Spur gear | Application, function, innovation

- Details

- Hits: 5957

The simply constructed ones Spur gears offer high efficiency and can effectively transmit torque between parallel shafts with minimal noise. This makes them suitable for use in manufacturing plants Automotive drives to wind turbines and other heavy industrial applications. This article highlights innovative New developments, applications and shows comprehensive Serviceservices that allow you to increase your efficiency and extend the operating life of your application.

Contents

- Helical gearboxes 2024 – The most important things in brief

- Spur gear innovations

- Bevel and spur gears can be smaller

- The spur gear of the future

- Industrial gears for hoists of all kinds

- Modular industrial gearboxes for heavy-duty tasks

- Industrial gears with oil compensation for large mixed technology

- Heavy-duty extruder gear for processing plastics

- Robust and safe drive solutions for continuous conveyors

- Industrial gearbox in monobloc housing with 190 kNm output torque

- Frequently asked questions

Helical gearboxes 2024 – The most important things in brief

Set spur gear one of the most robust Solutions in drive technology by precisely measuring torque and speed via parallel shafts Gears transmitted. The ongoing development of this type of gearbox includes advanced construction methods and the use of high-strength materials such as alloy steels, which enable increased load capacity and extended service life.

A central focus is on improving the Gear geometry through innovative Calculation method and simulation techniques. These optimizations result in more efficient power transmission while minimizing noise and vibration, which is particularly beneficial in noise-sensitive environments. Modern coating processes such as vacuum-Coating technology also helps to reduce the friction between the tooth flanks of the gears, which in turn increases efficiency and reduces energy consumption.

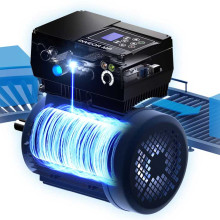

The Integration of sensors plays an increasingly important role in monitoring the condition of the gearboxes in real time. These sensors record critical operating parameters such as temperature, vibration and load conditions and enable precise condition monitoring. This not only leads to more effective maintenance planning, but also early detection of signs of wear and potential failures. This in turn increases the reliability and security of the systems.

These technological advances make spur gears into one Variety of industries used, from the automotive industry to mechanical engineering to energy production, and support companies in increasing their productivity while at the same time being more environmentally friendly.

Below we present you the latest developments in spur gears:

Bevel and spur gears can be smaller

10.01.2024/XNUMX/XNUMX | Current innovations in calculation technology and the integration of digital data models are key elements for improving the performance of the Xe series spur and bevel gearboxes SEW Eurodrive. The data obtained from extensive field tests, laboratory tests and simulations are continuously integrated into our own calculation tools, which increases the precision and reliability of these instruments.

On this basis, the mechanical and thermal configuration of the bevel and spur gears wereSeries Xe newly rated. The results show that previous component optimizations now lead to even higher thermal performance limits and a significantly improved service life of the bearings as well as an increase in the nominal torques at maximum shear load.

Smaller gearbox – less oil, energy and more

These technical advances enable users, among other things, smaller gear sizes to use. This leads to a reduction in oil volume, lower energy consumption and thus a reduced total cost of ownership. Furthermore, the optimizations enable a reduction in the space and weight required in the user's designs. This also increases mechanical safety and minimizes the risk of failure, especially when drives are subject to heavy loads. The lower oil bath temperature and longer bearing life also reduce the need for frequent maintenance during service life.

With 23 different sizes The Xe bevel and spur gear units cover a torque range of 7,2 to 500 kNm. The wide range of installation options and the diverse additional equipment allow great adaptability to different operating conditions.

The spur gear of the future

June 01.06.2023, XNUMX | Flender has the spur gear Flender one reinvented the transmission standard. “The Flender One is not a series product, although it is manufactured exactly that way. “Terms like modular systems will soon be a thing of the past,” comments Andrew Evertz, CEO of the Flender Group, at the market launch. The secret lies in the maximum individuality and variability in the configuration and production of the transmissions based on transmission intelligence.

The Flender engineers have managed to achieve this for applications that require particularly precise speed, such as pumps and paper machines narrowest translation range in the world with 103 levels between 1 and 7,1 per size. This allows the speed to be set almost ideally for maximum efficiency in these applications. The deviation between the desired speed and the available technical solution is a maximum of 1,5%.

Complete digitalization of the engineering process

Further expansion stages will make it possible in the future custom to configure for the respective application. Despite maximum individuality, customers will benefit from the advantages of series production. This is made possible by a real milestone in transmission production: the complete digitalization of the engineering process. He initiates the design exactly according to customer requirements and translates it into a fully automated manufacturing and delivery process.

Ordering gearboxes is child's play

An another world first in drive technology is the Flender One product configurator. The customer can configure their transmission online with just three pieces of information: application, power and speed. More detailed parameters can also be added. The full 3D data and a 360-degree preview of the transmission are available within a few seconds. When developing the configurator, Flender focused on customer requirements.

“We offer our customers the opportunity to take on the time-consuming preliminary considerations for them. We no longer ask about the specifications and properties of the gearbox, but only about the desired benefits. “Our customer tells us how and where he wants to use the gearbox, and we tell him which gearbox with which functions he needs,” says Dr. Jan Reimann, Project Manager at Flender One.

50% oversized? - Not anymore!

According to Andreas Evertz, most of the industrial gearboxes from all manufacturers in the field, including Flender, are up to 50 percent oversized and can prove this. “With Flender One we no longer need this oversizing,” says Evertz. With the help of the collected data, Flender is able to control the transmission just so big to dimension, like it for the respective application needed is.

According to Andreas Evertz, most of the industrial gearboxes from all manufacturers in the field, including Flender, are up to 50 percent oversized and can prove this. “With Flender One we no longer need this oversizing,” says Evertz. With the help of the collected data, Flender is able to control the transmission just so big to dimension, like it for the respective application needed is.

The optimized Wheelset Metaperform It also reduces power loss by up to 50% compared to previous gear solutions. This is made possible by the improved rolling behavior and the even more uniform contact surfaces of the teeth. Together with the new gear design, this increases the thermal capacity of the new spur gear. The striking cooling fins mean that additional, external cooling of the transmission is only necessary later or, depending on the application, completely unnecessary.

The transmission becomes smart

As mentioned at the beginning, the digital basis for all measurements and optimizations is the new one Gearbox intelligence AIQ from Flender. Its sensors continuously measure the torque and the analysis functions detect whether the gearbox and system are operating under overload or underload. This is the key to optimizing and automating the production processes and the perfect design and dimensioning of the gearboxes.

The AIQ integrated Sensor not only records operating states, but processes them directly, interprets them and gives recommendations for action to the operators - on site at the sensor, via app or permanently in the customer's own system. The detailed condition monitoring of the individual components detects deviations from the optimum at an early stage and enables the prediction of possible failures. Precisely planned maintenance becomes possible and downtimes are reduced.

Industrial gears for hoists of all kinds

Sep 02.09.2022, XNUMX | Lifting applications place special demands on the installation space of drives, which the new Maxxdrive XD from NORD Fulfills. The industrial gearbox has an increased center distance, making it very suitable for U-shaped configurations Transmission, Motor and rope drum.

With the new industrial gearbox, Nord Drivesystems is closing a gap in its portfolio: “We are now giving our customers the opportunity to purchase the chassis and hoist drives for cranes from a single source,” comments Jörg Niermann, Head of Marketing at Nord.

With the new industrial gearbox, Nord Drivesystems is closing a gap in its portfolio: “We are now giving our customers the opportunity to purchase the chassis and hoist drives for cranes from a single source,” comments Jörg Niermann, Head of Marketing at Nord.

As with all gearboxes from the manufacturer, this happens proven principle the robust one-piece block housing is used. The housing of the new industrial gearbox was specifically designed for lifting applications and optimized for downward loads. The stretched gear stage arrangement allows for mechanically precise dimensioning with sufficient center distances.

Five sizes with wheelbases between 509 and 963 mm and three or four gear stages are available. Housing dimensions and center distance are identical for the three- and four-axis versions. This allows standardization and reduction of variants in the design of crane systems. The three- and four-stage versions cover a wide range of translations. The maximum nominal gear ratio is i=355. The constant torque throughout the entire gear range ensures high efficiency.

Proven series parts used

In the components of the Maxxdrive XD the drive specialist relies on the proven series parts of its industrial gearboxes. This results in a wide variety of options and short delivery times. There are also inspection covers for the housing for visual inspection of the internal components. The gearbox is available in gray cast iron (GJL) or optionally in nodular cast iron (GJS).

The new series is suitable for the hoists of port and container cranes, bridge and gantry cranes as well as container and coil high-bay warehouses. In addition to ports, logistics and shipyards, the industrial gearbox is also ideal for the metal, chemical and paper industries, mining and bulk goods handling.

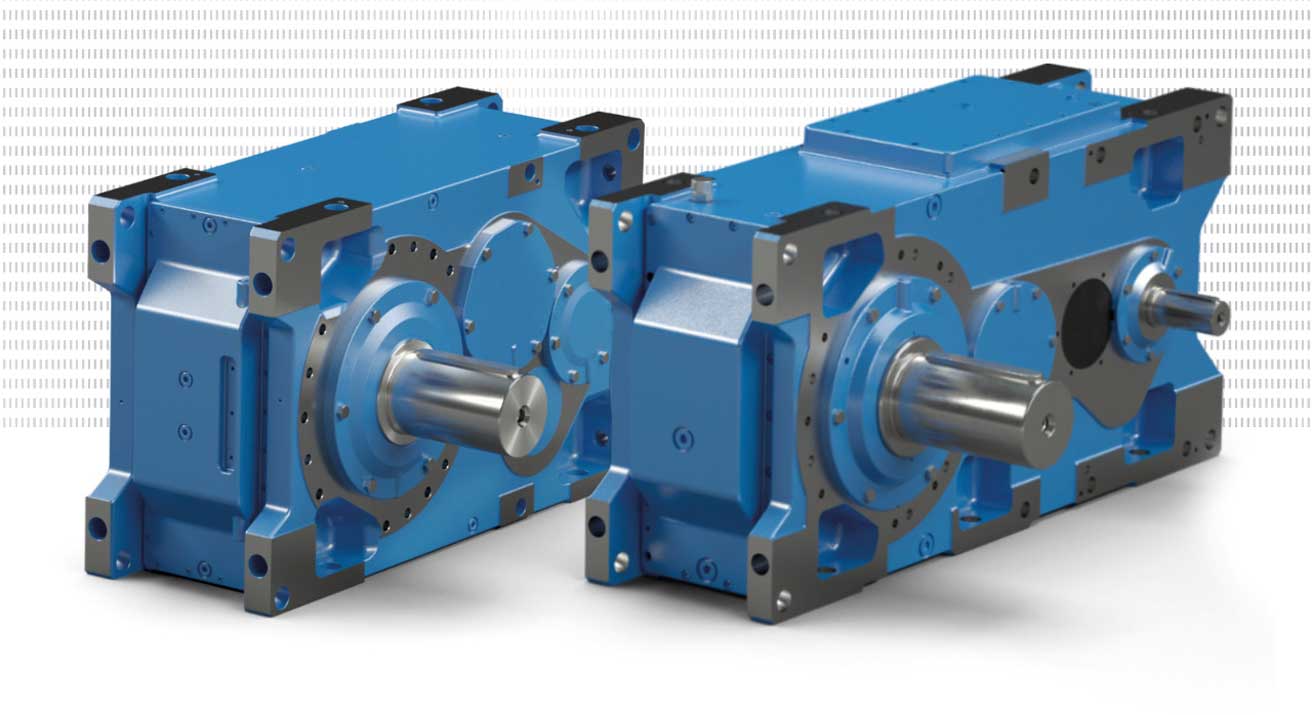

Modular industrial gearboxes for heavy-duty tasks

14.02.2021 | NORD has developed from a gear manufacturer into a value chain partner for complete drive technology solutions. The product portfolio also includes the Maxxdrive industrial gear series for maximum output torques of 282.000 Nm for heavy-duty applications. The example of one Bascule bridge shows how an individual drive solution is created with a short delivery time.

14.02.2021 | NORD has developed from a gear manufacturer into a value chain partner for complete drive technology solutions. The product portfolio also includes the Maxxdrive industrial gear series for maximum output torques of 282.000 Nm for heavy-duty applications. The example of one Bascule bridge shows how an individual drive solution is created with a short delivery time.

Industrial gears with oil compensation for large mixed technology

April 30.04.2020, XNUMX | The Maxxdrive industrial gearboxes from are suitable for use in large mixers NORD. The drive specialist is presenting a technical innovation for this mixing technology: the Safomi adapter. It is a flange with an integrated oil expansion tank to improve operational safety and save on wearing parts. The industrial gearboxes offer high output torques of 15 to 250 kNm.

April 30.04.2020, XNUMX | The Maxxdrive industrial gearboxes from are suitable for use in large mixers NORD. The drive specialist is presenting a technical innovation for this mixing technology: the Safomi adapter. It is a flange with an integrated oil expansion tank to improve operational safety and save on wearing parts. The industrial gearboxes offer high output torques of 15 to 250 kNm.

The Maxxdrive gearboxes ensure even under extreme operating conditions such as Mixing and stirring technology smooth operation. The compact design is FEM optimized. It allows operation under the highest external loads. The extensive modular system offers many options for tailor-made solutions. The Safomi (Sealless Adapter For Mixers) IEC adapter is used for agitator applications.

Special adapters in use

This special one IEC adapter combines the functions of a standard IEC adapter and an oil expansion tank in one component. Safomi is available for helical gearboxes in sizes 7 to 11 and therefore for maximum output torques of 25 to 75 kNm. The compact combination of industrial gearbox, adapter and drive motor is the optimal choice for mixers and agitators in order to reduce wear and add-on parts.

The compact, simple Safomi IEC adapter has a integrated oil compensation volume. Oil containers and oil hoses as well as the leakage and wear-prone shaft sealing ring between gearbox and IEC cylinder are therefore not necessary. By default, the combination of helical gearbox and Safomi adapter is only installed in the M5 installation position, i.e. with the output shaft pointing downwards.

Switching to a Safomi IEC adapter instead of the standard IEC adapter on Agitator drive leads to higher operational reliability and lower maintenance requirements. The oil level and the required oil volume are lower. Thanks to the lack of add-on parts, the installation space is reduced.

Heavy-duty extruder gear for processing plastics

February 04.02.2020, XNUMX | When it comes to the production and processing of thermoplastics, extrusion has established itself as the most important manufacturing process. Especially for use in extruders NORD an extruder gear that is optimized for heavy-duty use. In addition to the powerful Maxxdrive industrial gearbox, Nord also produces entire drive solutions in extruder versions.

February 04.02.2020, XNUMX | When it comes to the production and processing of thermoplastics, extrusion has established itself as the most important manufacturing process. Especially for use in extruders NORD an extruder gear that is optimized for heavy-duty use. In addition to the powerful Maxxdrive industrial gearbox, Nord also produces entire drive solutions in extruder versions.

So let's join the Maxxdrive industry extruder gears adapt almost all common connection dimensions. Generously sized Thrust bearing absorb the process forces safely and ensure a long service life. The extruder option from Nord Drivesystems can be individually tailored to the user's output shafts. It can be optimally adapted to the application using different bearing designs.

Plant constructors, manufacturers and processors of Plastic With this extruder gearbox you can design drives safely, highly reliably and particularly flexibly. Extruder versions are available for the Maxxdrive gearboxes in sizes 5 to 11 with nominal torques of 15 to 75 kNm available.

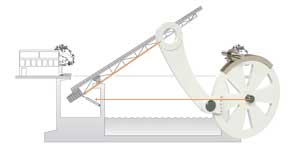

Robust and safe drive solutions for continuous conveyors

May 24.05.2019, XNUMX | For the transport of bulk goods NORD powerful drive systems. Reliable, safe and robust, these guarantee smooth operation even under the toughest environmental conditions. They can be individually controlled for precise, dynamic bulk material feed control.

May 24.05.2019, XNUMX | For the transport of bulk goods NORD powerful drive systems. Reliable, safe and robust, these guarantee smooth operation even under the toughest environmental conditions. They can be individually controlled for precise, dynamic bulk material feed control.

For the transport of bulk material conveyors are needed that are in the conveying direction, Mass flow, conveyor length and construction differ. The drives ensure an uninterrupted material flow. Belt conveyors are conveyor systems that are used for the constant transport of piece and bulk goods, for example in mining, mechanical engineering or in plastic and paper recycling.

Can be implemented particularly large conveying lengths, quantities and speeds. Belt conveyors are characterized by a circumferential belt made of rubber or plastic and tension members for stability. The conveyor belt is deflected over at least two drums, with at least one drum being driven and setting the belt in motion through wrapping friction.

Large belt conveyor

For big Belt conveyor The long-lasting and low-maintenance “Maxxdrive” industrial gearboxes, in which bearing points and sealing surfaces of the block housing are manufactured in a single clamping operation, are suitable for high capacity. The latest generation of Maxxdrive XT has been supplemented with an application-optimized two-stage bevel-helical gearbox - ideal for belt conveyor systems in the bulk materials and minerals industry. The power and speed range was specifically tailored to the target industries.

Ultrasonic and radar level sensor with IO-Link for the IIoT

Ultrasonic and radar level sensor with IO-Link for the IIoT

The Helical or bevel gears In the foot, flange or slip-on housing, thanks to the two designs, they can be planned axially parallel and at right angles into the conveyor system. They are mounted on a motor swing arm or frame together with a foot-mounted, high-efficiency IE3 motor and are connected to the motor via a hydraulic clutch.

Because most of them Bucket elevator applications are affected by the development of dust, there is a risk of explosion if the dust is combustible. Custom-made motors and geared motors with explosion protection are used here, which the drive specialist puts together from its modular system according to individual requirements. A practical maintenance package, consisting of protective measures and monitoring systems, ensures that the investment works even under adverse operating conditions such as continuous operation, dust development and weather influences.

Industrial gearbox in monobloc housing with 190 kNm output torque

03.05.2016 | NORD has on the Hannover Messe introduced a new size of its industrial gearboxes: With 190 kNm, the entire series covers torques from 25 to 250 kNm in 9 sizes. The new units with size 14 now allow even more precise designs.

03.05.2016 | NORD has on the Hannover Messe introduced a new size of its industrial gearboxes: With 190 kNm, the entire series covers torques from 25 to 250 kNm in 9 sizes. The new units with size 14 now allow even more precise designs.

With a one-piece Block housing The industrial gears achieve a longer bearing life than parting gears and ensure efficient force conversion as well as high tolerance to load peaks and impacts. They can be mounted as spur or bevel-helical gearboxes, with two or three stages and with nominal ratios from 7,1:1 to 400:1 and with advance gears up to 30.000:1.

The drive and output directions are freely selectable. All six pages are available for setup. The drive specialist uses products from its own production to configure industrial gear motors for a wide range of applications, from steelworks to process engineering.

Application-specific equipment options include, among others reinforced bearings and shafts, an increased bearing distance, extended output shafts, a drywell version with an additional oil drip disk and leakage oil indicator or oil sensor. Disc and drum brakes, dual gearboxes, auxiliary motors, IEC motor adapters, turbo couplings, axial fans, motor swings, a torque-limiting backstop, and cooling and heating systems are also available.

Frequently asked questions

What is a spur gear?

A spur gear is a mechanical device used to transmit torque and speed between two parallel shafts. A spur gear consists of at least two meshing gears gears with straight or helical teeth

How does the spur gear work?

The spur gear works by meshing two or more gears Gears on parallel axes. These gears transmit rotational motion and torque from an input shaft to an output shaft. By selecting different gear sizes and shapes, such as straight or helical, speed and torque can be adjusted to the specific requirements of the application.

Where can you find spur gears?

Spur gears are popular due to their robustness and reliability numerous Industrial applications widespread from mechanical engineering, energy technology, mobile work machines to the automotive industry or mine drive technology.

What is a bevel-helical gearbox?

A bevel-helical gear is a special form of gearbox that combines elements of both bevel gears and spur gears. This type of gearbox takes advantage of the advantages of both types of gearboxes to enable power transmission between intersecting or offset axles while maintaining power efficiency and compact design.

What are the advantages and disadvantages of gear transmissions?

Gear transmissions are valued for their precise and efficient power transmission in many industrial applications. To the Advantages include high reliability, robustness and the ability to transmit high torques. They also enable a compact design and have high energy efficiency.

Disadvantages of gear transmissions include potential noise generation under high load or high speed, especially if not optimally designed or maintained. Manufacturing and precision manufacturing costs can also be high, as can maintenance requirements to ensure long life and optimal performance.

Source: This article is based on information from the following companies: Flender, Gearbau Nord, SEW.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

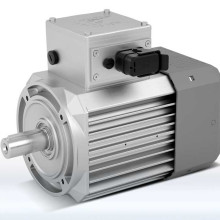

Gear motor integrated IE5 + motor in spur gear

Transmission North | The Block Case Inventor

IE5 + synchronous motor for variant reduction and TCO reduction

Easy-to-install IE3 asynchronous motor in eco-design

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.