CAD Software for R&D

Create creative freedom in product development with increasingly complex software with 3D CAD or 3D models

Image: Solidworks

CAD Software for R&D

Create creative freedom in product development with increasingly complex software with 3D CAD or 3D models

Image: Solidworks

CAE Software for R&D

Simulation, analysis, optimization or validation, DMU, FEM, CFD, MKS, CAQ and CAM as well as fluid or flow simulation

Image: Dualis

Hardware for R&D

Workstation, desktop, monitor or screen and 3D mouse - in short: tools for the designer and development engineer

Image: Hama

Configurators for R&D

With new software, tools and apps, the configuration of components and systems in product development becomes child's play

Image: IMI Precision

Here you can see the latest hardware and software tools for industrial Product development like CAD Hardware, CAD software and any CAE software for simulation and calculation as well as new tools for the Configuration – just everything that the developer needs.

Contents

The good old drawing board or the slide rule as well as formularies and scribblers are museum pieces. Today, all development work is done on a PC, also known as a workstation. There's artificial intelligence and virtual reality. CAE tools are used to calculate, design, configure, optimize and simulate. Yes the product developer today it is easy or not? After all, he has to Methods and Processes for product development as well as the software tools available on the market, so that the product development process is as efficient and reliable as possible and the ever-pressing market launch is a successful one. Not only must he operate the software, he also has to be able to update it continuously, learn the test methods and keep his hardware up to date.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Below you will find hardware and software for product development in general and for the Industrial machinery and equipment:

PTC has the world's first Micro turbo engine (Picture above) presented, which completely with the 3D printer was made. The only assembly was developed in the CAD software Creo. It contains all rotating and fixed components. The engine was printed with an EOS 3D printer from the material Inconel, a nickel-based, heat-resistant nickel-chromium alloy. It weighs only 3,6 kg.

PTC has the world's first Micro turbo engine (Picture above) presented, which completely with the 3D printer was made. The only assembly was developed in the CAD software Creo. It contains all rotating and fixed components. The engine was printed with an EOS 3D printer from the material Inconel, a nickel-based, heat-resistant nickel-chromium alloy. It weighs only 3,6 kg.

Dassault Systèmes has opened the first 3Dexperience Lab in Germany after Paris, Boston and Pune. The global Impact Lab aims to accelerate pioneering projects with a strong positive impact on society. The new hub in Munich supports young founders and local start-ups in implementing their disruptive ideas into reality. Innovators and doers should be able to fully develop their creativity.

Dassault Systèmes has opened the first 3Dexperience Lab in Germany after Paris, Boston and Pune. The global Impact Lab aims to accelerate pioneering projects with a strong positive impact on society. The new hub in Munich supports young founders and local start-ups in implementing their disruptive ideas into reality. Innovators and doers should be able to fully develop their creativity.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. For small series or series production in injection molding, a prototype from the 3D printer or semi-finished products, the plastics specialist has now developed an offline configurator for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. For small series or series production in injection molding, a prototype from the 3D printer or semi-finished products, the plastics specialist has now developed an offline configurator for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

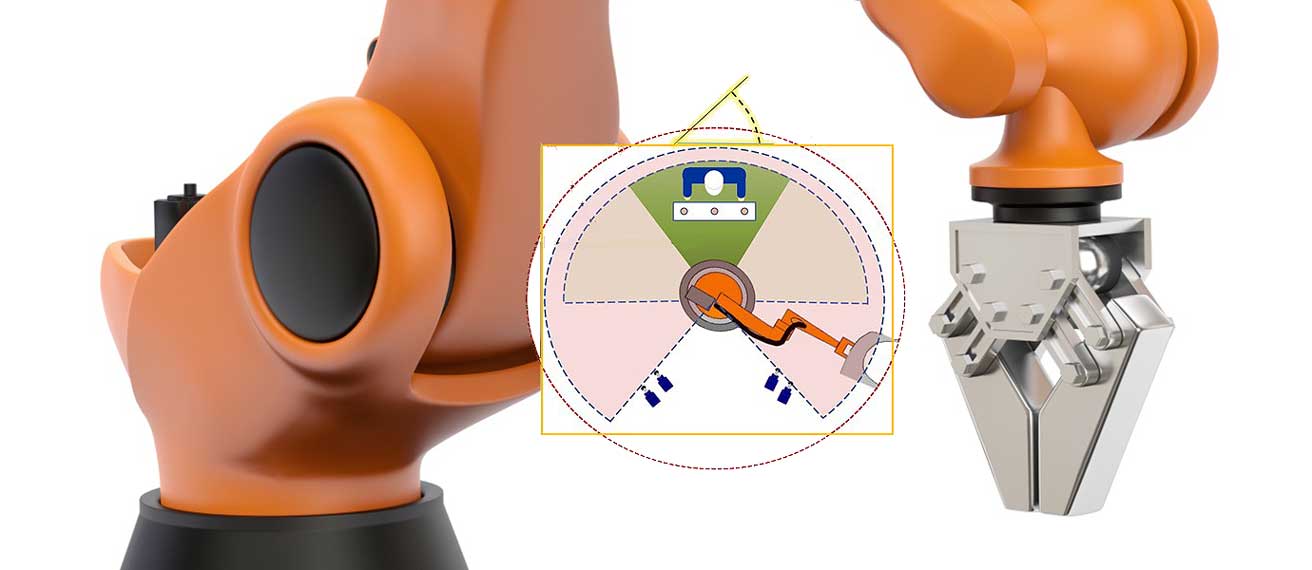

Work human and Robot Together without a protective fence, both can make full use of their advantages. Normative prerequisites have been created for their safe cooperation. In many companies there are already collaborative robot cells in use. But what about that? Planning and construction of such robot cells? This post by Schmersal shows you the way.

The Industrial Digital Twin Association (IDTA) is a significant digital twin initiative. It was launched by leading industry associations such as VDMA, ZVEI, Bitkom and the Industry 4.0 platform in 2019. Dassault Systems has now joined this club. Mike Billmann and Jeroen Buring have an interview about it on the Hannover Messe 2024 given. Find out the organization's news here:

The 3D CAD Software Solidworks by Dassault Systèmes brings hundreds of improvements every year. Many of them have arisen from the wishes and experiences of the users. This also applies to the brand new release SolidWorks 2024 with its user-centered innovations. Millions of developers, designers and engineers worldwide use 3D models for design and engineering solutions. This article informs you about the new developments.

Your carbon footprint More and more companies want to reduce in order to counteract climate change with various climate protection measures. In this way, tons and tons of dangerous greenhouse gases can be saved. We present you here product and process solutions, with which CO2-Let emissions be reduced for a sustainable, climate-neutral industry.

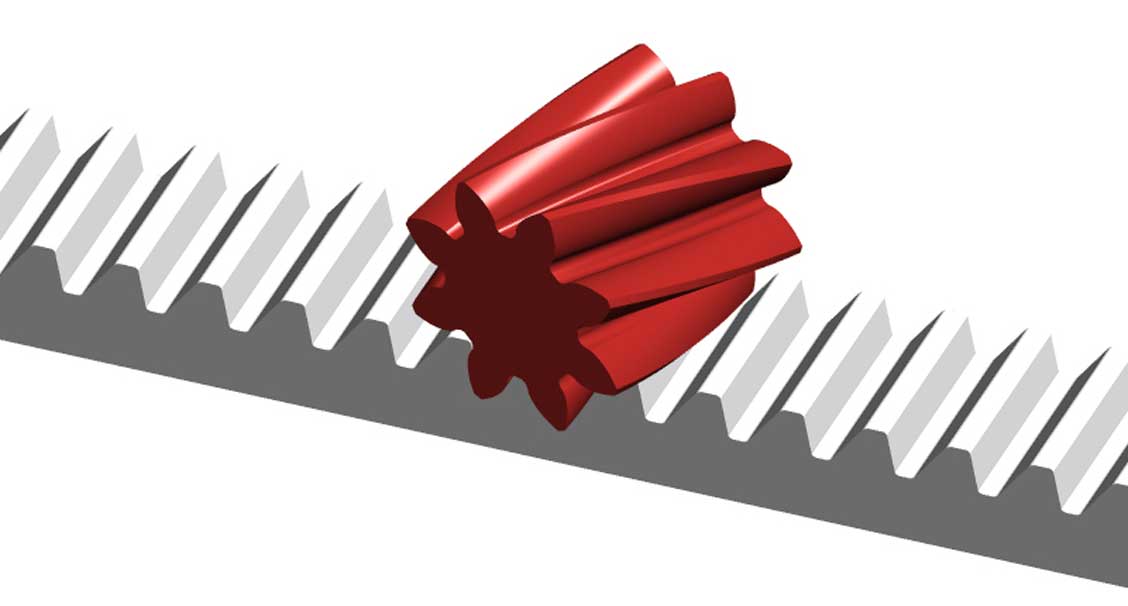

In vehicles, the transmission from the steering wheel to the steering the wheels are often carried out by a rack and pinion drive. KISSsoft has the option of using the ZE2019 module in the 7 release Helical gear with rack calculation integrated.

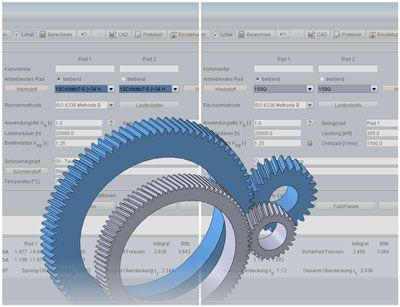

GWJ Technology integrated as the world's first manufacturer of professional calculation software for gear transmission high-purity steels from Ovako from Sweden. In close cooperation, the two high-purity steels 159X and 159Q were implemented in the gear modules for spur gears. They are based on case hardening steel 18CrNiMo7-6.

GWJ Technology integrated as the world's first manufacturer of professional calculation software for gear transmission high-purity steels from Ovako from Sweden. In close cooperation, the two high-purity steels 159X and 159Q were implemented in the gear modules for spur gears. They are based on case hardening steel 18CrNiMo7-6.

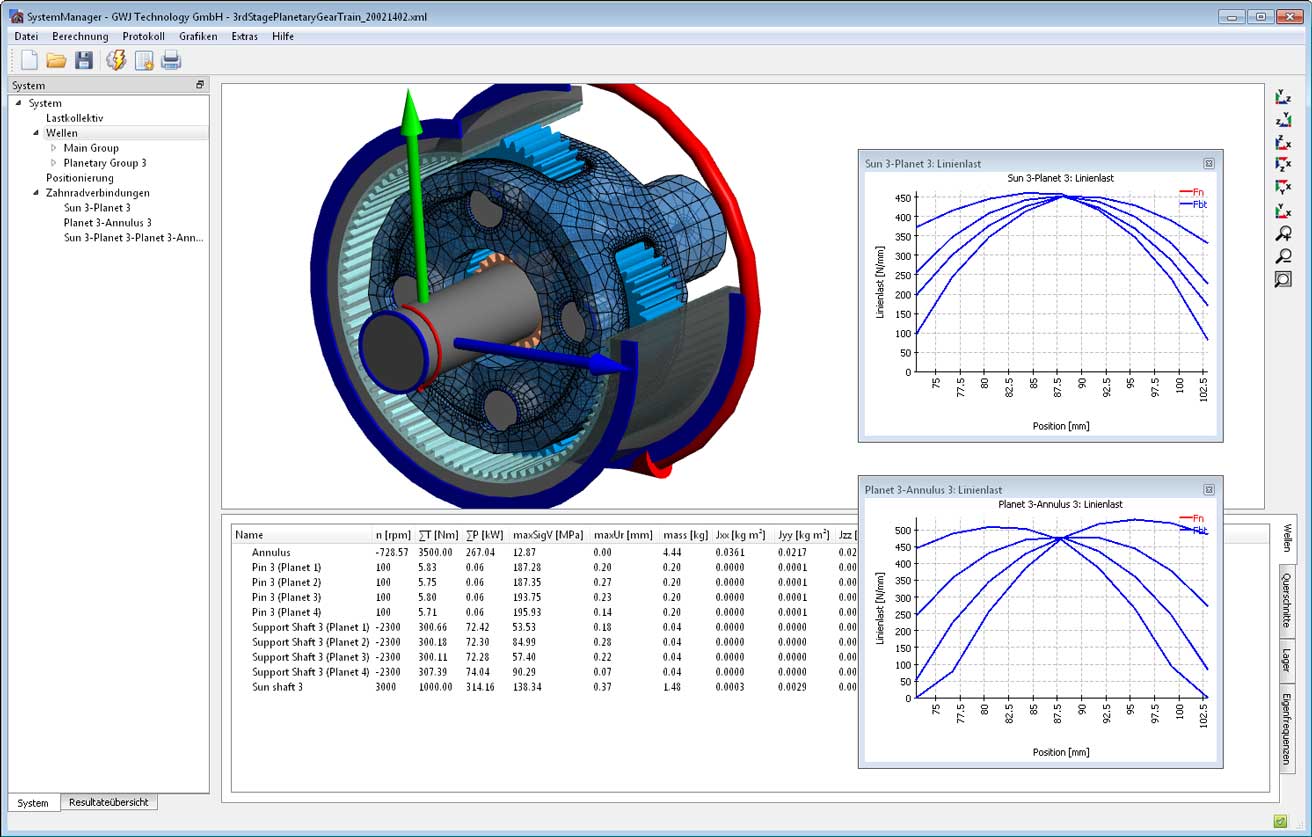

GWJ Technology provides a new and enhanced version of its software Transmissioncalculation for complete Geartransmission in front. The new version of the system manager as an extension of the standard solution Eassistant and TBK now also calculates shaft geometries of gears with the support of background graphics.

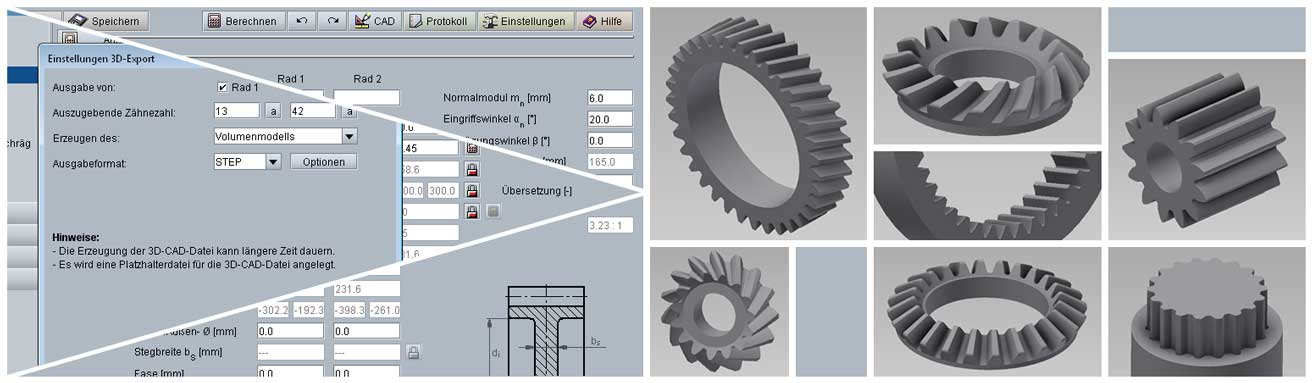

GWJ Technology offers software for the Gearcalculation im Transmission and mechanical engineering. The calculation professional from Braunschweig supports design and development engineers in their daily work. Here you will find further developments of the web-based calculation software eAssistant and the transmission software TBK. Recent additions are a Module for the Hirth toothing and a CAD functionality that supports the Export of gears supported in 3D STEP or Iges format.

In addition to Siemens and Deutsche Bahn, the Cologne-based plastics specialist is also experimenting Igus with the Industrial Metaverse. The resulting digital parallel universes could, like the introduction of assembly lines or Robotic have a disruptive effect on sales, engineering and service. I got straight into it Iguverse and felt like the leading lady of James Cameron's not-yet-made blockbuster "Avartar Industry".

Everyone in the office was yesterday. Home office is still today. Anyone who has set up a home office extends its use to the private sector. For example, do you want one? own cloud at home There are a few things to consider when setting up your system and becoming independent of external providers. This article shows you the essential steps private clouds Set up – quickly, safely and without losing quality or functionality.

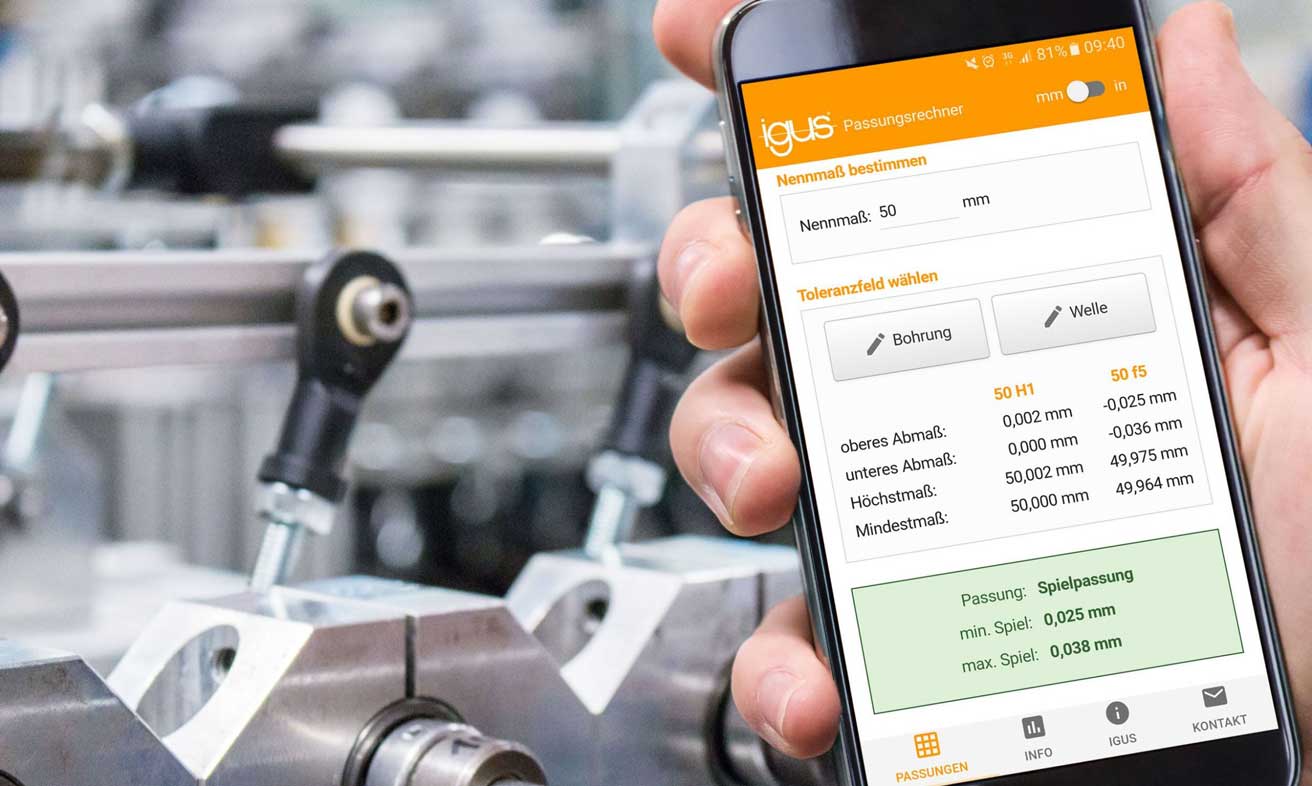

Do you want to adjust components with millimeter precision? The fit calculator helps you calculate fits and tolerances ISO 286. to calculate. Discover how nominal dimensions and tolerance classes are converted into a perfect fit and how you can work more efficiently with this tool. We provide you tolerance calculator various companies. This ISO Online of fits promise precise results and simplify your design work.

Sitting is the new smoking, the media write in large numbers today, it is about the topic of sedentary lifestyle by and large Ergonomic computer workstation in particular. Especially in the current one Home Office Establishment due to the corona epidemic, many have the problem of not being properly equipped. Therefore, we have put together a few tips from well-known office furniture manufacturers so that you are ergonomic sit properly or also stand.