with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

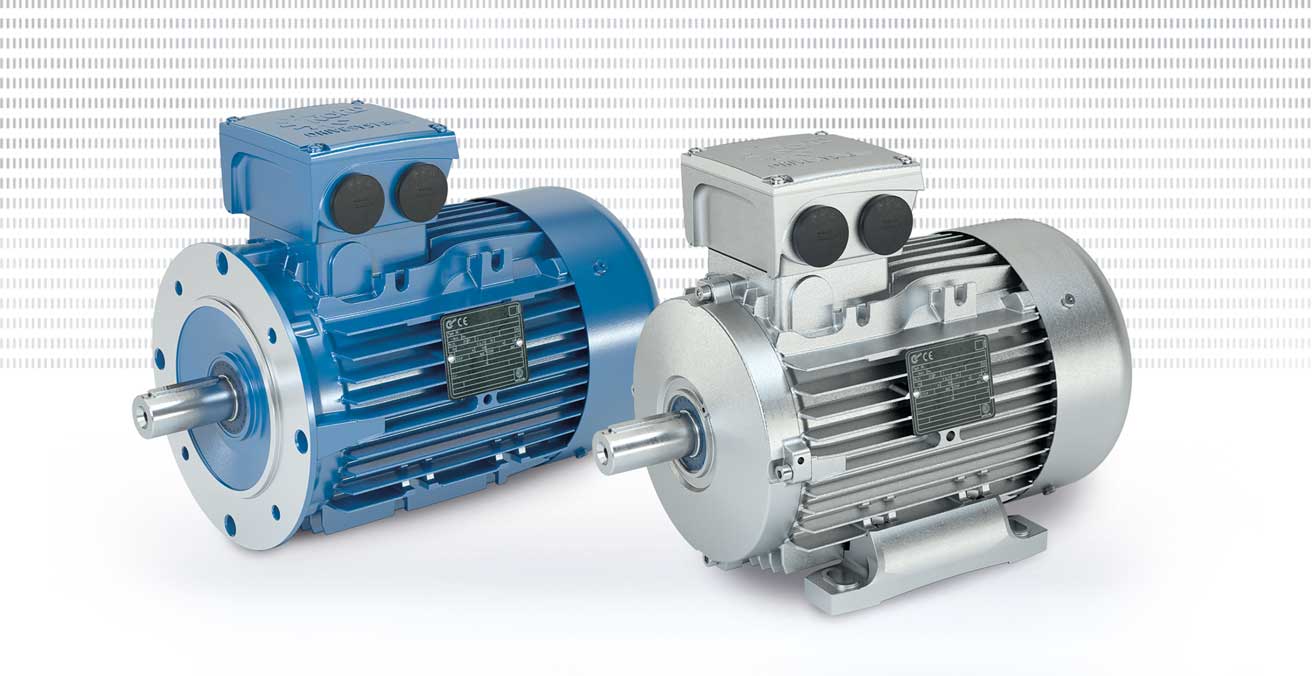

We present you the most modern Motor Technology for the Industry, including drives such as synchronous motors, asynchronous motors, gear motors, direct current motors, DC and BLDC, stepper motors, etc. for your cost-conscious design. The Electric motor for Machinery and equipment must be efficient, powerful, compact and quickly available.

Contents

Industrial motors are of very high quality. The conditions of use are very different. A drive in the mobile work machine must withstand the harsh environmental conditions, the gear motor in the Food industry or Medical Technology however, has many requirements to meet. The electric motor for Industry 4.0 should networkable . Energy Efficiency and compactness are always the order of the day. The brushless DC motor BLDC and the DC motor in 12V or 24V meet global requirements with mass suitability.

Below you will find motor innovations from Koco Motion, Minebea Mitsumi or Nord Drivesystems, among others. Regardless of what term they are called, be it gear motor, electric motor, AC, DC motor: they should all have one thing in common: long Lifespan at best Perfomance. Here are the novelties:

Stepper Motors have become indispensable in the industry for precise movements and flexibility in countless applications steering to ensure. They have high accuracy, are robust and offer a wide range of torques and speeds. They are therefore ideal for use in production, for example, Automation or Robotic. In this article we present the latest developments:

The Servomotor of today is characterized by the fact that it is compact, works precisely, highly dynamically and energy-efficiently and advances Industry 4.0. He is based on Synchronous- and asynchronous motor, alternating current motor, direct current motor or stepping motor, which over servo to be controlled. We present here the New Products the often small powerhouses and report on everything from the simple servo system tailored to the customer to the with Artificial intelligence provided servo drive.

A-Drive's NEMA 17 ZEN Hollow Shaft Actuator features a novel magnetic design that stepper motor gives previously unattainable properties. The features include very high accuracy, an extremely compact design and silent running. The stepper motor can be flexibly adapted to almost any application and opens up numerous new areas of application that were previously reserved for larger series.

A-Drive's NEMA 17 ZEN Hollow Shaft Actuator features a novel magnetic design that stepper motor gives previously unattainable properties. The features include very high accuracy, an extremely compact design and silent running. The stepper motor can be flexibly adapted to almost any application and opens up numerous new areas of application that were previously reserved for larger series.

NORD presents the patented Gear Motor Duodrive in hygienic washdown design. This becomes a highly efficient one IE5 + synchronous motor in the housing of a single-stage Spur gears integrated. The innovative drive concept significantly reduces energy consumption while offering a high power density. In addition, the variants can be reduced in a targeted manner. The extended one is brand new Power range up to 3 kW.

The Servomotor and servo portfolio of Mitsubishi Electric is very versatile. Combined with innovative maintenance, the latest servo systems make the machines more efficient, minimizing downtime and improving productivity. The automation company is now going one step further and equipping its servo motors Artificial intelligence (AI). We present these and other servo motor innovations and information to you here:

A prestigious building is only truly accepted by the residents of a city when it has been given a nickname. The cheese grater in London did it. But the sloping south facade not only gave the 225 m high commercial building a distinctive nickname, it also made it necessary to create a tailor-made facade access system. The associated one Drive Technology comes from NORD and ensures power and safety in the lifting technology.

The combination of interlock on the protective door and Standstill monitor im switch cabinet protects machines and systems from the dangerous overtravel movements of the Drives. Schmersal group now presents a new standstill monitor SSW303HV that works without sensors. Compared to the previous models of the AZR and FWS series, this security guard brings significant improvements.

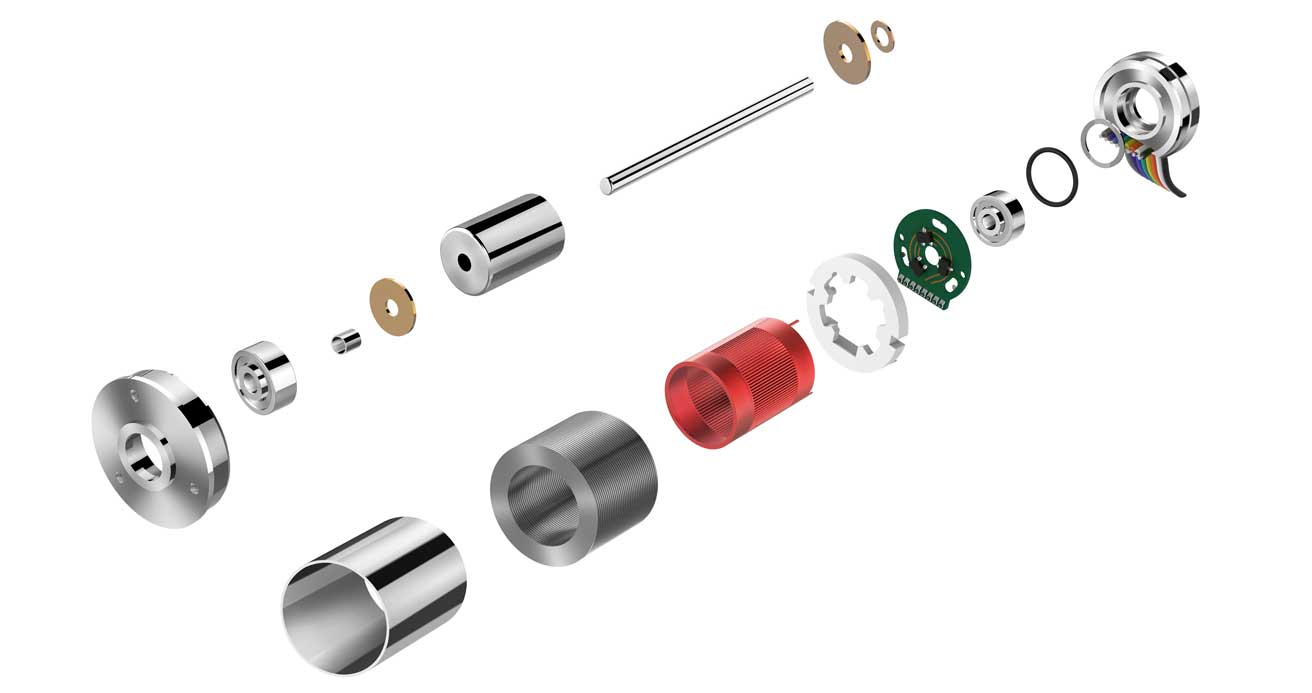

Comes a mechanically commutated DC Motor In terms of service life or performance at its limits, it is time to apply brushless DC motors to move. The demand for brushless DC motors is unbroken - and the trend is rising. This has become koco Motion and offers an extensive BLDC program that leaves (almost) no user wishes unfulfilled. Find out a lot of interesting facts about the small electric motors here:

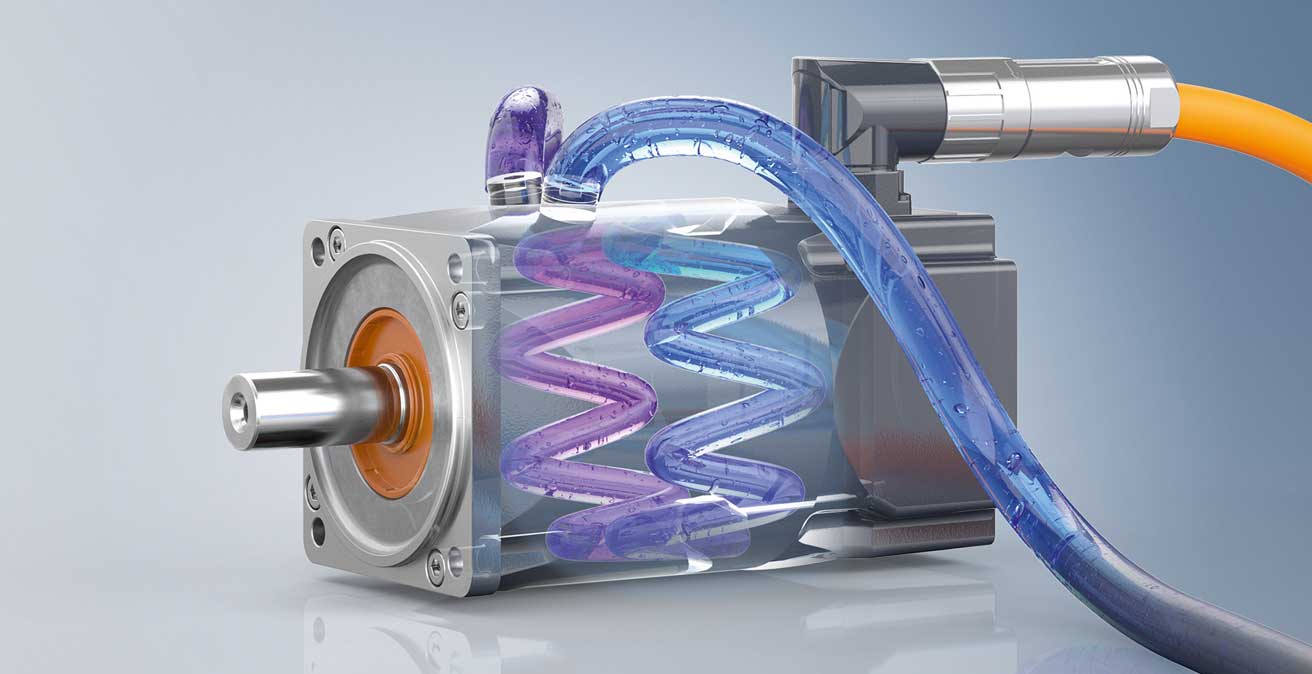

If the installation space is small and at the same time a high drive power is required, are water-cooled electric motors the drive of choice. They are very efficient and tend to be more efficient than air-cooled motors, as the latter generate far more heat and friction losses. In addition, water has the best thermal conductivity coefficient. We present to you below New developments from the field of water-cooled electric motors.

koco Motion and Adlos have their ingenious, unique servo motor platform can Motion revised. About better reference runs Users can now also look forward to series products. In addition, the cooperation partners now have the connection of DC motors implemented. Previously were at the Servomotor for 2nd generation made electronic and mechanical improvements and further developed the software.

Electric drives have a large share in industrial electrical energy consumption. According to Nord Drivesystems, up to 60 percent can be saved together with the application. Therefore supported NORD its customers with energy-efficient drives to tap this potential for savings. Below we present the innovations in the area Asynchronous motor.

The machining centers from Alzmetall are characterized by their extremely high static and dynamic rigidity, which enables the required accuracy when turning or milling. When it comes to the rotary axes, the Altenmarkt developers rely entirely on the torque motors from IDAM, which also have a number of other products from the Schaeffler Group such as bearings or linear guides entail.

The machining centers from Alzmetall are characterized by their extremely high static and dynamic rigidity, which enables the required accuracy when turning or milling. When it comes to the rotary axes, the Altenmarkt developers rely entirely on the torque motors from IDAM, which also have a number of other products from the Schaeffler Group such as bearings or linear guides entail.