Connectors for modular energy storage in Smart Grid

- Details

- Hits: 6747

A power supply based on renewable energies requires electrical storage capacity to compensate for voltage fluctuations in the grid due to fluctuating generation from sun and wind. Electricity storage systems increase flexibility here. Harting supplies the necessary interfaces for a modular structure for the storage cabinets of high-performance storage systems.

A power supply based on renewable energies requires electrical storage capacity to compensate for voltage fluctuations in the grid due to fluctuating generation from sun and wind. Electricity storage systems increase flexibility here. Harting supplies the necessary interfaces for a modular structure for the storage cabinets of high-performance storage systems.

Electricity storage systems reduce surpluses on the generation side and thus relieve the grid. On the load side, they help to cover short-term peak demand. Thus, a higher degree of utilization of (decentralized) generation facilities is achieved and the reliability of the network is increased.

The storage systems are integrated into the intelligent network management "Smart Grid" via an efficient communication infrastructure. They have a modular design so that they can be flexibly adapted to different generation capacities and configured redundantly. In this way, individual modules can be exchanged in the event of a failure without interrupting the operation of the entire system.

Powerful storage systems usually consist of several storage cabinets, which are arranged modularly to containers and contain inside drawer-shaped storage units. Harting connectors provide the necessary interfaces for the modular design: They are easy to assemble, facilitate service and thus help to limit downtimes.

Process-safe push-in contact

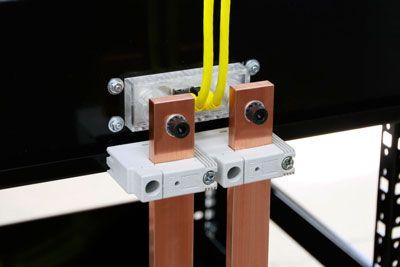

The core of the solution is the “Han Docking Frame” in conjunction with the “Han-Modular” modular connector series. The docking frame ensures reliable and process-safe plug-in contacting of the storage units. The manufacturer’s solution is an example Rittal. The storage cabinet drawers are equipped with two Han 200 A modules for power transmission, supplemented by two Han Megabit modules for data exchange.

The core of the solution is the “Han Docking Frame” in conjunction with the “Han-Modular” modular connector series. The docking frame ensures reliable and process-safe plug-in contacting of the storage units. The manufacturer’s solution is an example Rittal. The storage cabinet drawers are equipped with two Han 200 A modules for power transmission, supplemented by two Han Megabit modules for data exchange.

The Han Docking Frame is floating between the drawer and the power rail. It offers sufficient tolerance compensation so that the pins on the drawers can be inserted safely and smoothly onto the sockets of the Han 200 A module (guided insertion). The sockets are screwed directly onto the power rail on the cabinet rear wall, which reduces the cabling work for the storage cabinet.

The Han Docking Frame is the standard for energy storage systems. In addition to the high-current module, the Han-Modular 50 program provides further suitable interfaces. The docking frame is available in versions with room for 2 to 6 modules. Depending on the requirements, the modules, which are mounted in a Han-Modular hinged frame, can be integrated into the drawer system of the storage. The modular program includes power modules up to 200 A, high-poled signal modules, all known Ethernet interfaces as well as other robust communication interfaces.

Wiring costs are eliminated

Due to their modularity, battery storage systems are well scalable. Use of the Han Docking Frame increases the standardization of battery storage cabinet construction. Pre-assembled memory modules can be quickly assembled into memory cabinets, eliminating the wiring effort.

Due to their modularity, battery storage systems are well scalable. Use of the Han Docking Frame increases the standardization of battery storage cabinet construction. Pre-assembled memory modules can be quickly assembled into memory cabinets, eliminating the wiring effort.

There are also advantages for installation in the field. Hard wiring is still a frequently used alternative to the docking frame. It is very complex, especially with larger quantities. A modular one Battery storage usually achieves outputs between 1 and 3 MW. Each 1 MWh storage capacity requires around 80 drawers. The plug-and-play solutions in connection with the Han Docking Frame make work considerably easier. And the frame also helps save working time after installation: replacement and maintenance of the storage units become easier. Even employees who are not qualified electricians can easily replace the storage elements, as no installation work is required.

Energy storage is a key element in the strategy for reducing and avoiding CO2Emissions. In addition, trends in modularisation and decentralization can be observed in all sectors involved in energy production. Decisive for the market acceptance of the storage systems will be their technical and financial feasibility: The scalability of the systems on the basis of suitable interfaces is therefore an important building block for their commercialization.

Battery storage systems are coupled to energy generation systems. To be as efficient as possible, they have to communicate extensively with the other components of the energy generation and distribution system. Here the Harting portfolio offers additional components that can contribute to a holistic solution: switches in combination with pre-assembled patch cables ensure the external communication of the energy management system. Current sensors make it possible to monitor the quality of the electricity, for example on inverters. To control inverters and storage systems, printed circuit boards are used that ensure communication with other components. For this connection of the internal brain of a battery storage system z. B. PCB connectors of the series "Har-Flexicon" and "Har-flex" reliable options.

The author is Ingo Siebering, Energy Industry Sergment Manager, Global Business Unit Electric at the Harting Technology Group.

You might also be interested in...

industrial housing | Indoor and outdoor control boxes

Electrical Wires | From cable to assembly

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

Reduce carbon footprint | That's how it's done!