3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

Glass & ceramics for industry

Technical glass for displays or panes as well as high-performance ceramics, industrial ceramics, engineering ceramics or as a symbiosis of glass ceramics

Image: LPKF / Vitrion

plastics as an alternative

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

Metals for mechanical engineering

Steel, copper and precious metals, alloys or aluminum for lightweight construction as well as profiles, bent parts or laser parts for the development of new industrial goods

Image: HP Kaysser

Composites for new properties

High-performance compounds, natural fiber compounds, glass fiber reinforced plastics, thermoplastic composites and fiber composites

Image: Vienna University of Technology

Surface technology for the coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

Here you will find modern new ones Materials, Technologies and Process for their treatment or processing for mechanical and plant engineering as well as many other branches of industrial production, including materials such as glass, ceramics, plastics, Metals and Composites as well as procedures like 3D pressure and Surface Technology.

Contents

The development of modern Materials and processes for industrial applications are decisively characterized by energy saving, lightweight construction, environmental protection and sustainability. Material developers and researchers work on the performance and cost efficiency of new materials. And so materials science and materials science are subject to constant change and new alloys of steel or innovative filaments for 3D printing are being created, for example. Of course, all these materials also have to be processed. In addition, we examine manufacturing processes, the processing of raw materials and technologies for shaping, etc.

The following materials and processes are for specific industries like that Automotive industry, Renewable energies, Technical Building Services, Medical Technology, Microsystems Technology been developed. You will also find new materials here, which Applied research has developed.

The engineering of the modern material goes hand in hand with an efficient process that can process it. That happens especially in Machinery and plant engineering to carry. We report below on both sides: Innovations of new materials and new processes for their processing:

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

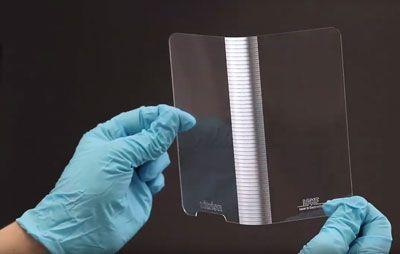

Current foldable displays are made of plastics and therefore tend to scratches, folds and premature failure. Conventional smartphone displays do not have these problems because they are made up of at least two layers of partially tempered glass. Due to the glass, these displays cannot be folded easily. With the "Lide" technology, LPKF presents a solution for this task.

Current foldable displays are made of plastics and therefore tend to scratches, folds and premature failure. Conventional smartphone displays do not have these problems because they are made up of at least two layers of partially tempered glass. Due to the glass, these displays cannot be folded easily. With the "Lide" technology, LPKF presents a solution for this task.

Rampf Tooling Solutions presents the brand new flame retardant plate "Raku Tool FP-0590". The semi-finished product made of polyurethane is certified according to the European fire protection class C-s2, d0, EN 13501-1 and UL94V0-2mm *. With its flame-retardant properties, it is particularly suitable for the production of interior fittings, wall cladding, ceiling and decorative elements as well as furniture.

Rampf Tooling Solutions presents the brand new flame retardant plate "Raku Tool FP-0590". The semi-finished product made of polyurethane is certified according to the European fire protection class C-s2, d0, EN 13501-1 and UL94V0-2mm *. With its flame-retardant properties, it is particularly suitable for the production of interior fittings, wall cladding, ceiling and decorative elements as well as furniture.

Electric drives open up new design options for vehicle bodies. With "Plexiglas Hi-Gloss NTA-5", Röhm Molding Compounds is presenting an impact-resistant special molding compound for black, high-gloss applications and at the same time robust components such as radiator grilles, ventilation grilles, decorative panels, mirror housings and pillar panels.

Electric drives open up new design options for vehicle bodies. With "Plexiglas Hi-Gloss NTA-5", Röhm Molding Compounds is presenting an impact-resistant special molding compound for black, high-gloss applications and at the same time robust components such as radiator grilles, ventilation grilles, decorative panels, mirror housings and pillar panels.

Hail-Tec is the first company in Germany to offer the ultrashort pulse method laser ablation (UKP laser ablation) as a service. With this high-tech variant of Material processing Laser pulses in the femtosecond range are used to manufacture high-precision workpieces. These meet even the highest demands in medical technology. The technical key figures of the ultrashort pulse laser alone are impressive.

Hail-Tec is the first company in Germany to offer the ultrashort pulse method laser ablation (UKP laser ablation) as a service. With this high-tech variant of Material processing Laser pulses in the femtosecond range are used to manufacture high-precision workpieces. These meet even the highest demands in medical technology. The technical key figures of the ultrashort pulse laser alone are impressive.

RIO has developed the new surface technology process "Betenio" for metal pretreatment, which offers significant advantages compared to the conventional processes of blasting and acid treatment.

RIO has developed the new surface technology process "Betenio" for metal pretreatment, which offers significant advantages compared to the conventional processes of blasting and acid treatment.

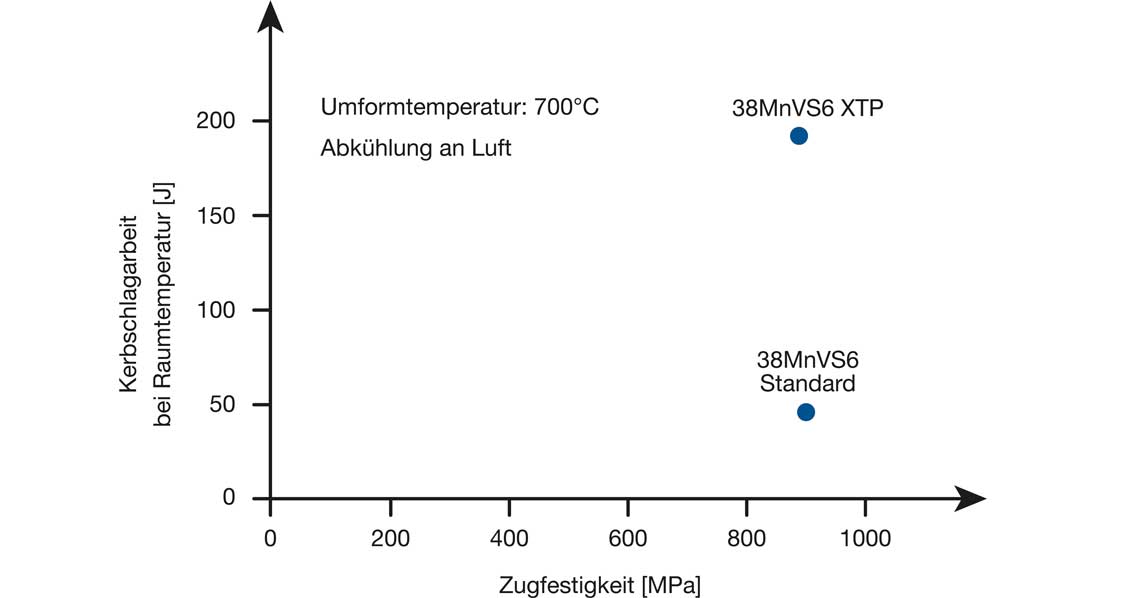

Steeltec (Schmolz + Bickenbach) opens up users of high-alloy steel now a solution that combines high performance with price stability. The subsidiary of the Schmolz + Bickenbach Group is turning its Xtreme performance Technology (XTP) on precipitation hardening ferritic-pearlitic (AFP) steels. The resulting fine grain increases the room temperature Impact strength by more than 50% up to 150 J with high strength.

Stainless steel naturally offers little chance of microbial colonization. But that's enough in the Health sector or at vending machines and counters in public spaces. Here effectively protects the antimicrobial coating from Sedlbauer. The special lacquer guarantees optically brilliant surfaces antibacterial, long-term resistant and gives germs no chance to settle.

TMD Friction develops and manufactures friction materials for industry and rail transport under the “Cosid” brand. The friction lining manufacturer is responding to the increasing specialization in rail transport with specially developed application-related product solutions. At InnoTrans 2010, the manufacturer will show that thanks to specialized engineers, its own development and test facilities and flexible manufacturing processes, it can specifically address the needs of rail transport.

TMD Friction develops and manufactures friction materials for industry and rail transport under the “Cosid” brand. The friction lining manufacturer is responding to the increasing specialization in rail transport with specially developed application-related product solutions. At InnoTrans 2010, the manufacturer will show that thanks to specialized engineers, its own development and test facilities and flexible manufacturing processes, it can specifically address the needs of rail transport.

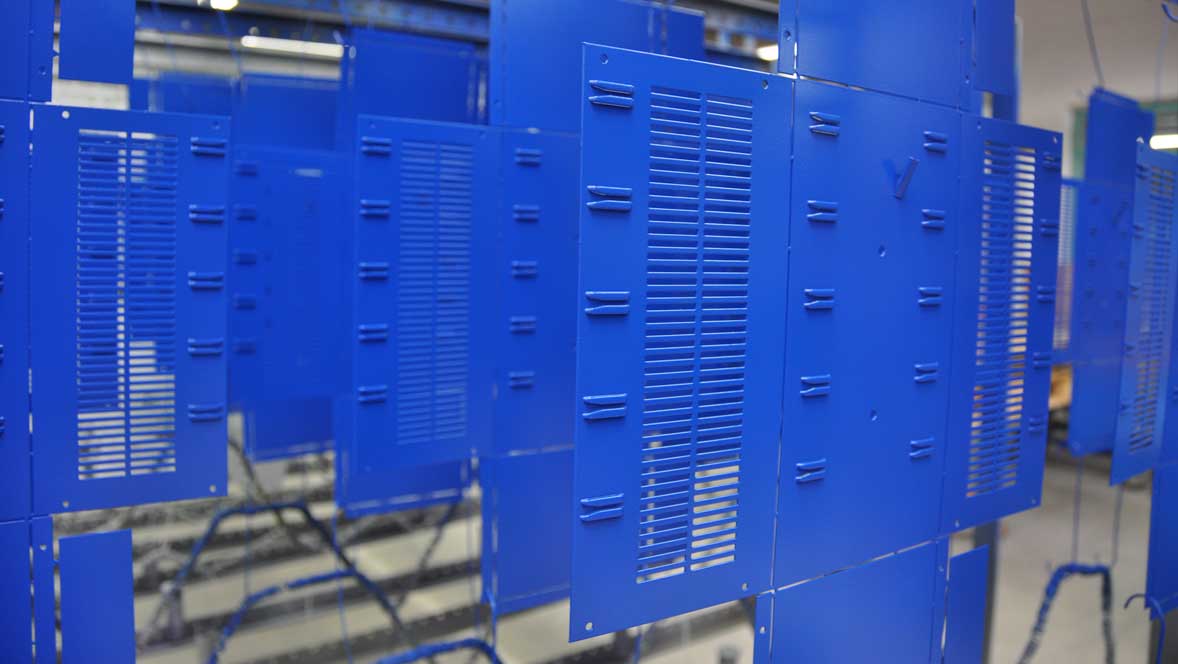

Benseler Sachsen GmbH & Co. KG shows the entire spectrum of its professional surface treatment and provides information on the processes of electrochemical metal processing, thermal deburring and wet painting. The wet paint coating for large-area plastic add-on parts such as spoilers in the automotive sector is one of the new surface coating processes. Since lighter components made of carbon fiber-reinforced plastics are increasingly being used in vehicle construction, the Saxon surface coater also has the necessary know-how for this.

Benseler Sachsen GmbH & Co. KG shows the entire spectrum of its professional surface treatment and provides information on the processes of electrochemical metal processing, thermal deburring and wet painting. The wet paint coating for large-area plastic add-on parts such as spoilers in the automotive sector is one of the new surface coating processes. Since lighter components made of carbon fiber-reinforced plastics are increasingly being used in vehicle construction, the Saxon surface coater also has the necessary know-how for this.

Wolfensberger is pressing ahead with the development of a molding and casting process for the manufacture of thin-walled cast steel parts. This could set the course for securing future competitive strength in sand casting. The aim of the new process is to manufacture cast steel parts using the sand casting process with wall thicknesses from 2 mm, which offer new and interesting market opportunities.

Wolfensberger is pressing ahead with the development of a molding and casting process for the manufacture of thin-walled cast steel parts. This could set the course for securing future competitive strength in sand casting. The aim of the new process is to manufacture cast steel parts using the sand casting process with wall thicknesses from 2 mm, which offer new and interesting market opportunities.

Klüber Lubrication presents new water-miscible sliding varnishes without flammable solvents for long-life dry lubrication as well as for special applications with pre-start lubrication. In addition to the well-known advantages of dry lubrication, the new product line offers a significant improvement in sliding and an increased tightness of O-rings due to reduced gas and liquid permeability.

Klüber Lubrication presents new water-miscible sliding varnishes without flammable solvents for long-life dry lubrication as well as for special applications with pre-start lubrication. In addition to the well-known advantages of dry lubrication, the new product line offers a significant improvement in sliding and an increased tightness of O-rings due to reduced gas and liquid permeability.

Sealing strips are also used everywhere in industry, be it in mechanical engineering or in the Electrical Engineering or food technology for example. Resogoo now presents a new platform for sealing strips. Users find their way here 2000 materialsn the largest selection in the world.