Battery storage systems are worthwhile in the stress test

- Details

- Hits: 5808

Weiss environmental technology has a special at the EU's research center, the Joint Research Center (JRC) test for lithium worthwhile storage planned and implemented. Of the Battery storage Test bench with high energy density allows for the first time CT recordings during the operation of the Batteries under stressful conditions.

The main environmental influences on the battery in Electric Cars, E-bikes, Solar power or photovoltaic system are heat, cold and moisture. The test system can be used to research how the batteries are used for Power storage change under environmental influences. The scientists at the JRC expect to be able to use the test results to improve the safety, service life and storage capacity of a battery storage system. The Development of EU standards is another goal of the battery storage test system.

Green hydrogen on the advance in Germany

Green hydrogen on the advance in Germany

Track chemical processes dynamically

In addition, the researchers want internal weak points of the battery storage with the help of Computed Tomography Find (CT) images. This allows the chemical processes within the battery storage to be dynamically tracked in the stress test.

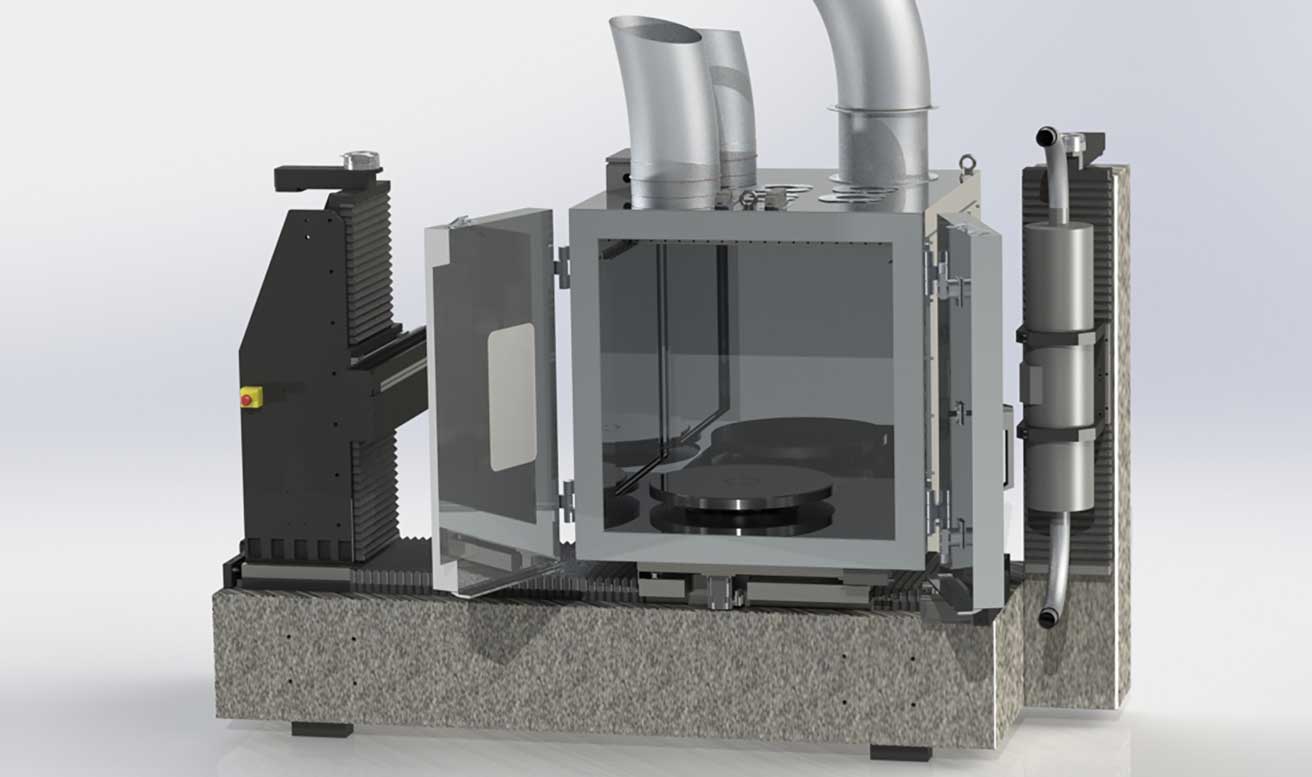

The external test room for battery storage is on one linear guide movable. This enables the CT images to be focused. In combination with a turntable is a 360 degree view the memory is possible during the stress tests. The battery storage systems are stressed beyond the usual load limits with extreme environmental conditions and simultaneous current load during the CT recording.

Hybrid regenerative energy generation from sun and wind

Hybrid regenerative energy generation from sun and wind

To protect the staff from the CT radiation, the external test room was built in a lead-sheathed installation room. Stressing the batteries can also lead to overheating, fire or even an explosion. In order to prevent an explosion, the test room has been built with protective measures for an Atex classification of zone 1.

Protective measures for battery storage test room

Weiss Umwelttechnik has the system with protective measures accordingly Eucar Hazard Level 6 fitted. The conditioning device is located outside the installation room that is not protected from the radiation. In order to avoid openings for escaping radiation, the supply pipes for air conditioning and piping for the gas discharge had to be led out of the lead-insulated room via a pipe labyrinth.

As a protective measure z. B. a permanent, oxygen-controlled Inerting implemented. In addition, only as much nitrogen is introduced as is necessary for safety reasons. Four different gas sensors monitor the test room. Two gas sensors inspect the lead-coated installation room so that leaks in the battery storage can be detected.

Seven good reasons for hydrogen propulsion and fuel cells

Seven good reasons for hydrogen propulsion and fuel cells

For the construction of the battery test bench in Petten, the Netherlands, the FraunhoferCompany commissioned. She also researched the material that allows the necessary permeability for the CT radiation and in return ensures the gas-tightness of the test room. Together with Diondo, specialist in industrial CT, Weiss Umwelttechnik planned and implemented the climatic part of the test system including all safety measures.