with future potential

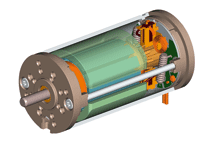

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

We present you the most modern Motor Technology for the Industry, including drives such as synchronous motors, asynchronous motors, gear motors, direct current motors, DC and BLDC, stepper motors, etc. for your cost-conscious design. The Electric motor for Machinery and equipment must be efficient, powerful, compact and quickly available.

Contents

Industrial motors are of very high quality. The conditions of use are very different. A drive in the mobile work machine must withstand the harsh environmental conditions, the gear motor in the Food industry or Medical Technology however, has many requirements to meet. The electric motor for Industry 4.0 should networkable . Energy Efficiency and compactness are always the order of the day. The brushless DC motor BLDC and the DC motor in 12V or 24V meet global requirements with mass suitability.

Below you will find motor innovations from Koco Motion, Minebea Mitsumi or Nord Drivesystems, among others. Regardless of what term they are called, be it gear motor, electric motor, AC, DC motor: they should all have one thing in common: long Lifespan at best Perfomance. Here are the novelties:

Siemens completes the range of "Simotics FD" low-voltage motors and now covers a power range from 200 to 1600 kW and shaft heights from 315 to 450 mm. The motors are optimized for converter operation and are particularly energy-saving in the partial load range. In combination with Sinamics low-voltage converters, they form an integrated drive system (IDS) and achieve system efficiency class IES2. Compared to the reference system of the standard, this means a reduction in losses of 35%.

Siemens completes the range of "Simotics FD" low-voltage motors and now covers a power range from 200 to 1600 kW and shaft heights from 315 to 450 mm. The motors are optimized for converter operation and are particularly energy-saving in the partial load range. In combination with Sinamics low-voltage converters, they form an integrated drive system (IDS) and achieve system efficiency class IES2. Compared to the reference system of the standard, this means a reduction in losses of 35%.

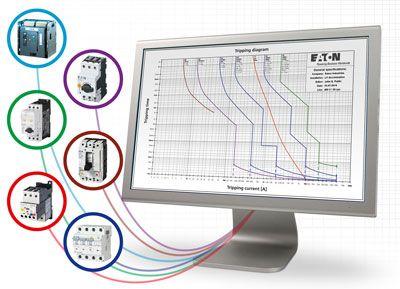

Eaton has updated and expanded the functionality of its free "Curveselect" software tool, which now also includes the adjusted characteristics of the "IE3 ready" motor protection switch. With the characteristic program, tripping characteristics of protective devices can be conveniently visualized, compared and documented. Curveselect enables users to competently assess the interplay between different Eaton devices and Eaton components in combination with other manufacturers' protective devices.

Eaton has updated and expanded the functionality of its free "Curveselect" software tool, which now also includes the adjusted characteristics of the "IE3 ready" motor protection switch. With the characteristic program, tripping characteristics of protective devices can be conveniently visualized, compared and documented. Curveselect enables users to competently assess the interplay between different Eaton devices and Eaton components in combination with other manufacturers' protective devices.

Without a rare earth one Efficiency of 97% achieve? That works with the alternative motor winding in the three-phase asynchronous motor (DAM) and three-phase generator, which the company Environmental technology marketing on the Trade press days 2020 has presented. These motors get by without permanent magnets.

The new 63 mm motor from Bühler is the latest in a series of brushed permanent magnet DC motors. It combines high performance, quiet operation and long life with a flexible design for easier integration into a wide variety of drive systems. By using the latest magnetic technology based on inexpensive ferrite magnets in combination with an optimized design of the magnetic circuit, the 12-part armature structure guarantees maximum power density. Optimized for maximum copper filling anchor plate section and the use of particularly low-loss material allow maximum torque while optimally utilizing the available space.

The new 63 mm motor from Bühler is the latest in a series of brushed permanent magnet DC motors. It combines high performance, quiet operation and long life with a flexible design for easier integration into a wide variety of drive systems. By using the latest magnetic technology based on inexpensive ferrite magnets in combination with an optimized design of the magnetic circuit, the 12-part armature structure guarantees maximum power density. Optimized for maximum copper filling anchor plate section and the use of particularly low-loss material allow maximum torque while optimally utilizing the available space.

The new generation of DST high torque motors in sizes 135 to 400 from Baumüller is now also available with a hollow shaft or integrated thrust bearing in addition to the solid shaft version. The different versions of the DST motors provide more degrees of freedom in the design and enable the motor to be optimally integrated into the machine concept.

The new generation of DST high torque motors in sizes 135 to 400 from Baumüller is now also available with a hollow shaft or integrated thrust bearing in addition to the solid shaft version. The different versions of the DST motors provide more degrees of freedom in the design and enable the motor to be optimally integrated into the machine concept.