Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

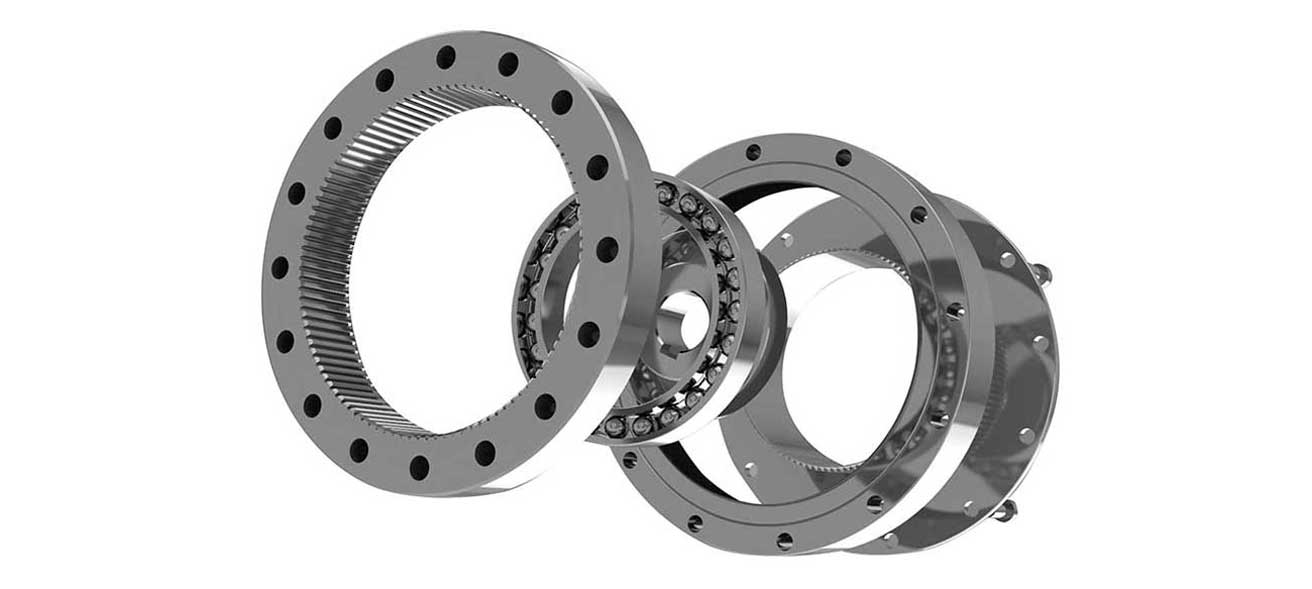

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

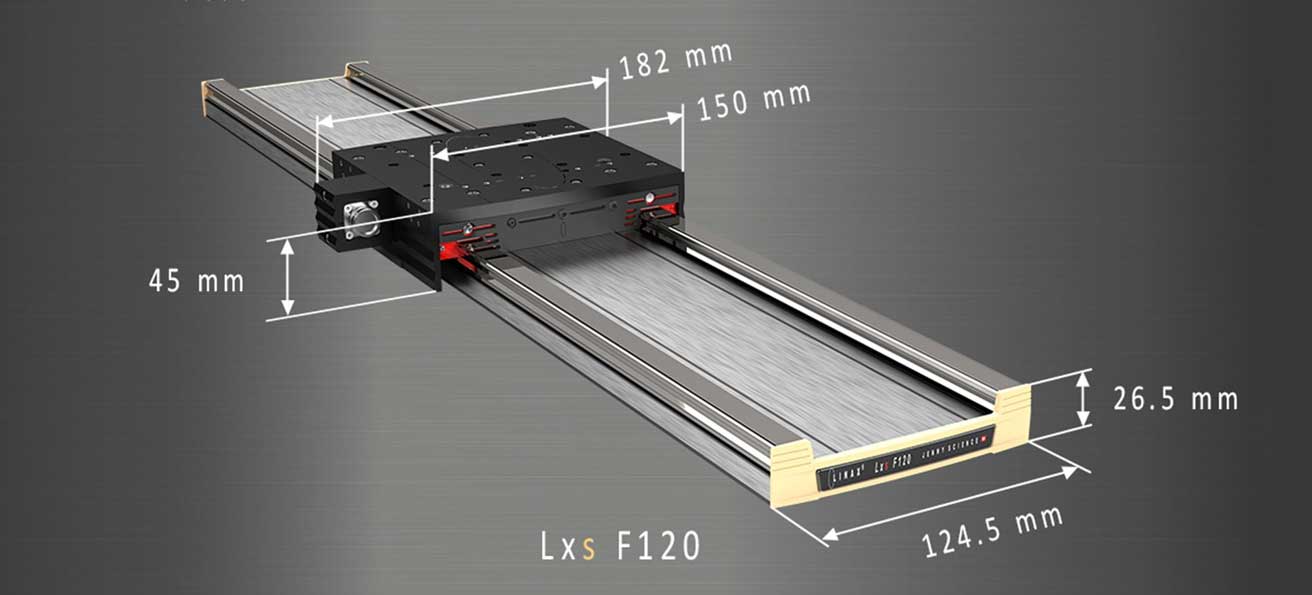

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

Stepper Motors have become indispensable in the industry for precise movements and flexibility in countless applications steering to ensure. They have high accuracy, are robust and offer a wide range of torques and speeds. They are therefore ideal for use in production, for example, Automation or Robotic. In this article we present the latest developments:

The Servomotor of today is characterized by the fact that it is compact, works precisely, highly dynamically and energy-efficiently and advances Industry 4.0. He is based on Synchronous- and asynchronous motor, alternating current motor, direct current motor or stepping motor, which over servo to be controlled. We present here the New Products the often small powerhouses and report on everything from the simple servo system tailored to the customer to the with Artificial intelligence provided servo drive.

The Linear motor, an integral part of modern Drive Technology, has made remarkable progress in recent years. This development goes hand in hand with the innovations Linear actuator and Electric cylinder. Our comprehensive overview presents the latest features and technology trends of these drive components. Read what various manufacturers have developed for your design.

A-Drive's NEMA 17 ZEN Hollow Shaft Actuator features a novel magnetic design that stepper motor gives previously unattainable properties. The features include very high accuracy, an extremely compact design and silent running. The stepper motor can be flexibly adapted to almost any application and opens up numerous new areas of application that were previously reserved for larger series.

A-Drive's NEMA 17 ZEN Hollow Shaft Actuator features a novel magnetic design that stepper motor gives previously unattainable properties. The features include very high accuracy, an extremely compact design and silent running. The stepper motor can be flexibly adapted to almost any application and opens up numerous new areas of application that were previously reserved for larger series.

An rigid coupling or Shell coupling offers advantageous properties such as a backlash-free shaft connection or high torque transmission. Find out how rigid couplings ensure precise power transmission and fail-safe connections in your drive solution. Optimize your systems with proven products that are known for their robustness and easy installation.

The Linear axis is a core building block in the Automation and precision metrology. We present new developments to you here various companies before, their functions and areas of application. Find out how you can generate advantages in your design with these linear axes.

Two international companies headquartered in Germany have successfully completed a project of great importance for the construction industry in the Persian Gulf. With Drive Technology from NORD has SMS Group A heavy section rolling mill was built in the Kingdom of Bahrain. Only the most robust electric drives can withstand heavy mechanical stress and extreme heat, dirt and steam, as an application video and the following article show.

A complete virtual image of drive trains and transmissions is only possible if transmission, Rolling- and gear specialists can digitally link their simulation models with each other. Therefore, cross-company and cross-system data exchange is one of the most important prerequisites for generating Digital Twins. Schaeffler and SEW have created such a data exchange.

Strain wave gear are suitable for applications that require precise positioning and high repeatability. the Schaeffler Group puts on the Hannover Messe equal three new precision wave gears before: for Cobots, Industrial robots and torque applications. The kit for fully integrated Tribo strain wave gear from Igus has everything a Cobot needed to accelerate low-cost automation. We present these and other innovations to wave gears to you here:

The simply constructed ones Spur gears offer high efficiency and can effectively transmit torque between parallel shafts with minimal noise. This makes them suitable for use in manufacturing plants Automotive drives to wind turbines and other heavy industrial applications. This article highlights innovative New developments, applications and shows comprehensive Serviceservices that allow you to increase your efficiency and extend the operating life of your application.

The Angle gear transmit torque efficiently between crossing shafts, making them suitable for complex drive systems in the Automotive industry, in mechanical engineering or in aviation makes it particularly valuable. Find out more about the latest developments from various manufacturers and the versatile application possibilities of angle gears, especially from Bevel gears.

NORD has changed from Transmissionmanufacturer to the value chain partner for complete solutions Drive Technology developed. The product portfolio also includes the industrial gear Maxxdrive series for maximum output torques of 282.000 Nm for applications in heavy-duty industries. The example of one Bascule bridge shows how individual drive solutions can be created with short delivery times.