Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

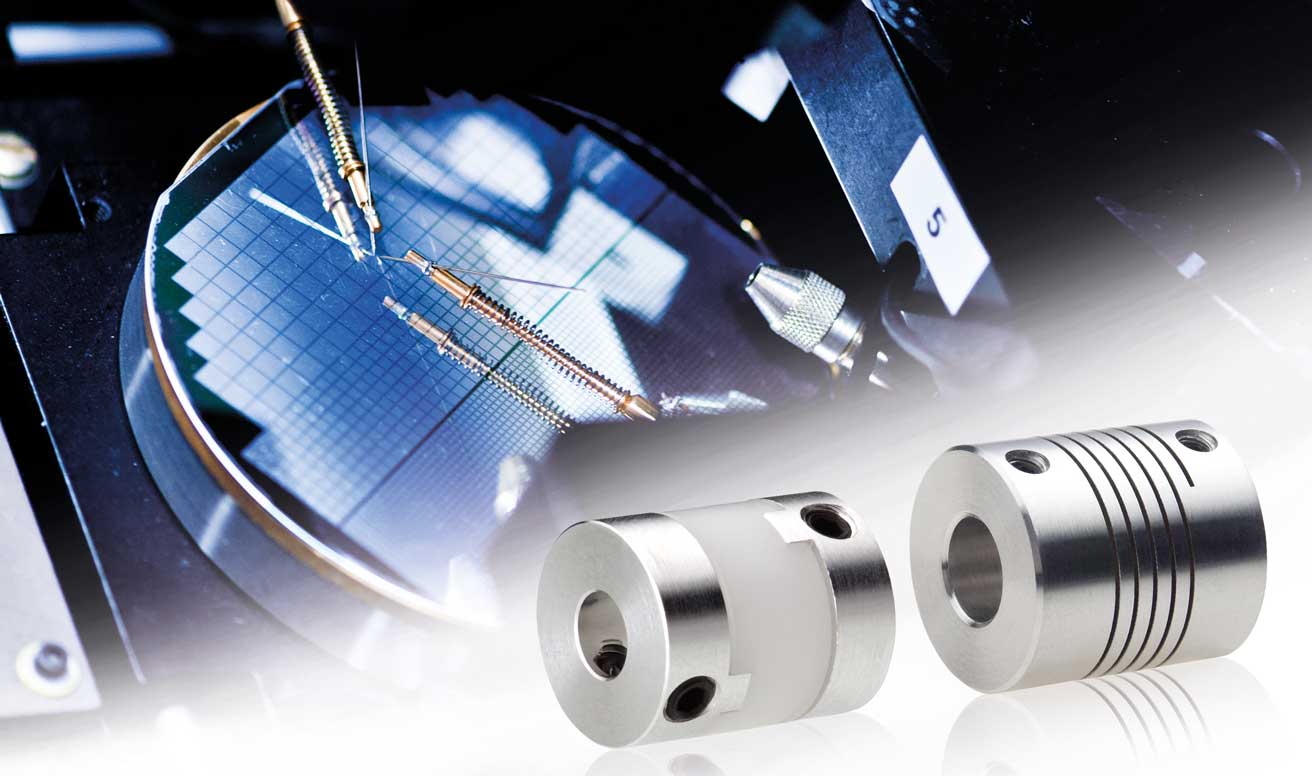

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

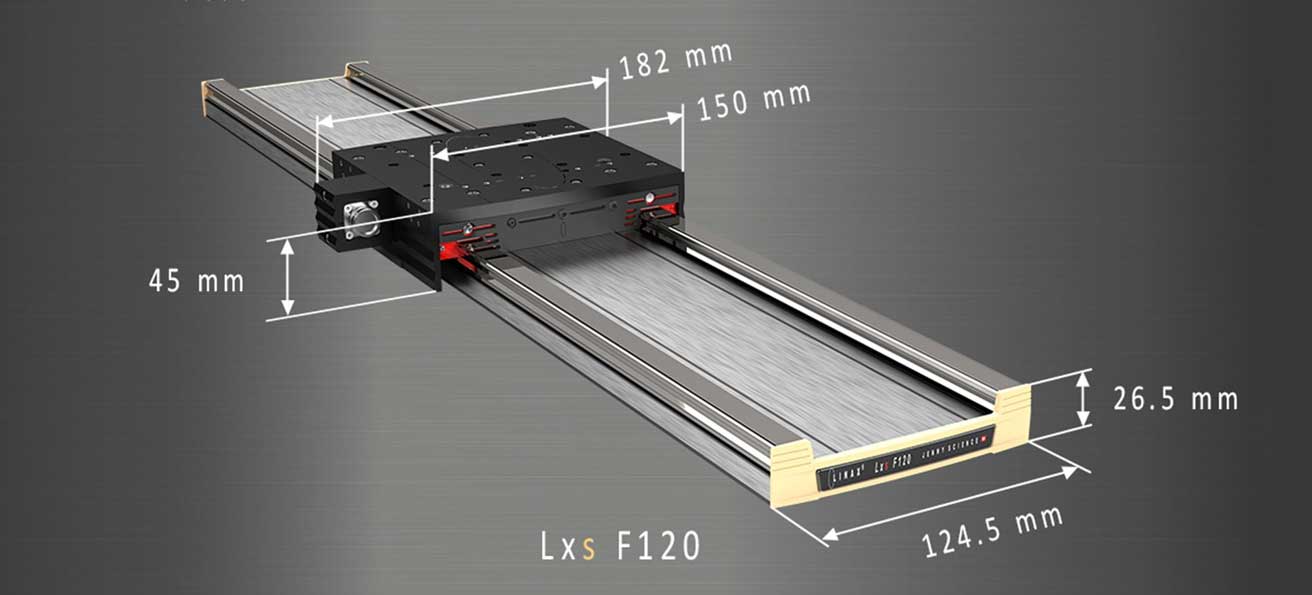

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

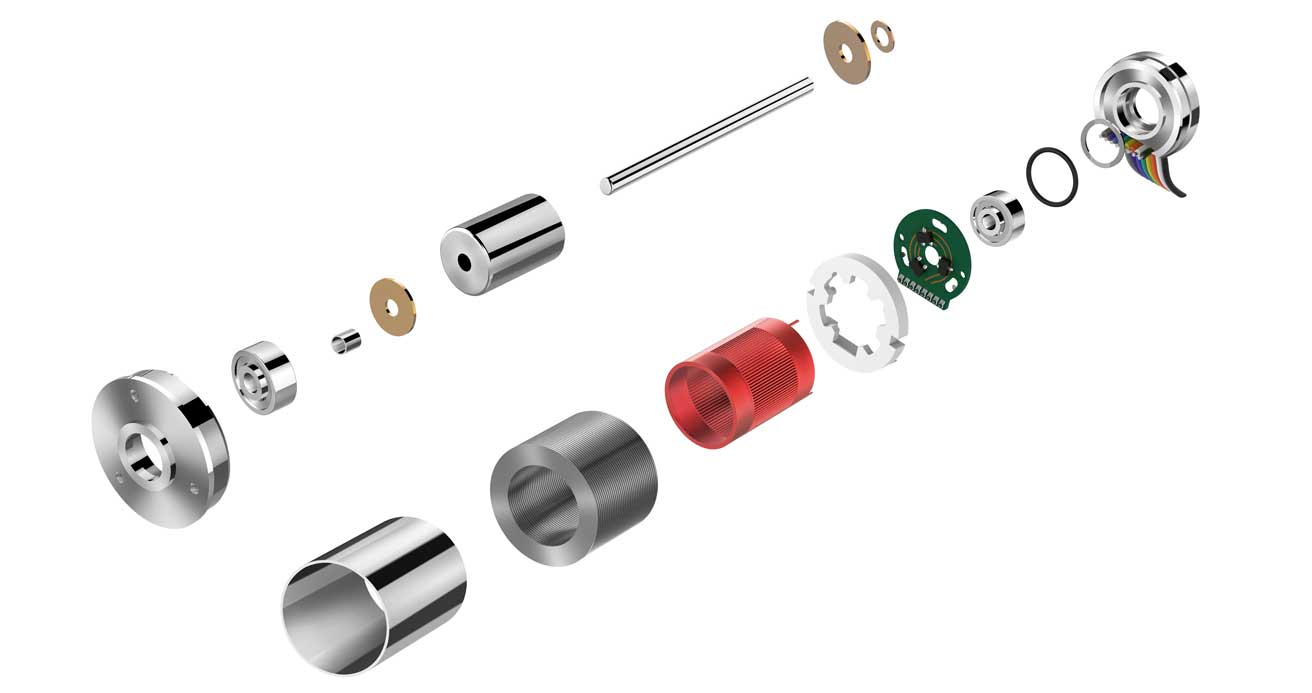

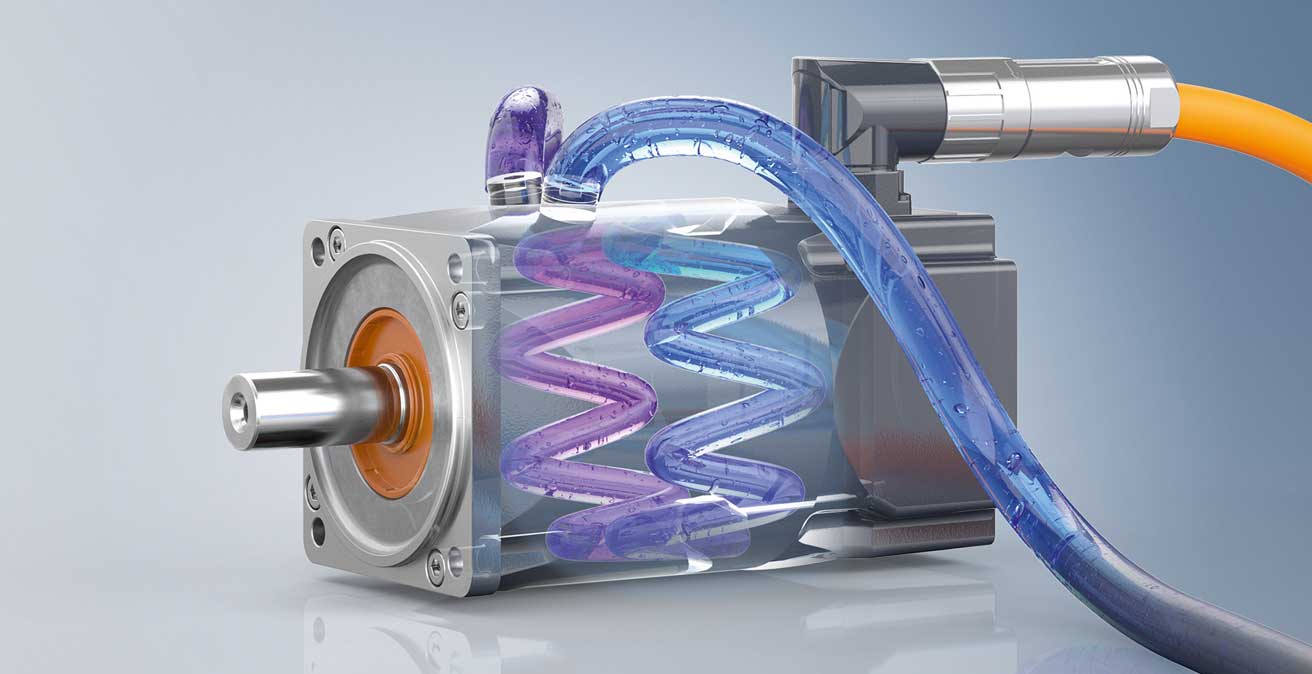

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

The future of production is modular, flexible and autonomous. This requires new systems with decentralized intelligence that can cope with the growing complexity of the processes. NORD developed for more than 30 years electrical drive technology. The pioneer of innovative converters offers a wide selection decentralized drive technology with frequency inverters that can be individually adapted to all desired applications and flexibly integrated in the system field. New ones are particularly noteworthy cabinet inverters and decentralized frequency converter for intralogistics.

With Flexible Couplings shaft misalignments, high tolerances or misalignments can be compensated. For the axial offset z. Claw couplings are used, for example, the Oldham coupling is suitable for radial misalignment, universal joint or ball joint couplings compensate for an angular misalignment, and a double toothed coupling is used for the combined misalignment. Below you will find New Products of torsionally rigid shaft couplings:

Stepper Motors have become indispensable in the industry for precise movements and flexibility in countless applications steering to ensure. They have high accuracy, are robust and offer a wide range of torques and speeds. They are therefore ideal for use in production, for example, Automation or Robotic. In this article we present the latest developments:

A modern one Linear unit allows precise and repeatable movements. It not only increases efficiency, but also the accuracy of various movement processes. Find out more about new developments with linear units in this article different manufacturers and what benefits each offers.

The combination of interlock on the protective door and Standstill monitor im switch cabinet protects machines and systems from the dangerous overtravel movements of the Drives. Schmersal group now presents a new standstill monitor SSW303HV that works without sensors. Compared to the previous models of the AZR and FWS series, this security guard brings significant improvements.

Comes a mechanically commutated DC Motor In terms of service life or performance at its limits, it is time to apply brushless DC motors to move. The demand for brushless DC motors is unbroken - and the trend is rising. This has become koco Motion and offers an extensive BLDC program that leaves (almost) no user wishes unfulfilled. Find out a lot of interesting facts about the small electric motors here:

The Linear axis is a core building block in the Automation and precision metrology. We present new developments to you here various companies before, their functions and areas of application. Find out how you can generate advantages in your design with these linear axes.

If the installation space is small and at the same time a high drive power is required, are water-cooled electric motors the drive of choice. They are very efficient and tend to be more efficient than air-cooled motors, as the latter generate far more heat and friction losses. In addition, water has the best thermal conductivity coefficient. We present to you below New developments from the field of water-cooled electric motors.

Be it drinks, clothes, electrical appliances, the delivery directly to the house is in. This also applies to supermarkets. One of them left the RM Customs GbR build a small series of e-trikes to slow down traffic jams and help protect the environment. For more comfort and safety To steer make Brake cylinder of ACE Shock GmbH installed.

In the realization of a new mountain and valley railway for the Eagle's Lair in Hinterzarten wiegand of Brakes-Technology from Ringspann. It made the BCS 600 brake control and monitoring system the linchpin of the safety concept of its rail-guided wagon train system. The special challenge: Only personal-safe braking systems that comply with the EU cable car directive may be used in cable cars and chair lifts.

Handbikes are the Formula 1 cars among wheelchairs. For this reason, modern sports equipment for disabled people has also replaced classic wheelchairs in city marathons. This applies all the more the more the focus is on sporting competition. However, on rain-soaked roads, these vehicles sometimes run into problems in the curves. Dutchman Ad Aarts has developed such a handbike specifically for artificial and natural ice rinks. These are braked Oil brakes from ACE.

With the new Linear gantry robot "LGR-3" offers Fibro Läpple a modular system for loading and unloading machines as well as for handling workpieces. This allows a wide variety of customer requirements to be implemented flexibly. In the electrical design of the portal, the company uses to secure the Vertical axis on electromagnetic brakes "Roba-linearstop" from Mayr Antriebstechnik.