yesterday | Archive for machine elements

- Details

- Hits: 1472

If you ever fall into memory mode, you can remember previous developments of all types of machine elements here 2011 – 2018. Plug-and-play, service life and ease of maintenance were just some of the requirements that shaped the development. Exciting déjà vu and have fun remembering!

Contents

Sliding and rolling bearings

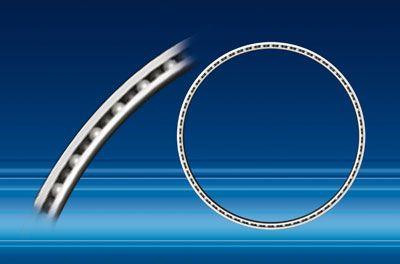

Thin section bearings 2017 to 2010

You can find the latest thin section bearing innovations here here.

- Thin section bearing in an artificial knee joint with automatic transmission

- Precise and slim thin ring bearings for the semiconductor industry

- Lubrication-free hybrid thin section bearings for clean room and vacuum

- Thin ring bearing technology for robotics

Thin section bearing in an artificial knee joint with automatic transmission

01.07.2017/XNUMX/XNUMX | Despite miniaturization, thin-section bearings from Rodriguez achieve a comparable performance and service life as normal roller bearings. With them, the gear unit in the knee joint can be Exoskeletons store without complicated and space-consuming auxiliary structures. They are also used in a bicycle with an automatic transmission.

01.07.2017/XNUMX/XNUMX | Despite miniaturization, thin-section bearings from Rodriguez achieve a comparable performance and service life as normal roller bearings. With them, the gear unit in the knee joint can be Exoskeletons store without complicated and space-consuming auxiliary structures. They are also used in a bicycle with an automatic transmission.

The one created at ETH Zurich varileg (Variable Impedance LEG) wants to enable paraplegic people to walk again. It differs from existing exoskeletons mainly through mechanically adjustable stiffness in the knee, which is ensured, among other things, by actuators with variable impedance. Slopes and stairs are therefore not a problem. Powerful motors also enable the user to stand up and sit down.

In this way, the natural functioning of a knee joint can be imitated as far as possible. To the gear unit To be able to store them as compactly as possible, the researchers chose metric thin-section bearings. The decisive factors were the low weight of the bearings and the large inner diameter with a small space requirement - perfect for the application at hand.

Bicycle with CVT transmission

The CVT transmission installed in a bicycle can be infinitely variable and shifts automatically, the driver no longer has to worry about it. The electrically operated solution - a development project at the HTL Rennweg in Vienna/Austria - uses parameters such as cadence, effort, wheel speed and inclination to determine the appropriate gear ratio.

Total in the CVT transmission two Rolling Required: One of the bearings is installed in the shifting element of the gearbox; the second bearing is responsible for stabilizing the lead screw, which is connected to the servo. A small installation size was particularly important for both bearings, which is why thin section bearings were chosen. Despite their compact design, these bearings can absorb both radial and one-way axial forces and are therefore ideal for use in so-called CVT bikes.

Precise and slim thin ring bearings for the semiconductor industry

23.11.2016/XNUMX/XNUMX | Compact and lightweight, but particularly powerful and precise: With these special properties, the thin section bearings from Rodriguez have proven themselves in the Semiconductor industry. They come in, among other things lens apertures of photolithographic systems:

23.11.2016/XNUMX/XNUMX | Compact and lightweight, but particularly powerful and precise: With these special properties, the thin section bearings from Rodriguez have proven themselves in the Semiconductor industry. They come in, among other things lens apertures of photolithographic systems:

Since these screens should be as compact and flat as possible, thin section bearings are the first choice. The lightweight bearing types offer a small cross-section that remains the same as the bore diameter increases. That Kaydon Rodriguez's thin section bearing range includes around 250 storage types with the optimal solution for every application as well as for the precision mechanics in the lithographic systems for semiconductor production.

"In the semiconductor industry, however, there are many other application examples for thin-section bearings," says Ulrich Schroth, Business Unit Manager Value Added Products at Rodriguez. "For many years we have been supplying Kaydon thin-section bearings made of stainless steel to a customer who installs them in single-wafer systems." On the basis of thin section bearings, however, complete, ready-to-install assemblies are also created, which are precisely tailored to the respective application.

These customer-specific special solutions fall within the business area Value Added Products, which is one of the core competencies of the company. Here customers not only receive customer-specific system solutions or entire assemblies in the smallest quantities, but also comprehensive all-round service. "Here, too, there is an example from semiconductor technology: one of our complete systems has proven itself in fully automatic high-speed measurement systems for wafers," says Ulrich Schroth.

Lubrication-free hybrid thin section bearings for clean room and vacuum

17.04.2015/XNUMX/XNUMX | non-corrosive, dry running thin section bearings with stainless steel inner and outer rings and rolling elements made of abrasion-resistant and high-temperature-resistant ceramic are ideal for clean room and vacuum applications. Surface wear and particle formation have been minimized in these bearings. They are also extremely precise, compact and light. Rodriguez offers the durable hybrid thin section bearings, for example, as cage versions with Teflon cages, Plastic (PFTE) or as a full complement version without cages.

17.04.2015/XNUMX/XNUMX | non-corrosive, dry running thin section bearings with stainless steel inner and outer rings and rolling elements made of abrasion-resistant and high-temperature-resistant ceramic are ideal for clean room and vacuum applications. Surface wear and particle formation have been minimized in these bearings. They are also extremely precise, compact and light. Rodriguez offers the durable hybrid thin section bearings, for example, as cage versions with Teflon cages, Plastic (PFTE) or as a full complement version without cages.

thanks to the ceramic balls The bearings only require a minimum of lubricant (lack of lubrication) or no lubrication and are significantly less susceptible to aggressive cleaning substances and corrosive liquids than conventional all-metal thin-section bearings. In addition, unwanted abrasion or the formation of foreign bodies can be avoided.

Additionally they offer ceramic balls Due to their physical properties such as precision, hardness, low weight, additional advantages such as improved repeatability, lower moments, higher rigidity. Due to these properties and their low particle removal, hybrid thin-section bearings are, for example, very suitable as bearings for optics in wafer production or for use in aerospace.

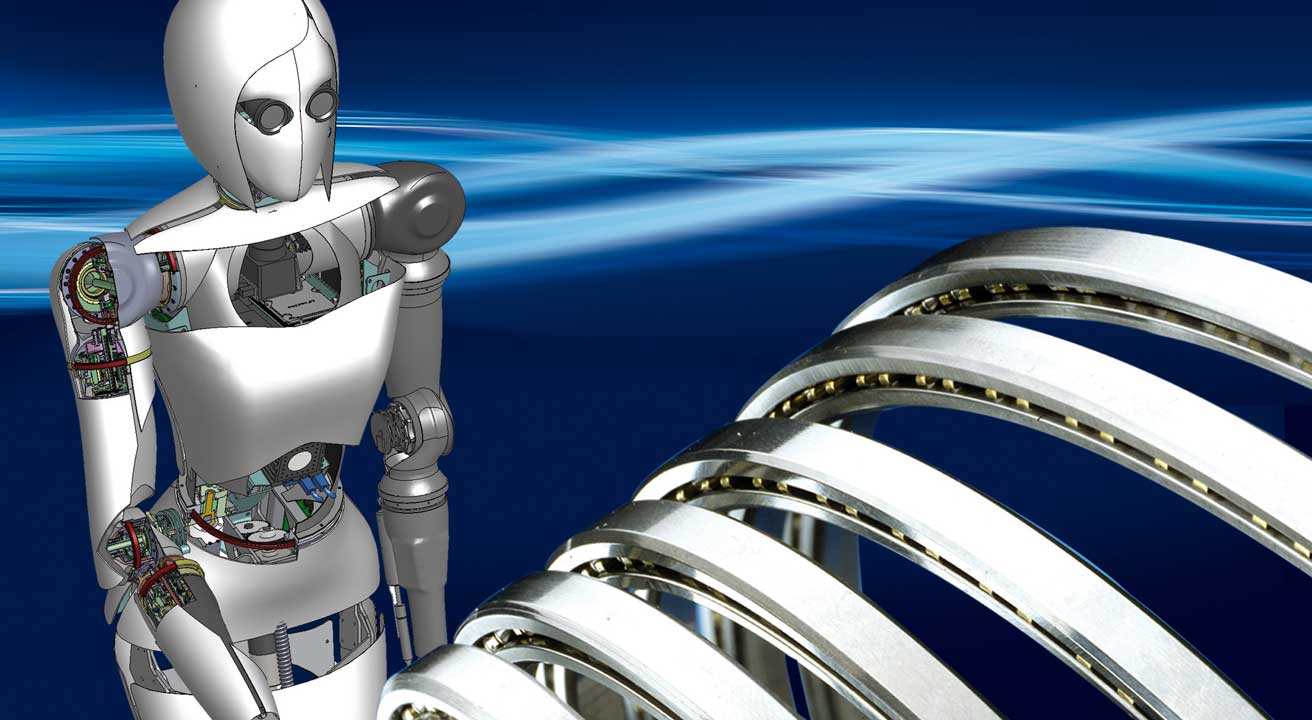

Thin ring bearing technology for robotics

10.09.2010/XNUMX/XNUMX | Due to its properties, the slim, thin-section bearing technology from Rodriguez is now the most important rolling bearing solution in the robot industry. Whether high-tech developments in Aerospace or down-to-earth robotic solutions for assembly and handling tasks – they require compact designs with the lowest possible weight. This can be realized with Kaydon thin section bearings. They are distinguished from comparable products by a particularly small cross-section with large bore diameters.

This remains the same within a series with increasing inner diameter. Despite the filigree design, the precision bearings have a high level of performance and up to 3,5 times longer service life than thin section bearings from other suppliers. Whether imperial or metric, as a hybrid, ultra slim or customer-specific design - with over 250 thin section bearing types, the Eschweiler bearing specialist offers the optimal bearing solution for every robotic application.

This remains the same within a series with increasing inner diameter. Despite the filigree design, the precision bearings have a high level of performance and up to 3,5 times longer service life than thin section bearings from other suppliers. Whether imperial or metric, as a hybrid, ultra slim or customer-specific design - with over 250 thin section bearing types, the Eschweiler bearing specialist offers the optimal bearing solution for every robotic application.

So also for the autonomous Robot Aila, which was recently developed by the DFKI Robotics Innovation Center, Bremen, as part of the BMBF research project "Sem Pro M". The anthropomorphic body has two arms, each with seven joints, a torso with four degrees of freedom, and a head that can swivel and tilt. In the robot system, Kaydon bearing technology from the "Real Slim" series of various sizes and types is used in the neck, body and the interface to the mobile substructure. The main advantage is the large bore diameter of the bearings, so that all energy, data line and control lines can be guided within the joints.

In the autonomous movement process, maximum precision is required when handling objects. Therefore, the bearings have been preloaded for increased rigidity. They offer particularly smooth running and concentricity for correspondingly precise guidance of the mounted connection constructions. Those are available Real Slim Stock in the types of radial ball bearings, angular contact ball bearings and four-point bearings. The latter allow alternative designs, since a single four-point bearing can often replace two bearings, thus simplifying the design of the bearing point: the pointed arch profile of the inner and outer ring means that a single bearing can accommodate three types of loads at the same time – radial, axial and moment loads. This means that components in the design can also be saved.

Linear Technology

You can find the latest linear technology innovations here.

linear guides

You can find the current linear guides here.

Archive for linear guide innovations 2019

- Miniature profile rail guide for industry and laboratory automation

- Sensor technology for reliable operation of linear guides

- Masking tape and sealing plugs reduce installation time

- Durable profile rail guide with 60% higher load rating

- Roller guides compensate for self-aligning tolerances

- Robust linear guide for all mounting positions in all lengths

Miniature profile rail guide for industry and laboratory automation

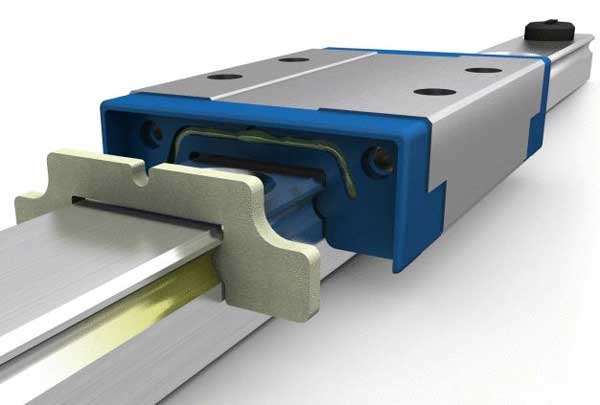

October 24.10.2019, XNUMX | The new miniature profile rail guides of the LLS design from Ewellix are extremely compact and run very smoothly. They work quietly, have a long service life and enable precise movement sequences. This makes them suitable for applications in industry and in the laboratory.

October 24.10.2019, XNUMX | The new miniature profile rail guides of the LLS design from Ewellix are extremely compact and run very smoothly. They work quietly, have a long service life and enable precise movement sequences. This makes them suitable for applications in industry and in the laboratory.

High availability and minimal maintenance effort play a role in fully automatic applications such as Pick and place stations, chemical analyzers or also 3D printers a crucial role.

For this reason, Ewellix pre-greases the LLS guide carriages at the factory. The supplied lubricant reservoir ensures the best possible long-term lubrication of the entire linear guide system.

The improved seal design reliably keeps the lubricant in the linear carriage and prevents contamination. An optimized ball circulation ensures smooth running. This protects the material, reduces friction and increases positioning accuracy at speeds of up to 5 m/s and accelerations of up to 140 m/s².

The LLS linear guides will turn off corrosion-resistant steel manufactured and comply with ISO 12090-2. Sizes 7, 9 and 12 are available with both standard and long carriage types.

Sensor technology for reliable operation of linear guides

09.10.2019 | Schaeffler Durasense monitors the tribological condition of the linear guide based on vibration signals. The system consists of carriages with sensors specially developed for this task and a pre-processing unit for up to seven sensors.

09.10.2019 | Schaeffler Durasense monitors the tribological condition of the linear guide based on vibration signals. The system consists of carriages with sensors specially developed for this task and a pre-processing unit for up to seven sensors.

Masking tape and sealing plugs reduce installation time

17.06.2019 | sealing caps for profile rails have to fulfill significantly more functions than you might imagine at first glance. Fulfilled with the patented sealing plugs “KA-TN/B”. Schaeffler these important customer requirements.

17.06.2019 | sealing caps for profile rails have to fulfill significantly more functions than you might imagine at first glance. Fulfilled with the patented sealing plugs “KA-TN/B”. Schaeffler these important customer requirements.

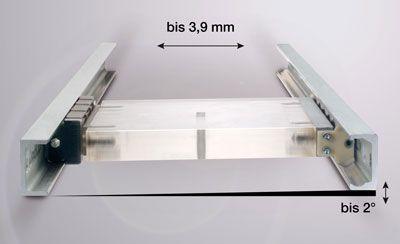

Roller guides compensate for self-aligning tolerances

21.05.2019/XNUMX/XNUMX | The versatile ones Compact Rail Rollon linear rails are dirt-resistant and can be moved at speeds of up to 9 m/s. Since they are very compact, they can also be easily accommodated in constructions with a small installation space.

21.05.2019/XNUMX/XNUMX | The versatile ones Compact Rail Rollon linear rails are dirt-resistant and can be moved at speeds of up to 9 m/s. Since they are very compact, they can also be easily accommodated in constructions with a small installation space.

The Compact Rail system includes three product lines: fixed bearing rail (T-profile), floating bearing rail (U-profile) and compensation rail (K-profile). With combinations of these three rail types parallelism errors of the mounting surface can be perfectly compensated in one or two planes. Manufacturing tolerances, for example in machine housings, can be easily compensated.

The raceways are on the inside of a C profile and are optimally protected against dirt. This ensures a long service life and a particularly compact design - ideal for harsh environments and constructions in which only little space is available. The runners with a steel or nickel-plated aluminum body and radial roller bearings lubricated for life offer very smooth and quiet running and guarantee smooth movements.

Calculate fit calculator easily online

Calculate fit calculator easily online

Rails and runner body are galvanized as standard according to ISO 2081. For higher requirements in terms of corrosion protection, application-specific surface treatments are available, such as nickel-plated versions with approval for use in the food industry. Rollon supplies the automation components in rail lengths from 160 to 3600 mm and in rail widths of 18, 28, 35, 43 and 63 mm. Greater lengths can be achieved by joining two or more rails.

The large selection of sizes and designs from the specialist for linear movements enables a multitude of combinations and thus ensures a high degree of application flexibility. Whether robots, manipulators, industrial machines or packaging systems: the modular Compact Rail is suitable wherever linear movements are to be carried out reliably and compactly in an automated manner. Sectors such as medical technology, logistics and the aviation industry also benefit from the specific properties of the robust roller guides.

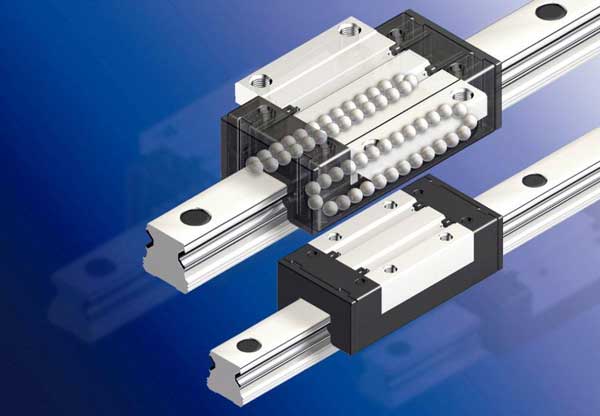

Durable profile rail guide with 60% higher load rating

08.01.2019 | Dr. Tretter presents the new version of the C profile rail guide, which is now also available from stock in sizes 15 to 65. The load rating of the linear guides has been increased by up to 60% thanks to an optimized rail geometry and longer carriages – this means a 4,5-fold increase in service life.

These linear guides offer high rigidity and load capacity, and they are compact. And because the Grooves are arranged at 4 x 45 degrees, they can be loaded equally in every direction in terms of pressure, tension and lateral force. The installation position of the profile rail guides is therefore irrelevant. In addition, the linear guides compensate for assembly and misalignments better through this X-arrangement of the raceways.

The linear technology specialist also has a profile rail guide in its range, in which the base body of the rail and the guide carriage consist of a Aluminum wrought alloy consist. The profile rail guides are anodized and thus ensure increased corrosion resistance.

The linear technology specialist also has a profile rail guide in its range, in which the base body of the rail and the guide carriage consist of a Aluminum wrought alloy consist. The profile rail guides are anodized and thus ensure increased corrosion resistance.

Thanks to stainless steel inserts, the aluminum systems are highly resilient and at the same time around 60% lighter than corresponding steel solutions. The manufacturer offers a for this profile rail guide magnetic position measuring system that works without contact and is therefore wear-free.

Double row products made of stainless steel

In addition, at Dr. Tretter double row Miniature linear guides made of stainless steel with two circumferential rows of balls. These impress with raceways ground in a Gothic profile.

This results in a four-point contact for the balls. The miniature profile rail guide can thus be loaded equally in every direction. In order to increase the rigidity of the profile rail guide or to make it play-free, they are available with the appropriate preload depending on the requirement.

Linear unit with spindle guide as standard and special solution

Linear unit with spindle guide as standard and special solution

quality NSK Profile rail guides of the NH and NS series can be freely combined and optionally equipped with a lubrication unit. The NH linear guides have backlash-free exchangeable flange guide carriages. These are designed narrow or as flange wagons.

The NS series linear guides are compact and suitable for a wide range of standard applications. It can take high loads and is also made of stainless steel. It is available in sizes 15 to 35, shipping from stock, can also be ordered by e-mail.

Roller guide for harsh environments

The roller guides for dirty environments achieve high speeds and accelerations with low moving masses and minimal rolling friction. The carriage made of anodized aluminum have four castors, which are optimized in two rows Angular contact ball bearings rest. Two of the rollers are eccentric to adjust the play. The closed carriages are equipped with a felt wiper and a lubrication unit. The open trolleys are suitable for simple applications.

Linear guides 2018 to 2014

- Needs-based relubrication for recirculating ball unit

- Robust linear guide for all mounting positions in all lengths

- Plastic linear guide for educational 3D printer

- Load-bearing, precise recirculating ball bearings with a long service life

- Extremely stiff linear guides with roller chain and roller guides

- Customized linear guides for rail vehicles

- Linear guide made of steel and CFK runs 20% faster

Needs-based relubrication for recirculating ball unit

12.02.2018 | Schaeffler integrated Sensor technology and vibration analysis in linear guides and offers automated relubrication with these mechatronic components. The "Durasense" function, which was already implemented for roller guideways in 2017, is now also available for recirculating ball bearings. With Durasense, each individual linear guide is relubricated according to the load and requirements.

12.02.2018 | Schaeffler integrated Sensor technology and vibration analysis in linear guides and offers automated relubrication with these mechatronic components. The "Durasense" function, which was already implemented for roller guideways in 2017, is now also available for recirculating ball bearings. With Durasense, each individual linear guide is relubricated according to the load and requirements.

Robust linear guide for all mounting positions in all lengths

30.06.2017 | Madler provides with the linear guide Series DFG 115 a less sensitive solution than the very commonly used, ball-bearing profile rail guide. This linear guide is dimensionally interchangeable with the ISO 12090 size 15 version. The rails and carriages of the linear guides are made of hard-anodized aluminum.

The Sliding elements The guides are made of highly developed polymer plastic and enable a long service life with high resilience. There are three carriage variants to choose from: non-adjustable, manually adjustable and self-adjusting. The non-adjustable aluminum carriages have play and can be used as floating bearings on parallel rails.

Heavy duty rails | High loads welcome

Heavy duty rails | High loads welcome

There are four rail lengths to choose from, which have already been drilled and can be individually cut to length by the customer. Several carriages can be used per rail. The sliding guide is insensitive to vibrations and even a damaged rolling element does not lead to total failure. The maintenance-free linear guide is corrosion-resistant, suitable for high-pressure cleaning and can be installed in any position.

Plastic linear guides for educational 3D printers

05.04.2017 | Tech-savvy startups are more daring than other companies in converting emerging technologies into new, marketable products. Fabmaker has one too 3D printer developed for the school and training sector. However, when selecting the functional elements and components that they install in their "educational printer", the employees around Managing Director Dean Ćirić rely on industry-tested linear technology from Igus.

05.04.2017 | Tech-savvy startups are more daring than other companies in converting emerging technologies into new, marketable products. Fabmaker has one too 3D printer developed for the school and training sector. However, when selecting the functional elements and components that they install in their "educational printer", the employees around Managing Director Dean Ćirić rely on industry-tested linear technology from Igus.

Load-bearing, precise recirculating ball bearings with a long service life

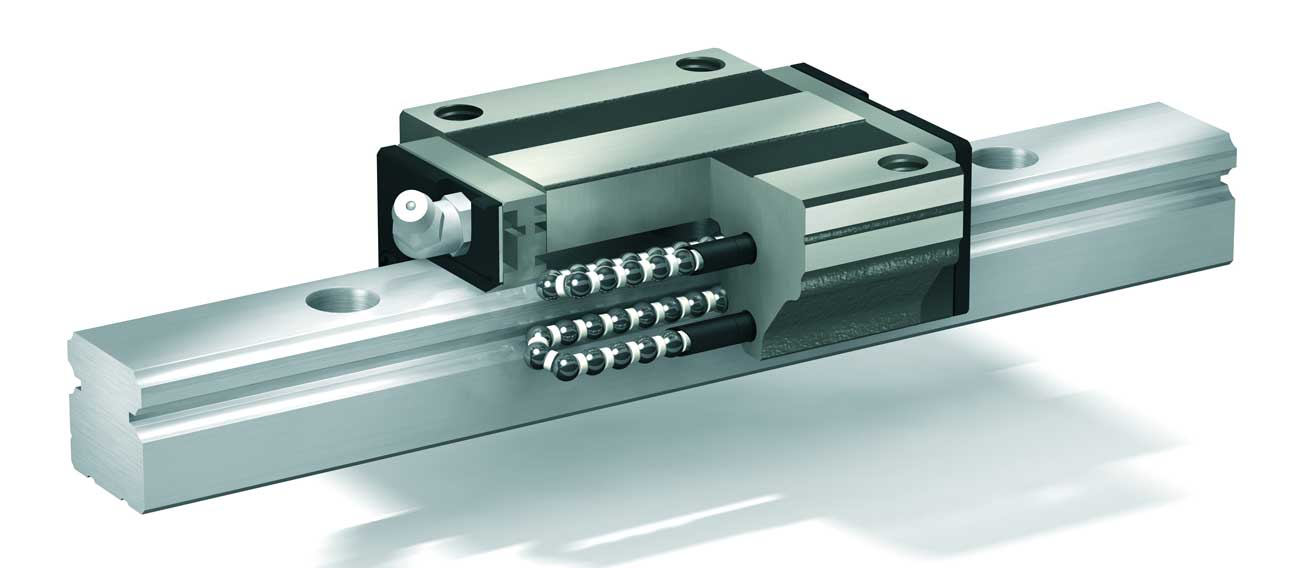

11.02.2016 | HepcoMotion presents the new recirculating ball system HLG, which replaces the previous version LBG. Due to improved manufacturing accuracy, the HLG offers the usual high stability and long service life at significantly reduced prices. HLG is available from stock in all common standard variants and with short delivery times. It enables loads of up to 180 kN and speeds of over 1,5 m/s. In addition, the HLG works particularly quietly and with little friction.

11.02.2016 | HepcoMotion presents the new recirculating ball system HLG, which replaces the previous version LBG. Due to improved manufacturing accuracy, the HLG offers the usual high stability and long service life at significantly reduced prices. HLG is available from stock in all common standard variants and with short delivery times. It enables loads of up to 180 kN and speeds of over 1,5 m/s. In addition, the HLG works particularly quietly and with little friction.

By special lubrication channels and lubricant reservoir, the carriage can be permanently supplied with lubricant. This eliminates the hassle of relubrication and the guide system is almost maintenance-free. A connection to the central lubrication is also possible. In addition, seals provide effective protection against contamination. The system is rounded off by Clamping elements, which enable the carriages to be locked when they are adjusted manually.

Zimmer clamping elements fix machine tool axes

Zimmer clamping elements fix machine tool axes

The HLG is available in Rail sizes from 5 to 55 mm, with carriages in flange or compact design and long or short version. An addition is the miniature version MLG in sizes from 5 to 20 mm in standard and wide versions. MLG is always made of stainless steel and is therefore also in the food technology and pharmaceutical industry.

Extremely stiff linear guides with roller chain and roller guides

02.09.2015/XNUMX/XNUMX | the indunorm Movement technology presents the THK linear guides with roller chain of the type SRG/SRN. These extremely rigid guide systems are particularly smooth-running and low-maintenance. They are available directly from stock with short and long carriages in various preload and accuracy classes in sizes 25 to 65.

02.09.2015/XNUMX/XNUMX | the indunorm Movement technology presents the THK linear guides with roller chain of the type SRG/SRN. These extremely rigid guide systems are particularly smooth-running and low-maintenance. They are available directly from stock with short and long carriages in various preload and accuracy classes in sizes 25 to 65.

Because the Chain keeps the rollers at a defined distance from each other, they rotate evenly, and the otherwise typical Roll tilting is eliminated. The rolling elements therefore also do not rub against each other. This ensures significantly less wear and lower displacement resistance. The spaces between the rollers serve as a lubricant reservoir. With every movement, these continuously and efficiently supply the rolling elements with grease or oil.

This results for the user significantly longer maintenance intervals. The manufacturer has optimized the ratio of roll diameter and length. This significantly reduces the deflection of the rolling elements under load. This makes the guide system even stiffer. In addition, it can be loaded evenly in all directions.

The extensive range of track roller guides is used in machine and vehicle construction for use. The guidance systems are usually less precise, but simpler and more robust. This makes them suitable for high speeds and in dirty environments. they have one low frictional resistance and therefore run smoothly and evenly. The portfolio includes standard, U, V, C, solid block or heavy-duty systems made of aluminum, steel or both.

Customized linear guides for rail vehicles

24.09.2014/XNUMX/XNUMX | When it comes to opening and closing automatic doors on passenger trains, the focus is primarily on good running properties and a sufficiently high load-bearing capacity. Rollon For such projects, he relies in particular on the SNK recirculating ball bearing guide from the "Easyslide" linear ball bearing product family. It is very compact and has a long service life thanks to guide rails and runners made of cold-drawn roller bearing steel and hardened balls and running surfaces.

24.09.2014/XNUMX/XNUMX | When it comes to opening and closing automatic doors on passenger trains, the focus is primarily on good running properties and a sufficiently high load-bearing capacity. Rollon For such projects, he relies in particular on the SNK recirculating ball bearing guide from the "Easyslide" linear ball bearing product family. It is very compact and has a long service life thanks to guide rails and runners made of cold-drawn roller bearing steel and hardened balls and running surfaces.

Handicap access to passenger compartment requires extendable sliding steps in the entrance area of the doors. The "Compact Rail" has proven itself here with its many designs and self-alignment in two levels. It achieves high travel speeds and is insensitive to dirt - an important criterion for applications on the floor and at the transition to the outside area.

A pair of adjustable table was designed on the basis of the embossed "X-Rail" guide rails. This product family is suitable for applications where a good price/performance ratio and high resistance to corrosion are required.

The tip of the front of the train is often built in so that it can be moved for maintenance purposes or to lower the coupling unit - exactly the right place for the Full extension OptiRail LTH. Thanks to the high moment of inertia, this type of telescopic slide is extremely compact and very rigid with high load ratings. Pull-out battery boxes also have to carry special loads. The application engineers recommend type DSS telescopic rails for this. They have the necessary rigidity with a slim design. This results in a high load capacity with low deflection when extended. Adjusting the driver's seat is also a practical example.

Linear guide made of steel and CFK runs 20% faster

22.07.2014 | xperion presents with the "X-Girder" a CFRP steel construction that has already proven itself in practical use and has led to a twenty percent increase in speed without loss of quality. However, the connection of the different steel materials in the guide rail and CFRP as the carrier body brings with it challenges itself:

22.07.2014 | xperion presents with the "X-Girder" a CFRP steel construction that has already proven itself in practical use and has led to a twenty percent increase in speed without loss of quality. However, the connection of the different steel materials in the guide rail and CFRP as the carrier body brings with it challenges itself:

During the CFRP carrier almost thermostable is, steel expands under the influence of heat. A rigid connection would lead to warping when the operating temperatures fluctuate and thus jeopardize the repeat accuracy. With a patented fastening solution, it has been possible to allow the guide rail to expand axially, thereby eliminating all concerns about repeat accuracy.

"A complex steel component can never be replaced 1:1 by a CFRP component," explains the managing director Thomas Henss. “CFK shaping that is suitable for the material can differ significantly from that of a steel part. That's why CFRP components are created in close cooperation between our material specialists and our customers' designers.” CFRP allows a degree of customization that no other material offers. It makes it possible to remove previous limits set by material properties.

Linear guides 2013 to 2010

- Linear guide with integrated measuring system for machine tools

- Square guide for high forces from all directions

- From the lightweight recirculating ball bearing guide to the ball bushing

- Dirt-resistant linear guide for 2 tons of load

- Roller guides for dirty environments

- Inductive length measuring system for recirculating ball unit

- Precision flat cage guides with roller bearings

- Miniature linear guide and precision miniature roller table

Linear guide with integrated measuring system for machine tools

25.09.2013/XNUMX/XNUMX | With the measuring system "AMS absolute" offers Schneeberger offers the machine tool market integrated magnetoresistive measurement technology, also with an absolute, digital interface. The system also offers reliable, high-precision scanning and includes a reading head for all sizes and one-piece guides with an integrated measuring system up to 6 m in length.

The AMS Absolute was equipped for industrial use in the harsh machinery market. A LED indicates the most important operating states and also offers a configuration and diagnosticspossibility via a serial interface. Furthermore, it offers increased operational reliability through the processing of redundant information.

The general structure of the AMS absolut is a measuring standard with incremental and code track integrated in the "Monorail" linear guide. The material measure is made by a very hard and welded to the linear guide rail masking tape protected from interference. The reading head is embedded in a perfectly sealed add-on housing and mounted directly on the carriage. In this way, the information on both tracks can be continuously detected by the pressed sensor and calculated into absolute information in the measuring position.

Square guide for high forces from all directions

01.07.2013 | Igus With the Drylin-Q 20, it expands its product range for lubrication-free, non-rotating linear guides. This Square guide self-supporting absorbs forces of up to 10 Nm from all directions. The bearing play of the guide carriage can be adjusted manually. In addition, a hollow profile offers space for supply lines. The square guide system with a profile edge length of 20 mm offers a lot more in addition to the freedom from lubrication and maintenance.

01.07.2013 | Igus With the Drylin-Q 20, it expands its product range for lubrication-free, non-rotating linear guides. This Square guide self-supporting absorbs forces of up to 10 Nm from all directions. The bearing play of the guide carriage can be adjusted manually. In addition, a hollow profile offers space for supply lines. The square guide system with a profile edge length of 20 mm offers a lot more in addition to the freedom from lubrication and maintenance.

From lightweight recirculating ball bearings to ball bushings

13.08.2012 | Dr. Tretter presents its recirculating ball bearing guides made of aluminium. In certain applications, these can be a significantly more economical solution compared to versions made of steel.

13.08.2012 | Dr. Tretter presents its recirculating ball bearing guides made of aluminium. In certain applications, these can be a significantly more economical solution compared to versions made of steel.

They are used when the user is concerned with cost and weight savings - for example in the light engineering, for simple handling and positioning movements or for moving elements in the Technical Building Services. These aluminum guides are highly resilient thanks to the steel inserts and at the same time around 60% lighter than corresponding steel versions.

high precision Drive Elements The torque ball bushings are used for torque transmission, which can be accommodated in the smallest of spaces with simultaneous translational movement. The ball rolling element is used in these drive elements, which takes over the transmission between the ball bushing and the shaft with ground-in grooves. Torque ball bushings are used in a similar way to splined shafts. However, they have the advantage that they can be adjusted without play via the ball size and their rigidity can be increased via appropriate preload.

The provider's miniature tours are available as full tour (carriage and rail) from size 3 from stock. From size 7, carriages and rails can also be supplied individually, for higher transverse moments also in a wide version. The miniature roller tables are suitable for requirements with particularly smooth running. The compact axis series "Monocarrier" enables precise guiding and feed movements in a simple way. They are available in the standard version MCM and as a highly rigid type MCH. Standardized aluminum axles with Timing belts or Ball Screwsn of El.More or solutions such as the NSK rail guides, roller guides with measuring system, C-rail guides, Ball Transfer Units or even the Tolerance sleeves complete the portfolio.

Dirt-resistant linear guide for 2 tons of load

04.09.2012/2/25 | Linear technology, which is lubricant-free and dirt-resistant, can now also withstand the weight of a well-equipped mid-range station wagon of up to XNUMX t. The new "Drylin W" size XNUMX linear guide from igus is one ball-bearing linear guide. This means that the versatile linear guide now has new application options, for example in Agriculture, the vehicle construction but also in medical technology and the packaging industry.

04.09.2012/2/25 | Linear technology, which is lubricant-free and dirt-resistant, can now also withstand the weight of a well-equipped mid-range station wagon of up to XNUMX t. The new "Drylin W" size XNUMX linear guide from igus is one ball-bearing linear guide. This means that the versatile linear guide now has new application options, for example in Agriculture, the vehicle construction but also in medical technology and the packaging industry.

Roller guides for dirty environments

20.06.2012 | Dr. Tretter offers economical solutions for dirty environments with its roller guides. With the insensitive system, high speeds and accelerations can be achieved with low masses to be moved and minimal rolling friction.

20.06.2012 | Dr. Tretter offers economical solutions for dirty environments with its roller guides. With the insensitive system, high speeds and accelerations can be achieved with low masses to be moved and minimal rolling friction.

The carriages off anodized aluminum have four wheels. Two of them are mounted eccentrically to adjust the play. The rollers are mounted in optimised, double-row angular contact ball bearings. A reinforced outer ring with a precise support profile enables precise rolling with a high radial and axial load capacity at the same time. The rollers are fixed in the carriage with steel bolts. The rails are also made of anodized aluminum. Two steel shafts are pressed in as guide elements. The carriages run on them in an open or closed design.

The casters are designed in such a way that they and the open car can also be combined with profiles of the user or with supported shafts of the provider. This allows them to be adapted to individual requirements. For applications where there is a risk of corrosion, there are rust-protected carriages and rails.

A Guidance accuracy of 0,5 mm/m the system runs very smoothly. The maximum speed is 10 m/s and the acceleration is 50 m/s². For sizes 25 and 36 there is also a magnetic length measuring system for positioning tasks. The user can also use this in a dirty environment. Depending on the resolution, the repeatability of the measuring system is between ± 1 and ± 100 µm.

Integrated inductive length measuring system for recirculating ball unit

22.11.2011/XNUMX/XNUMX | The business area expands with an integrated inductive length measuring system (LMSA). INA linear technology Schaeffler Group Industrial developed the modular system of the four-row recirculating ball bearing units of the "Kuve-B" type. This means that the stroke or displacement path can now be measured directly. A recirculating ball unit KUVE-B with LMSA then consists of a guide carriage, an adapted measuring head and a guide rail.

22.11.2011/XNUMX/XNUMX | The business area expands with an integrated inductive length measuring system (LMSA). INA linear technology Schaeffler Group Industrial developed the modular system of the four-row recirculating ball bearing units of the "Kuve-B" type. This means that the stroke or displacement path can now be measured directly. A recirculating ball unit KUVE-B with LMSA then consists of a guide carriage, an adapted measuring head and a guide rail.

Roller bearings Precision Flat cage guidance

01.08.2011/XNUMX/XNUMX | Longitudinal guides with roller bearings are indispensable wherever ease of movement with low construction and maintenance costs is important. The Company Egis from Switzerland has specialized in the manufacture of high-precision longitudinal guides for over 40 years. Precision flat cage guides that can be delivered at short notice are a specialty of the company, which favors needle and cylindrical rollers.

01.08.2011/XNUMX/XNUMX | Longitudinal guides with roller bearings are indispensable wherever ease of movement with low construction and maintenance costs is important. The Company Egis from Switzerland has specialized in the manufacture of high-precision longitudinal guides for over 40 years. Precision flat cage guides that can be delivered at short notice are a specialty of the company, which favors needle and cylindrical rollers.

With high demands on accuracy, load capacity and rigidity, as is particularly the case with Machine Tools are common, precision longitudinal guides with needle or cylindrical roller flat cages enable an optimal solution. Compared to other linear systems, they require little installation space, are used as fixed or floating bearings depending on the design and are suitable for high accelerations.

Due to the movement of the cage relative to the two raceways, they are particularly suitable for limited strokes. In contrast to longitudinal guides with rolling element circulation, the rolling elements in the cage guides are located between the raceways during the entire movement process. This ensures a extraordinary smoothness and high running accuracy of the workpieces.

Taking into account a given installation space, the needle roller the longest contact length with the greatest possible number of load-bearing rolling elements. The large number of linear contact points guarantees high resilience and rigidity. There is also the option of increasing the rigidity by preloading. This can be done with small preloads using pressure screws on the back of the rail, with higher preloads using guide rails with type ML infeed wedge. If the requirement for rigidity is not the top priority, the cylindrical roller as a rolling element gives a guide greater elasticity. The high load-bearing capacity, which is characteristic of all these guides, is retained.

Egis has specialized in the manufacture of high-precision linear guides for over 40 years. Your product range includes guide rails in the M+V, ML and J+S profile forms, both in standard and design lengths, as well as the associated flat or angled flat cages. This flat cages enable the smooth running of the longitudinal guides and, thanks to precise rolling element guidance, ensure full utilization of the very good running properties of hardened rolling elements. All flat cage types can be adjusted in length to any combination of stroke and rail length. Thanks to the prefabricated stocks, both guide rails and flat cages can usually be delivered at short notice.

Miniature linear guide and precise miniature roller table

29.07.2010 | Dr. Tretter puts its focus at the fair on its miniature linear guides and the precision miniature roller tables. The range includes B. High-speed trolleys (up to more than 5 m/s) in sizes 9 to 15 with integrated additional lubrication. In addition, the miniature guides are available from stock as a complete guide (carriage and rail) in all sizes and interchangeable carriage and rail in sizes 7 to 15. They are supplied with restricted play and rails screwed on from above in the high-precision class.

They are also available in a wide version in the standard width and for higher transverse moments. Even with rail size 3, rail lengths of 500 mm or more are available from stock. The manufacturer also delivers on request other preloads, accuracy classes and rails that can be screwed on from below. The precision miniature roller tables meet the highest demands for accuracy, ease of movement and load-carrying capacity. They are available in sizes 7, 9 and 12. Because they are not sealed with plastic elements, they can also be used at higher ambient temperatures. There are versions for temperatures up to 150 °C, 200 °C and 300 °C.

tool technology

Clamping technology 2017 to 2016

You can find the latest clamping technology innovations here.

- Double clamp from the modular system for over 300 variants

- Flexible clamping system for 5-axis machining

- Workpiece clamping with universal plug-and-work media transfer

- Freeze clamp workpieces with the power of nature

- Pneumatic swing and lever clamps

- Expansion sleeve mandrel for full automation

- Workpiece clamping with jaw changes in seconds

- Centering clamping element and zero point clamping system

Double clamp from the modular system for over 300 variants

20.07.2017/XNUMX/XNUMX | The new double tensioner D2 from gressel completes Gressel's modular system for individual and process-reliable workpiece clamping that is to be machined.

20.07.2017/XNUMX/XNUMX | The new double tensioner D2 from gressel completes Gressel's modular system for individual and process-reliable workpiece clamping that is to be machined.

With the individual series C2, S2 and D2 and the widths of 80, 125, 160 millimeters and selection options for system jaws, interchangeable jaws and accessories, there are more than 300 equipment and design variants.

This means that users now have a complete clamping technology kit at their disposal, from which they can put together the ideal workpiece clamp for the respective machining task.

The individual components can be combine with each other in any way, resulting in great variability. The range of system jaws extends across all three series. The flexibility of use is further increased by the compatible top jaws.

The D2 offers full encapsulation for maximum process reliability and minimum cleaning requirements, an induction-hardened base body and case-hardened jaws for high long-term accuracy and a very long service life, higher precision thanks to improved guides and very good transmission of the clamping forces thanks to long guide bearings.

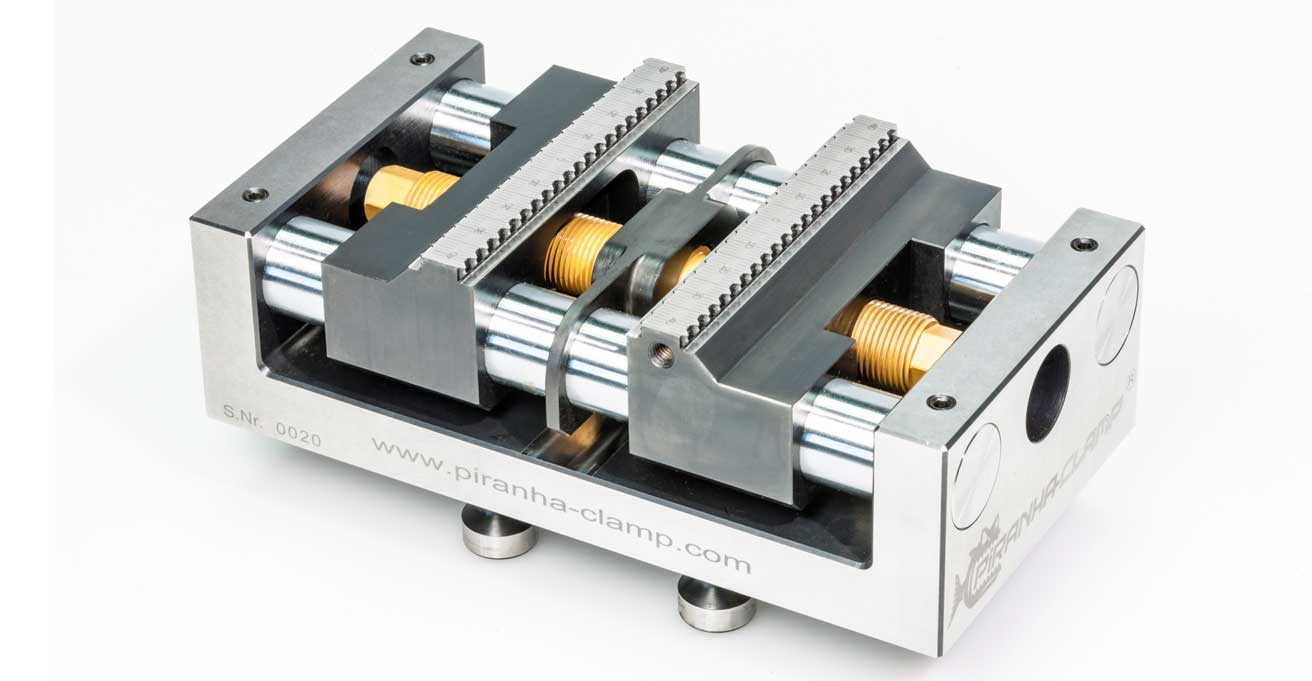

Flexible clamping system for 5-axis machining

05.06.2017 | With piranha clamping offers IBT – Thiermann engineering office a precise and reliable clamping system. This was specially developed for automated machines in 5-axis machining. Users can use it to do a variety of Materials process reliably and benefit from high holding forces and short non-productive times.

Piranha clamping also has bulky and heavy workpieces firmly under control. This is ensured by the very high clamping force - the spindle easily withstands pressures of over 1300 N/m2 out. With a clamping depth of just 3 millimeters and the low overall height, the system is suitable for use in many machine rooms.

All elements of Piranha Clamping are specially hardened to meet machine room requirements. To the Protection against corrosion most parts are surface treated. Spindle and guide columns have a special coating. This withstands high pressures and reduces friction on the guide elements. Different clamping jaw variants are available:

The snapper cheek has a double row of teeth; the lower row ensures the pull-down, while the upper row securely positions the component. In addition, high-precision jaws for finishing, soft steel versions and high-strength aluminum versions for form-fitting parts are available. Users can exchange the different variants within a few seconds. Piranha Clamping has its own zero-clamping system, which enables the optimal interface to the machine for each center clamp.

Intelligent CNC control for new + old machine tools

Intelligent CNC control for new + old machine tools

The Snapper center vise is particularly suitable for machining raw parts of steel and non-ferrous metalsmetall and Plastic. It can be used in all types of CNC machines. The basic bodies are hardened and ground on all sides. You provide one Positioning accuracy of ±0,02mm. The precise spindles are thermally treated and coated, the robust guide pillars are hard chrome-plated and polished. The snapper absorbs clamping pressures of up to 250 N/m2 on. In the high-end machining, the center tensioner Gepard with its high-precision base jaws enables repeatability in the thousandth range. This variant is available with different top jaws. This allows workpieces from raw to finished parts to be processed with just one clamping solution.

Pneumatic swing and lever clamps

03.09.2016/XNUMX/XNUMX | Pneumatic clamping elements have long been part of the portfolio Pascal. However, due to increasing demand, the company has placed a focus on the further development of these articles over the course of the last year. A pneumatic lever clamp with a special mechanism to increase the output force is presented for the first time. The force with a 14 mm piston rod is 1,07 kN.

03.09.2016/XNUMX/XNUMX | Pneumatic clamping elements have long been part of the portfolio Pascal. However, due to increasing demand, the company has placed a focus on the further development of these articles over the course of the last year. A pneumatic lever clamp with a special mechanism to increase the output force is presented for the first time. The force with a 14 mm piston rod is 1,07 kN.

The pneumatic one is also celebrating its premiere swing clamp with a double cylinder, also to increase the output power, as well as the pneumatic zero-point clamping system, which has become a lot more compact. The repeat accuracy is 3 μm. With all elements from this area, the focus is not only on increasing the force, but also on reducing the size of the elements. For example, the swing clamp has shrunk by 50%, while the output force has increased by a good 10%. The force with a 16 mm piston rod is 1,43 kN.

Expansion sleeve mandrels for full automation

25.08.2016 | Ringspann introduces its patented HDDS mechanical expansion sleeve mandrel. With this world first, metalworkers in gearing technology and fine machining in particular receive a high-precision and economically attractive alternative to hydraulic expansion clamping tools. The mandrel offers a concentricity of ≤ 5 µm.

25.08.2016 | Ringspann introduces its patented HDDS mechanical expansion sleeve mandrel. With this world first, metalworkers in gearing technology and fine machining in particular receive a high-precision and economically attractive alternative to hydraulic expansion clamping tools. The mandrel offers a concentricity of ≤ 5 µm.

In addition, it can machine a workpiece with bores up to Tolerance class IT10 and reduces the effort for the required feed and positioning technology considerably when used fully automatically.

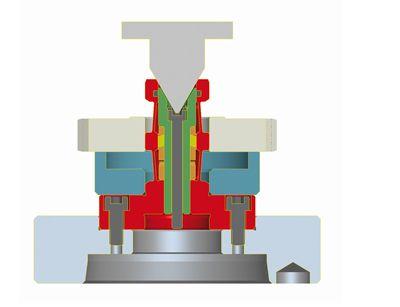

The multi-part vise and plug-in construction suitable for manual or power clamping: the mandrel consists of a tension bolt on which a package of clamping discs sits; Above this is an expansion sleeve with a slit in the middle. This is bolted to a flange. When the tension bolt is actuated axially, the clamping discs are expanded evenly over the entire circumference - and the slotted expansion sleeve is also expanded at the same time.

Reinforced by conical deformation webs, the expansion sleeve is shortened, which means that the clamped workpiece experiences a planar tightening to the system. With an additional quill or centering point, the expansion sleeve flange mandrel achieves the rigidity and accuracy required for machining.

Workpiece clamping with universal plug-and-work media transfer

21.06.2016 | Schunk expands the world's largest modular system for stationary workpiece clamping with the compact, universally usable media transfer Vero-S MDN. With it, pneumatically, hydraulically or vacuum-actuated components on Vero-S NSL plus clamping stations can be put into operation in a matter of seconds via plug and work. In the automated machine loading, the interaction of the quick-change pallet system and media transfer enables a quick and reliable change of different clamping devices.

21.06.2016 | Schunk expands the world's largest modular system for stationary workpiece clamping with the compact, universally usable media transfer Vero-S MDN. With it, pneumatically, hydraulically or vacuum-actuated components on Vero-S NSL plus clamping stations can be put into operation in a matter of seconds via plug and work. In the automated machine loading, the interaction of the quick-change pallet system and media transfer enables a quick and reliable change of different clamping devices.

Alternatively, components for automated querying or cleaning can be supplied via the module. The media transfer can be flexibly combined with new or existing Vero-S NSL plus clamping stations, so that expensive and complex Isolated or special solutions are not required. Optionally, it can be attached from above or below. The module is equipped with two independently controllable fluid passages and is designed for a system pressure of up to 250 bar.

Like all components from the module range, the stainless media transfer robust and durable. Low-maintenance, specially sealed couplings ensure process-reliable replacement and operation. It is controlled either on the floor via channel bores in the clamping station or on the side via hose lines. If required, two media transfer modules can be combined to form a 4-way media interface. The overall height of 39 millimeters is exactly matched to the height of the quick-change pallet modules in partial installation.

Freeze clamp workpieces with the power of nature

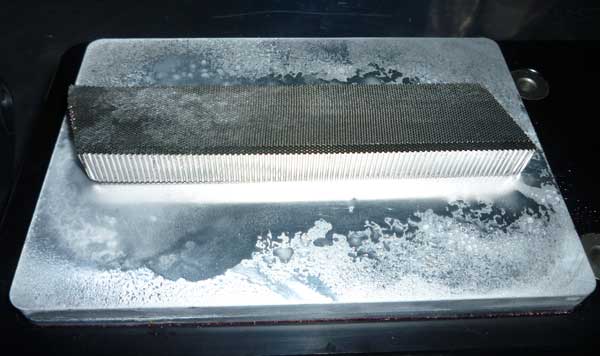

21.01.2016 | Witte presents a new possibility for workpiece clamping with the freeze clamping technology. This is suitable for clamping on a milling center in mechanical production or on a coordinate measuring machine. Here, the workpieces to be machined, regardless of the material, are simply placed on the clamping plate by means of frozen water Ice Vice clamping system frozen solid.

21.01.2016 | Witte presents a new possibility for workpiece clamping with the freeze clamping technology. This is suitable for clamping on a milling center in mechanical production or on a coordinate measuring machine. Here, the workpieces to be machined, regardless of the material, are simply placed on the clamping plate by means of frozen water Ice Vice clamping system frozen solid.

With the different systems of this clamping method, the clamping process within seconds take place. The time it takes to transform the aggregate state from water to ice depends on the performance of the device, the type, volume and size of the clamping surface.

Possible uses of this clamping method can be found in mechanical production grinding, drilling and milling in many industries. In particular, workpieces with smaller dimensions and/or pressure-sensitive materials can be elegantly and safely clamped with this method.