Industrial connector for long distances in transport systems

- Details

- Hits: 5840

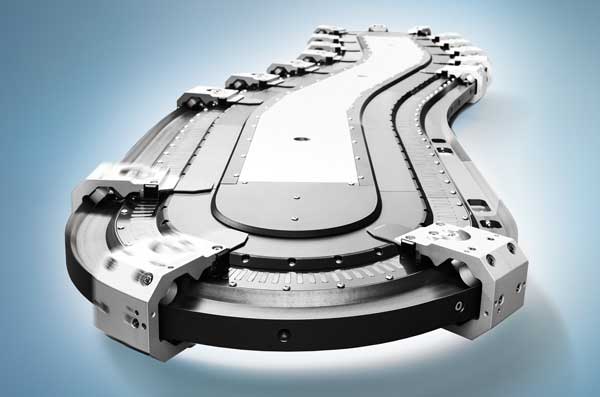

The intelligent one XTS transport system from Beckhoff combines the advantages of linear and rotary drives. It creates completely new possibilities for flexible machine concepts. Of the Connectors IX Industrial from Harting enables a double number of ports in this transport system. In this way, long distances can be realised. A report on innovative product transport, the potential of clever Ethernet interfaces and a webinar on July 1, 2020.

Contents

- Secret of the fast transport system

- The XTS is made up of three main components

- Industrial plug turns 12 into 24 ports

The XTS transport system from Beckhoff enables individual and continuous product transport. It works almost maintenance-free, has a modular structure and is ready for use with a minimum of parameterization.

Secret of the fast transport system

Core of the eXtended Ttransport Systems is a Replacement of common drive components. In most conventional linear drives, electrically connected movers usually travel on static magnetic rails. In the XTS system this happens exactly the other way around. The static one Linear motor, a parallel guide rail and the passive mover represent the three main components.

Core of the eXtended Ttransport Systems is a Replacement of common drive components. In most conventional linear drives, electrically connected movers usually travel on static magnetic rails. In the XTS system this happens exactly the other way around. The static one Linear motor, a parallel guide rail and the passive mover represent the three main components.

The concept makes the transport system the first Linear drive that goes around in a circle. With independent passive slides that do not require any data or power supply via drag chains or sliding contacts, the movers can travel straight and curved paths. This enables closed, efficient cycles to be formed. While linear systems usually cover work and passive travel, the movers reduce idle travel in one cycle.

The XTS is made up of three main components

The motor forms a fully integrated unit Power electronics and position detection. Controlled solenoid coils set a passive mover in motion through a double air gap. The motor gives the movers speeds of up to 4 m / s with precise positioning on straight lines or in curves.

For correct guidance, the motor modules are fitted with suitable Guide rails combined. The slides can be moved inside or outside on the radii.

The MOVER forms the third component. It has the necessary magnetic plates that generate the propulsive force with the motor module. Thanks to the clever geometry and opposing magnetic field exciters, hardly any driving forces act on the bearings, even in force-intensive applications. This saves storage and energy for the drive.

The Applications there are hardly any limits to the XTS transport system. The movers accelerate, brake, position and synchronize. They can also position themselves relative or absolute to one another, group, accumulate or generate clamping forces in motion. You are driving just as fast as you are driving through the curve. They also recover energy through regenerative braking and use the outward and return routes for transport. All these processes are position-regulated, vibration-free, backlash-free, without material fatigue, very low-wear and maintenance-free.

While conventional transport systems require maintenance-requiring conveyor belts, chain drives, bearings, sliding contacts and trailing cables, the XTS works with one Minimum mechanically moving parts.

Transport flexibly and safely

The Format adaptation changing products is much easier with the new transport system. Only the finished engine parts and rails need to be reconfigured to rebuild the transport route. If parameters change on the same route, all that is required is a simple change to the software parameters.

Miniature connectors for safe signal transmission

Miniature connectors for safe signal transmission

In conventional transport systems, the drive takes place via Chains, straps or ribbons. Long stretches of transport media are often mechanically linked. Of the Power Type has to raise the total force for the sum of all individual forces of the funding. If there is a malfunction or a collision, the total force of the entire system acts on one point. Such forces quickly lead to serious destruction. The XTS works always only the individual force of a mover, which is significantly lower in each case. This greatly increases operational reliability.

Features of the linear motor

With this Linear motor result in the following Advantages for drive technology:

- Linear motor properties even on a closed track

- several movers on a common route

- modular structure, easy adaptation to the application

- low energy and space requirements

- simply implement demanding transport tasks

- low effort for project planning and assembly

Three computer cards combined with one another

The movers follow their schedule movement patterns on the track, by unlocking, braking, clamping, releasing, etc., the control calculates the switching and energization of the relevant motor modules. For this purpose, three computer cards can be combined with each other with XTS.

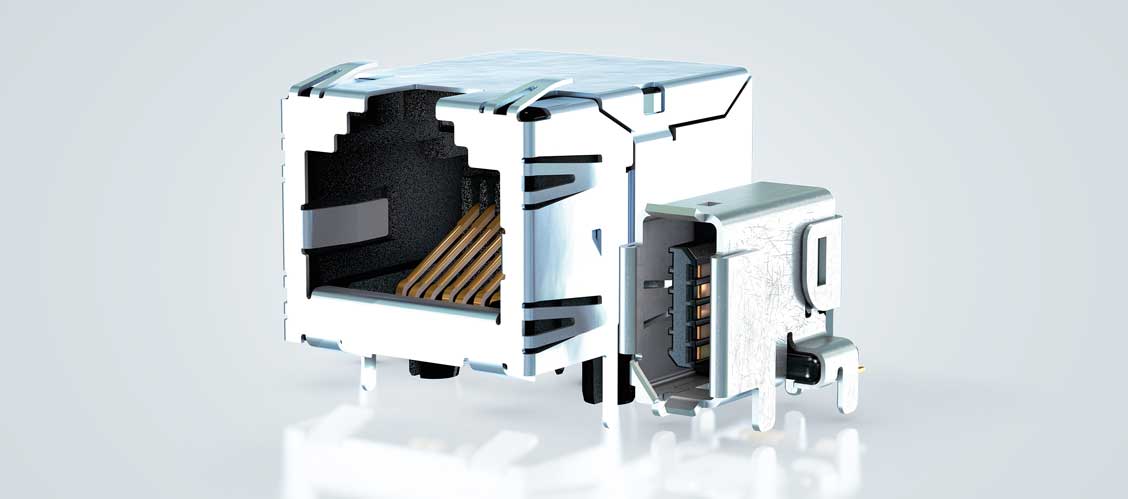

Up to now they each had four RJ45 sockets as ports. A length of the Motormodule of 1,5 m controlled. Even if the requirements regarding the complexity and size of the transport tasks increase, the compact dimensions of the individual components should be retained. Here came Harting with its IX Industrial Ethernet Connectors in the game.

Energy efficient radio network for AGVS in intralogistics

Energy efficient radio network for AGVS in intralogistics

The industrial connector in the device is at least half as large as RJ45 interfaces. However, the connector is much more robust and equipped with a stable metal lock. The 5000 possible mating cycles are irrelevant for Beckhoff with the XTS, but they underline the robust design of the industrial connector.

The power transmission takes place via PoE / PoE +. It is just as secure as the reliable hold on the circuit board thanks to several THR shield contacts. The IX interface, standardized according to IEC 61076-3-124, is not a specialized island solution, but an open standard. For Beckhoff, only a standardized solution was possible.

Industrial plug turns 12 into 24 ports

In addition to the large space savings per port and the more robust interface, there were above all one reliable shielding and very good data transfer rates are important for Beckhoff.

Single Pair Ethernet | for IIot and Industry 4.0

Single Pair Ethernet | for IIot and Industry 4.0

With the small designs of 1/10 Gbit / s Ethernet Interfaces, it is always a particular challenge to minimize crosstalk between individual data pairs with very close contacts. One between the two rows of contacts hidden shielding effectively prevents crosstalk. The IX Industrial connector has ten contacts, eight of which transmit data and two contacts on the circuit board are connected to the ground potential. These serve as further shielding.

Due to the shield plate and the grounded contacts, the arrangement of the signal-carrying contacts in the industrial connector is similar to that of an X-coded M12 connector. Each wire pair is well shielded from its neighbors in its own cable or Connectors Quadrant. The protects against crosstalk and thus a perfect data transfer is implemented.

The particularly good shielding has been used for the XTS system. Two 100 Mbit Ethercat connections are implemented for each IX industrial connector.

Altogether it could be on the same circuit board eight instead of four ports installed and two instead of one EtherCAT channel per port. Calculated on three circuit cards, this results in 24 ports with 48 EtherCAT strings instead of the previous twelve.

Connectors for the three zones of the food industry

Connectors for the three zones of the food industry

This allows routes with a length of up to 100m realize. The potential of the miniaturized and powerful Ethernet interfaces for IIoT and Industry 4.0 So applications is enormous.

Live webinar on the transport system and industrial connector

Harting is holding a live webinar on the subject on July 1st at 11 a.m. with the motto This is how Beckhoff masters the challenges of miniaturization: Harting IX Industrial meets XTS. Ask the experts as part of the Harting Experts Camphow IX Industrial provides a great benefit in the XTS application. You can also optimize your application with miniaturized connectivity.

You might also be interested in...

industrial housing | Indoor and outdoor control boxes

Electrical Wires | From cable to assembly

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

Reduce carbon footprint | That's how it's done!