Capacitive sensor for measurement under temperature fluctuations

- Details

- Hits: 8214

A pair of capacitive sensor is used wherever precise measurement results are required. Due to the very good temperature stability, the capacitive measuring principle is particularly suitable for applications in which temperature fluctuations appear. Other sensor technologies such as laser sensors, which record a strong temperature drift in the signal, are also interesting. The capacitive sensors from Micro-Epsilon are often used for quality assurance in the process or as measurement sensors for complete control loops. The sensors measure vibrations, deflection, expansion, path, deflection, deformation, thickness and much more.

Contents

Capacitive sensor for conductive objects

As a electromagnetic process As a standard, a capacitive measuring system measures all conductive objects with consistent sensitivity and linearity. The system evaluates the reactance of the plate capacitor, which changes with distance.

As a electromagnetic process As a standard, a capacitive measuring system measures all conductive objects with consistent sensitivity and linearity. The system evaluates the reactance of the plate capacitor, which changes with distance.

Capacitive sensors can also under certain conditions Insulator materials measure, whereby the sensor mass usually acts as a counter electrode and the insulator material acts as a coupling medium. An approximately linear output signal is also possible for insulators through electronic circuitry.

Sensors with almost ideal linearity

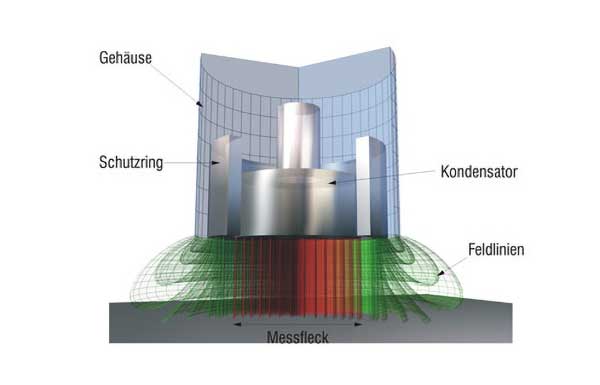

The Capa NCDT Sensors come in two versions. The more common version is a completely triaxial sensor design, in which the protective ring electrode and grounding are located on the front edge of the sensor next to the measuring electrode. These sensors can therefore be installed completely flush even in conductive materials. In addition, touching the sensors is permitted during multi-channel measurements. But there are also sensors that have a housing that is set back to the side.

With this type of capacitive sensor, the field can also be on the side Electrode spread. This has the advantage that a larger measuring range can be achieved with a smaller sensor diameter. In order to avoid field distortions and thus non-linearity, an active protective ring is mounted around the electrode in the Capa NCDT sensors.

Maintained electrically at the same potential as the electrode, it concentrates the electrode's field. This creates a very homogeneous measuring field. The field lines emanating from the protective ring are not taken into account during the measurement. The Capa NCDT sensors fully implement the protective ring capacitor principle and thus take advantage of the advantages of a homogeneous electrical field between the sensor and the measurement object. Thanks to the homogeneous field, they achieve an almost ideal linearity characteristic in practice.

Measurement on all material surfaces

Since the measurement can be carried out on all conductive objects, it is not influenced, for example, by the optical properties of the measurement object. So are they transparent or reflective Capture surfaces with maximum measurement accuracy.

Since the measurement can be carried out on all conductive objects, it is not influenced, for example, by the optical properties of the measurement object. So are they transparent or reflective Capture surfaces with maximum measurement accuracy.

The Capa NCDT systems can also be linear or one-sided Dickenmessung of insulators can be used. The field lines penetrate the insulator and close with the electrical conductor. If the thickness of the insulator changes, this affects the reactance Xc of the sensor. The distance to the counter electrode must be constant. Examples of non-conductive measurement objects are (including glass fiber reinforced) plastics, ceramics, steatite, porcelain, glass, adhesives, resins, oils or gelatin.

The electrically conductive For materials such as metals, two-sided thickness measurement is possible by mounting the sensors opposite each other. Thanks to the capacitive measuring principle, the measurement is carried out exclusively against the surface, without the field penetrating the measurement object. This means that the thickness of even very thin materials can be reliably measured.

Each of the two sensors delivers a linear output signal depending on the distance between the sensor face and the surface of the measurement object. If the distance between the sensors is known, the thickness of the measurement object can be easily determined. If the measuring channels are synchronized, measurement is also possible against non-grounded measurement objects. Examples of conductive measurement objects are metals, graphite, silicon, CFRP, water

Numerous applications - also in safety-critical areas

Capacitive sensors from Micro-Epsilon have proven themselves in various applications for decades. Thanks to the reliable technology, they are also in safety-critical areas used. Numerous fields of application can be covered with over 25 standard sensors with measuring ranges from 50 µm to 10 mm.

The sensor models are available in a cylindrical design Plug as well as integrated Cables, as a flat sensor and in a printed circuit board design. Different materials and manufacturing technologies are used.

The sensor models are available in a cylindrical design Plug as well as integrated Cables, as a flat sensor and in a printed circuit board design. Different materials and manufacturing technologies are used.

In addition to the standard version made of stainless steel or Invar, sensors are also available Titan available. The ECT sensors offer a special feature. ECT stands for Embedded Capacitor Technology, in which the sensor element is embedded in a particularly stable carrier element.

These ECT sensors offer increased long-term and Temperature stability and are particularly suitable for low temperatures, UHV and clean rooms. The measuring electrode in the ECT sensor is very flexible in its geometric design. As a plate electrode, it can be custom-built in different geometric shapes.

FAQ

What do capacitive sensors measure?

Measuring capacitive sensors Changes in capacity, which are caused by the proximity or contact of an object with an electrically conductive or dielectric surface. They are commonly used to detect the presence or position of an object, measure the thickness or density of materials, and monitor levels of liquids or bulk solids. These sensors are particularly effective in applications that require non-contact detection.

What does a capacitive sensor do?

A capacitive sensor detects the presence or proximity of objects, by measuring changes in electrical capacity. This is done by creating an electric field and observing how this field is affected by the proximity of materials with dielectric properties (such as metals, liquids, plastics). The sensor responds to the change in capacitance that occurs when an object enters or moves within the field.

Where do you use capacitive sensors?

Capacitive sensors are popular in many industries due to their reliability, durability and accuracy in non-contact detection, especially where non-contact detection and measurement are required. Some of the most common areas of use include:

- Industrial Automation to detect the presence or position of parts on conveyor belts, in machines and assembly processes,

- level measurement for monitoring liquid and solid levels in tanks and containers,

- Touchscreens in smartphones, tablets and other interactive devices to recognize touch and gestures,

- security systems to detect unauthorized access or monitor access points,

- Vehicles for controlling interior functions such as light switches or infotainment systems.

What is the difference between inductive and capacitive?

Inductive sensors are based on electromagnetic principles and are specialized in detecting metals, while capacitive sensors are based on changes in electrical capacitance and can detect a wider range of materials. The main difference between inductive and capacitive sensors is how they work and the types of objects they can detect:

Inductive sensors

- Functionality: Inductive sensors use an electromagnetic field to detect metals. They create an alternating field around a coil. If a metallic object enters this field, it changes the inductance of the coil, which is detected by the sensor.

- Application: mainly for detecting metallic objects

- Features: robust against environmental influences such as dust, dirt and moisture

Capacitive sensors

- Functionality: Capacitive sensors utilize the change in electrical capacitance that occurs when an object, metallic or non-metallic, approaches the sensor. They create an electric field between their active surface and the object to be detected.

- Application: used to detect a wide range of materials including metals, plastics, liquids and even human bodies

- Features: They can measure through non-metallic materials and are sensitive to materials with high dielectric properties.

You might also be interested in...

Thermal Imaging Camera | Innovations for industrial applications

Optimize weld seam with calculation and profile measurement

Interferometer | Ultra-precise length and angle measurement

Distance measurement with laser triangulation and blue laser

Stefan Stelzl is Product Manager Sensors

at Micro-EpsilonGmbH & Co. KG in Ortenburg.