Intelligent CNC control for machine tools

- Details

- Hits: 13529

Mitsubishi Electric shows how machine tools in networked production systems, with smarter CNC Control, Edge Computing and increase productivity through partner solutions. In this article you will find information about the innovations for EMO 2023, the connection of robots via a plug-and-play integration or the new one CNC Control M8V with direct WiFi connection.

Contents

- NC Optimizer and NC Virtual Simulator

- CNC control for research in bending technology - user report

- Innovations for the smart factory of the future

- CNC control, motors and peripherals for the retrofit

- Networked production, smart CNC control, edge computing

NC Optimizer and NC Virtual Simulator

14.08.2023/XNUMX/XNUMX | Mitsubishi Electric will be exhibiting in the fully networked smart manufacturing world at the EMO 2023, how new software tools and advanced automation sustainably advance companies in the age of Industry 4.0.

14.08.2023/XNUMX/XNUMX | Mitsubishi Electric will be exhibiting in the fully networked smart manufacturing world at the EMO 2023, how new software tools and advanced automation sustainably advance companies in the age of Industry 4.0.

For this purpose, an abstract production line is simulated, in which a EDM machine automation is integrated. The production line is continuously monitored and evaluated by the NC Optimizer so that energy and resource consumption can be tracked and analyzed in real time. This reduces energy consumption, reduces material waste and makes production more efficient. In addition, an NC Virtual Simulator is integrated into the production line, which represents a virtual test machine. Test cuts can be made on , which significantly reduce material and tool consumption.

With the introduction of Tool Wear Diagnostic Software would like to take the company to make production more sustainable. Based on integrated algorithms, the software enables precise and efficient monitoring of tool wear by optimizing production processes that reduce resource consumption.

Also in terms of sustainability, Mitsubishi Electric return defective parts, refurbishes them and puts them in like-new condition. This cycle ensures long-term and reliable availability of high-quality spare parts over a period of up to 40 years. At the same time, the service concept minimizes waste. This is illustrated by the maintenance cycle of an MDS-C drive at the EMO. 3D-printed components are also used for repairs. These underline the competence for advanced manufacturing techniques. Even very old products can be processed in this way.

CNC control for research in bending technology

03.11.2022 | At the Technical University of Munich (TUM) has taken on the processing of new materials with existing manufacturing methods in bending technology. Using the practical example of a free-form bending machine from J. Neu GmbH The IoT CNC control module DAU from Mitsubishi Electric plays an important role in mechanical engineering and trade. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology. The PhD students Lorenzo Scandola M.Sc., Matthias Werner, M.Sc. and Daniel Maier, M.Sc. examine individual aspects of the bending process in independent research programs.

"Know-how also arises at the chair through such projects," says Matthew Werner. “With our projects, we move in the field of applied research, which directly benefits the industry. The main purpose is to generate new knowledge in a specific field that will help solve a technical problem."

"Know-how also arises at the chair through such projects," says Matthew Werner. “With our projects, we move in the field of applied research, which directly benefits the industry. The main purpose is to generate new knowledge in a specific field that will help solve a technical problem."

Lorenzo Scandola adds: "In concrete terms, we hope to gain insights into how new materials can be bent that were previously difficult or impossible to bend like new ones due to their special properties plastics or Composites. Otherwise, the trial and error method would remain the same as before, which is time-consuming and costly and produces a lot of rejects. Especially for the Automotive industry a cost saving would be very interesting.”

6 axis bending machine

The test workshop with various machines for practical tests is located near the TUM campus in Garching near Munich. Since 2019 there has also been one among them free-form bending machine the company New. The manufacturer of bending machines, long-bed milling machines on the one hand and sawing technology on the other, responded positively to a request from the TUM and made the TYPE NSB 090-S free-form bending machine with 6 axes available for scientific research. The machine has a high bending capacity and an unlimited bending direction of 360°. It bends tubes and profiles made of steel, stainless steel, aluminum and other materials with a diameter of 6 mm to 90 mm. The controllable axes and a fully synchronized CNC control from Mitsubishi Electric offer almost unlimited freedom for the production of bent components.

The interest of Professor Dr.-Ing. Wolfram Volk at Freiformbiegetechnologie was unexpected for Neu GmbH, but not unwelcome. On the contrary. “We are very innovative ourselves,” says Lothar Kummermehr, project manager at Neu. "However, we believe that TUM could find new approaches parallel to our own research and thus advance bending technology quite a bit."

Compensate for deviations resulting from material fluctuations

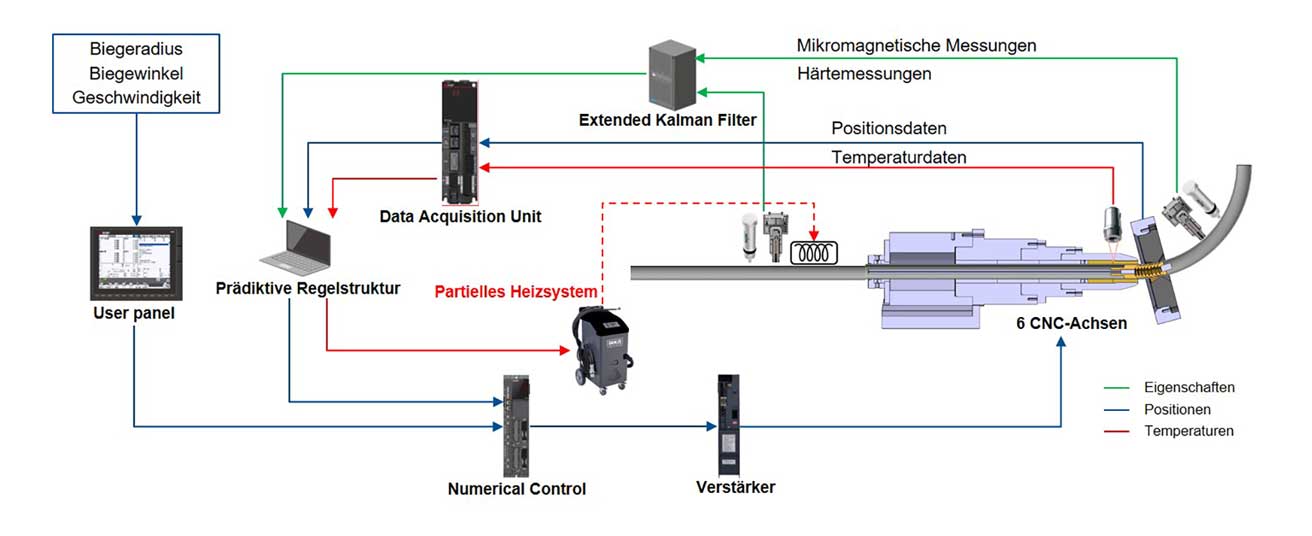

Daniel Maier's topic "Property-controlled process design of free-form bending taking into account the semi-finished product properties" is about the implementation of a Soft sensor based control structure. This measures the fluctuations in the mechanical properties of the semi-finished products and reacts to them in the forming process. Deviations resulting from material fluctuations are to be compensated for by inline measurement and control technology. Such a rule has so far been impossible. That should change now.

The desired process control was not possible with the standard controller because it cannot intervene in the process in real time. "We asked Mitsubishi Electric for support for this process in early 2020," says Daniel Maier. "And it turns out that they were working on a unit like this that you can use for the rule structure."

At Mitsubishi Electric, the newly developed Data Acquisition Unit module, DAU for short, was found to be suitable for the TUM project. Christopher Krekels, a specialist for CNC applications at Mitsubishi Electric, found the request very interesting: “It is a highly complex topic and we definitely see ourselves as pioneers here. We developed the DAU because we saw a long-term need for it.”

At Mitsubishi Electric, the newly developed Data Acquisition Unit module, DAU for short, was found to be suitable for the TUM project. Christopher Krekels, a specialist for CNC applications at Mitsubishi Electric, found the request very interesting: “It is a highly complex topic and we definitely see ourselves as pioneers here. We developed the DAU because we saw a long-term need for it.”

After 1 ½ months, the control module was implemented in the bending machine and included in the control loop. The aim was Position data in real time read, process and create new process requirements. "Optimization through feedback and adaptive control would be real added value for free-form bending," says Daniel Maier. "Other industries can also use the new development for themselves afterwards."

The DAU can be different drive data such as position, speed, load etc., sample, record and collect external sensor data and RIO (Remote Input/Output) with high speed and guaranteed time synchronization between the data. The collected data can e.g. B. can be used to monitor machine operation, to diagnose machining or for preventive maintenance.

External sensors are designed to optimize the bending process

"TUM is researching how to optimize the bending process with the help of external sensors that Material behavior of the workpieces during the bending process analyze.” explains Christoph Krekels. All data can be permanently synchronized with the DAU. By synchronizing the position data with the sensor data, the area on the pipe can be precisely identified and examined. For example, if the material is too thin after bending, the process must be optimized. It is also possible to react to batch fluctuations. Ultimately, the production of faulty or poor-quality workpieces in series should be reduced.

"TUM is researching how to optimize the bending process with the help of external sensors that Material behavior of the workpieces during the bending process analyze.” explains Christoph Krekels. All data can be permanently synchronized with the DAU. By synchronizing the position data with the sensor data, the area on the pipe can be precisely identified and examined. For example, if the material is too thin after bending, the process must be optimized. It is also possible to react to batch fluctuations. Ultimately, the production of faulty or poor-quality workpieces in series should be reduced.

The new control module is also suitable for Tool monitoring in a machining process. Vibrations occur when a tool touches or processes the workpiece. These are recorded via sensors connected to the analogue input (AI input of the DAU). Anomalies are detected and tool wear is assessed. If necessary, the tool is replaced.

"The new interfaces are a sensation," says Daniel Maier. "Even though the project is still in its infancy, we can already say that the first results are very promising are.” The second phase of the project should be completed by the end of 2023. The control loop then has to run, even if not in real time. The third phase, the transfer of theory into industrial practice, should be completed by 2025.

Innovations for the smart factory of the future

Mitsubishi Electric Mechatronics CNC offers a wide range of digitization solutions to optimize the production processes on the CNC machine. Components and technologies optimally adapted to customer requirements help to equip production technology for the future. Artificial intelligence pulls here within the framework of the strategic Project Maize also entered the factory halls. On the AMB 2022 the company shows practical examples for the CNC (Computerized Numerical Control) machine. filter

CNC control with direct WiFi connection

The new M8V series As the only CNC control with a direct WiFi connection, Mitsubishi Electric is an important pioneer for future-oriented Industrial Internet of Things environments (IIoT) in smart, automated production such as CNC milling, turning or in the machining center. Users can access CNC machines from anywhere and at any time via connected devices such as tablets.

The design is immune to interference, operation and monitoring is safe and reliable. An interactive display supports 4 point multi-touch gestures and can be operated in a similar way to a modern smartphone. The most important processing parameters can be controlled and monitored intuitively. The M8V-CNC controller offers high precision and speed.

Graphic HMI operator terminals for industrial automation

Graphic HMI operator terminals for industrial automation

The control combines a special CPU optimized for CNC with innovative OMR-CC control (Optimum Machine Response - Contour Control) with automatic cutting load control (Cutting Load Control, CLC). Machining times can be shortened with this CNC control. This results in high quality products with clock rates at least 11% below previous models. The path errors are 15% lower.

The high number of axes for machining centers and lathes also scores points. The processing speed of the NC program was up to 540 instruction blocks/min doubled.

Digitization optimizes production

At the AMB 2022, Mitsubishi Electric will also be showing a wide range of digitization solutions for optimizing production processes using solution islands. For Lenord + Bauer Mitsubishi Electric presents the new i³SAAC Precision System, which for integrated, intelligent, interactive Sensors and autonomous actuators and controllers. It was for Rotary Tables, swivel axes or Tools developed axes.

Positioning accuracies in the range of a few angular seconds can be achieved on the basis of electronic error compensation. Last but not least, the automation specialist is demonstrating its Industry 4.0 and AI expertise as part of the Maisart strategy project. There are practical examples at Wire and die sinking machines from EDM to see.

CNC control, motors and peripherals for the retrofit

02.05.2022/XNUMX/XNUMX | Retrofitting is a sustainable and economical decision. The general overhaul and modernization is currently very much in vogue. Against the background of sustainability, delivery time, resource efficiency and of course costs, more and more companies are updating their existing machines. The machine manufacturers are partly doing the retrofit themselves. In the meantime, however, numerous companies have also specialized in it like the KPS grinding machine service GmbH with a focus on retrofitting grinding machines.

Modernization of an external cylindrical grinding machine

The latest project is the complete modernization of a 3 m long external cylindrical grinding machine. This weighs 14 t and, as a comparable new machine, costs almost one million euros with a delivery time of around one year. The base and geometry as well as that Machine bed were still absolutely in tact with this grinding machine. It would have been a shame to scrap it. The service company therefore looked for a tailor-made solution for its customer. KPS has set itself the goal of supplying grinding machines that will work at least as productively as a new investment over the next few years. The costs are usually only 40% of the new price with a delivery time of four to six months.

Rotary encoders for axes in drives, machines and systems

Rotary encoders for axes in drives, machines and systems

Modernizing the mechanical components is the easier part. The know-how lies in equipping the grinding machine with a new CNC control and the corresponding Drive Technology equip. KPS has been consistently building on this for years Mitsubishi Electric as a system partner. From him you get a new CNC control as well Engines, engine control units, Cables and Relais. With these components, the switch cabinet completely new and space-saving wiring.

Easily programmable CNC control for the retrofit

Within the framework of the cooperation, Mitsubishi Electric is characterized in particular by its high level of solution orientation and intensive personal support. The experts develop together with the customer customized packages, which a medium-sized company can also afford. The response time is extremely short and promises are reliably kept. The CNC controls also offer technological advantages for retrofitting. The controllers are absolutely reliable and stable. They are very easy to program, very fast, accurate and open to additional functions. The user interface of the CNC control is extremely user-friendly. Employees use them after just one day.

Servo motor made of DC / stepper motor with controller and encoder

Servo motor made of DC / stepper motor with controller and encoder

Also, Mitsubishi Electric provides the customer as special service experienced programmers available. You program the appropriate modules according to individual needs. There are no unnecessary features. The user, on the other hand, finds exactly the functions that are relevant to him and that support him in his work. The retrofit of the above external cylindrical grinding machine was completed in just eight weeks. Since then, the grinding machine has been running even faster and more precisely than before.

Networked production, smart CNC control, edge computing

06.09.2019 | Mitsubishi Electric shows how machine tools in networked production systems, with intelligent controls, edge computing and through partner solutions increase productivity. Connecting robots to machine tools to increase speed and productivity is made easy with plug-and-play integration.

The latest CNC controls of the M8 series are with the functionality Direct robot control (DRC) equipped. This allows both Mitsubishi Electric and Kuka robot programmed and be served. The robot can be set up and operated via the CNC control in the G-code programming language, so no special robot programming knowledge is required.

Compact fieldbus 4 I/O module for intralogistics

Compact fieldbus 4 I/O module for intralogistics

concepts of predictive maintenance (Predictive maintenance) for machine tools can reduce operating costs and downtime. For this purpose, the automation company and its eF@ctory Alliance partner Lenord + Bauer have developed a condition monitoring solution based on intelligent encoders and direct communication with the Machine controls based. In addition to the process parameters, the machine status is recorded and monitored. The data obtained in this way can be used as a basis for planning maintenance work by announcing necessary maintenance or repair measures at an early stage.

Artificial intelligence and predictive maintenance

Help Artificial intelligence (AI), predictive maintenance can then be made even more efficient. The company is demonstrating exactly how this works with a cloud-based solution based on the IBM Watson AI platform Operational data analyzed. In this way, maintenance routines for robots and other devices such as machine tools can be recommended and optimized based on actual use and signs of wear.

stepper motor | Precise low cost positioning

stepper motor | Precise low cost positioning

Mitsubishi Electric is showing how the digitization of production can be supported The crowd (universal machine tool interface). This is a universal interface that can securely integrate machine tools into customer-specific IT ecosystems. The Association of German Machine Tool Builders (VDW) describes the system as “one Quantum leap in the implementation of Industry 4.0 in production".

You might also be interested in...

Artificial Intelligence | trends and developments

Predictive maintenance for robotics, machines and systems

Mitsubishi Electric | Automating the World

Cobot | Discover collaborative robots as a new employee

battery production | Facts and Technologies

Programming Robots | software and controls

Alica Krüger is CNC Marketing Coordinator Europe at Mitsubishi Electric Europe BV CNC Mechatronics.