Integrated wheel hub motor for driverless transport systems

- Details

- Hits: 3434

Framo Morat and MinebeaMitsumi present their jointly developed hub motor. This is a highly integrated wheel hub drive that offers above-average performance in the tightest of spaces. Due to its compact design, the modular and scalable drive is ideal for use in driverless transport vehicles or automated guided vehicles.

07.11.2022 | the logistics industry is in Germany behind the Automotive industry one of the largest sectors of the economy. The new challenges today include sustainability, climate neutrality, a shortage of skilled workers, transport bottlenecks, the energy transition and same-day delivery. These requirements are met with the use of artificial intelligence (AI), big data and the Industrial Internet of Things (IIoT). Automation and contribute to higher efficiency.

The heart of driverless transport systems are the Automated Guided Vehicles (AGV) and the Automated mobile robots. Both have become indispensable in modern logistics and are becoming more and more compact. Therefore, they primarily require compact yet powerful components.

BLDC motor for smooth running and long runtime

BLDC motor for smooth running and long runtime

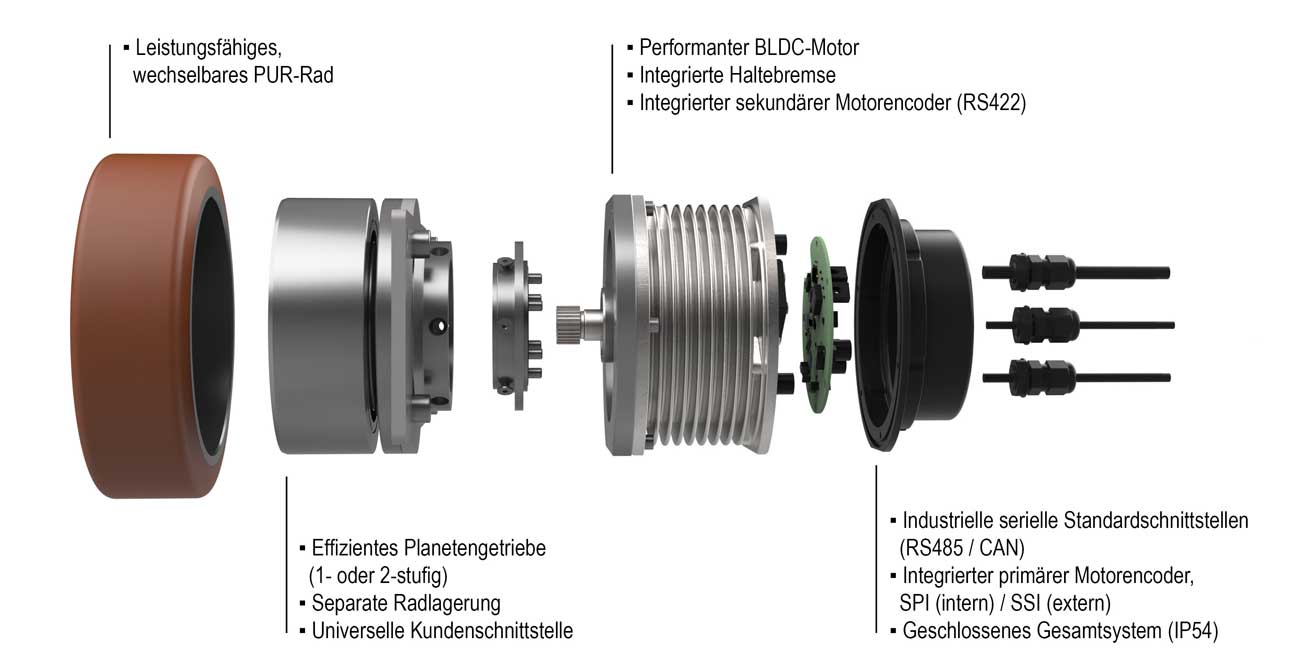

Framo Morat GmbH and MinebeaMitsumi Technology Center Europe GmbH (MTCE) are now presenting their innovative wheel hub motor, which they have optimized for driverless transport vehicles. The hub motor is predestined for applications that require high performance in the tightest of spaces. The new wheel hub motors are All-inclusive power packs and combine all functional elements such as running wheels, with high precision planetary gear, powerful electric motors, Brake and Electronics in one compact unit. Adjustments in terms of payload, torque, interfaces, sensors and steerings profiles are easily possible thanks to the modular and scalable electric motor system.

Wheel hub motor with high power density

The combination of bike and Transmission from Framo Morat and motor, brake and electronics from MTCE enables the above-average power density. Due to the high level of vertical integration in the components, motors winding and assembly, the cooperation partners short delivery time Offer. Thanks to the space saved in the drive, the vehicles can either be made smaller or equipped with larger batteries, which in turn extend the running time.

The wheel hub motor is available for two basic payload ranges: A standard payload of 250 to 500 kg per axle and 500 to 1000 kg are possible. For the smaller payload comes the BLDC motor 65 and that hub gear NG250 is used, for the larger the BLDC 85 and the NG500. The high radial loads of the wheel hub motors are realized with constantly high acceleration and speed. In addition, they score with a long service life, which is made possible, among other things, by the constructive separation of gear and impeller.

The modular design makes the wheel hub drive extremely maintenance-friendly. The intelligent one Plug-and-play Wheel hub motor can optionally be equipped with sensors to control central parameters. Thanks to standard interfaces such as RS485 or CAN, holistic drive control as an e-axle is possible. Customizations are also offered.

You might also be interested in...

Artificial Intelligence | trends and developments

smart city | Mega buildings, infrastructure, technologies

Load cell, weighing electronics, industrial scales from Minebea Intec

MinebeaMitsumi | Precision as a drive

Planetary gear | for numerous applications