Diondo uses Igus components in CT for marine research

- Details

- Hits: 8385

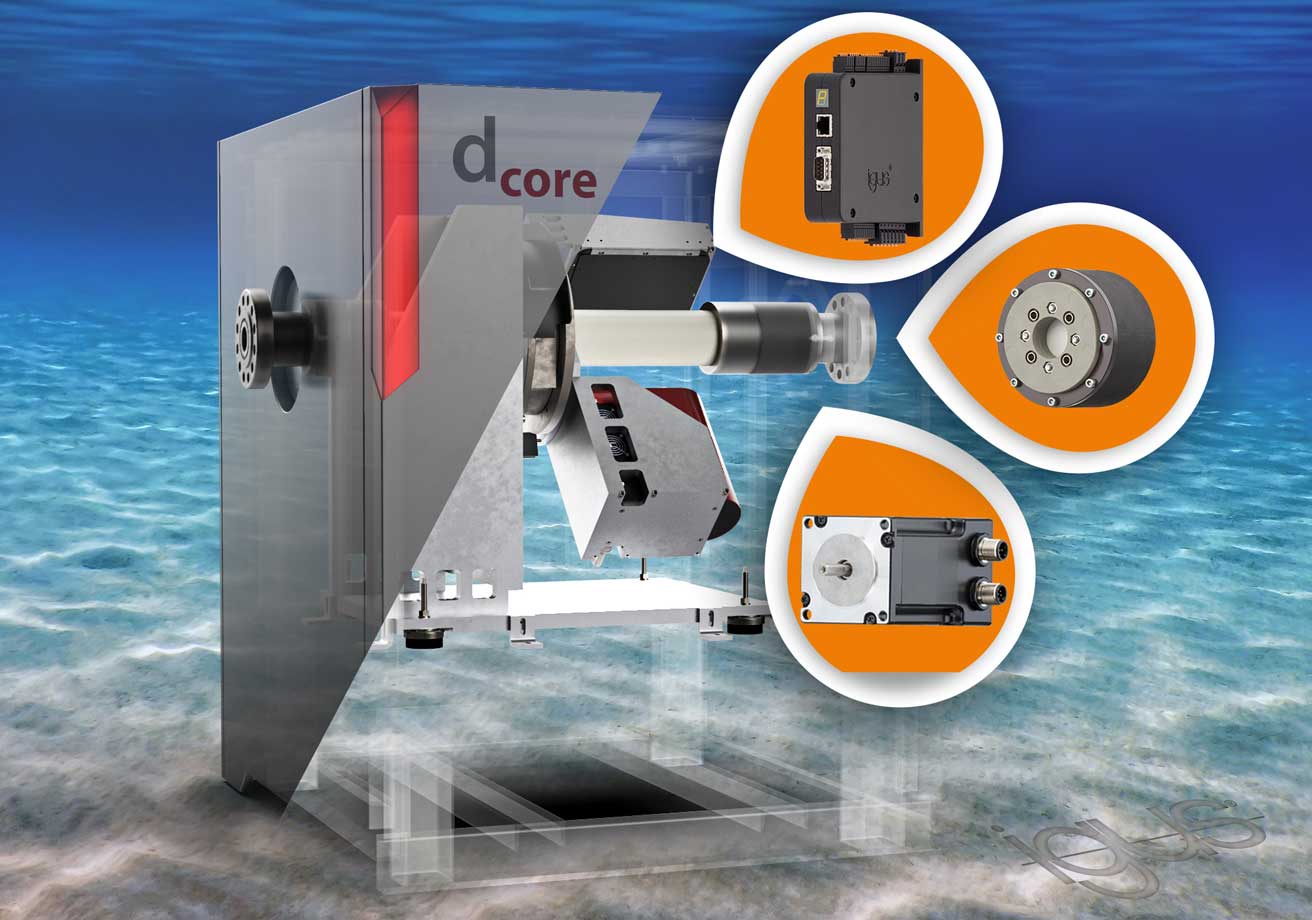

Developed for the analysis of drill cores from the seabed on a Chinese drilling platform Diondo an Computed tomograph of a special kind. The Hattingen specialist relies on non-destructive material testing and metrology Motor Components of Igus. You can find out here what makes drive and control so successful in use:

Contents

Contents

- Who is Diondo?

- Components from Igus

- Recognize even the finest structures in the sedimentary rock

- Gas hydrates as the energy source of the future

Who is Diondo?

Diondo is a leading manufacturer and service provider for system and software solutions for non-destructive material testing and metrology with worldwide applications. The X-Ray specialist from Hattingen has been building computer tomographs (CT) for the implementation of unusual industrial applications for 25 years. "Routine never comes back, every customer inquiry is a challenge," says Sebastian Maas, Head of Product Engineering at Diondo GmbH.

“A few months ago, we received an order from Chinese researchers to develop a computed tomography system. On a Drilling platform are to be used to analyze drill cores from the seabed, ”says Mr. Maas, describing the interesting application. This is anything but a routine job, because the requirements were very specific.

The whole world of igus robots

The whole world of igus robots

“The system should be able to withstand a salty atmosphere, high humidity, fluctuating temperatures and vibrations. It should also be compact enough to fit into a shipping container, including its peripherals. Now Diondo had to have one special because of the tight research budget cost-optimized solution Find."

Components from Igus

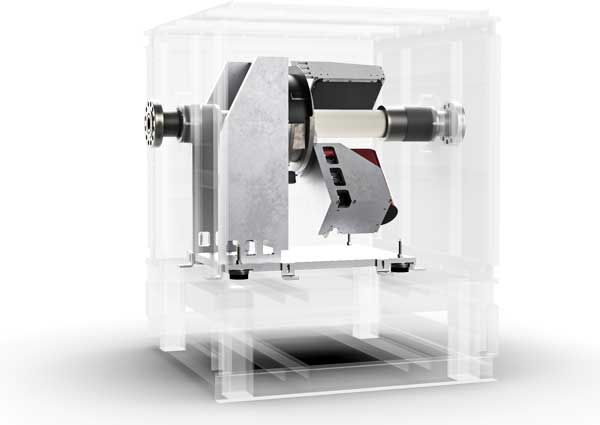

Sebastian Maas started looking for cost-effective components for the with a comprehensive catalog of requirements Computed tomograph. In industrial CT systems, the sample, which is clamped in a manipulator, usually moves. The movement takes place over up to seven axes between an imaging system consisting of an X-ray source and a detector.

Sebastian Maas started looking for cost-effective components for the with a comprehensive catalog of requirements Computed tomograph. In industrial CT systems, the sample, which is clamped in a manipulator, usually moves. The movement takes place over up to seven axes between an imaging system consisting of an X-ray source and a detector.

Drylin stepper motors save installation space

However, the system manufacturer was unable to implement such a structure because of the unstable sample. The solution promised a construction similar to one Medical technology CT. In such a computer tomograph, the X-ray source and X-ray detector rotate around the drill core.

And this is where the motion plastics specialist Igus from Cologne came into play for the first time: To implement this rotation, the designers at the CT manufacturer Diondo have a Robotic joint of Robolink series used by Igus. In the plastic case were a worm gear and Rotary table bearings Iglidur PRT integrated.

That is a maintenance free one polymer bearingswhich works without lubricants. The bearings is very flat and takes up little space. It is also resistant to dust, dirt and moisture. This makes the polymer plain bearing suitable for use on a drilling platform in the sea.

An electric one stepper motor of the series Drylin from Igus takes over the Power Type. “The motors are compact and resistant to harsh environments. We can deliver the protection class IP68 ”, says Markus Ziermann, Project manager for electrical drive technology. "This makes them perfect for use in this special CT system, the central functional unit of which is only 1,4 m long, 1,3 m wide and 1,5 m high."

Diondo saves time with motor control from Igus

Thanks to the Dryve D1 Motor Control can the Motor easy to program. That saves time. The developers call up a user interface on a PC, tablet or smartphone with a web browser using an IP address. Parameters such as feed rate and travel distance can be changed here.

Water-cooled electric motors: compact, powerful, quiet

Water-cooled electric motors: compact, powerful, quiet

“The central simplification of the engine control lies in the driving profiles, which changeable live are ”, explains Ziermann. “So the user can save a time Automation without transferring and loading processes. ”In addition, live values such as speed, motor current as well as the actual and target position can be displayed. Last but not least, the motor control reduces the project costs. “We were looking for an inexpensive alternative to a PLC steering wanted, which, including the licenses, can cost around 12.000 euros. The Dryve D1, on the other hand, only costs 338 euros. "

Recognize even the finest structures in the sedimentary rock

The designers have programmed the motor of the CT system in such a way that the detector and X-ray source become one during the examination 270 ° rotation around the drill core carry out. Up to 7.300 measurements take place here per revolution. With every measurement, X-rays penetrate the drill core.

The designers have programmed the motor of the CT system in such a way that the detector and X-ray source become one during the examination 270 ° rotation around the drill core carry out. Up to 7.300 measurements take place here per revolution. With every measurement, X-rays penetrate the drill core.

Depending on the density of the material, the rays are attenuated to different degrees. Using the attenuation images, an algorithm generates 3D sections. In the Tomograms areas of material with high density appear light, areas of low density appear dark. “The resolution is 1.920 by 1.536 pixels with a pixel size of 128 micrometers. On these 3D representations, the researchers recognize even the finest structures in the sedimentary rock. "

Gas hydrates as the energy source of the future

Diondo's computer tomograph will go into operation at the end of 2020. It supports the researchers in analyzing the structural Sedimentary rock build-up in the seabed. But why is that necessary? So-called gas hydrates occur in the sea floor. These are crystalline solids with trapped methane. They are among the possible energy sources of the future.

However, caution is advised when it comes to funding. Uncontrolled mining could be catastrophic, for example if the sea floor slides on a slope and causes a tidal wave. To prevent this from happening, researchers are evaluating the Gas hydrates and their structure. “The CT images are important input variables for a Simulation the flow when the hydrates are transported in the sedimentary rock, ”explains Sebastian Maas.

Computer tomograph planned for education and research

Products such as the motor control from Igus continue to develop in joint projects: this also shows Cooperation between Diondo and Igus. "We immediately implemented the design engineers' wishes in updates," says Markus Ziermann. "In this way we were able to control digital inputs and outputs via the BUS system and save a separate I / O module."

Drive technology increases efficiency in wave power plants by 80%

Drive technology increases efficiency in wave power plants by 80%

And so it is not surprising that Diondo will continue the cooperation. The company plans, among other things, inexpensive CT systems for education and Research. "The robustness, the problem-free integration into the system concept and the excellent price-performance ratio were decisive for the cooperation with Igus", sums up Mr. Maas. "The experience is so good that we will also use the Igus motor control in future CT systems."

Igus exhibits at the Hannover Messe 2021.

You might also be interested in...

Sustainability plastics – CO2 neutral with recycling

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.

linear guide | Precise, light, durable

The author Oliver Cyrus is Head of Press + Advertising at igus GmbH in Cologne.