Trade fair for assembly & handling

Handling technology, feeding technology, material flow and automation as well as Bondexpo, trade fair for adhesive technology

Image: Sound measurement

Trade fair for assembly & handling

Handling technology, feeding technology, material flow and automation as well as Bondexpo, trade fair for adhesive technology

Image: Sound measurement

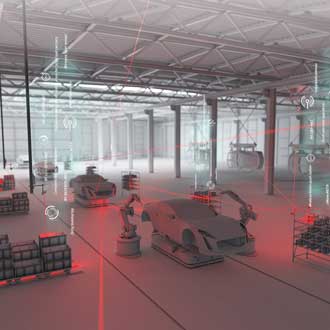

The Motek Fair is a trade fair for production and assembly automation. Products and systems for handling technology, feeding technology, material flow and Automation with the aim of rationalization for Industry 4.0. PE sound is the organizer of the event. The BONDexpo, Trade fair for Bonding technologies at the Stuttgart Exhibition Center.

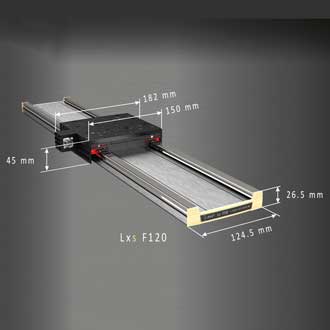

Our Fair Special to the annual Motek trade fair, international trade fair for production and assembly automation in Stuttgart, shows you the highlights of the exhibitors. Exhibition areas are assembly plants and basic systems, handling technology, process technology for joining, processing, testing and marking, components for special machine construction as well as software and services.

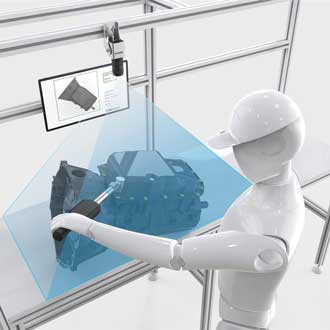

This year's Motek trade fair focuses on 10. to 13. October 2023 on three main topics: smart production components, assembly assistance systems and user-friendly implementation solutions. Project manager Rainer Bachert emphasizes the practical relevance of the trade fair and the advancing digitalization in all areas. Software and Artificial intelligence play a central role in optimizing production efficiency and sustainability. The fair serves as a platform for current technological innovations and offers practical approaches to the challenges of the manufacturing industry.

In our trade fair special at Motek in Stuttgart, exhibitors and trade visitors and those who do not have time to come to Stuttgart will find new products from the exhibitors for industrial handling and automation before and after the trade fair. Use our service, we will keep you up to date. The date for the next Motek is October 08th to 11th, 2024 in Stuttgart.