for food and beverage industry

Drives, materials, machine elements and automation technology according to special, strict standards - regionally and nationally

Image: Harting

for food and beverage industry

Drives, materials, machine elements and automation technology according to special, strict standards - regionally and nationally

Image: Harting

Here you will find new products and solutions for food technologists, engineers and other food technology professionals. In the field of the food industry, not only are ecological and economic resources converted into food and raw materials processed, but a high nutritional value and enjoyment value can also be achieved.

There are the following processes in food technology for the production of food ingredients: Mechanical processes like crushing, pressing, mixing; thermal processes such as heating and cooling; biological processes such as alcoholic fermentation or use of bacteria and fungi as well chemical processes how to coagulate proteins. This is implemented with specially approved machines. Drives, Machine Elements, Automation services, Materials etc. for food technology must therefore special and strict standards, regional, state or international. Food technology is next to that Medical Technology one of the industries with the highest circulation.

Below you will find components, systems and applications that washdown capable and FDA allowed are. The devices, machines and systems for processing raw materials for beverages and foodstuffs have to withstand the harsh cleaning processes.

14.03.2024/XNUMX/XNUMX | On the Anuga Foodtec 2024 presents Schaeffler linear guides for food technology. Such profile rail guides are used in a variety of linear movements when processing and packaging food. An example is the four-row ball recirculating unit from the KUVE..B series.

14.03.2024/XNUMX/XNUMX | On the Anuga Foodtec 2024 presents Schaeffler linear guides for food technology. Such profile rail guides are used in a variety of linear movements when processing and packaging food. An example is the four-row ball recirculating unit from the KUVE..B series.

07.02.2024 | NIR spectrometer from Polytec allow reliable and non-destructive measurements of a wide variety of ingredients directly in the production lines of e.g. B. dairy products and baked goods, meat products, confectionery or cooking oils. For olives, oil and acidity can be determined directly after harvesting on the conveyor belt.

07.02.2024 | NIR spectrometer from Polytec allow reliable and non-destructive measurements of a wide variety of ingredients directly in the production lines of e.g. B. dairy products and baked goods, meat products, confectionery or cooking oils. For olives, oil and acidity can be determined directly after harvesting on the conveyor belt.

Igus is a member of the EHEDG and developed the first linear sliding guide that was consistently based on the hygienic design guidelines. This is ensured by FDA-compliant materials such as the high-performance polymer, high-alloy stainless steel and the flushable internal construction of the slide. The Drylin W linear guide features a gap-free design.

Igus is a member of the EHEDG and developed the first linear sliding guide that was consistently based on the hygienic design guidelines. This is ensured by FDA-compliant materials such as the high-performance polymer, high-alloy stainless steel and the flushable internal construction of the slide. The Drylin W linear guide features a gap-free design.

17.05.2023 | Kollmorgen is expanding its AKMTM servo motor portfolio with a new high-performance servo motor. The focus of its development was cleanability, longevity and versatility. The motor features a hardened, anodized aluminum surface and offers machine designers a cost-effective and hygienic alternative to stainless steel.

17.05.2023 | Kollmorgen is expanding its AKMTM servo motor portfolio with a new high-performance servo motor. The focus of its development was cleanability, longevity and versatility. The motor features a hardened, anodized aluminum surface and offers machine designers a cost-effective and hygienic alternative to stainless steel.

At the Interpack booth of Mitsubishi Electric is all about the chocolate in a modular, open and fully integrated line. The advanced quality control of chocolate bars and their packaging will be demonstrated together with partners industrial robots.

At the Interpack booth of Mitsubishi Electric is all about the chocolate in a modular, open and fully integrated line. The advanced quality control of chocolate bars and their packaging will be demonstrated together with partners industrial robots.

Schmersal introduces the new Safety light barriers SLB440 series. This is particularly suitable for hygiene-sensitive applications in the packaging and food industries such as dairy farming and meat processing. A single-beam light barrier from the SLB series is very compact with a diameter of 62 mm and a height of 115 mm. They are therefore ideal for use on thermoforming machines for packaging.

Schmersal introduces the new Safety light barriers SLB440 series. This is particularly suitable for hygiene-sensitive applications in the packaging and food industries such as dairy farming and meat processing. A single-beam light barrier from the SLB series is very compact with a diameter of 62 mm and a height of 115 mm. They are therefore ideal for use on thermoforming machines for packaging.

When it needs to be extra precise in corrosive or special atmospheric operating conditions, you need ones designed for it Sensors and encoder reliable compensating couplings. The encoder coupling Sensorfit from Schmidt coupling meets this requirement, is resistant to high temperatures and designed for the requirements of the food industry.

When it needs to be extra precise in corrosive or special atmospheric operating conditions, you need ones designed for it Sensors and encoder reliable compensating couplings. The encoder coupling Sensorfit from Schmidt coupling meets this requirement, is resistant to high temperatures and designed for the requirements of the food industry.

For his 75th company anniversary Jumo come up with something very special: a own anniversary beer brewed on a specially developed and manufactured highly efficient brewing system, in which the relevant for the brewing industry Jumo products are installed. The result is a golden yellow, tasty pilsner with a pleasant bitter note.

For his 75th company anniversary Jumo come up with something very special: a own anniversary beer brewed on a specially developed and manufactured highly efficient brewing system, in which the relevant for the brewing industry Jumo products are installed. The result is a golden yellow, tasty pilsner with a pleasant bitter note.

The new detectable keypads has Kipp for the food technology and pharmaceutical industry designed. Leave with them for contamination in the manufacturing process prevent major failures. When small splinters come loose from damaged components and get into the products, it is often the consumers who first discover the fault. Expensive product recalls are the result.

The new detectable keypads has Kipp for the food technology and pharmaceutical industry designed. Leave with them for contamination in the manufacturing process prevent major failures. When small splinters come loose from damaged components and get into the products, it is often the consumers who first discover the fault. Expensive product recalls are the result.

Are roller chains in the Food industry used, they have to withstand high loads or be serviced and replaced regularly. Put users a quality roller chain from Tsubaki they have a service life that is twice as long as comparable chains on the market. They also drastically reduce maintenance to the point of being maintenance-free. This is ensured, among other things, by oil-impregnated sintered bushings and the patented stamping ring compression. Find out some product information and find out more about the Roller Chain, also based on Success Stories.

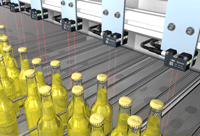

For the detection of all types of beverage packaging Baumeralso offers its "Smart Reflect" technology in the form of the "Next Gen" sensors O300 and O500. This combination ensures measurable added value through the reduction of operating costs and through maximum process reliability. Smart Reflect is the first light barrier that works without a reflector.

For the detection of all types of beverage packaging Baumeralso offers its "Smart Reflect" technology in the form of the "Next Gen" sensors O300 and O500. This combination ensures measurable added value through the reduction of operating costs and through maximum process reliability. Smart Reflect is the first light barrier that works without a reflector.

The rugged beauty of the Highlands with its fabled lakes and castles, the picturesque old town of Edinburgh and its unique tradition of bagpipes and kilts - this is Scotland. Connoisseurs and connoisseurs think of Scotland's world-famous single malt. Pepperl + Fuchs helps ensure efficient process control in the production of liquid gold, which is offered in an increasingly diversified manner.

Five applications from the food technology show the diversity of Mayr brakes and clutches from Mauerstetten. A linear brake secures the Cheese production by Chalon Mégard. Packing and Palletizing of beverages disk pack couplings safely transmit the torques in the drive. A shaft coupling masters high temperature differences baking lines. The input and output disconnection in an emergency packaging equipment take over slip hubs, which are also in the ice making provide the necessary security.

Turck extends his TX700 Human Machine Interface, short HMI or Programmable Logic Controller, in short PLC Device series. For systems in the Food industry these are two variants of the TX700FB, (Food & Beverage). There are also two versions with particularly bright displays for better sunlight readability TX700HB, (High Brightness).

Food producers stand by that Connectors So far, use in sensitive areas has often been skeptical. They fear that interfaces with their outlines will break through the easily washable, smooth surfaces. But you need them in the product-related area for the Cleaning. For such applications Harting an Special connector developed. The Han F + B withstands intensive cleaning.

Because the worldwide consumption of confectionery is constantly growing, manufacturers of chocolate and other products have to set up their production facilities quickly, flexibly, economically and safely so that they can remain competitive. A powerful, ultra-modern Industrial scale and Inspection solution from Minebea Intec can help to increase efficiency in the confectionery industry.

technical articles

technical articles

NORD presents his new synchronous motor before that a significant improvement in Energy Efficiency familiar with the Surface finishing NSD Tuph combined. This makes it suitable for the demanding environmental conditions and high hygiene requirements in the Beverage logistics and production. Also to be seen: the standardized drive concept for lauter tuns and the new one switch cabinetconverter "Nordac Pro SK 500P".

During the Food industry Flexibility is becoming an increasingly important characteristic. At the same time, companies prefer security systems that offer operational efficiency and cost advantages in addition to the necessary security function. The system for processing cold cuts from shows how these requirements can be implemented Weber mechanical engineering, They were secured with a modular safety control from Schmersal, The service package included commissioning and validation by the service division tec.nicum.

During the Food industry Flexibility is becoming an increasingly important characteristic. At the same time, companies prefer security systems that offer operational efficiency and cost advantages in addition to the necessary security function. The system for processing cold cuts from shows how these requirements can be implemented Weber mechanical engineering, They were secured with a modular safety control from Schmersal, The service package included commissioning and validation by the service division tec.nicum.

Bienen Ruck has been purchasing customer-specific motors from Groschopp for 20 years and equipping 90% of its motor-driven extractors with them. The special drives are installed in the dealer's tangential and self-turning honey extractors. Above all, they have to be robust and durable.

Bienen Ruck has been purchasing customer-specific motors from Groschopp for 20 years and equipping 90% of its motor-driven extractors with them. The special drives are installed in the dealer's tangential and self-turning honey extractors. Above all, they have to be robust and durable.

The new vacuum cooler from ensures high efficiency in the bakery of commercial and industrial bakeries drought. Vacuum cooling improves the shelf life of baked goods and significantly increases efficiency in the bakery. This is what customers in the baking industry appreciate about these systems.

NORD offers reliable drive technology for the grain industry all over the world. In 2019, Lachenmeier Monsum A / S installed a grain terminal in Fredericia, DK, with a storage capacity for 40.000 t of grain. As a partner for the Drive Solutions they chose north to operate the terminal.