Magnetic field sensor series for detecting the piston position

- Details

- Hits: 3726

The magnetic field sensor is mainly used in pneumatic cylinders for non-contact measurement of the piston position. For use in welding or hazardous areas and for analog queries Turck individual magnetic field sensors. The magnetic proximity sensors allow thanks to EMC resistance and in protection class IP67 high system availability. Below we present the innovations:

Contents

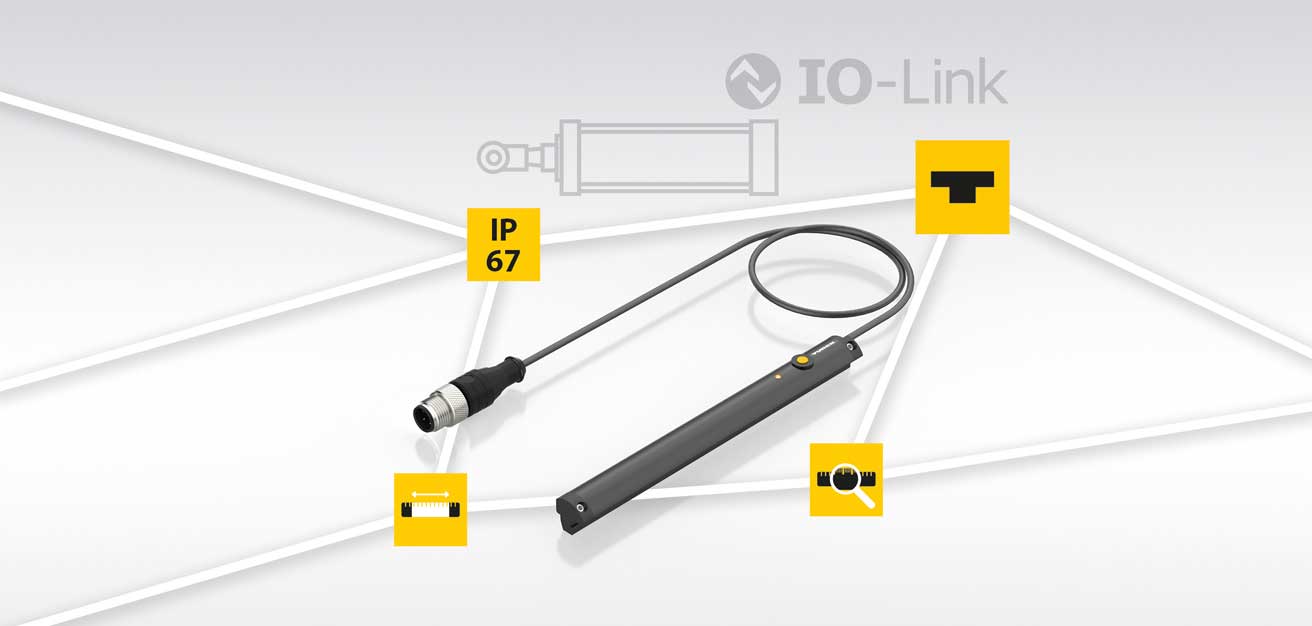

Magnetic position sensors with IO Link

05.09.2022 | With the WIM IOL Magnetic field sensor series Turck supplements its range of compact position sensors for detecting magnetic pistons in pneumatic cylinders or hydraulic cylinders. The series includes eight magnetic field sensors with IO-Link 1.1 with measuring ranges from 32 mm to 256 mm.

Via IO Link and an integrated button, users quickly and conveniently teach the measuring range of the sensors to the stroke of the pistons in the cylinder. Compared to analog Sensors this simplifies the assembly considerably, because these are either assembled exactly on the dead centers or have to be corrected with correction factors in the steering work. The IP67 sensors work with a resolution of 15 bits.

Typical applications are the feed rate detection in screw machines or plastic injection molding machines, monitoring the film tension in packaging machines or the positioning of a welding head in ultrasonic welding.

Turck is exhibiting at the FMB 2022 and the SPS 2022.

Magnetic field sensor for SMC pneumatic cylinders

11.03.2019/XNUMX/XNUMX | The magnetic field sensor portfolio from Turcks for Pneumatic cylinder is growing: the magnetic field sensor Series BIM-UNC has been optimized for installation in C-slot pneumatic cylinders from SMC. A BIM-UNC sensor can be inserted into the groove from the side with one hand and without mounting accessories.

11.03.2019/XNUMX/XNUMX | The magnetic field sensor portfolio from Turcks for Pneumatic cylinder is growing: the magnetic field sensor Series BIM-UNC has been optimized for installation in C-slot pneumatic cylinders from SMC. A BIM-UNC sensor can be inserted into the groove from the side with one hand and without mounting accessories.

About a quarter turn of the screw, the thread presses the sensor against the cylinder and fixes it shakeproof. A tightening torque of 0,1 Nm is sufficient to fasten the sensor without damaging the cylinder.

The BIM-UNC sensor series is suitable for applications in the Materials Handling, automated assembly or for punching machine and Industrial robots. Magnetic field sensors particularly record the piston position of the pneumatic cylinders. The IP67 sensors of the UNC family can withstand temperatures from -25° to 70°C. As standard there is a 2 M cable version and pigtails in M8 or M12, optionally with the output functions PNP or NPN.

You might also be interested in...

IO module secures Resato hydrogen filling stations

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

LED signal light with and without IO-Link

Turck | Your global automation partner

Fieldbus and network technology - communication IO!

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.