Distance measurement with laser triangulation and blue laser

- Details

- Hits: 9287

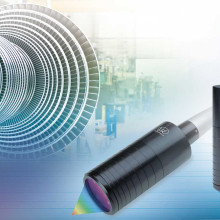

Optical, contactless and precise: The Laser triangulation is one of the most popular industrial processes Distance measurement. Red laser light has always been used because the receiving elements used have the highest sensitivity. However, when it comes to glowing objects and transparent or organic materials, the red laser has deficiencies that can affect the measurement accuracy. The sensors with the blue laser from Micro-Epsilon solve this problem reliably – not only in one-dimensional distance measurement, but also in profile and contour detection.

Contents

Laser triangulation as a standard optical measuring method

Laser triangulation sensors are among the standard optical measurement methods. The triangulation realized optical distance measurement by calculating angles within a triangle. A laser diode emits a laser beam that is directed at the measurement object.

Laser triangulation sensors are among the standard optical measurement methods. The triangulation realized optical distance measurement by calculating angles within a triangle. A laser diode emits a laser beam that is directed at the measurement object.

The reflected radiation is imaged onto a digital photo element (CCD line) via optics. The distance of the object to the sensor is calculated from the position of the light spot on the receiving element. The data is evaluated via the usually internal controller and output via digital or analog interfaces.

This is due to physics CCD element significantly more sensitive in the infrared (IR) range than in the ultraviolet (UV), which is why conventional sensors work with red laser light (wavelength of 670 nm) close to the IR range. This approach works on many objects. However, some measurement tasks cannot be solved with this. Various objects such as glowing metal emit high levels of infrared radiation.

This radiation interferes with the sensor, which is trimmed to “red”, so that it starts operating at a temperature of approx. 700 ° C no longer carries out a reasonable measurement. Unlike sensors with red lasers, the blue laser works with a shorter wavelength of 405 nm and therefore close to the UV region of the spectrum. A blue laser is therefore at a maximum distance from the infrared so that emitted IR radiation does not disturb it.

Blue laser penetrates the surface

Depending on the measurement object, the conventional one penetrates red laser light more or less strongly into the measurement object and is scattered there. This effect is particularly noticeable with organic measurement objects. Since there is no clean image point on the surface, an exact distance cannot be defined.

Depending on the measurement object, the conventional one penetrates red laser light more or less strongly into the measurement object and is scattered there. This effect is particularly noticeable with organic measurement objects. Since there is no clean image point on the surface, an exact distance cannot be defined.

In contrast, this is urgent blue-violet laser light With such materials, the shorter wavelength means it does not penetrate as far into the measurement object. The blue laser forms a minimal laser point on the surface and ensures stable and precise results even on critical measurement objects.

Exact distance measurement also in 3D

The Advantages of triangulation with the blue laser diode applies not only to one-dimensional measurements such as distance, material thickness and vibration but also to multi-dimensional quality control such as profile and contour measurement.

This is how the series became 2D/3D laser scanner expanded with the models with blue laser diode. The special properties of the short wavelength enable use under conditions that were previously impractical. Precise measurements are also possible on surfaces whose reflection properties or transparency would actually exclude other optical measurements.

Distance sensor with fast time-of-flight measurement method

Distance sensor with fast time-of-flight measurement method

The models Scan Control 2600BL and 2900BL have a particularly compact design thanks to the integrated control electronics. This enables use in complex machines that leave little space for sensors.

The models Scan Control 2600BL and 2900BL have a particularly compact design thanks to the integrated control electronics. This enables use in complex machines that leave little space for sensors.

Profile frequencies of up to 4000 Hz create the basis for use in high-speed applications, for example for measuring rails on moving trains.

There are different measuring ranges from 25 up to 140 mm available in both the Z direction (distance) and the X direction (laser line length). An Ethernet (UDP, Modbus) and a serial interface (RS422, Modbus) are used to transmit measured values.

In addition, analog signals or digital switching signals can be output via an output unit. The blue laser profile scanners Scan Control 2600BL and 2900BL are particularly suitable for measurements on red-hot metals as well as (semi-)transparent and organic materials.

Laser profile measurement with Scan Control

FAQ

How does a laser sensor work?

A laser sensor works by directing a laser beam at an object and the reflected light measures to obtain information about the object's position, distance or other properties. There are different types of laser sensors for distance measurement, which are based on different principles: laser triangulation, laser time-of-flight, laser Doppler effect.

What is Laser Triangulation?

Triangulation is a measurement principle that uses angles in a triangle to determine the position or distance of a point. The principle is based on the fact that in a triangle whose side lengths and angles are known, the position of the vertices can be clearly determined. In practical use, particularly in laser triangulation, a laser beam is directed at an object and the reflected beam is detected by a detector. The distance to the object can be calculated from the angle between the emitted and reflected beam and the known distance between the laser source and detector.

What do laser triangulation sensors do?

Laser triangulation sensors measure the distance to an object by evaluating the angular deviation of the reflected laser beam. The sensor emits a laser beam that hits the object and is reflected back to the sensor. The position of the reflected beam on a detector indicates the distance to the object.

You might also be interested in...

Optimize weld seam with calculation and profile measurement

Distance sensors | Distance, path, distance & Co.

Accelerometer | Measuring forces and direction

Cable pull transmitter | Cable pull sensor and cable pull displacement sensor

Capacitive sensor for measurement under temperature fluctuations

Optical sensors | Light scanner, lidar sensor, laser sensor

Christian Kämmerer, MBA

Product manager laser profile scanner at Micro-Epsilon Messtechnik GmbH +Co. KG, Ortenburg.