Pepperl und Fuchs presents hybrid at the Digital Expo and SPS

- Details

- Hits: 25873

The Digital Expo from Pepperl and Fuchs goes on and is combined with that SPS Appearance in Nuremberg. Previously took place in April this year the first digital expo instead, which was co-organized by the subsidiaries VMT and Ecom Instruments. With the company's own event platform www.your-future-automation.com, the automation company has a virtual venue for events under the motto last year Your future automation brought to life.

Content of the event report

- Pepperl + Fuchs connects Digital Expo with SPS appearance

- Digital Expo for Future Automation

- Your Future Automation second online summit

- Your Future Automation first online summit

Pepperl + Fuchs connects Digital Expo with SPS appearance

20.10.2021: Space for new ideas and hybrid concepts is created where the boundaries between the real and the digital world merge. Against this background combined Pepperl and Fuchs are now making their first appearance on the SPS fair from 23 to 25.11.2021 November XNUMX in Nuremberg with the free in-house digital trade fair Digital Expo, which will take place from November 15th to 26.11.2021th, XNUMX.

Under the motto Your Future Automation there should be an interaction between the respective advantages of analog and digital communication. Both events are intended to transform visitors into a holistic hybrid experience.

Contents of the 3D environment complement personal dialogue at the trade fair

As part of its in-house exhibition, the Mannheim-based company is equipping the virtual, browser-supported 3D environment Digital Expo with new, detailed exhibits for the Factory and process automation. At the same time, the 3D models are supplemented by a few selected classic trade fair exhibits and presented at the SPS in an adapted form on digital touch tables.

FMB Bad Salzuflen - supplier trade fair on the home straight

FMB Bad Salzuflen - supplier trade fair on the home straight

Visitors receive information about the digital exhibit in direct dialogue with the Pepperl + Fuchs experts. After your visit to the fair, you can then use the virtual Digital Expo continue to deal with the product digitally. Additional digital content such as brochures or 3D animations are also available free of charge. In addition, those interested can watch the live lectures from the SPS via stream within the Digital Expo.

Focus on future automation topics

At both events, Pepperl und Fuchs will address three overarching focal points for global issues in German and English Automation market:

- E-Mobility - New Solutions for New Production Processes

- Functional Safety - from Extraordinary Products to Customized Safety Concepts

- Industrial Communication - Digitized Processes for Hazardous Areas

Register now for free under the adress www.pepperl-fuchs.com/expo-2021-pr for the Digital Expo by Pepperl and Fuchs. The one-time registration also includes access to all content from the two previous digital trade fairs. Free tickets for the SPS 2021 are available here: www.pepperl-fuchs.com/sps-ticket.

Digital Expo for Future Automation

23.04.2021: Pepperl and Fuchs go with you VMT and Ecom Instruments breaks new ground with the first in-house digital expo. The free virtual event format took place from April 19 to 23, 2021 and ends today. It offered the participants a compact digital insight into the current products and solutions of industrial sensor technology and the explosion protection of the specialists for industrial Automation. Right in the entrance area, the visitors were greeted by virtual people at the information desk and by the real CEO Dr.-Ing. Gunther Kegel welcomes:

The new event format stands out from the Online Summit by having a less pronounced conference character. And it really worked. The focus is on User interaction with application solutions. Visitors to the German and English language event can move independently through a virtual showroom with detailed, interactive 3D models. The navigation is very easy and a lot of information is offered.

Ama Association: Sensor + Test trade fair takes place digitally

Ama Association: Sensor + Test trade fair takes place digitally

To the virtual exhibits there is plenty of additional information, including interesting expert interviews, numerous explanatory video presentations, technical white papers and other digital content. The exhibits have been open since April 19.04. can be explored around the clock. International experts from Pepperl + Fuchs have until April 23.04rd. answered questions from participants in a live chat around the clock. And best of all: the platform is still accessible afterwards.

Industrial sensors and explosion protection in four topics

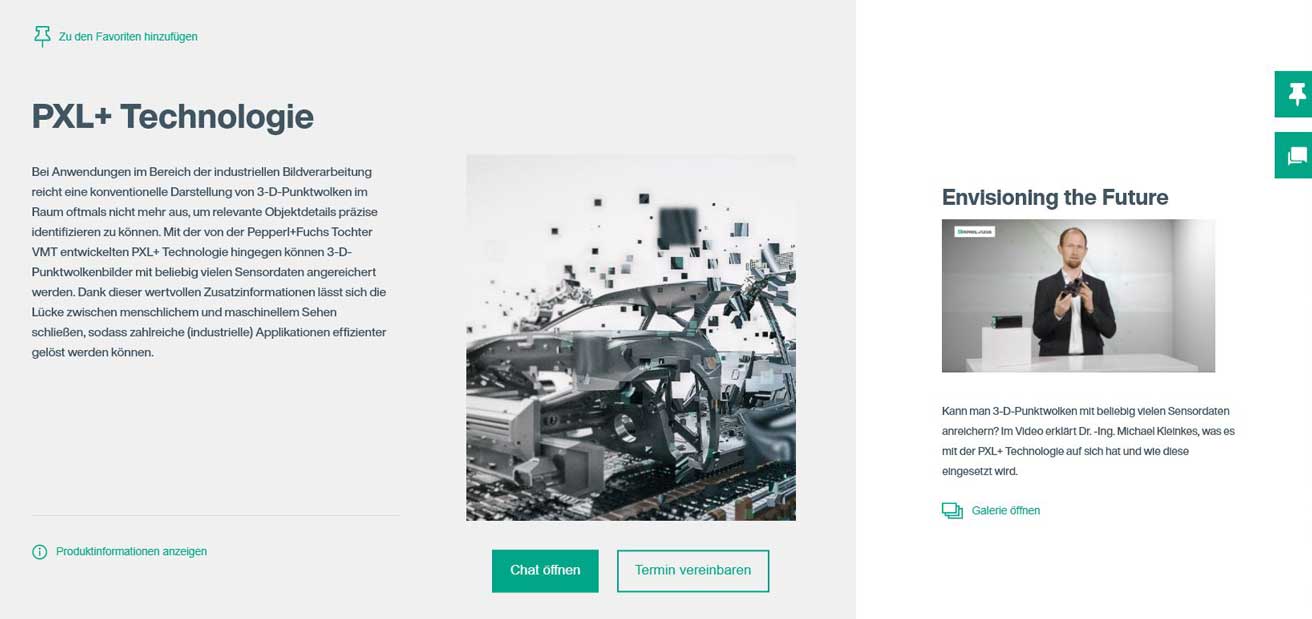

In line with Your Future Automation, the Digital Expo covers a broad spectrum of promising topics in automation technology. Particular attention is paid to the one developed by VMT PXL + technology. It can be used to enrich 3D point clouds with any number of sensors. This pixel plus information provides information about the color, temperature and surface properties of scanned objects.

Location technology standard Omlox with UWB, RFID, 5G,GPS

Location technology standard Omlox with UWB, RFID, 5G,GPS

For example be Robot in the Automotive industry able to recognize the smallest damage in the paint, which would not be visible in a 3D representation. This creates a flexibly adaptable multi-sensor system that contributes to the optimization of existing solutions. This allows access to completely new areas of application. A special virtual exhibit illustrates the PXL + technology. The visitors could playfully compete against each other on a task. Finally, Pepperl + Fuchs raffled five virtual reality headsets among them.

The topics of the first Digital Expo are:

- Envisioning the future - Vision Technology Powered by PXL +

- Leading the way for Automated Guided Vehicles - Proven Applications and Innovative Technologies

- Joining the IIoT revolution - Technologies, Components and Applications

- Experiencing the Ex evolution - Digitalization, Solutions and Industrial Communication in Hazardous Areas

“Constant technological progress is reflected in the solution portfolio of the Pepperl + Fuchs Group as well as in the evolution of our event concepts. We are pleased to present customers and interested parties with the Digital Expo, a new and extremely entertaining event format in a 3D environment, in which the boundaries between the analog and digital world are blurred, ”comments Dr. Michael Kleinkes, Managing Director of the Pepperl + Fuchs subsidiary VMT, before the start of the event.

Visitors to the last Online Summit can use their existing access data for the Digital Expo. New prospects register at www.pepperl-fuchs.com/expo-2021-pr and thus also get access to the contents of the previous Online Summit. Registrations are free of charge.

Your Future Automation second online summit

17.-19.11.2020:

Pepperl und Fuchs invites you to the second Online Summit Your Future Automation a. The virtual event followed on from the pilot event in July 2020, but addressed new sub-topics. A particular focus was the increasing amalgamation of Operation Technology (OT) and Information Technology (IT). In times of the Covid-19 pandemic, the digital event offers a format in which customers and interested parties can get in touch with Pepperl and Fuchs experts.

The focus on that Merging OT and IT is reflected in three central subject areas. They each take up one event day. Keynotes, presentations and panel discussions by experts from Pepperl and Fuchs as well as partner companies highlight the following topics:

- Driving the IIoT Revolution - Challenges, Benefits and Simple Next Steps

- digitization in Service and Maintenance - Process Industry in Transition

- Next level of Ultrasonic Technology - Intelligent, Functionally Safe and Autonomous

Driving the IIoT revolution

In the age of Industrial Internet of Things (IIoT), products, systems and plants are becoming more and more networked. Combining IT and OT intelligently in an industrial environment is the basis for efficient and transparent processes. The production costs are thus reduced and completely new business areas can be opened up. Exciting examples from practice illustrate how a symbiosis of both worlds opens up potential. The following aspects will be brought closer to the participants in presentations, keynotes and panel discussions:

The multitude of deterministic available fieldbuslog and IIoT protocols like OPC UA, MQTT and Rest API does not make it easy to keep an overview. The differences between the individual protocols and the applications for which they are suitable are explained using concrete advantages for the user.

It was difficult to control time-critical processes from the PLC and at the same time Scada and to give cloud systems access to the determined sensor data. The Parallel communication the IO-Link master with multilink technology.

If companies want to modernize their systems effectively and make Industry 4.0 ready, this is coming RetrofitSolution into play. It was explained how this looks without replacing the control or interfering with an existing system.

The industry today benefits from hybrid systems with a combination of cloud and control. The participants learn how the transition to completely cloud-based systems can take place without higher-level control and which application scenarios are conceivable here.

Digitization in service and maintenance

Tools like Remote monitors, Smartphonesand Tablets applications, software and real-time information replace clipboards and pens today. Exciting applications from the process industry and an outlook on what smart maintenance will look like in the future will be conveyed by the organizers in the context of keynotes, presentations and panel discussions. The following aspects are discussed in more detail:

The use of mobile devices is limited far beyond the pure Communication out. Smartphones and tablets play a major role in inspections and maintenance in industrial and potentially explosive areas. The thematic block sheds light on how the working environment and the way mobile workers work has changed since then and conveys the resulting benefits for users and companies.

Predictive Maintenance and Remote Assistance in the age of Industry 4.0. What is behind this and what challenges companies expect in the implementation are presented in detail.

According to experts, the Remote Support in the case of maintenance tasks, it is estimated that it will make up 60% of augmented reality applications in the future. Would you like to find out more about the challenges and potential of maintenance?

Next level of ultrasonic technology

Ultrasonic sensing has proven itself from a former niche product to a key technology developed in automation. As the market leader in this area, Pepperl + Fuchs provides insights into current trends and future developments. The following aspects were examined in more detail in the form of keynotes, presentations and panel discussions:

The time when Ultrasonic sensors only provided a simple distance value is now a thing of the past. Thanks to ever more precise options for Parameterization and a stronger preprocessing of the data, ultrasonic sensors today offer many advantages in the implementation of typical measurement and control applications.

In addition, it was previously difficult to build a SIL / PL suitability for ultrasonic sensors. The technology has numerous properties that make it ideal for safety applications. The latest generation of ultrasonic sensors provides a remedy here.

In Industry 4.0 applications the measuring points are spatially far away and the data processing takes place in IT platforms outside of the classic control loops. This requires specially designed automation products. The wireless M + O ultrasonic sensor technology, which is more in demand today, was therefore discussed at the summit.

Your Future Automation first online summit

20.-24.07.2020:

In the digital event, users were also informed about the latest solutions and trends in the field of Factory automation and process automation informed. Pepperl and Fuchs examined the following automation focus topics in detail in the form of live shows, keynotes and panel discussions.

- Digital Kanban Management

- Mobile Devices and Services Drive Digital Transformation

- Smart intralogistics Solutions with RFID and Lidar Technology

- Ethernet Advanced Physical Layer (Ethernet APL)

- The power of 3D measurement Technology

Digital Kanban Management

Kanban systems are becoming more and more popular in companies and production is indispensable. Error-prone, manual workflows and a low degree of digitization still offer great potential for optimization. With this in mind, have Pepperl + Fuchs, Neoception and Bosch Connected Industries In a joint project, the processes for supplying and removing Kanban shelves are digitized and automated throughout.

Ethernet APL | Current status, applications and implementation

Ethernet APL | Current status, applications and implementation

In addition to his automation know-how, Pepperl and Fuchs brought the necessary Sensors in the project. Special a newly developed, tentative one Sensor bar plays a major role in this application. The resulting overall solution makes Kanban shelves fit for Industry 4.0 and is also suitable for greenfield projects and retrofits.

Mobile devices and services drive digital transformation

Work equipment and tools such as smartphones, tablets or digital workflows are now an integral part of the modern working environment. Ecom As the world market leader for intrinsically safe mobile devices, accompanies its customers in implementing such an environment. The Pepperl and Fuchs brand supports the individual configuration, management, analysis and evaluation of mobile device data in real time.

With a well thought out Mobile worker concept the Ecom products enable lean processes, better data quality and thus increased productivity, which includes the safety of employees. The ready-to-use service from Pepperl and Fuchs accompanies its users from the individual configuration of their devices to diagnostics. It combines automated staging, mobile device management and device analytics.

Smart Intralogistics Solutions with RFID and Lidar Technology

Instead of individual components, requires a precisely coordinated one material flow and Flow of goods today well thought-out and innovative complete solutions. All criteria in the form of individually adapted sensors, smart components for the infrastructure, cabling, System integration and software development into account.

Pepperl + Fuchs presents practical examples together with customers. They show how to use custom solutions RFID and Lidar Technology arise.

Ethernet Advanced Physical Layer

Already said at the trade press days of the RBS Stutensee in February 2019 Michael Kessler, Executive Vice President Components + Technology PA, said the time was right for Ethernet APL. With the new Ethernet Advanced Physical Layer (APL), Pepperl and Fuchs, together with other companies, are creating a basis for future Internet of Things (IoT) applications in the process industry.

Field devices can be connected to higher-level systems via the new physical layer. Consistent, transparent and uniform communication across all hierarchical levels becomes possible. The experience and needs of the process industry such as long distances of cables, two-wire Lines, interoperability and use in explosion protection areas up to Zone 0/Class 1, Div. 1 combines Ethernet APL.

The Power of 3D Measurement Technology

With the advent of Industry 4.0, the requirement to guarantee XNUMX% quality while shortening conversion times is growing. That's it Engineering of automated companies are facing increasingly complex challenges. Pepperl+Fuchs and its subsidiaries provide the necessary measurement technology, quality assurance and positioning tasks 3D.aero, VMT and Space 6D Complete solutions for 3D measurement technology. Conventional tasks can thus be transferred to a digital environment up to and including a digital twin.

Pepperl + Fuchs is exhibiting at SPS 2022.

You might also be interested in...

Industrial radar sensor with CAN interface

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies

Level sensor for every level measurement

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.