microscope | from stereo microscope to laser microscope

- Details

- Hits: 6956

Stereo microscope, Laser microscope or High-speed microscope are used in industrial quality control. They are also indispensable in research and development, where they provide detailed insights into the microstructure and composition of materials. In this article, learn how these modern magnification tools are redefining the boundaries of visual analysis and in which areas of application they are particularly effective.

Contents

- Ocular stereo microscope for ergonomic microscopy

- Digital laser microscope for deeper tissue

- High-speed microscope with intuitive gesture control

Ocular stereo microscope for ergonomic microscopy

25.10.2020 | Vision Engineering presents the Lynx EVO, an eyepiece-free stereo microscope that can be used very ergonomically for many inspection and manipulation tasks. The ergonomics combine the stereo microscope with top optical performance and digital documentation. It was developed based on Vision Engineering's globally patented Extended Pupil technology and is therefore very user-friendly.

The Expanded Pupil Technology is based on the patented optical microarray surfaces or microarrays. These maximize the possible head/body movement, hand-eye coordination, peripheral vision and sensor information of the stereo microscopes. The microscope allows users to sit further away from the eyepiece. This leads to improved sitting posture, reduced fatigue and increased accuracy and efficiency.

Stereo microscope provides real-time information across locations

With the Lynx EVO stereo microscope, cross-location development and production can be improved. Detailed real-time information about complex supply chains for production and sales can be exchanged. This is already being used worldwide in applications such as medical technology, telecommunications technology, aerospace, automotive and other industries with extended supply chains for critical manufacturing processes. The export share of Vision Engineering's stereo microscopes is 95%.

The stereo microscope was Queen's Award for Enterprise 2020 awarded in the innovation category. The award is considered the highest British distinction for companies. It recognizes exceptional achievements by British industry.

Telecentric Lens | new developments

Telecentric Lens | new developments

“We are delighted to have received the highest award available to UK businesses for our Lynx EVO eyepieceless stereo microscope. This confirms our belief that the use of the most modern Microarray technologies and by addressing our customers' digital expectations, deliver significant benefits in workplace throughput and efficiency across a range of industries worldwide, through increased operator convenience, productivity and the communication of information across multiple locations. The development of Lynx EVO and other products in our range has enabled us to leverage our unique expertise in the complex science of optical microarray surfaces and enable vision engineering to deliver multiple cutting-edge disciplines to combine with a good commercial effect. "

Digital laser microscope for deeper tissue

Aug 02.08.2020, XNUMX | With that of dr Catherine Philip developed digital Laser microscope can be in particular deeper layers of tissue examine how they z. B. found in patients in the thyroid gland. For her outstanding dissertation, Dr. Philipp with the Bertha Benz Prize 2020 honored.

Aug 02.08.2020, XNUMX | With that of dr Catherine Philip developed digital Laser microscope can be in particular deeper layers of tissue examine how they z. B. found in patients in the thyroid gland. For her outstanding dissertation, Dr. Philipp with the Bertha Benz Prize 2020 honored.

High-speed microscope with intuitive gesture control

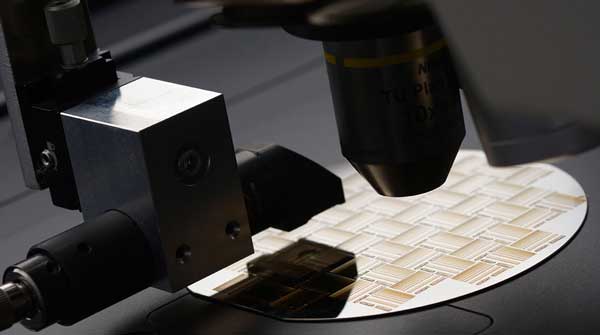

May 03.05.2019, XNUMX | For quality control of large-scale objects from the semiconductor and electronics industry or for quick checking of biological samples Fraunhofer Institute for production technology IPT has developed a high-speed microscope that digitizes samples at up to 500 images per second.

May 03.05.2019, XNUMX | For quality control of large-scale objects from the semiconductor and electronics industry or for quick checking of biological samples Fraunhofer Institute for production technology IPT has developed a high-speed microscope that digitizes samples at up to 500 images per second.

On Control The measurement technicians are now showing for the first time how this system can be used Smart Glasses Combine with gesture control and thus be controlled and operated even more efficiently.

Conventional microscope images of large components often take so long at high magnifications that 100% exams have to be omitted due to time constraints and only random samples can be examined. For this reason, the researchers have developed a new recording process that combines a large number of images to create a large overall image impression:

The Microscope table To do this, the object moves continuously throughout the entire recording in order to digitize the sample at very high frame rates. Since the object is only exposed to a flash for an extremely short time, the recording is free of motion blur and is imaged with depth of field at every point thanks to real-time hardware autofocus systems.

The additional smart glasses consist of one 3D glasses, which shows the user an interactive virtual environment. The glasses are connected to a sensor for gesture recognition: If the user holds their hand over this sensor, they can use it to control the image displayed. The system combines the high-resolution images from the high-speed microscope into a large overall image that the user can not only view, but also move, zoom, freeze and save with intuitive hand movements.

The scanning process combines real-time data handling with powerful image pre-processing, which runs almost without delay thanks to GPU support. The current developments also include methods of Machine learning such as deep learning and convolutional neural networks (CNN).

Source: This article is based on information from the following companies: Fraunhofer IPT, TU-Dresden, Vision Engineering.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Artificial Intelligence | trends and developments

3D printer | Additive manufacturing of plastic parts

3D printer metal | Amazing Possibilities

Programming Robots | software and controls