3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

Glass & ceramics for industry

Technical glass for displays or panes as well as high-performance ceramics, industrial ceramics, engineering ceramics or as a symbiosis of glass ceramics

Image: LPKF / Vitrion

plastics as an alternative

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

Metals for mechanical engineering

Steel, copper and precious metals, alloys or aluminum for lightweight construction as well as profiles, bent parts or laser parts for the development of new industrial goods

Image: HP Kaysser

Composites for new properties

High-performance compounds, natural fiber compounds, glass fiber reinforced plastics, thermoplastic composites and fiber composites

Image: Vienna University of Technology

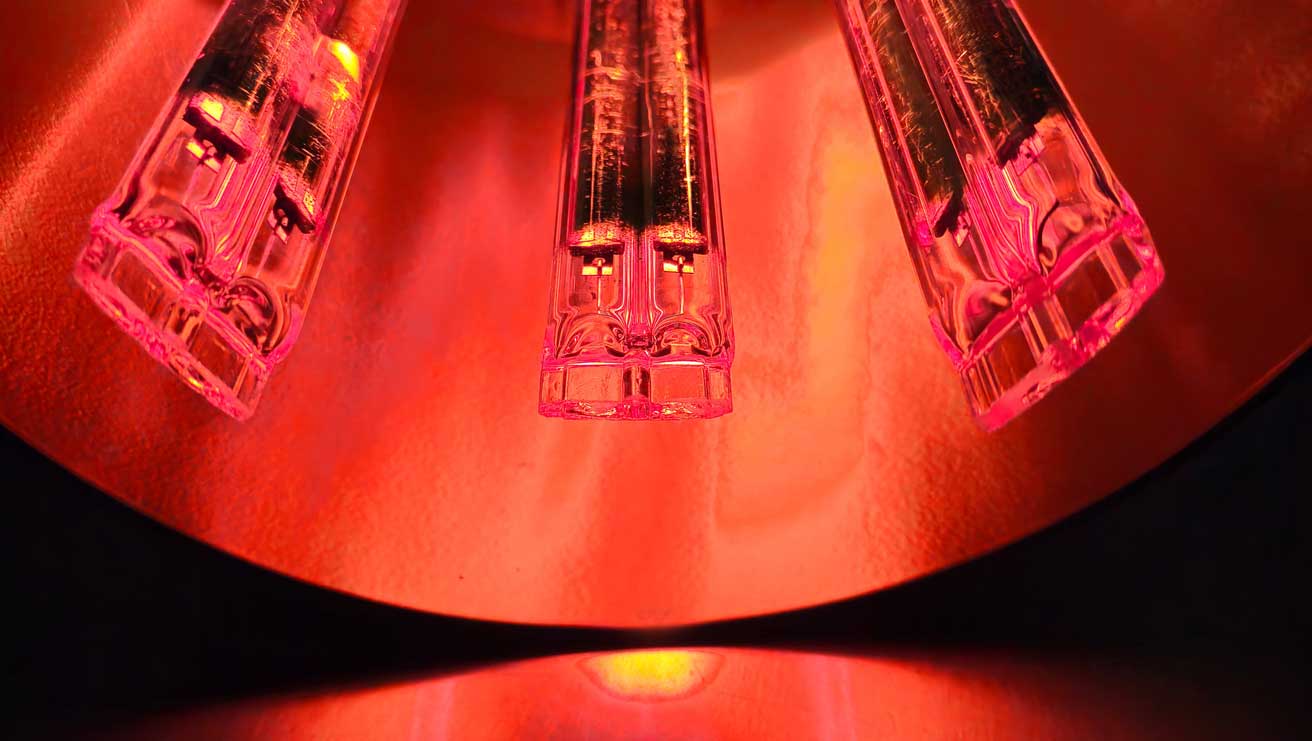

Surface technology for the coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

Here you will find modern new ones Materials, Technologies and Process for their treatment or processing for mechanical and plant engineering as well as many other branches of industrial production, including materials such as glass, ceramics, plastics, Metals and Composites as well as procedures like 3D pressure and Surface Technology.

Contents

The development of modern Materials and processes for industrial applications are decisively characterized by energy saving, lightweight construction, environmental protection and sustainability. Material developers and researchers work on the performance and cost efficiency of new materials. And so materials science and materials science are subject to constant change and new alloys of steel or innovative filaments for 3D printing are being created, for example. Of course, all these materials also have to be processed. In addition, we examine manufacturing processes, the processing of raw materials and technologies for shaping, etc.

The following materials and processes are for specific industries like that Automotive industry, Renewable energies, Technical Building Services, Medical Technology, Microsystems Technology been developed. You will also find new materials here, which Applied research has developed.

The engineering of the modern material goes hand in hand with an efficient process that can process it. That happens especially in Machinery and plant engineering to carry. We report below on both sides: Innovations of new materials and new processes for their processing:

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

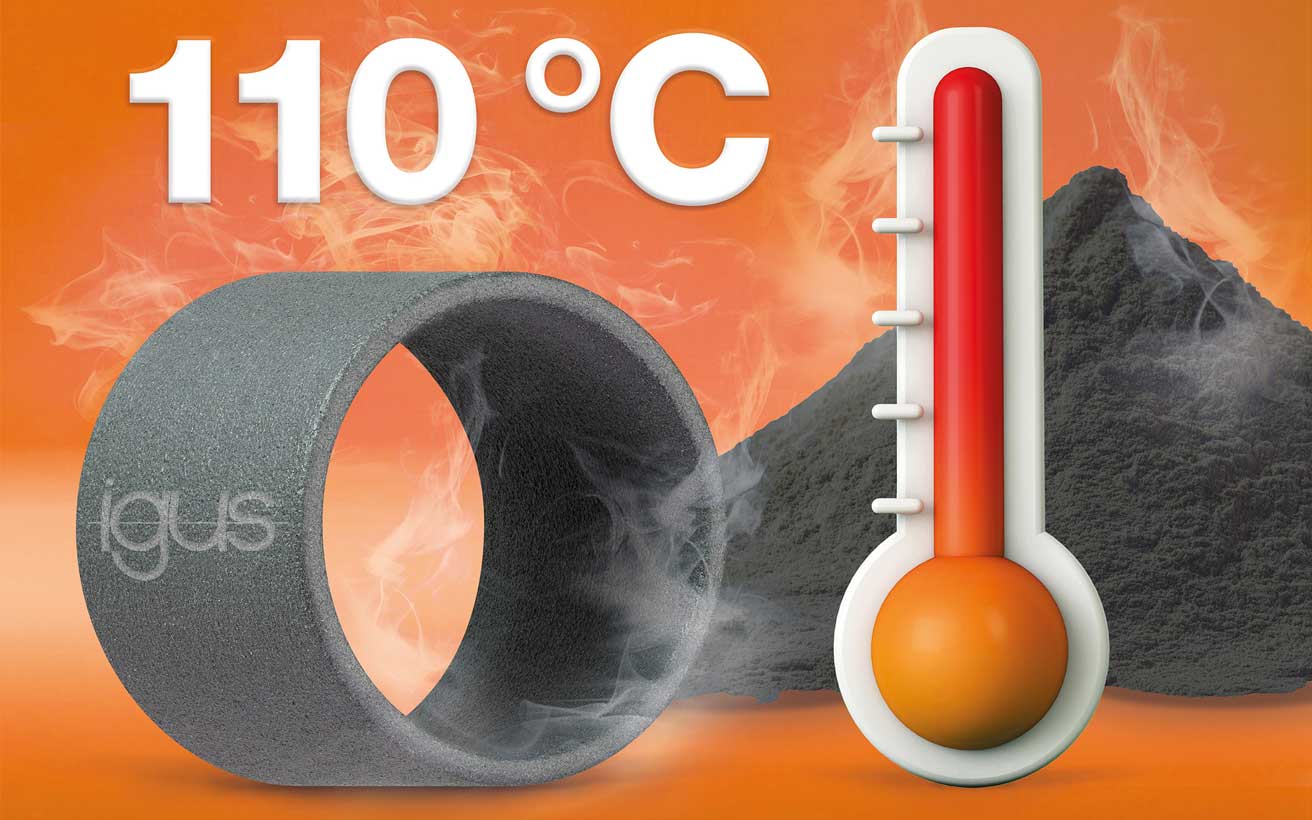

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

Infrared heater from Excelita's Noblelight play a crucial role in modern industry. With their ability to deliver heat precisely and efficiently, they optimize numerous industrial processes, from material processing until final production. Find out how Infrared Heaters Make industrial applications more efficient and of better quality and why they are considered a key technology for energy-efficient heating processes.

Plasmatreat has with his Openair plasma technology an innovative surface coating for Surfacespretreatment of Plastic, Metal or Glass developed. Due to its activation power, the Openair plasma increases the surface energy significantly. Two application examples illustrate the innovative development for plasma pretreatment.

Digitization and the associated changes in the manufacturing industry have also affected the area of laser-based manufacturing technologies. There are now more and more platforms like HP Kaysser Laserteile4you or Laserhub, on which one Bent parts and laser parts online can calculate and order. In the future now Artificial intelligence Assess the manufacturing process and improve real-time ordering. You can find out more about this in this article.

Has been building for a few years Igus the division for additive manufacturing with 3D Print, Filamentdevelopment & co. Brand new are a new one Lifetime Calculator for 3D printing parts and there is a 3D printing service for XXL parts up to 3 m in size. With 4K for 3D, the Cologne company offers one Multi-material printing for multifunctional components. These and all other innovations in additive manufacturing at igus can be found below:

Maintenance-free, lubricant-free, sustainably produced and rustproof sets the new urban bike from Igus new standards in sustainable mobility. The bike off recycled plastic will transport generations of people. On the Hannover Messe The plastic visionary had the new one in 2022 Igus: bike Platform presents the groundbreaking concept. Here you can follow the development to date.

For several years there has been a clear trend towards more Plastic recycling due to the worldwide increasing demands on a Recycling for plastic. Some industrial companies are already responding to this trend – and the trend is increasing. We report on their investments, strategies and innovations here.

3D printer at Igus also manufacture components with different filaments. in the 2-component printing Various material properties can be easily combined. For example, B. 3D printed components achieve particular rigidity and high wear resistance. The latest 3D printing materials are temperature-resistant Iglidur i230 for SLS or the resin Iglidur i3000 for DLP printing. The article introduces you to these and other new developments:

The Filaments and materials for 3D printing are constantly evolving. The current state of development indicates an increasing variety and higher performance 3D printer Materials, which last but not least meet the often robust requirements in industry. In addition to sustainability, the components must also be increasingly high-performing. In this article you will find out what is available and where the journey is going.

Whether additive manufacturing, generative manufacturing or rapid prototyping, components are manufactured in these processes on one 3D printer. Meanwhile he is 3D Print arrived a little further in the industry and is therefore also suitable for series and mass production. Here we present innovations and applications of 3D printers for plastics before:

For the resource-efficient use of Plastics develops that Fraunhofer Institute for environmental, safety and energy technology "prudence" new materials. The focus is on bioplastics, a circular plastics economy and strategies to reduce macro- and microplastics in the environment.

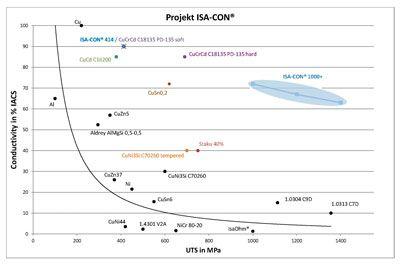

For certain tasks, wires with high electrical power are used conductivity and at the same time high strength properties are required. Wires made of pure copper, the best of all electrical conductors used industrially, are generally not suitable for this because their mechanical strength is too low. On the other hand, wires made from “ISA-CON” from Isabellenhütte, which optimally combines both properties, are ideal.

For certain tasks, wires with high electrical power are used conductivity and at the same time high strength properties are required. Wires made of pure copper, the best of all electrical conductors used industrially, are generally not suitable for this because their mechanical strength is too low. On the other hand, wires made from “ISA-CON” from Isabellenhütte, which optimally combines both properties, are ideal.

Machine beds are used as a stable base for the assembly and fixation of various machines such as metal cutting machines, machining centers or Robot deployed. The ones used for this Materials have individual properties that show their advantages depending on the application. The Mineral casting machine bed for example, is suitable for high-precision machines, for example. Below you will find new innovations for machine frames and beds.