for the automated factory

Articulated arm robots or Scara robots, bionic, assembly, service robots and cobots as well as components and manufacturer know-how

Image: Mitsubishi Electric

for the automated factory

Articulated arm robots or Scara robots, bionic, assembly, service robots and cobots as well as components and manufacturer know-how

Image: Mitsubishi Electric

Would you like to automate your production? Then Here you will find extensive specialist knowledge from the manufacturers and their latest innovations on the subject Robotic. Industrial robots such as articulated arm robots or Scara robots, bionic robots, assembly robots, service robots and collaborative cobots with their very simple programming are also presented Robot components and users with their interesting Applications.

Below we present New developments by and for robots. Mitsubishi Electric, Yaskawa, Kuka, Fanuc, ABB e.g. B. are classic robot manufacturers; Low-cost axes and cobot units are available from Igus, for example, while Gimatic supplies the grippers or Schaeffler supplies the gearboxes. With their innovations, they are all helping to make the vision of the fourth revolution come true.

The world of robots is constantly evolving and offers a variety of types of robots, which can be categorized according to their scope and functions.

Find out now about new robot innovations on the market:

Welcome to the future of collaboration: the arrival of Cobot or the Human-robot Collaboration into the production halls is in full swing. This revolutionary robotic technology works hand in hand with people and optimizes work processes. Discover the exciting world of cobots and their diverse applications in industry and everyday life.

Industrial robots are the key players in modern manufacturing. They've been around for a long time, but now you're experiencing a new evolutionary stage in which you Artificial intelligence equipped and also becoming smarter thanks to new technologies such as machine learning. Read about many innovations and examples, like that industrial robotics Production processes are transformed and what tasks they can take on in the various industries.

Every robot consists of individual components and systems, which in turn are three basic components are integrated: The manipulator: This is the robot body, an operating element and the robot controller. Further down the robot is divided into the robot frame, the carousel, the swing arm, the robot arm and the robot hand.

All components must meet specific requirements in order to function and Safety of the robot. Depending on their environmental conditions, they must be robust and durable; work accurately, efficiently and repeatably; they should be light; meet safety standards; be compatible with other components and networkable. We present some robot components:

Which one Lawn Mower is the right one for your garden? Save time and effort with the best models for different lawn sizes. This article will guide you through tests and criteria to find the ideal automatic lawn mower. At the same time we provide you with the latest models .

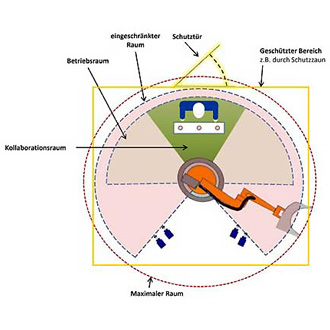

If humans and robots work together without a protective fence, both can make full use of their advantages. Normative prerequisites have been created for their safe cooperation. Collaborative robot cells are already in use in many companies. But what about that? Planning and construction of such robot cells? This article from Schmersal will show you the way.

The free robotics white papers “This is how automation works” by Artiminds analyzes the five most underestimated stumbling blocks when using robots and shows which aspects users should pay attention to in order to avoid possible pitfalls. In addition, different areas of application and robot-based solution approaches are presented.

Whether it's industrial robots or cobots: without the right ones Software and an interactive one Programming robots nothing or nothing works easily. With new trends such as cloud-based programs or the use of artificial intelligence, robot programming is becoming increasingly easier and therefore increasingly efficient. Read how this can be done and what software is already available for this.

Among the best known in Germany robot manufacturers These include Dürr, Kuka, Yaskawa, Fanuc, ABB, Mitsubishi Electric, Igus.... Many more German companies, on the other hand, deal with components for robots. For the following companies we give you a detailed insight into the portfolio:

Artimind's Robotics offers software solutions, advice and services related to robot-assisted automation. With Artiminds RPS and LAR, users receive consistent and flexible programming software that does not require any programming knowledge. This saves you time and money.

Artiminds Robotics supports the robotics industry with innovative software solutions, the the Programming robots, operate and simplify the integration of industrial robots. The pioneer for sensor-based robot applications supports the implementation of advanced projects such as force control and image processing and offers comprehensive advice - from planning to optimization. Read what's new at Artiminds:

Goal of Kirk, a research and development project for AI-based robot calibration is to implement new software-driven calibration methods for industrial robots Machine learning to develop and increase their accuracy. The initiators of the joint project are the University of Stuttgart, the DHBW Karlsruhe and Artiminds Robotics.

With its Low Cost Automation offer is Igus set out to lower the barriers to entry into the age of automation. Affordable and user-friendly robotics with Motion Plastics from Cologne, plus various online tools for design, calculation and configuration are available to get you started.

The RBTX.com platform has also been part of the igus low-cost portfolio since 2019. In the partner network, 78 manufacturers are currently bidding over 300 robotic components and more than 150 complete solutions from practice (as of January 23.01.2023, XNUMX) - including guaranteed hardware and software compatibility. On the Online marketplace users can easily find a cost-effective and suitable automation solution as a complete system for their individual application. Planned customer applications can be tested live together in customer testing areas at various locations around the world before they are purchased.

Igus offers a wide variety of articulated arm robots, gantry robots, delta robots and Scara robots. If you can't decide, there is a solution: virtual Iguverse (Metaverse) provides the perfect playground to get robot applications and programming up and running and then into reality with ease. Looking to the future, igus predicts how people working collaboratively in the Metaverse and, for example, controlling robots from virtual worlds will change the way we work together.

Low cost automation is easy with the Robolink Implement the modular system from igus. This is made possible, among other things, by the long-lasting and at the same time cost-saving Tribo plastic Strain wave gear, which are used in the Robolink robot arm. For example, pick-and-place tasks, assembly work or cleaning work are suitable for this. Find out more about the simple and flexible articulated arm robot.

In logistics, care, kitchens, bars or in the fields: the potential for service robotics is great. Cobots help with monotonous or unergonomic tasks. For the simple, cost-effective implementation of such lightweight robots, Igus is introducing a gearbox kit for cobots. The focus is on the fully integrated Tribo strain wave gear with motor, absolute value encoder, force control and controller. Used in the Rebel service robot, igus is now accelerating low-cost automation. Here you can find out what's new about cobots and gears.

For robotics and automation Mayr Antriebstechnik powerful and tailored to the industry Safety brakes. These are used successfully in countless robot applications worldwide.

That way robotic arms in the event of a power failure, after the power has been switched off or in an emergency stop, the safety brakes from Mayr Antriebstechnik will keep them from falling or falling in an uncontrolled manner servo axes reliable and secure in their position. The company offers a whole range of proven robot brakes for this purpose. In the Roba-power stop series, the company has slim, lightweight spring-loaded brakes for servomotors adapted to the high requirements of robotics.

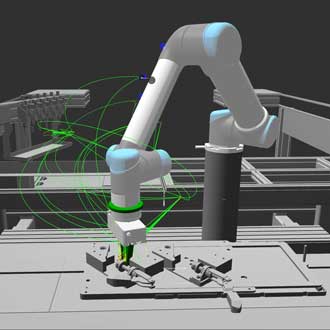

The industrial robots and collaborative robotics of Mitsubishi Electric support numerous intelligent applications in the Industry 4.0 factory. Artificial intelligence is also on board from time to time. The offering ranges from articulated arm and Scara robots to cobots.

The merging of robotics and CNC technology brings competitive advantages for machine builders and OEMs. With the integration of the robot into the machine tool, the advantages of automation can be fully exploited. With the development of a uniform programming environment, Mitsubishi Electric creates a direct robot controller, which allows robot programming via G-codes in the CNC machining center.

Industrial robots are increasingly used today to increase productivity and precision in manufacturing. They also relieve people of tiresome, repetitive tasks. Cobots or collaborativeAlso collaborative robots go one step further here. They actually work together with humans. The article provides insights into Mitsubishi Electric's collaborative robot know-how and cobot portfolio.

Whether the traditional Industrial robots due to the incoming tide Cobots will soon no longer be needed, Mitsubishi Electric answers with "Of course no". Therefore, the automation company still offers a whole range of industrial robots melfah series, develops them further and even equips them with artificial intelligence. Below you will find everything you need to know about the topic and we will introduce you to the latest innovations:

The melfah Industrial robot series from Mitsubishi Electric includes among others Articulated. Thanks to their high-performance motor and amplifier, these are suitable for applications that require high precision and speed. The industrial robots can also be combined with other devices from the manufacturer, such as one SPS or with one Servomotor.

With Artificial intelligence (KI) you are already smart beforehand. Mitsubishi Electric uses its corporate AI now also for Predictive Maintenance for machines, systems and robots. Maintenance reaches a new level through the analysis of operating parameters recorded in real time. Maintenance requirements are identified at an early stage, even before they arise. In this way, necessary measures can be planned in advance and reduced to a minimum.

Schaeffler offers advanced technologies and components for robotics, particularly focused on Precision bearings, drive technology and linear systems focus. The portfolio includes high-precision bearing solutions and mechatronic systems that are crucial for increasing the performance and efficiency of robots. Schaeffler also offers innovative solutions in these areas sensors and actuators that expand the intelligence and functionality of robot systems and Predictive Maintenance enable.

Precision gears have a significant influence on the dynamics, positioning and repeatability or the service life of a construction. Schaeffler has in the young company Ultra Precision Drives developed two types of gearboxes that surpass the current state of the art: the Strain wave gear Series RT and the planetary gear the PSC series. Find out how you can use it to take your robotics application to a new level.

The bearing technology in articulated arms from lightweight robots usually uses crossed roller bearings. Schaeffler has now further improved the design of such bearings in terms of tipping stiffness. In order to achieve significant progress in this regard, a new development approach was required. Schaeffler engineers considered this as a promising alternative with the needle roller and finally the two-row one Angular needle bearing XZU

Schmersal offers a range of Safety Technology for robotics, including Safety switches, Light grids and curtains as well as emergency stop devices, which are essential for securing robot workstations. Their solutions also include intelligent ones safety controllers and magnetic safety sensors used to monitor and control safety-critical functions in automated environments. These products aim to maximize safety in robotics without compromising efficiency and productivity.

If humans and robots work together without a protective fence, both can make full use of their advantages. Normative prerequisites have been created for their safe cooperation. In many companies there are already collaborative robot cells in use. But what about that? Planning and construction of such robot cells? This post will show you the way.

The tec.nicum offers seminars on the topic Safety and Robotic to: The next events will be dedicated to this Safety in integrated robot manufacturing systems and the Human-robot collaborations.

As already described above, the various types of robots already indicate their use. Industrial robots and cobots, on the other hand, are the robots for industrial use on machines and systems. Such robotics applications can be found in countless sectors from the automotive industry to medical technology. Take a look with us behind the scenes of classic applications:

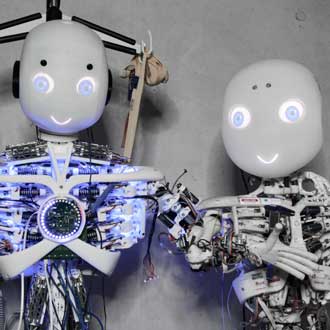

Research in the field of robotics has made significant progress in recent years, resulting in new areas of application and technologies. scientists and engineers from different disciplines work together on research projects to develop innovative robotic solutions that can revolutionize the way we work and live.

Some important results of research projects in robotics are as follows: Collaborative robots take on dangerous tasks and increase productivity; Autonomous mobile robots (AMR) move independently in an environment, can navigate and transport goods. With the integration of artificial intelligence and machine learning in robotics, robots are becoming increasingly intelligent and can independently learn and perform increasingly complex tasks. In soft robotics, the development of soft robots made of flexible materials allows better adaptability and safety in sensitive applications such as medical technology or in human-machine interaction.

Many of these developments have been preceded by research projects that have the potential to advance automation and create new ways for robots and humans to work together, as the following articles show:

A general robot definition describes robots as programmable machines that can perform various tasks. Originally inspired in science fiction, robots have evolved into real-world technology. Robots often have multiple axes. This allows them to perform complex movements. These movements are carefully planned and controlled with regard to the movement sequence and the freedom of movement of the axes. Robotics has the potential to improve human life in various areas and streamline operations in many industries.

The Automation is unthinkable without robotics. The world's first manufacturer of industrial robots was neither ABB, Kuka nor Fanuc, it was called union and is from the USA. The first robot stopped in Germany Hydraulic Systembasis Entry into automobile production at Mercedes-Benz in 1970. Kuka built the first German industrial robot with six electromechanical axes in 1973, followed by ABB with the fully electrically driven robot, which was presented a year later. Today, robotics is an integral part of the factories of the present and even more so of the future.

The world of robotics has made impressive strides in recent years. According to the International Federation of Robotics, more than 2022 million industrial robots were in use worldwide by the end of 3. A significant proportion of these robots are found in the automotive industry, which accounts for over 40% of total robot installations. In addition, the service robotics market, including household, medical and logistics robots, has seen unprecedented growth over the past five years. It is estimated that this market will be worth $2025 billion by 37. These impressive figures clearly show that robotics plays a crucial role in our technology-driven society and is evolving at a rapid pace.

There are several trends in robotics that will shape the future of robotics and automation. Here are some of the most important:

These trends in robotics have the potential to fundamentally change the way we work and live and can help improve efficiency, safety and sustainability in various industries.

The robotics is an interdisciplinary research area dealing with the development and application of robots. It brings together different disciplines such as Drive Technology, automation, Electrical Engineering and computer science. With the components and systems from these specialist areas, intelligent machines can be developed, which then carry out tasks independently and efficiently. Because the robots can be used so flexibly, they are ideally suited to the requirements of the smart factory, which, among other things, offers the greatest variety of variants down to batch size 1.

Robot definition: Robots take on repetitive and complex tasks. This can relieve human workers and increase productivity. They do this with a high degree of accuracy and repeatability in performing their tasks, which in turn improves the quality and efficiency of products and processes. Robots consist of several axes whose movements are matched to the application in terms of working space.

Sources: This article is based on information from the following companies: ABB, Artiminds, Camozzi, Denso, Fraunhofer IPA, Gimatic, Igus, KUKA, Mayr Antriebstechnik, KIRK, Mistubishi Electric, Robco, Rollon, Roboy, Schaeffler, Schmalz, Schmersal, Stäubli, Weiss Robotics.