Image processing for quality assurance

Embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors, etc. to avoid errors and determine position

Image processing for quality assurance

Embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors, etc. to avoid errors and determine position

Communication: Technology for Industry 4.0

Gateways, switches, networks, standards such as Ethernet Ethercat, OPC UA or IO-Link and much more for digital transformation

Image: Pepperl + Fuchs

IPC for manufacturing and production

HMI, smartphone, tablet, mobile phone, monitor and accessories for harsh industrial environments and hazardous areas

Image: Ecom

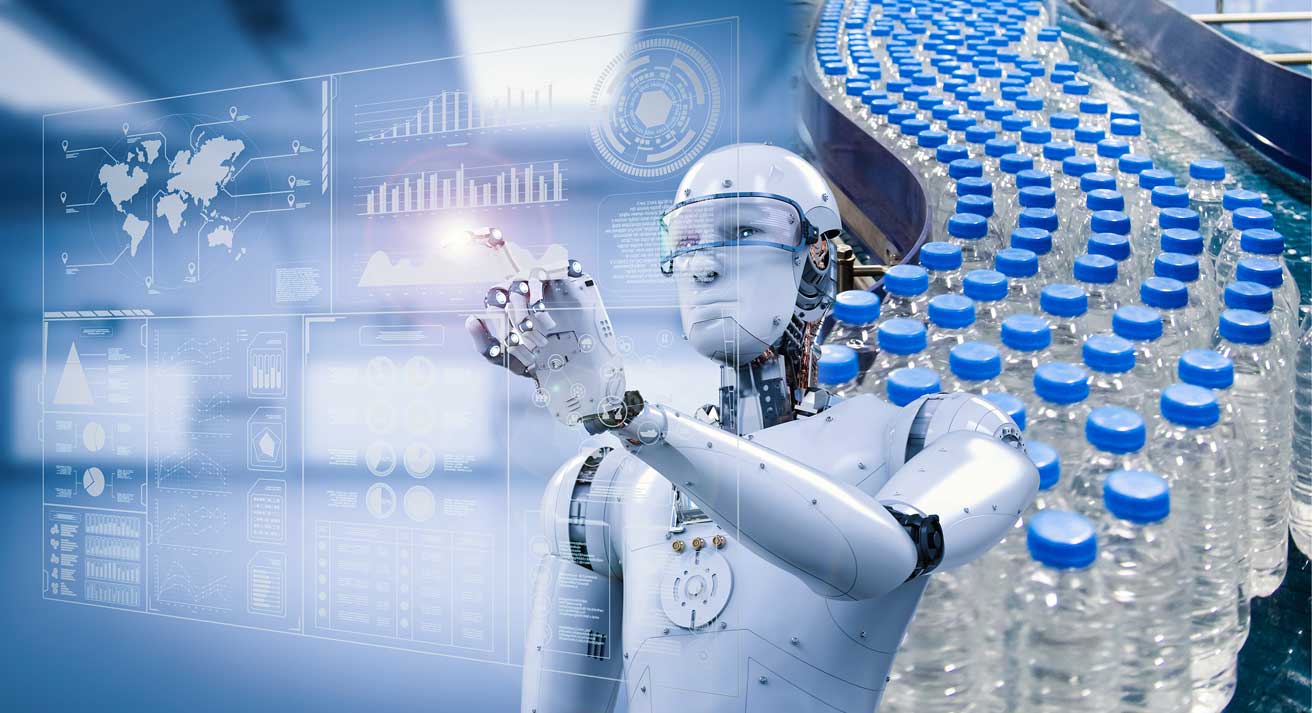

Robots for the automated factory

Articulated robots or Scara robots, bionic, assembly, service robots and the collaborative cobots as well as grippers and accessories

Image: Mitsubishi Electric

Sensors for the Internet of Things

Safety sensors, torque sensors, optoelectronic sensors or magnetic sensors, also for various types of protection

Safety technology for man-machine protection

Light grid, light barrier, safety interlock, safety light curtains, safe field box, signal lights for occupational safety and machine safety

Controls for mechanical engineering

Programmable logic controls, CNC controls, TNC controls or safety controls with digital twin and control technology

Here you will find numerous innovations from the industrial sector Automation services for the Industry 4.0 Age. We provide information about components, systems of the Image Processing, IPC, communication technology, Robot, Sensors Safety Technology and Controllers. We report on processes and technologies which the industrial Revolution serve in the world of work. In these automated processes, workplaces are becoming increasingly automated, freeing up manpower for less monotonous work.

Contents

Artificial intelligence is increasingly finding its way into the world of work and advancing automation technology. The products, systems, machines and plants for automation are networked with each other up to completely autonomous machines as part of the larger whole smart manufacturing. Our coverage shows the components, systems and applications of automation technology for process and factory automation from the sensor to grab, Communication technology, control and regulation technology, IT up to and including robots.

Special industries like Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations. You will also find news from and for the here Applied research.

The automation technology also forms Electrical Engineering, Drive Technology and other engineering scientific disciplines form the basis of such buzzword-rich developments as Industry 4.0, digital transformation or smart factory, which is particularly important in... Industrial machinery and equipment change our industrial production and manufacturing forever at a rapid pace. The following innovations are part of the bigger picture:

Igus presents the Service robot Rebel. Just one year after the first presentation of the modular gearbox for cobots, igus is already recording 20 automation projects per week. In doing so, igus relies entirely on its Motion Plastics expertise: the use of plastic makes the robot, weighing 8,2 kg, the lightest service robot with cobot function in its class. All mechanical components in the Rebel are developed and manufactured by igus.

Igus presents the Service robot Rebel. Just one year after the first presentation of the modular gearbox for cobots, igus is already recording 20 automation projects per week. In doing so, igus relies entirely on its Motion Plastics expertise: the use of plastic makes the robot, weighing 8,2 kg, the lightest service robot with cobot function in its class. All mechanical components in the Rebel are developed and manufactured by igus.

A pair of Robotic arm consists of various components such as drives, Sensors, controllers and end effectors, some of which are integrated in the robot flange. Some manufacturers offer robotic arms with flexible modularity that can be adapted to the needs of different industries. If you are looking for a robotic arm, it is worth asking one or the other of the providers presented here.

Which one Lawn Mower is the right one for your garden? Save time and effort with the best models for different lawn sizes. This article will guide you through tests and criteria to find the ideal automatic lawn mower. At the same time we provide you with the latest models before:

Efficient and transparent processes are essential in modern production. Identification systems such as RFID and barcodes offer optimization possibilities here. In combination with the proven Kanban-Method, they develop their full potential, for example. In this article, we use industrial Applicationshow RFID-supported systems and barcode technology make production more efficient, present new products and convey a little basic knowledge.

Pepperl + Fuchs is a specialist in RFID and optical identificationsystems that are used in industrial production and logistics. This opens up comprehensive tracking and tracing options for the user. Material flows can be controlled and precise processes ensure on-time delivery and optimal inventory management. We present new developments and application examples.

Whether the traditional Industrial robots due to the incoming tide Cobots soon no longer needed will be answered Mitsubishi Electric with “Of course not.” Therefore, the automation company still offers a whole range of industrial robots melfah Series, develops them further and even equips them Artificial intelligence out of. Below you will find everything you need to know about the Mitsubishi world of industrial robotics and we will introduce you to the latest innovations:

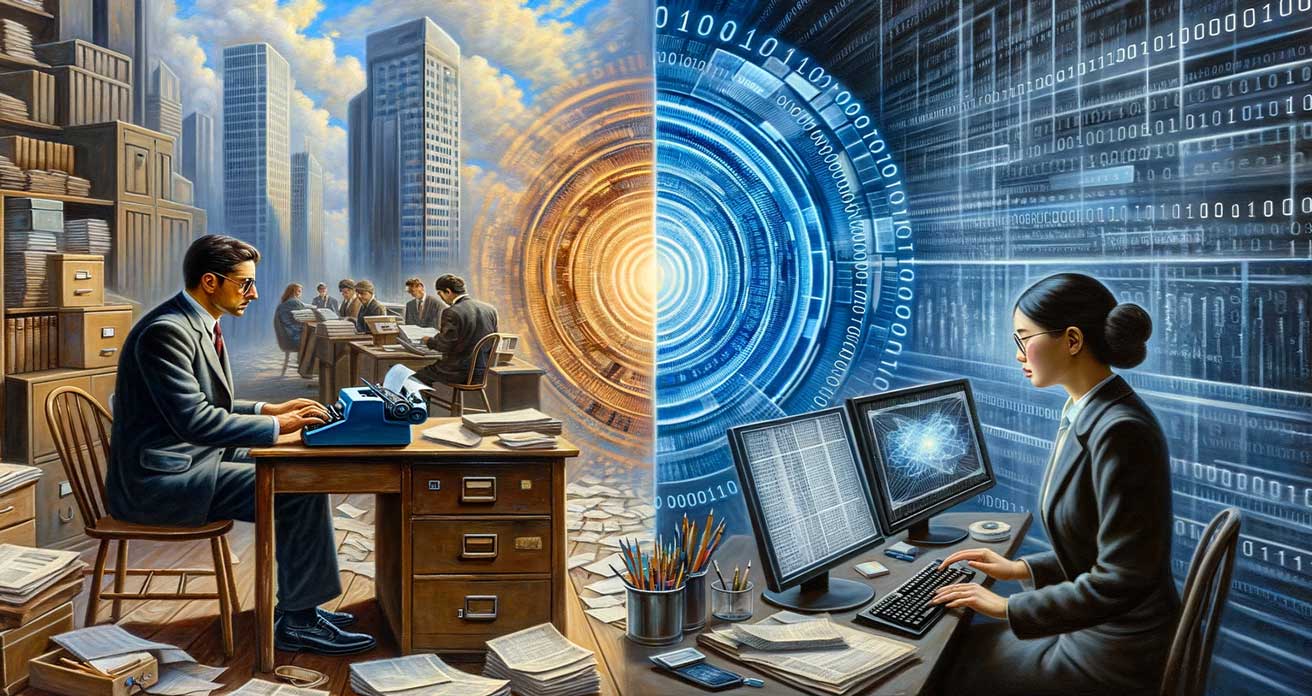

In digital manufacturing, the latest trends aim to connect the virtual and physical factory environment. This is what the term stands for Digital transformation. It aims to increase productivity, efficiency and profitability. For change, companies must combine a number of cutting-edge technologies in order to successfully complete the changes. We present the know-how of Mitsubishi Electric as an experienced partner.

With a high degree of Automation provides the Rodinger plastics technology GmbH (RKT) ensures the required quality and economy in the production of various plastic parts for the automotive industry, electronics industry, communication technology and medical technology. The automation technology for the plastic injection molding machine comes from the Industry 4.0 specialist Mitsubishi Electric, including numerous 6-axis Robot RV-2FR and the Human machine interface (HMI) GOT2000.

What does Scada mean today? In the past, Scada systems were used for monitoring, control and regulation and were appropriately used to manage systems and processes. Today, with the digitalization of industry and the associated new business models, it is becoming an important part digital transformation. And so has Mitsubishi Electric brought its proven platform Maps 4 to a new level. For the EMEA markets, Genesis64 complements the Maps software for system monitoring and process control.

The Martinshof, Workshop for people with disabilities, preferably works with Manual workstations, because they are perfect for integrating people with physical or cognitive disabilities into working life. The Japanese “Poka-Yoke” principle and the Guided Operator Solutions (guided manufacturing solutions) from Mitsubishi Electric ensure the high quality.

The Martinshof, Workshop for people with disabilities, preferably works with Manual workstations, because they are perfect for integrating people with physical or cognitive disabilities into working life. The Japanese “Poka-Yoke” principle and the Guided Operator Solutions (guided manufacturing solutions) from Mitsubishi Electric ensure the high quality.

The Gimatic booth at K 2013 was transformed into a fan block from two sides: on the one hand, customers and trade visitors were captivated by three decades of football history, on the other hand, a vacuum gripper for organic sheets and many other gripper innovations were convincing. Customers such as Prautec, Gerhardi and Hahn Automation also gave insights into the collaboration with the mechatronics technician, who not only impressed them with half the delivery times. Last but not least, we learned what a soccer world champion thinks of the controversial technology in goal.

The Gimatic booth at K 2013 was transformed into a fan block from two sides: on the one hand, customers and trade visitors were captivated by three decades of football history, on the other hand, a vacuum gripper for organic sheets and many other gripper innovations were convincing. Customers such as Prautec, Gerhardi and Hahn Automation also gave insights into the collaboration with the mechatronics technician, who not only impressed them with half the delivery times. Last but not least, we learned what a soccer world champion thinks of the controversial technology in goal.

The digital transformation has a lasting impact on our working world and society. This is not just about introducing new digital tools, but also about a fundamental change in the way we work and create value. The goal is to become more efficient, develop new business models and adapt to a constantly changing digital environment. Read how technology leader Master the transformation and support your customers in the process.

The SCARA robot from Mitsubishi Electric are suitable for a wide range of applications including assembly of small parts, heavy payloads, and handling and packaging applications. With his extraordinary motor and amplifiersystem, the robots work with high precision at high speeds. Discover the new and further developments of the Scaras: