Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Vacuum technology for industry

Innovations and further developments in vacuum technology such as vacuum pumps, grippers and compressors for industrial applications

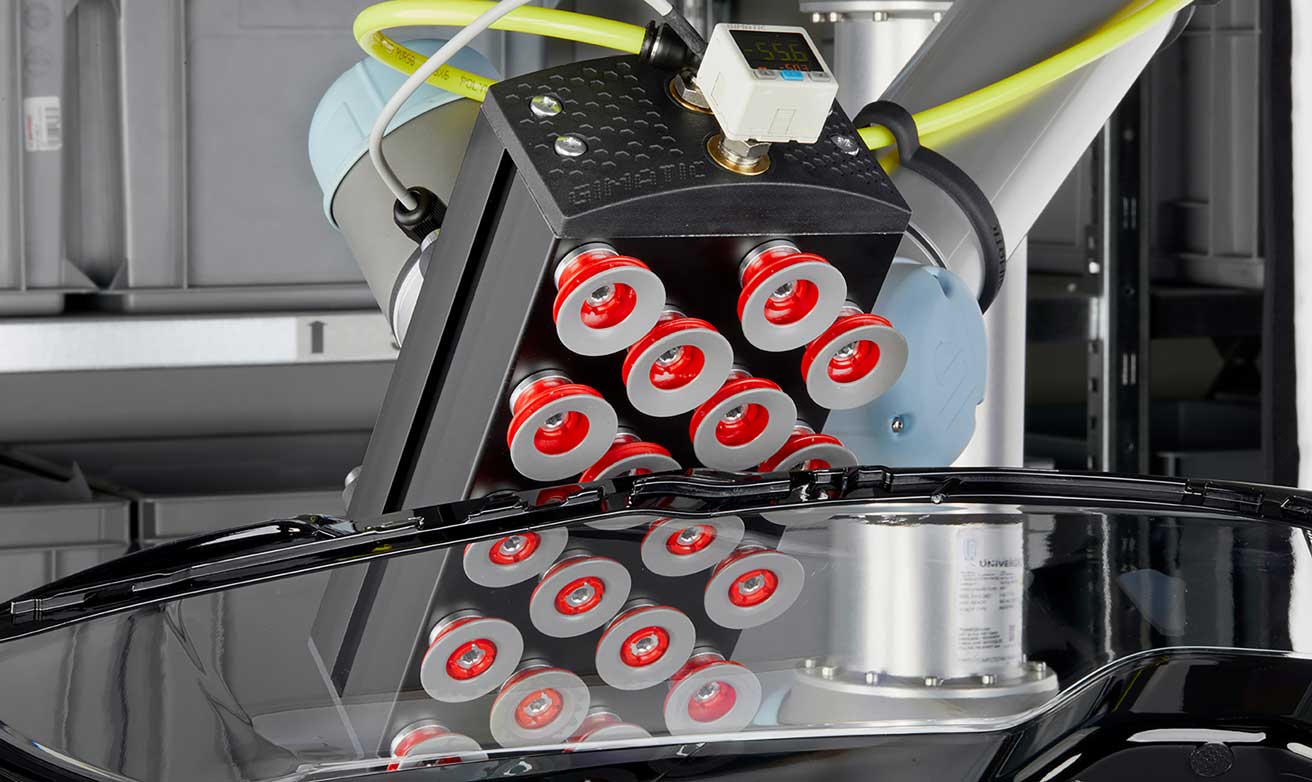

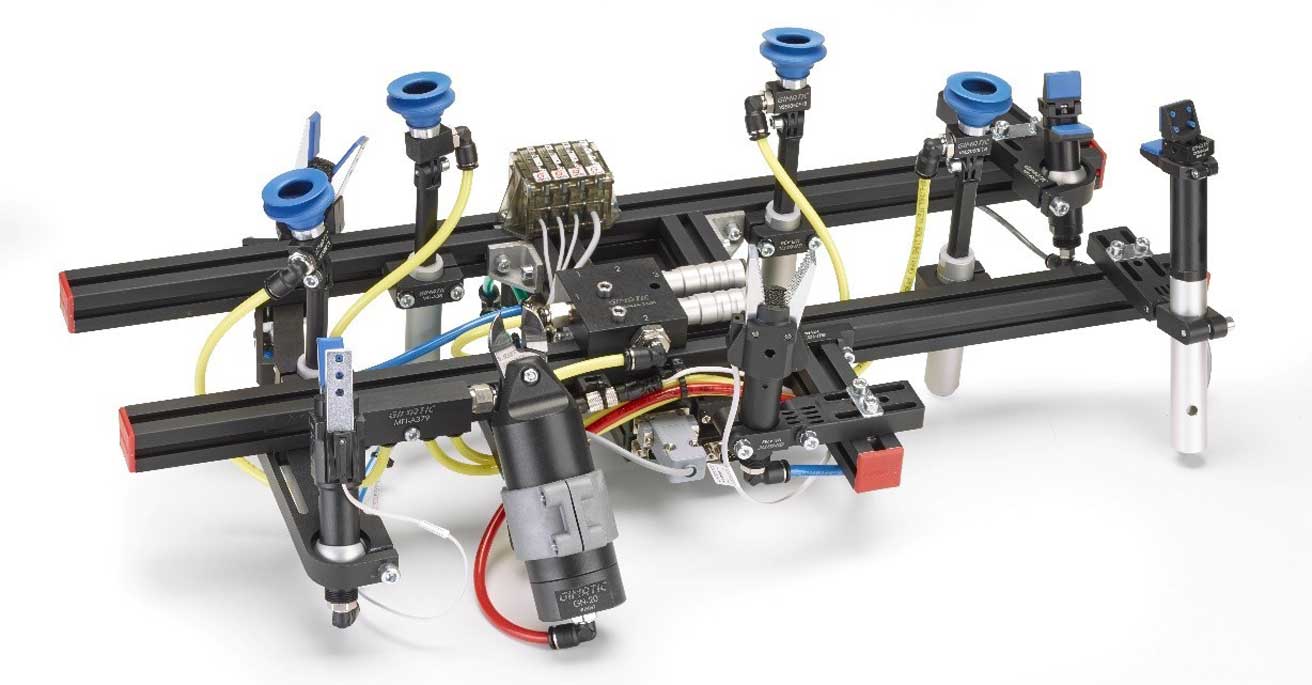

Image: Gimatic

Pneumatics for drives and tools

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

Contents

Fluid power deals with components, systems and technologies that are linear and rotating Transfer forces and Generate movements. Oil is used in hydraulics, air in pneumatics, more precisely compressed air, and vacuum technology creates a vacuum that can be used to grip components, for example. While the good old hydraulics are easy to control high forces is predestined, pneumatics is suitable for applications that require high speeds, but more low forces have to transfer. Fluid technology can be found in the drive technology for machines and systems of all kinds.

Find out about the news from the Fluid Technology for industrial manufacturing with a focus on Energy saving and precision. Here you will find fluid technology components and systems such as pumps, valves, controls and fluids such as cooling lubricants that are required for fluid technology in hydraulics. The innovations out Hydraulic System, Pneumaticsand Vacuum Technology are used in Drive Technology, Manufacturing and assembling.

Special industries like Automotive industry, Renewable energies, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations in the field of fluid technology.

Renewable energies

food technology

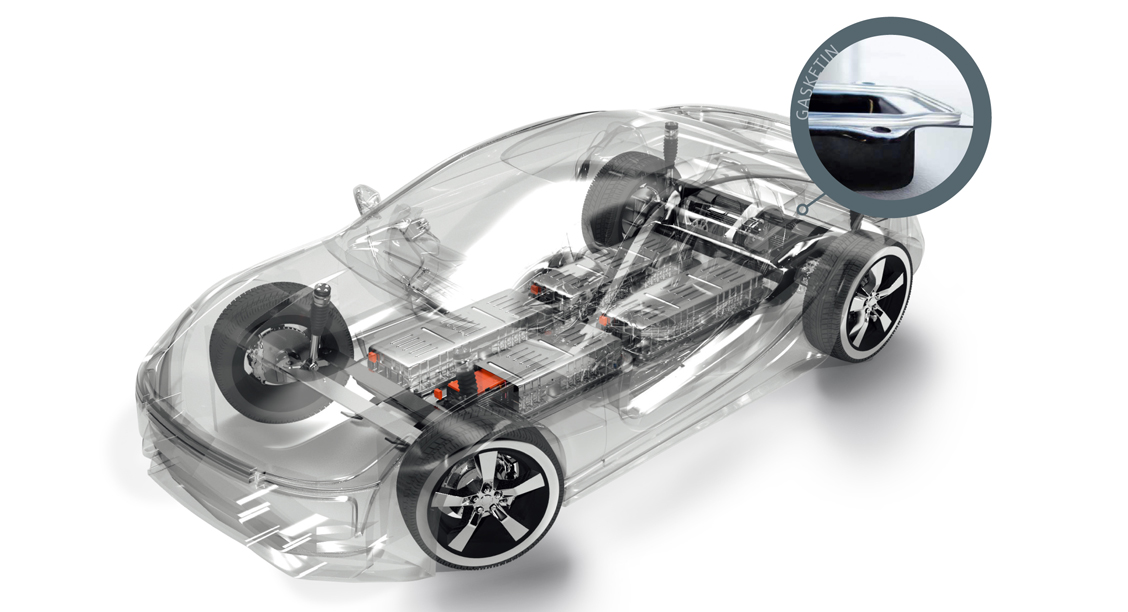

Automobile

Fluid technology fulfills the requirements in plant and mechanical engineering often drive engineering tasks. It is used to generate linear and rotating movements or forces hydraulically or pneumatically. If the application requires high, easily controllable forces, this is a task for the hydraulics. Pneumatics, on the other hand, are predestined when high speeds with low forces are required. In vacuum technology, on the other hand, negative pressure is generated. One area of application is the handling of parts.

Different measurement principles are used to record limit levels or measure fill levels. Turck offers a comprehensive portfolio for various media and environmental conditions. These include the one presented below Ultrasonic level sensor and the radar sensor for level measurement. IO-Link interfaces do that Sensors IIoT suitable.

More and more are obtained through agriculture and industrial processes micropollutants into our waters. Medicines and cosmetics in private households also lead to residues in the water. We are presenting new technology here Waste water treatment and wastewater treatment in sewage treatment plants such as a new ozone plant from Prominent or the colorimetric analysis system for ammonium from Endress + Hauser.

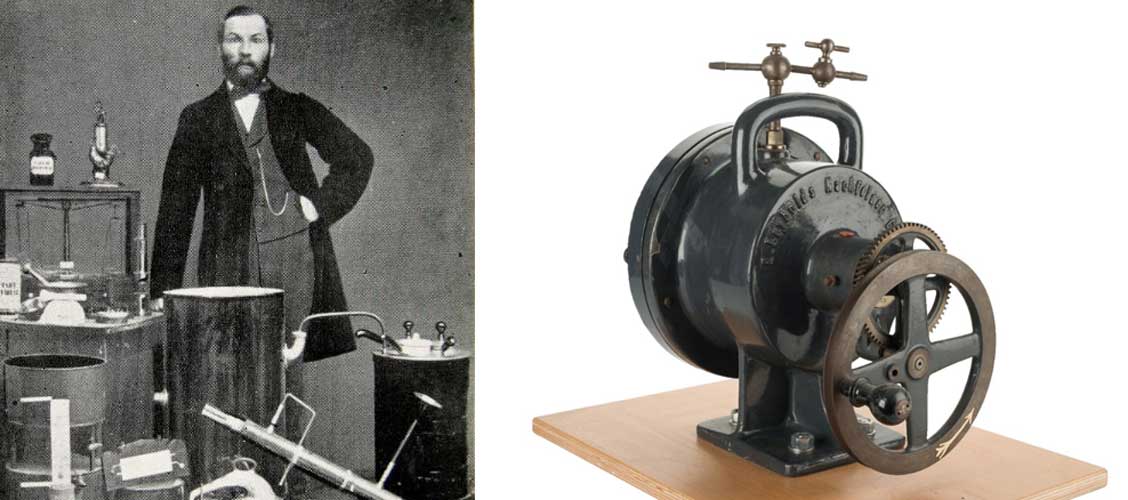

Traditional companies are only sustainable if they are innovative. The specialist for Vauum technology Leybold this combination of tradition and innovation has been impressively successful over the course of its company history. Today the company is proud of its 170. Birthday to celebrate a very special milestone in 2020.

With the new Hydro Lubricants, Klüber Lubrication has succeeded in developing homogeneous lubricants with a functional water content and thus harnessing the positive aspects of water. This offers enormous advantages not only in terms of the performance of the lubricants, but also in terms of their sustainability.

With the new Hydro Lubricants, Klüber Lubrication has succeeded in developing homogeneous lubricants with a functional water content and thus harnessing the positive aspects of water. This offers enormous advantages not only in terms of the performance of the lubricants, but also in terms of their sustainability.

hydraulic cylinders play a central role in many technical systems. In this comprehensive overview, we not only offer the latest innovations in the industry but also basic knowledge. You will also receive practical tips Troubleshooting with defective hydraulic cylinders and exciting insights into them Applications for linear actuatore. Trust in the manufacturers’ in-depth expert knowledge and stay up to date.

The requirements for Pneumatic cylinder are constantly increasing in terms of design, hub, maintenance and energy efficiency. SMC offers ISO cylinders from the CP96 series in accordance with DIN ISO 21287, specifically double-acting in four new versions. They include an ISO standard and compact version, an ISO-based version with energy return and an energy-efficient compact cylinder. This special pneumatic cylinder with energy recovery and the compact cylinder offer a reduction in compressed air consumption of up to 48% - one world first.

As late as possible, as early as necessary: This is the formula for the optimal time to replace filters in high and medium pressure hydraulic filtersto ensure trouble-free operation in hydraulic systems. A new two-stage contamination indicator from Stauff lowers the costs for the user Hydraulic system, The revised version of type HI-D024 considerably simplifies checking the contamination status of the filters.

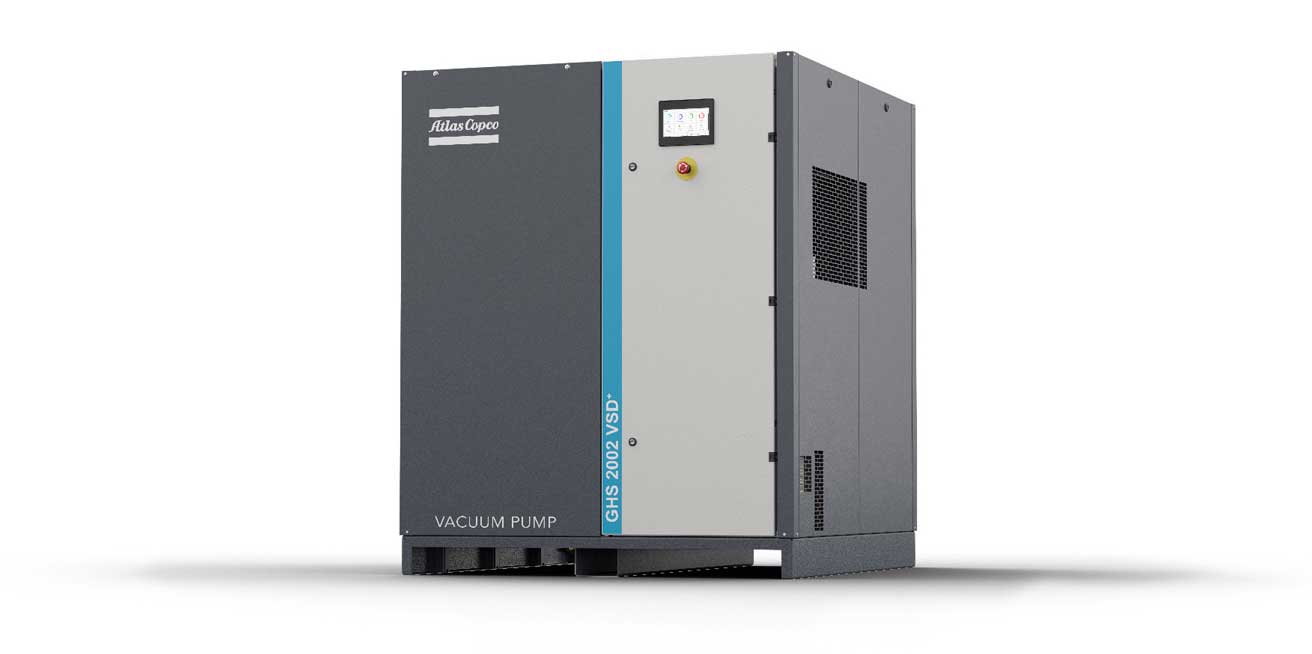

High-quality, energy-efficient, quiet and much more must be Vacuum pump for industrial applications today. Intelligently controlled, it is also ideally suited for use in Industry 4.0. We present you here New developments before, including a new speed-controlled screw vacuum pump from Atlas Copco, which can be intelligently networked.

Gimatic, a member of the Barnes Group, has expanded its mechatronics product range to include a range of Vacuum Technology like Vacuum pump, suckers, Sensors and accessories expanded. The newcomers are energy efficient, high quality and food safe. There are many applications for them in a wide variety of industries.

In the in-house, ultra-modern technology center in Switzerland, Blaser Swisslube puts the cooling lubricants through their paces as early as the development phase. The new technologies include the crystal clear "Synergy 735", the high-performance grinding oil "Blasogrind GTC 7" and the latest "B-Cool MC 610" for mixed production.

In the in-house, ultra-modern technology center in Switzerland, Blaser Swisslube puts the cooling lubricants through their paces as early as the development phase. The new technologies include the crystal clear "Synergy 735", the high-performance grinding oil "Blasogrind GTC 7" and the latest "B-Cool MC 610" for mixed production.

Pfeiffer Vacuum and Glimo have jointly developed the "Vacu²" multi-stage vacuum process for die casting, in which the casting chambers and mold cavities are evacuated in two stages. The vacuum created in this way leads to very good part quality.

Pfeiffer Vacuum and Glimo have jointly developed the "Vacu²" multi-stage vacuum process for die casting, in which the casting chambers and mold cavities are evacuated in two stages. The vacuum created in this way leads to very good part quality.

The new Vacuum gripper Series FGS-120 from Gimatic is modular, very flexible and energy efficient. With the modular vacuum grippers, differently shaped components in various sizes and different porosities can be handled very easily. A integrated vacuum generator provides the vacuum and makes the grab suitable for use in various industries. In packaging technology or intralogistics, the vacuum cups or vacuum plates reliably grip sheet metal, Plastic, Glass, wood, cardboard or cans.