Safety coupling: when + why?

- Details

- Hits: 11304

The safety clutch reliably protects machines and systems from damage that can be caused by overload. Therefore, the question should always be asked when designing: safety coupling Yes or no? It is best to like an expert Mayr Antriebstechnik to ask. You can read up on it here. This article provides a lot of clutch know-how and shows some applications in practice.

Contents

- Why it is so important to install a safety clutch

- Training for the right selection of the coupling

- Configurator for the appropriate safety coupling

- Backlash-free servo couplings for vertical axes in machine tools

- Element, idle and shaft coupling portfolio expanded

- Corrosion-protected safety couplings protect against overload

- The safety coupling in practice – reports from users

- FAQ

Why it is so important to install a safety clutch

05.07.2021 | machine builders should actually know how important it is to have a safety clutch in the powertrain to install Actually. However, their design does not always meet the high speeds and precision of modern machines, because there are cheaper alternatives. We can find out from the experts at Mayr Antriebstechnik what speaks in favor of using safety couplings instead, what types there are at all, how to choose the right one.

Safety coupling - yes or no?

Modern machines with their high speeds and accuracies must have a corresponding one Stiffness exhibit. Errors in operation or programming, just like the effects of foreign bodies, can lead to an overload in the drive train. In the worst case, such an incident could result in a hard collision. The torques that are then set too high can damage or even destroy the Drives .

Does the designer have a safety clutch provided, this springs a Overload case from. Mechanical safety clutches, overload clutches or torque limiters that disconnect in a flash, precisely limit the torques. This protects the components from excessive stress.

Ferdinand Mayr presents innovations at the SPS

Ferdinand Mayr presents innovations at the SPS

While the production manager has an interest in it, inevitable Machine downtime as short as possible to keep the damage to a minimum, the decision to install a safety coupling lies with the machine manufacturer. If the latter wants to deliver highly available machines, protect their drive train with a safety clutch from the outset and is not focused on the spare parts business, that is good for the end user. Of course, he can also demand that the construction be secured by a safety coupling. If neither is the case, alternatives are used. Let's look at the disadvantages of such solutions:

Alternatives for safety couplings and their disadvantages

A small additional effort is the use of an electronic monitoring function of the machine control. The work process can be permanently monitored using the motor current that is regularly recorded anyway. A Motor current control can be used for low dynamic applications and soft collisions.

A small additional effort is the use of an electronic monitoring function of the machine control. The work process can be permanently monitored using the motor current that is regularly recorded anyway. A Motor current control can be used for low dynamic applications and soft collisions.

In the case of a hard collision, this is Method too slow. Because it often happens unexpectedly. The control process that switches off the system does not start until after the collision - timely countermeasures are not available. The overload clutch located directly in the drive train reacts much faster here. It continuously records the current torques and reacts within a few milliseconds. In the event of an overload, it opens the drive train and decouples the following masses.

A pair of software based system is another alternative for collision prevention. It detects impermissible approaches of machine components in the work area. But that only makes it relatively rough and requires a high level of computer performance. Faulty components are not recorded at all.

Types of safety couplings and their function

A safety coupling optimizes the Total Cost of Ownership (TCO). Compared to the investment costs, these are often even lower than just a single overload damage.

There are two types of safety couplings: load holding and load separating. These include friction clutches, magnetic permanent slip clutches and locked clutches. Load-holding Safety clutches limit the torque to the specified value. In the event of an overload, the torque limiters do not interrupt the torque transmission. This is especially important with vertically or obliquely moved masses so that the load does not fall in an uncontrolled manner.

Compensation coupling for high temperatures

Compensation coupling for high temperatures

Load disconnector Safety clutches are divided into latching, disengaging, switchable and controllable. The torque is transmitted positively. In the event of an overload, the load-separating safety clutch interrupts the power or torque transmission and separates the drive side from the output side.

Mayr offers every clutch design for all conceivable applications, including the EAS safety clutches, which we will go into in more detail below.

Electrically disengageable safety clutch

EAS series the drive specialist launched an electrically disconnectable safety clutch on the market more than half a century ago. The portfolio includes a load-holding version and several load-separating versions. The large standard portfolio covers a large number of applications. For this purpose, permanent adjustments to speed and dynamics are made in Mauerstetten. From the currently 15 series, we present three overload versions in detail below:

Isolating clutch for torques up to 3000 Nm

The new standard series EAS compact F is a new clutch for torques up to 3000 Nm. The load-separating clutch transmits the torque positively and supplies a signal about the state of the drive train. If the clutch is disconnected once in the event of an overload, it is immediately ready for use again after the fault has been eliminated.

The new standard series EAS compact F is a new clutch for torques up to 3000 Nm. The load-separating clutch transmits the torque positively and supplies a signal about the state of the drive train. If the clutch is disconnected once in the event of an overload, it is immediately ready for use again after the fault has been eliminated.

The EAS-compact F has sealed functional parts.: O-rings reliably prevent lubricants from escaping from the Clutch is thrown. In the improved adjusting nut with its symmetrical structure, the scaling is easier to read and the balancing quality is higher. The cost-effective safety coupling is for speeds in the range of 12.000 min-1 designed.

Element coupling for high speed

For high-speed applications, the EAS-HSE high speed Element coupling developed. With torques between 32,5 Nm and 15.000 Nm are suitable for speeds of 25.000 rpm-1 with the small and 8000 min-1 with the large sizes. The compact couplings are available in new lightweight designs.

An example is a safety coupling with an outside diameter of 90 mm and less than 3 kg in weight. This power density is based on the compact design. The small outer diameter is offset by a relatively large bore diameter. The low-vibration safety clutch works very precisely when triggered thanks to the integrated, symmetrically arranged elements.

High-torque element coupling up to 440.000 Nm

A new series with torques of up to 440.000 Nm in the standard version is offered by the EAS-HT high-torque element clutch. Even more are possible in the special version. In addition to an improved power density, the EAS-HT offers a significantly wider selection of possible holes. With this clutch, the torque is set at the factory and is available again immediately after disengagement.

A new series with torques of up to 440.000 Nm in the standard version is offered by the EAS-HT high-torque element clutch. Even more are possible in the special version. In addition to an improved power density, the EAS-HT offers a significantly wider selection of possible holes. With this clutch, the torque is set at the factory and is available again immediately after disengagement.

The following application illustrates the potential of the EAS-HT: ArcelorMittal Ostrava (AMO) protects the components of the drive train in its roll stands with EAS-HT safety clutches. The overload clutches sit between Motor and Transmissionwhere they get the torque to the set value of 170.000 Nm at a maximum speed of 400 min-1. Read the full user report here .....

Intelligent shaft coupling for predictive maintenance

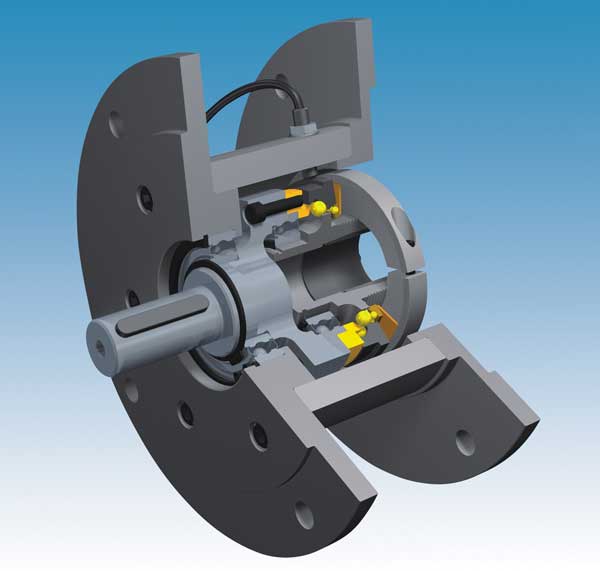

Of course, the drive specialist also equips its safety coupling for the Entry of Industry 4.0. In the modern drive train, the combination of an overload clutch with a measuring system is the method of choice. Not only that no other electronic system separates the drive and output sides as quickly as the overload clutch. If you also combine them with Measurement Technology, load limits can be shifted on the basis of the measurement results in real time. This means that the machine or system can be used to capacity much better. The intelligent shaft coupling is for such purposes Roba DSM (Picture above) can be combined with an overload clutch.

Compensating Couplings | Innovations Overview of various manufacturers

Compensating Couplings | Innovations Overview of various manufacturers

Of course, Mayr can still see here Potential for the future. In Mauerstetten, for example, they are investigating what can still be read out of the machine status from measured values such as speed, torque, temperature, etc. B. can be used for predictive or preventive maintenance. It is conceivable to plan the maintenance or the replacement of components as soon as the clutch has disengaged x times. But the whole thing must also be put in context with the resulting costs. Using the safety coupling as an indicator in addition to protection and reducing TCO costs with it is definitely a trend for them Drive Elements.

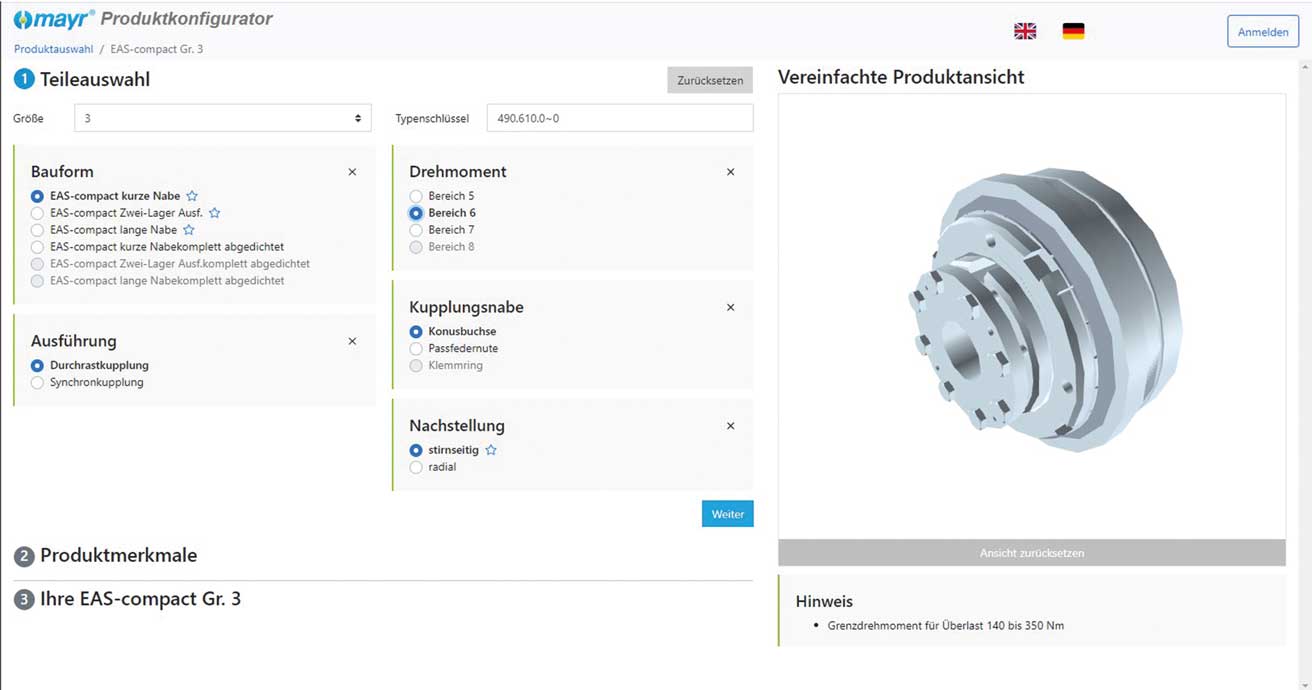

Configurator for the appropriate safety coupling

05.07.2021 | In order for a torque limiter to function reliably, it must be tailored to the respective application. There is no one overload clutch for all applications. To the users make the selection easier, the drive specialist offers a configurator for simpler applications and for the pre-selection of special applications. On the basis of technical data such as the type of drive, speed, torque or transmission behavior, the designer selects the right coupling for his application.

Slipping clutch and overload clutch limit torques

Slipping clutch and overload clutch limit torques

He can be here relatively easily Detect space requirements. The dimensions of the individual coupling types are the same, regardless of whether the mechanical function is locking, synchronous or disengaging. Once the clutch has been selected, the Mayr specialists are of course available to confirm or fine-tune it - especially because the selection of overload clutches in the past was 80% very advice-intensive. Because in the end, the safety coupling must still function reliably even if its use is only necessary after a very long time.

Training for the right decision

05.07.2021 | Mayr offers various online courses from its new training center practical webinars including basic seminars on safety clutches and safety brakes for specialists and managers, designers, developers and safety officers. They are all qualified at expert level to select and dimension the respective safety components, taking into account all physical conditions and influencing factors, so that they can rule out personal injury and property damage.

For the more demanding application, however, it is generally recommended to use one Consulting to consult. For very special customer applications that require customer-specific development, the drive specialists should be brought on board as early as possible.

Backlash-free servo couplings for vertical axes in machine tools

08.07.2019 | With its clutches and brakes, Mayr Antriebstechnik offers complete solutions from a single source for the reliable protection of Machine Tools and Machining centers. For example, a wide range of backlash-free, high-performance servo couplings ensures a secure connection between the shafts.

08.07.2019 | With its clutches and brakes, Mayr Antriebstechnik offers complete solutions from a single source for the reliable protection of Machine Tools and Machining centers. For example, a wide range of backlash-free, high-performance servo couplings ensures a secure connection between the shafts.

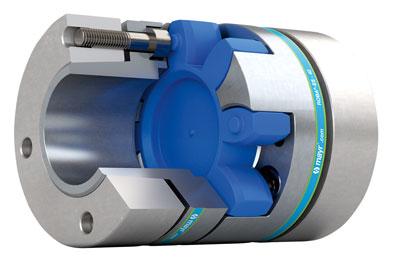

Depending on the application, these servo couplings are subject to very different requirements. That is why the drive specialist has different Metal bellows, elastomer and plate pack couplings in program. The company has recently added numerous new hub designs and intermediate sleeves to its standard modular system – most recently a new, long intermediate sleeve for the "Roba-ES" elastomer couplings.

with the big one Variety of variants the company is able to offer solutions for all drive constellations in servo technology, easily and quickly. Because the intelligent modular system also ensures high availability, short delivery times for standard components and low prices.

Element, idle and shaft coupling portfolio expanded

04.02.2019 | In addition to safety brakes and the associated control and monitoring modules, Mayr has been developing and manufacturing tried-and-tested safety clutches and shaft couplings for decades and stands for reliable products Complete solutions from a single source. And so the company has also significantly expanded the performance range of its safety couplings. The power density has been improved with the new series "EAS-HT High-torque" element clutches and the selection of possible bores has been significantly expanded.

04.02.2019 | In addition to safety brakes and the associated control and monitoring modules, Mayr has been developing and manufacturing tried-and-tested safety clutches and shaft couplings for decades and stands for reliable products Complete solutions from a single source. And so the company has also significantly expanded the performance range of its safety couplings. The power density has been improved with the new series "EAS-HT High-torque" element clutches and the selection of possible bores has been significantly expanded.

There is also a new series of EAS compact clutch, into which the company has incorporated its many years of experience and the knowledge gained from numerous test series. The couplings thus take into account the constantly increasing demands on speed and dynamics. In addition, the "EAS-HSE" high-speed element clutches for high-speed applications have been expanded by two small sizes.

In the field of shaft couplings, the engineers have, among other things, expanded the torque range of the large "Roba-DS" disk pack couplings and thus also offer for areas greater than 100.000 Nm reliable connections for measuring flanges. Last but not least, the standard modular system for the backlash-free, high-performance servo couplings has been enlarged. New, modern manufacturing processes also ensure low prices and short delivery times.

Corrosion-protected safety couplings protect against overload

08.05.2012/XNUMX/XNUMX | Corrosion-protected safety couplings to protect against overload damage have proven themselves in numerous applications where moisture and dirt are part of the daily environmental conditions. In the event of malfunctions and collisions, they limit the torque in the drive train to a defined value, thus avoiding damage, downtime and repairs. Mayr Antriebstechnik has expanded the "EAS-HTL" series by a size with a torque of 2400 Nm.

08.05.2012/XNUMX/XNUMX | Corrosion-protected safety couplings to protect against overload damage have proven themselves in numerous applications where moisture and dirt are part of the daily environmental conditions. In the event of malfunctions and collisions, they limit the torque in the drive train to a defined value, thus avoiding damage, downtime and repairs. Mayr Antriebstechnik has expanded the "EAS-HTL" series by a size with a torque of 2400 Nm.

The housing couplings of Series EAS-HTL can also be retrofitted into existing constructions and systems. The dimensions of the housing flanges and shafts comply with IEC/B5 and Nema standards. The extremely short overall length of the coupling facilitates integration into the existing drives. In addition, the high rigidity of the solid steel housing allows hanging loads to be attached. In addition to preventing dirt and moisture from penetrating, the housing seal also prevents lubricants from being washed out of the built-in EAS-NC or EAS-compact safety clutch.

These safety couplings transmit the torque in trouble-free operation over the entire service life backlash free and are therefore also suitable for sophisticated and dynamic drive concepts. They are set at the factory to the desired limit torque. If this torque is exceeded due to overload or collision, the clutches disengage and separate the input and output within a few milliseconds.

An integrated limit switch detects the disengagement movement and outputs a signal that can be used, for example, to switch off the drive. The disengagement time depends on the stiffness of the axle as well as the hardness and speed of the collision.

metal bellows coupling | Innovations, applications and special features

metal bellows coupling | Innovations, applications and special features

When freaking out, the disc spring with a negative characteristic for the fact that the torque drops immediately and not only after a significant increase in torque, which has to be accepted with many other locking body clutches. The re-engagement behavior after an overload situation varies depending on the design of the safety clutch that is integrated in the EAS-HTL.

snap-through clutches automatically snap into any position and are immediately ready for use again. Synchronous clutches behave in a similar way, but with the special feature that they can only engage at a precisely defined position on the input and output side. Overrunning clutches, on the other hand, remain disengaged until re-engaged by hand or devices. The stored energy of the rotating masses can run out freely. The disengaging version is preferred for large mass moments of inertia and high speeds.

The safety coupling in practice – reports from users

- Safety coupling protects non-destructive tunnel boring machines

- Patented shaft coupling for beverage technology

- Powerful shaft coupling for bakery technology

- Safety couplings when used in the packaging industry

- Reliable coupling secure ice cream and cream cheese production

- Robust safety clutch in the rolling mill from Acelor Mittal

Safety clutch protects non-destructive tunnel boring machines

10.01.2020/XNUMX/XNUMX | Two tunnel boring machines are the largest machines on the construction site Semmering Base Tunnels. The safety clutch provides overload protection EAS HT from Mayr drive technology. This Couplings trigger reliably and comprehensibly and protect the drive components sustainably.

10.01.2020/XNUMX/XNUMX | Two tunnel boring machines are the largest machines on the construction site Semmering Base Tunnels. The safety clutch provides overload protection EAS HT from Mayr drive technology. This Couplings trigger reliably and comprehensibly and protect the drive components sustainably.

Patented shaft couplings for beverage technology

18.09.2019 | Bayer mechanical engineering plans, develops and builds efficient packing and palletizing systems for the beverage and food industries. The patented “Roba-DS” Disc pack clutch von Mayr transmits precise torques in these systems. In lifting applications, the "Roba-linearstop" safety brakes reliably ensure the safety of people and material.

18.09.2019 | Bayer mechanical engineering plans, develops and builds efficient packing and palletizing systems for the beverage and food industries. The patented “Roba-DS” Disc pack clutch von Mayr transmits precise torques in these systems. In lifting applications, the "Roba-linearstop" safety brakes reliably ensure the safety of people and material.

Powerful shaft coupling for bakery technology

14.01.2019/XNUMX/XNUMX | In large European bakeries they are running Baking streets sometimes around the clock for the production of baguettes. The bakery technology with all its components must therefore be able to withstand the high demands. That's why a manufacturer relies on the robust and powerful Roba-DS Couplings from Mayr Antriebstechnik.

14.01.2019/XNUMX/XNUMX | In large European bakeries they are running Baking streets sometimes around the clock for the production of baguettes. The bakery technology with all its components must therefore be able to withstand the high demands. That's why a manufacturer relies on the robust and powerful Roba-DS Couplings from Mayr Antriebstechnik.

Safety couplings when used in the packaging industry

17.10.2017 | Safety couplings ensure in packaging machines and bottling plants for the reliable protection of people and material. They separate input and output at lightning speed and thus prevent expensive damage. To ensure that the coupling optimally fits the respective application, Mayr Antriebstechnik has developed a wide range of torque-limiting safety couplings.

17.10.2017 | Safety couplings ensure in packaging machines and bottling plants for the reliable protection of people and material. They separate input and output at lightning speed and thus prevent expensive damage. To ensure that the coupling optimally fits the respective application, Mayr Antriebstechnik has developed a wide range of torque-limiting safety couplings.

Robust safety clutch in the rolling mill from Acelor Mittal

04.05.2017 | From iron ore mining to steel rolling mills, Mayr offers drive technology for the Iron and steel pioneering safety clutches with high power density. And so also in the rolling mills of Arcelor Mittal the couplings from Mauerstetten for maximum operational reliability and maximum productivity.

04.05.2017 | From iron ore mining to steel rolling mills, Mayr offers drive technology for the Iron and steel pioneering safety clutches with high power density. And so also in the rolling mills of Arcelor Mittal the couplings from Mauerstetten for maximum operational reliability and maximum productivity.

Reliable couplings secure ice and fresh cheese production

June 30.06.2016, XNUMX | Mayr has a wide range of options to ensure that the coupling is optimally suited to the respective application torque limiters developed. For areas of application such as the food industry, where moisture and cleaning fluids are part of everyday environmental conditions, the company offers corrosion-protected drive elements made of rust-free materials.

June 30.06.2016, XNUMX | Mayr has a wide range of options to ensure that the coupling is optimally suited to the respective application torque limiters developed. For areas of application such as the food industry, where moisture and cleaning fluids are part of everyday environmental conditions, the company offers corrosion-protected drive elements made of rust-free materials.

What is a safety coupling?

A safety clutch transmits Reliable torques and limits that to a defined value. By separating both sides of the drive train in a fraction of a second, it increases system availability, lowers operating costs and significantly minimizes repair work.

You might also be interested in...

High-performance brake wind turbine with monitoring

Robco robot kit with safety brake from the construction kit

Safety brakes: innovations + tips for installation

Predictive maintenance for clutches and brakes

Mayr drive technology | Inventor of the freedom to play

Whisper-quiet elevator brake secures elevators and escalators

Simone Dauer is a press officer at Chr. Mayr GmbH + Co. KG, Mauerstetten