Inductive sensor with a reliably high switching distance

- Details

- Hits: 8300

Inductive sensors from Pepperl + Fuchs are used in a wide variety of applications and industries in the process industry and industrial automation. Regardless of whether it is used to detect the position of metal objects or as a proximity switch in the machine tool inductive sensor from the manufacturer reliably detects metallic objects even with a large sensing distance. Below you will find some information about the new products:

Contents

- Inductive double sensor for the process industry

- Inductive sensor with a reliably high switching distance

- Inductive position measurement with patented multi-coil technology

- FAQ

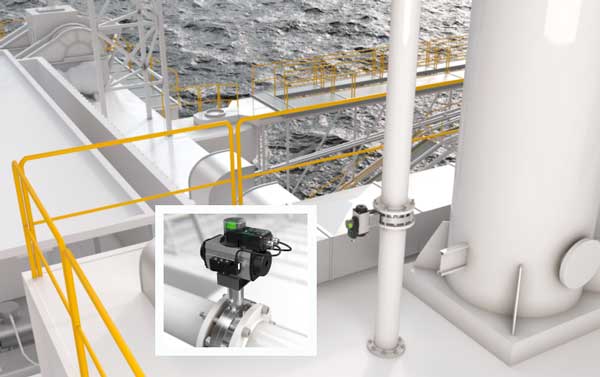

Inductive double sensor for the process industry

Aug 18.08.2022, XNUMX | The inductive double sensor F31K2 represents an innovative solution in the process industry, especially for demanding outdoor environments such as seawater desalination plants, oil rigs and phosphate mines. With its high density, corrosion-free Housing This sensor provides reliable valve position feedback under extreme conditions.

Aug 18.08.2022, XNUMX | The inductive double sensor F31K2 represents an innovative solution in the process industry, especially for demanding outdoor environments such as seawater desalination plants, oil rigs and phosphate mines. With its high density, corrosion-free Housing This sensor provides reliable valve position feedback under extreme conditions.

In addition to the non-intrinsically safe version with IECEx approval for hazardous areas in Zone 2/22, the low-power version enables easy modernization of existing systems with mechanical limit switches.

Robustness and durability for extremes

The outstanding robustness and durability of the F31K2 is designed for use in harsh conditions such as heat, cold, salt water or UV radiation. Its non-contact and wear-free detection of the valve position thanks to two separate inductive sensor elements, combined with a high-density housing IP69, makes the sensor insensitive to water and dust.

The material selection made from V4A stainless steel, specialplastics and coated aluminum provides additional protection against corrosion, while the extended temperature range of -40 to +70/+100 °C and an available protective cover to protect the actuator from mechanical damage and contamination.

Versatile variants for maximum flexibility

The double sensors of the F31K2 series are available with different approvals and electronic outputs. A special highlight is the 2-wire DC low power-Variant: Thanks to patented Pepperl+Fuchs technology, this inductive double sensor has a virtually potential-free contact. As a result, the residual current is so low that the sensor works in conjunction with all programmable logic controllers and process control systems can be used. A modern inductive solution is also available for systems that previously relied on mechanical contacts.

Factor 1 sensors for applications in logistics

Factor 1 sensors for applications in logistics

In areas where explosive atmospheres rarely occur, the 2/3-wire DC variants ensure uncomplicated explosion protection: The sensors are designed with the Ex ec (increased safety) and Ex tc (protection through housing) types of protection and are certified according to Atex and IECEx for Zone 2/22. This means that when these devices are used, they are neither isolating amplifiers nor intrinsically safe wiring required to ensure reliable explosion protection.

The intrinsically safe is suitable for potentially explosive areas up to Zone 0/20 Namur-Version of the F31K2 that has appropriate Atex and IECEx approvals. This variant of the inductive double sensor can also be used in safety applications up to SIL 2.

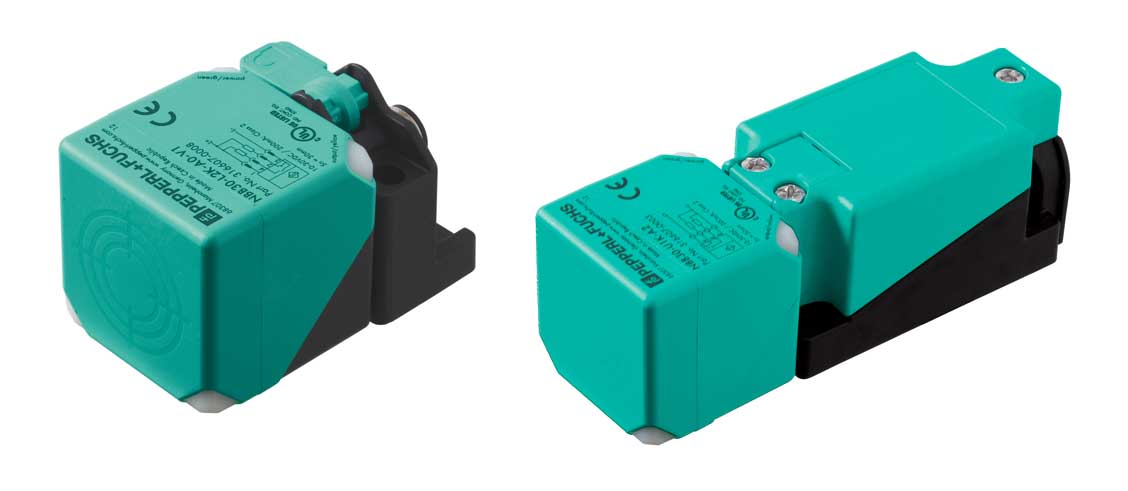

Inductive sensor with a reliably high switching distance

April 15.04.2020, XNUMX | Pepperl+Fuchs now achieves consistently increased switching distances with the inductive sensor Varicont L2. Thanks to the used Active Shielding Technology This works regardless of the type of installation and the installation material. By actively detecting the surrounding metal during installation, the switching distance to the object is kept constant.

When recognizing metallic objects an inductive sensor is the first choice. If the switching distance is increased, the sensor becomes more sensitive to the object to be recognized and the surrounding metal of the installation increasingly influences the electromagnetic fields. When installed, the sensor is pre-damped and changes its switching distance.

Actively record the installation environment

The inductive sensor detects with the newly developed technology from Pepperl + Fuchs Varicont the installation environment is active and keeps the switching distance constant. The whole thing happens regardless of the type of metal.

IoT sensor monitors level and position remotely

IoT sensor monitors level and position remotely

Due to the stable high switching distances of flush 30 mm and non-flush 50 mm, systems with these inductive sensors can be planned more reliably. In addition, mechanical tolerances in machines can be fully exploited. That is particularly simple Status control the inductive sensor from every perspective thanks to all-round visible corner LEDs.

Inductive position measurement with patented multi-coil technology

March 14.03.2018, XNUMX | The inductive positioning system PMI F90 from Pepperl+Fuchs can not only precisely record the absolute position of one actuator but also the distance between two actuators. Thanks to IO-Link, it has comprehensive communication capability and is equipped for Industry 4.0 applications. Its patented multi-coil technology guarantees the highest measurement accuracy.

March 14.03.2018, XNUMX | The inductive positioning system PMI F90 from Pepperl+Fuchs can not only precisely record the absolute position of one actuator but also the distance between two actuators. Thanks to IO-Link, it has comprehensive communication capability and is equipped for Industry 4.0 applications. Its patented multi-coil technology guarantees the highest measurement accuracy.

The PMI F90 works with a unique, patented multi-coil system: The absolute position of the actuator can be precisely determined from the measurement signals of the individual coils. In addition to outputting the analog position signal, switching points can also be defined. The distance sensor can detect two actuators and the distance determine between them. In this way, dynamic positioning tasks can be solved with the least amount of measurement effort.

Positioning system with IO-Link interface

With his IO-Linkinterface, the device allows consistent data flow, not least in applications with Industry 4.0 architecture. Event logs, error messages, data on signal quality, device status and operating hours can be read out directly via the IO-Link master.

Distance sensor with fast time-of-flight measurement method

Distance sensor with fast time-of-flight measurement method

The PMI F112 and PMI F166 sensors from this product family are available for confined spaces and harsh environments. Her compact design allows installation in the smallest of spaces; a robust metal housing protects it from external influences.

The advantages of the inductive measuring principle apply to all devices: non-contact, wear and maintenance-free, dirt-resistant, interference-proof. In principle, all components or objects made of steel can be used as actuators, since the inductive system is not dependent on magnetic actuators.

FAQ

What does an inductive sensor do?

An inductive sensor is a device that detects the presence of metals without direct contact. It works by creating an electromagnetic field and measuring changes in that field that occur when a metallic object comes close. These sensors are often used in automation technology to monitor positions, speeds and presence of metal parts.

What is the difference between inductive and capacitive?

The main difference between inductive and capacitive sensors is how they work and the types of materials they can detect:

- Inductive Sensors only detect metallic objects such as iron or steel. They work by creating an electromagnetic field and measuring changes in that field when a metal comes near them.

- capacitive Sensors can detect both metallic and non-metallic materials, including liquids and plastics. They create an electric field and measure changes in the capacity of that field when an object, regardless of its material, comes close.

You might also be interested in...

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies

Level sensor for every level measurement