Dispense liquid sealant directly onto automotive components

- Details

- Hits: 11498

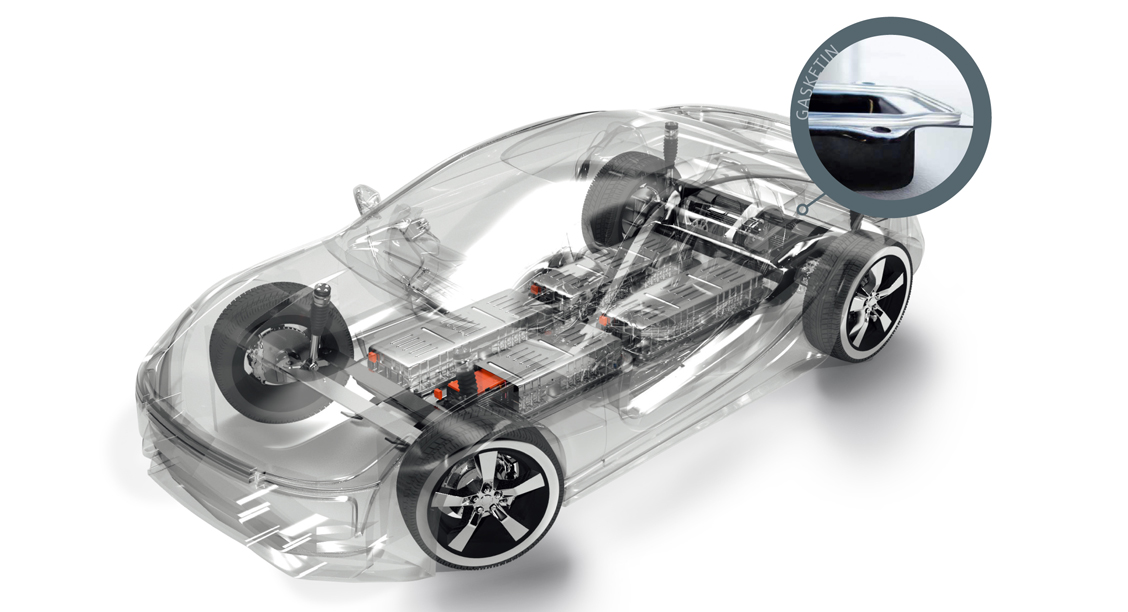

A milestone for them Automobileproduction presented Henkel now with a new technology for that Liquid seal. With the directly meterable polyacrylate sealing technology from Loctite AA 5884 users receive an increased Oil resistance and the proven lower gas permeability. This can reduce overall costs.

During the Automotive industry especially the use of Lightweight materials like Plastics driven to meet fuel efficiency and sustainability targets. Electronics Components, Motorcovers, TransmissionCovers and other components such as expansion tanks are increasingly being integrated into plastic assemblies. They have to be sealed off from their core units.

Speed-dependent dosing technology halves throughput time in series

Speed-dependent dosing technology halves throughput time in series

The most common sealing method for Metal-Plastic substrates is that Press-in-place process (PIP). A pre-formed rubber seal or an O-ring is inserted here manually. The seal can slip when pressed together. Complex reworking or leaks are the result.

A milestone in the automotive industry

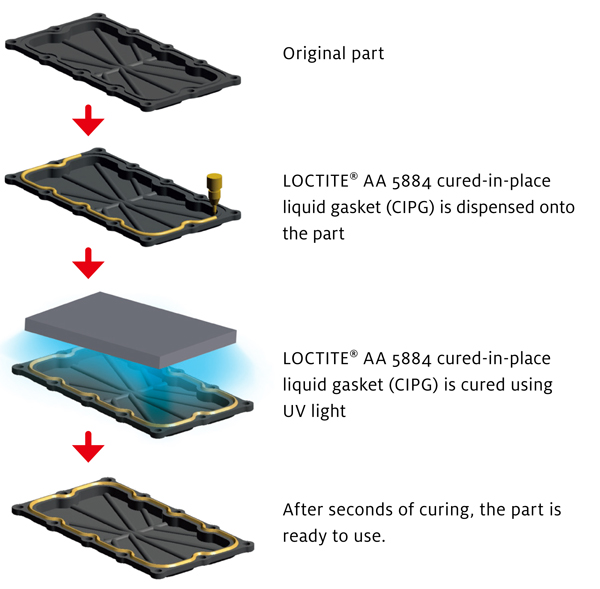

Polyacrylate sealing technology Henkel enables liquid sealant to be dispensed directly onto components. This static liquid seal is applied between two flanges. To prevent liquids or gases from escaping and to close the joints between the surfaces, hold Fasteners the flanges together.

Polyacrylate sealing technology Henkel enables liquid sealant to be dispensed directly onto components. This static liquid seal is applied between two flanges. To prevent liquids or gases from escaping and to close the joints between the surfaces, hold Fasteners the flanges together.

So that a function of the liquid seal leak-free connection is permanent, the seal must be resistant to the sealed medium. In addition, it must withstand pressures and operating temperatures in the application as well as the micro-movements of the connection.

Such seals are in the form of a liquid elastomer bead applied by means of automated precision devices. The liquid seal is cured in a few seconds under UV light. So it forms a seamless and tight pressure seal. The process reduces the risk of leaks and rework. This increases productivity and reduces overall costs, not least because the complexity of pre-formed PIP seals is eliminated.

The new polyacrylate liquid seal is high resistant to oils and automatic transmission lubricants (ATF) and does not cause foaming. Henkel sees Loctite AA 5884 as Milestone in process development for the automotive industry. The new liquid seal combines real added value for the fast and efficient production of pressure seals with a sustainability advantage. Industrial liquid gasket, adhesive and potting compound

Industrial liquid gasket, adhesive and potting compound