated side with a very low emissivity. This is a major challenge for infrared measuring devices.

Digital camera integrated in thermal imaging camera

19.04.2022 | Seek Thermal The Shotpro model combines a high-precision thermal imaging camera with a digital camera, making it a versatile professional tool. The thermal imaging camera can be used day and night in buildings, industry or trade. The high thermal resolution of 320 x 240 pixels ensures precise thermal images.

19.04.2022 | Seek Thermal The Shotpro model combines a high-precision thermal imaging camera with a digital camera, making it a versatile professional tool. The thermal imaging camera can be used day and night in buildings, industry or trade. The high thermal resolution of 320 x 240 pixels ensures precise thermal images.

Leaks, poor insulation or defects in components are on the 3,5-inch color touch screen good to see. The digital camera with 640 x 480 pixels is housed in the robust and compact housing. Videos and photos can thus be compared with the thermal images on site. With the Seek Vista Mobile App, a live heat image view can be streamed to mobile devices via Wifi.

With the new thermal imaging camera can be seen for the human eye vulnerabilities and defects, that are not visible can be easily detected. High levels of heat generated by electrical faults can be detected quickly and reliably by checking electrical switchboards, connections and fuses. With the precise Shotpro, users can check whether grilles, registers and diffusers in ventilation systems are optimally installed and sealed.

For the people invisible leaks on pipes are also visible. By scanning a large duct system, users can detect air leaks. The energy efficiency of buildings can also be improved, for example by diagnosing inefficient ventilation. The practical thermal imaging camera also detects inadequate insulation and thermal bridges. The temperature range extends from -40° to +350°C. Of course, it can also be displayed in Kelvin or Fahrenheit.

Infrared thermometer for Smartphones & tablet app

Infrared thermometer for Smartphones & tablet app

The user interface is simple. On the large touch screen you can data in real time to be analyzed. Various settings such as Span/Level, Hi/Low and Spot help with this. Operators can view up to three box analyzes from a smaller portion of the image. If colleagues are to be involved in the analysis, the data can be shared via live stream. The camera has a thread for attachment to a tripod and is protected against splash water and dust according to protection class IP54. The long-life battery allows four hours of use. Power is supplied via USB-C.

Thermal imaging camera with spot finder for series applications

03.02.2022 | The thermal imaging camera Thermoimager TIM41 from Micro-Epsilon was developed for the high demands of industrial series applications. The IR camera precisely records temperatures from -20° to +900 °C. The thermal imaging camera is focused via an integrated motor focus. Hot and cold spots can be monitored automatically.

The robust thermal imaging camera offers high resolution for monitoring machines and systems. She can up to three measuring fields at the same time focus and continuously monitor. The thermal imaging camera can also be focused from a distance using the integrated motor focus. The measured values can be output to a controller. If the limit value is exceeded, further steps such as opening the door, alarming, cooling or switching off can be carried out.

Commissioning is easy using the included TIM Connect software possible. Measured values are output via Ethernet or process interface (4 to 20 mA). No additional PC is required for operation in autonomous mode.

Thermal imaging camera with auto hot spot finder

31.05.2021/410/XNUMX | The thermal imaging cameras of the Xi XNUMX series from Optris have a Fast Ethernet interface. The infrared cameras can be conveniently powered via PoE. This enables uncomplicated installation of the thermal imaging cameras, even over greater distances from the PC. The auto hotspot finder function integrated into the infrared cameras reliably measures the temperature of moving objects.

Archive for thermal imaging camera news

- Infrared camera with ±0,3° measurement accuracy and IoT connection

- Versatile thermography system with high resolutions

- IR camera for laser processing below 1900 °C

- IR camera with cooling housing, air purge attachment and shutter

- IR camera with robust accessories for the glass industry

- Thermal imaging cameras for quality control in plastics production

- Thermal imager with resolution up to 640 480 pixels x

- IR camera for precise high-temperature measurement and visualization

Infrared camera with ±0,3° measurement accuracy and IoT connection

27.07.2020 | AT - Automation Technology has expanded its IRS product family with the smart temperature reference radiator AT Smart-Blackbody IRS Calilux. With this new development, the temperature measurement accuracy of an IR camera can be increased to the limits of what is technically feasible - and failsafe.

The reference source provides a non-contact temperature measurement high-precision temperature reference value available to correct temperature readings from the IR camera. The measurement accuracy of such thermal imaging cameras can thus be improved to an unprecedented accuracy class of ±0,3 degrees of measurement accuracy.

The subtle difference in the corona pandemic

In times of Corona-Pandemic has the measurement accuracy of thermal imagers when measuring body temperatures with the mobile Access control Febriscan made the decisive difference to the competition by AT. The reference value is independent of the ambient conditions. Even strongly changing temperatures or drafts do not affect the precision of the device.

The IRS Calilux also determines the current values for ambient temperature and humiditywhich are essential parameters for non-contact temperature measurement. The accuracy when determining object temperatures with a thermal imaging camera can thus be significantly improved.

Communication-enabled thermal imaging camera

The connection to infrared cameras or other components is bidirectional via Ethernet or WiFi. The high-precision reference values can be transmitted or all settings of the black body can be set and queried. For easy integration into systems, the temperature reference radiator has integrated IoT protocols such as fieldbus, Rest API and MQTT.

The connection to infrared cameras or other components is bidirectional via Ethernet or WiFi. The high-precision reference values can be transmitted or all settings of the black body can be set and queried. For easy integration into systems, the temperature reference radiator has integrated IoT protocols such as fieldbus, Rest API and MQTT.

With the smart infrared camera from the IRSX series from AT, for example, data is exchanged directly with the cameras. The dataeffective communication but can also be built with peripheral components for non-intelligent infrared cameras that are operated with a computer and evaluation software.

The temperature reference radiator, together with a thermal imaging camera, allows the reliable build-up of a suitable temperature Surveillance systems. The continuous temperature monitoring of production processes, the thermal monitoring of systems or early fire detection are examples of the use of the thermal imaging camera. The AT Smart Blackbody is the crucial component for the Fail-safe operation such surveillance systems.

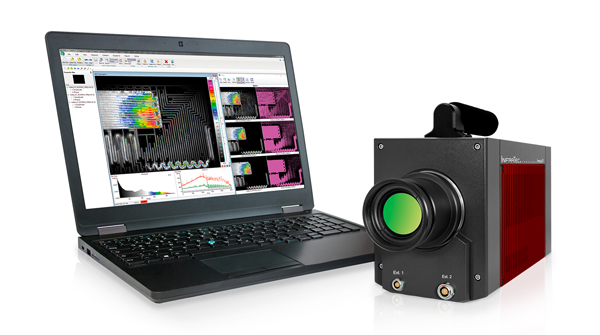

Versatile thermography system with high resolutions

10.02.2020 | infratec presents the thermal imaging camera "Image IR 9400". Trade Shows and checking various tasks. The high-end infrared thermography system is precisely tailored to the specific application. With the infrared camera, very different tasks can be solved at the highest level.

10.02.2020 | infratec presents the thermal imaging camera "Image IR 9400". Trade Shows and checking various tasks. The high-end infrared thermography system is precisely tailored to the specific application. With the infrared camera, very different tasks can be solved at the highest level.

The flexibility combines functions that are otherwise only found in several different types of high-end thermographic systems. The camera thus offers a unique combination of outstanding geometric, thermal and temporal resolution.

Cooled FPA photon detectors with the native format of 1280 × 1024 IR pixels, a pixel pitch of 10 µm and digital readout form the basis of the high thermal and geometric resolutions of the thermography system. Thanks to the optionally available optomechanical microscanThe image format can be increased to up to 2560 × 2048 IR pixels. Each of these 5,2 megapixels is equivalent to a temperature measuring point on the respective measuring object.

Special lenses of different focal lengths allow thermographic temperature measurements on macroscopic objects of various dimensions. Extremely small structures are revealed using high-quality microscope lenses. Microthermography with pixel sizes of up to 1,3 µm meet the requirements for thermal images resulting from miniaturization and increasing power density in Electronics and materialresearch result.

Seven good reasons for hydrogen drive from Bosch

Seven good reasons for hydrogen drive from Bosch

A high geometric resolution does not have to be in contradiction to a very good temporal resolution. With different Image IR 9400 types Thermography recordings with extremely high frame rates, which can reach up to 622 Hz in binning full screen mode and up to 3343 Hz in partial image If highly dynamic thermal processes and the moving object are examined, the thermal imaging cameras can be used to record sequences with individual snapshot images following each other less than 0.001 s apart.

Thermal resolution 20 mK

The integration times can be extremely short with just a few µs and ensure distortion-free imaging and reliable thermal analysis. Via an ultra-fast 10 GigE interface The loss-free transfer of the thermography data to the control and evaluation PC of the thermography system If necessary, the thermal image repetition rate with the maximum camera can take much longer than is usual with comparable thermography systems on the market. With the original “Irbis” family of thermography software from Infratec, images and sequences can be evaluated online and offline on the PC.

Suitable for very demanding tasks in the precise measurement of minimal temperature gradients, the Image IR 9400 thermal imaging camera offers a very good, through operation in the Binning full screen method additionally increased thermal resolution of 20 mK. Like every member of the Image IR series, the 9400 is modular. It has optics, detector and interface module. This means that the can be individually configured and adapted to highly demanding applications Research and industry oriented.

The robust design and high-quality material as well as the quality manufacturing of the thermal imaging camera enable high reliability, long service life and thus a high level of investment security when using infrared thermography to measure temperatures on objects in industry and science.

IR camera for laser processing below 1900 °C

19.11.2019 | When measuring the temperature in processes where lasers are used, the IR camera be insensitive to the scattered light of the laser. The new PI 08M from Optris is ideal for such applications because it has a very narrow-band spectral sensitivity at 800 nm. Typical applications are laser welding, laser soldering or laser hardening processes where temperatures play an important role.

19.11.2019 | When measuring the temperature in processes where lasers are used, the IR camera be insensitive to the scattered light of the laser. The new PI 08M from Optris is ideal for such applications because it has a very narrow-band spectral sensitivity at 800 nm. Typical applications are laser welding, laser soldering or laser hardening processes where temperatures play an important role.

IR camera with cooling housing, air purge attachment and shutter

08.04.2019 | The infrared cameras of the Compact Line Xi 80 and Xi 400 from Optris have been supplemented with new industrial accessories for use in extreme conditions. The system has a modular structure, so the water cooling housing, the Purging attachment and the shutter can be used individually or in combination. The shutter, made of stainless steel, basically serves to protect the optics from dirt and incident objects.

08.04.2019 | The infrared cameras of the Compact Line Xi 80 and Xi 400 from Optris have been supplemented with new industrial accessories for use in extreme conditions. The system has a modular structure, so the water cooling housing, the Purging attachment and the shutter can be used individually or in combination. The shutter, made of stainless steel, basically serves to protect the optics from dirt and incident objects.

IR camera with robust accessories for the glass industry

20.11.2018 | Optris launched two special infrared cameras for the glass industry in 2014 and 2016 with the PI 450 G7 and PI 640 G7. In order to meet the industry-specific requirements, a laminar air purge was developed in addition to the robust cooling jacket. The first well-known customers are using the system for 24/7 line scan applications. The overall system offers easy integration.

20.11.2018 | Optris launched two special infrared cameras for the glass industry in 2014 and 2016 with the PI 450 G7 and PI 640 G7. In order to meet the industry-specific requirements, a laminar air purge was developed in addition to the robust cooling jacket. The first well-known customers are using the system for 24/7 line scan applications. The overall system offers easy integration.

Thermal imaging cameras for quality control in plastics production

09.10.2018 | The 882 and 885 thermal imaging cameras from Text ensure precise situation analyzes and thus support process control and quality assurance on the plastic product. The thermal imaging cameras enable reliable thermographic recording, documentation and evaluation of the measurement objects.

09.10.2018 | The 882 and 885 thermal imaging cameras from Text ensure precise situation analyzes and thus support process control and quality assurance on the plastic product. The thermal imaging cameras enable reliable thermographic recording, documentation and evaluation of the measurement objects.

At a glance, in addition to foreign bodies in production processes Anomalies in heat distribution from Plasticcomponents are recognized quickly and without contact. The ongoing operation does not have to be interrupted for the measurement.

The two thermal imaging cameras are suitable for targeted Monitoring of the cooling process. Because injection-moulded parts cool down very irregularly, different material densities occur within the injection-moulded part. This leads to low stability and poor fitting accuracy. With the help of thermography, the cooling process can be easily monitored and documented. The high resolution of the easy-to-use cameras ensures top image quality.

Thermal imager with resolution up to 640 480 pixels x

25.01.2017 | Text launches four new thermal imaging cameras. The high resolution of up to 320 x 240 pixels guarantees the best image quality, which can even be increased to 640 x 480 pixels with the Super Resolution technology. The camera offers functions such as automatic setting of the emissivity, objective comparison of thermal images or smart thermography.

Thermography app the user's smartphone or tablet becomes the second display and remote control for the thermal imager. In addition, the new cameras can be wirelessly connected to the 605i thermo-hygrometer and the 770-3 current clamp. The measured values of the two measuring devices are transmitted to the cameras via Bluetooth. This way you can quickly and clearly see exactly where you are in a Buildings damp spots are located or with what load switch cabinet running.

Temperature scale and coloring of thermal images can be customized. It is therefore possible, for example, that the thermal insulation behavior of a building is misinterpreted. The newly developed function scale assist adjusts the color distribution of the scale to the inside and outside temperature of the measurement object and their difference. This ensures objectively comparable thermal images of the thermal insulation behavior of buildings.

IR camera for precise high-temperature measurement and visualization

22.07.2013/320/640 | The stationary infrared cameras "Pyroview XNUMXN compact+" and "Pyroview XNUMXN compact+" from Dias Infrared are specially designed for fast high-temperature measurements. Main areas of application are, for example, process control and monitoring as well as quality control in the metal, glass and cement industries.

22.07.2013/320/640 | The stationary infrared cameras "Pyroview XNUMXN compact+" and "Pyroview XNUMXN compact+" from Dias Infrared are specially designed for fast high-temperature measurements. Main areas of application are, for example, process control and monitoring as well as quality control in the metal, glass and cement industries.

The Pyroview 640N compact+ is able to record temperatures without contact in the range from 600 to 1500 °C (optionally up to 2.500 °C). In order to reduce the influence of the emissivity on the measurement accuracy at high temperatures of the measurement object, the camera works with a measurement spectrum in the near infrared range (NIR) of 0,8 to 1,1 µm.

The signal characteristics of the highly dynamic Si NIR Arrays is not linear like other infrared cameras, but logarithmic. This enables the wide, continuous measuring range with a high spatial resolution of 640 x 480 pixels and up to 25 frames per second. With the Pyroview 640N compact+, the process parameters can be specifically varied during operation in order to analyze and perfect the production process. Lenses with different opening angles are available as an option, so that the camera can be mounted at different distances from the measurement object.

The infrared camera series Pyroview 320N compact+ is equipped with an Ingaas array with 320 x 256 pixels and enables non-contact continuous temperature measurements from 300 to 1200 °C, optionally up to 2000 °C. The Pyroview 320N compact+ measures in the spectral range 1,4 to 1,6 µm, in which the emissivity influence on the temperature measurement accuracy of the results is also significantly lower than the usual 8 to 14 µm. The camera has an Ethernet connection for online image transmission at a frame rate of 100 images per second.

Source: This article is based on information from the following companies: Automation-Technology, Dias-Infrared, Fluke, Infratec, Micro-Epsilon, Optris, Seek-thermal, Testo.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Infrared heater for efficient heat processes in industry

Control Fair 2024 | The industry is already looking forward to Stuttgart

Optical measurement technology know-how directly from the manufacturer Optris

Optimize weld seam with calculation and profile measurement

Learn everything about infrared camera measurement technology at Optris

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.